RIGID HVAC CO., LTD

- SMALL COOLING SYSTEMS

For the past 12 years, Rigid Technology has stood the test of time for the highest level of performance, quality, safety and innovation. All Rigid Standard Cooling Systems (1. Liquid Chiller System; 2. DC Condensing Unit; 3. Micro DC Aircon) are designed and manufactured with complete control of every step to ensure that Rigid's uncompromising standards for ultimate performance, unmatched reliability and highest durability are met. Besides standard chiller modules, Rigid also custom-made refrigeration units according to clients' demand. For more details, feel free to click here.

RIGID product's pocket size and portability and very competitive price enable us is irreplaceable. RIGID Technology is well known for its unique design and high tech precision manufacturing, resulting in products that outperform and outlast any other brand on the market today.

- Where Small Vapor Coolings Meet SolutionsThe “Core” Power emitting the charm of science and technology

RIGID Technology has developed unparalleled compact thermal management products based on patented miniature refrigeration technology.

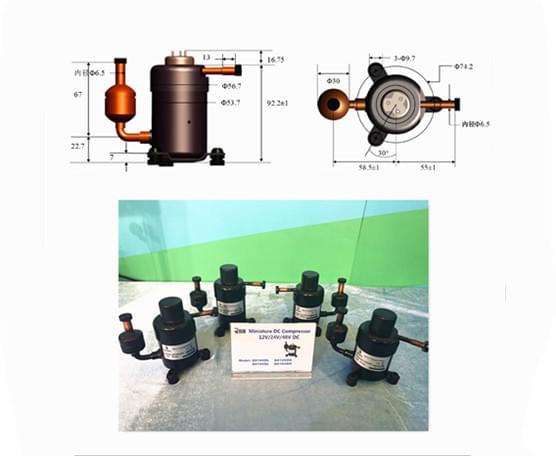

Nowadays, many engineers are facing the biggest challenges of compact and precise thermal management. The conventional scroll compressor is too big which isn't suitable for small devices and personal use. In the industry of compact and mobile refrigeration, there are no logical bits and bytes, nor industry qualification standards. Hence the design of a cooling system and the choice of the right technology, supplier and products can only be based on knowledge and experience in those fields.

RIGID Technology has nearly 10 years of focuses on the miniature refrigeration systems, has built a comprehensive knowledge base in compact and portable thermal management, enabling us to provide customers with complete solutions. Besides standard small cooling units, RIGID accepts customized order and OEM production. More product details, go to our Blog.

With nearly 10 years of experience in manufacturing & designs of small cooling systems, Today's RIGID is the miniature compressor innovation leader in China. We keep looking for novel solutions in compact & portable cooling system.

With a strong Design & Development team, together with complete Testing & Validation facilities, has enabled RIGID comes up with latest products for DC refrigeration applications and market segments.

RIGID operates out of 2 factories. One is for compact cooling units manufacturing; the other is for large DC Refrigeration. Each one of them focusing on specific product lines and market segments, thereby working towards excellence in the respective areas.

The factories meet ISO 9001: 2015 Quality Management Certificates.

Outstanding Performance Cooler for Body Cooling

Model Name: LC1910E-PRO

DC 12V & 24V, and AC 110V power supply are available. The cooler kit adopts variable speed inverter compressors, with the adjustable speed at 1500 ~ 6500 rpm, is suitable for miniature freezer systems and small mobile refrigeration applications. Features: Compact Size, Excellent Power and Portability.

- 6.8 kgs/15lbs;

- Size: 300x170x170mm (11.8x6.7x6.7 inch);

- Compact, Light, Rugged compact and portable cooler kit;

- All necessary parts included as well as digital display, plug and play.

Parts included:

1pcxPower cord+2pcsxLiquid pipe+4pcsxQuick connector+1pcxDustproof net.

Notice: Product color is subject to inventory. RIGID accepts customer's design and logo when the order reaches 20 units.

The World's Smallest Liquid Chiller System with Digital Display

Model Name: LC3220E-H

24V brushless direct current mini compressors, with the adjustable speed at 1500 ~ 6500 rpm. The most compact size, minimal weight and industrial-class reliability is essential liquid chiller for various cooling applications.

- 5.0 kgs/11lbs;

- Voltage: DC 24V

- Capacity: 100~550W

- Size: 339x208x235mm (13X8.2X9.2 inch)

- Powerful Compact Liquid Chiller Package

- Refrigeration rotary compressor efficiency to enable peak performance.

RIGID specializes in volume manufacturing of refrigeration systems tailored to your application.

Coil Type Small Cooling System 12V / 24V / 48V

The Coil-E type liquid chiller module is a compact cooling module used as heat transfer system for small liquid cooling. It is widesly used for laser, medical-aesthetic, and many other small cooling applications. It meets customer's specific demand where weight and space is critical. The small cooling module is very compact and lightweight.

- 3 kgs/6.6lbs;

- Size: 275x175x138mm;

- Compact & small liquid chiller;

- 12V/24V/48V dc compressor to enable peak performance.

The World's Smallest DC Condensing Unit

The stainless steel Coil-S type liquid chiller module is a compact cooling module used as heat transfer system for small liquid cooling. It applies for laser, medical-aesthetic, and many other small cooling applications. It meets customer's specific demand where weight and space is critical. The small cooling &refrigeration unit is very compact and lightweight.

- 3 kgs/6.6lbs;

- Size: 275x175x138mm;

- Compact & small liquid chiller;

- 12V/24V/48V dc compressor to enable peak performance.

Plate-P Type Heat Transfer System 12V / 24V / 48V

The Plate-P type chiller module is the circulatory cooling subsystem. The plate chiller unit is facilitated installation and assures end-users with excellent cooling performance with tiny refrigerated compressors. The miniature cooling system especially applies to the microclimate cooling system like small liquid cooling, medical device, laser, electronics, EV battery, and e-mobility, etc. It provides extraordinary cooling capacity for extremely hot environments and confined spaces.

- 3.5 kgs/7.7lbs;

- Size: 330x200x138mm;

- Compact & portable water cooler;

- 12V/24V/48V mini compressor to enable peak performance.

Coaxial-C Type Small Water Cooling System 12V / 24V / 48V

This Coaxial-C water cooler is a type of closed-loop liquid chiller system. It provides compact and reliable circulatory liquid cooling. The small water-cooled chiller uses an S-316 coaxial stainless steel evaporator, widely applies for aesthetic and medical device cooling and pure water cooling.

- 5 kgs/11lbs;

- Size: 330x200x150mm;

- Environmental small cooling unit;

- 12V/24V/48V tiny compressor to enable peak performance.

DC Air Conditioner Module-Portable AC Unit 12 Volt / 24V / 48V

This DC A/C system is a compact solution for small & confined space cooling, such as small cabins, cuddy cabins and electric vehicles etc. It uses recirculated air in a sealed environment as the cooling mechanism. The Small dc refrigerated air conditioner module removes heat from the air which is circulated through the system to cool the heat source. Features: Compact Size, Lightweight, High Efficient and Portability.

- 5 kgs/11lbs;

- Size: 330x200x150mm;

- Electric & solar power air conditioner dc power;

- Refrigeration compressor efficiency to enable peak performance.

The World's Smallest DC Condensing Unit

DC 12V, 24V, 48V variable speed inverter compressors, with adjustable speed at 1500 ~ 6500 rpm, is suitable for miniature freezer systems and small mobile refrigeration applications.

- 2.5 kgs/5.5lbs;

- Size: 240x180x138mm;

- DC Micro compressor refrigeration system;

- Refrigeration compressor efficiency to enable peak performance.

Features: Compact Size, Low Noise and Portability.

Specification Download PDF

RIGID DC LIQUID CHILLER

Compact and Reliable Small Liquid Cooling Solutions

WHAT’S RIGID LIQUID CHILLER?

Liquid Chiller cooling refers to cooling by means of the convection or circulation of a liquid. It is a method of heat removal from components and devices. As opposed to air cooling, liquid is used as the heat conductor.

Usually, water is the best best heat conductor. Water cooling is commonly used for cooling precise instrument, laser, lab test. Recently, small water chiller also is used for various major components cooling.

For example, it is applied to inside high-end personal computers such as CPU, GPU, and motherboards. The main mechanism for water cooling is convective heat transfer. It includes:

- Water cooling

- Liquid cooling for computers

- Cooling by convection or circulation of coolant

- Liquid Cooling and Body Vest Cooling

- Laser and Precise Instrument Cooling

HOW’S RIGID LIQUID CHILLER MODULES?

RIGID liquid chiller module is an integrated cooling sub-system. It is specially used for small footprint cooling applications where space and weight are critical.

The LCM includes Miniature Compressor, Driver Board, Condenser, Evaporator and other small cooling parts. It provides core cooling and refrigerant control mode is capillary tube. This subsystem is full charged with R134a and oil and ready to use. It allows end users to adapt to the coolant fittings for ultimate flexibility.

RIGID liquid chiller module is world’s lightest weight and very compact footprint. It particularly designed for small liquid circulatory cooling, such as laser manufacturers, laboratory, hospital lab, large end users and system integrators.

RIGID patent mini dc compressor drives the refrigerant directly through the heat exchangers. This concept eliminates the need for a water cooling loop (water pump, reservoir and associated tubing) resulting in a greatly simplified cooling system.

HOW’S RIGID LIQUID CHILLER MODULES?

RIGID liquid chiller module is an integrated cooling sub-system. It is specially used for small footprint cooling applications where space and weight are critical.

The LCM includes Miniature Compressor, Driver Board, Condenser, Evaporator and other small cooling parts. It provides core cooling and refrigerant control mode is capillary tube. This subsystem is full charged with R134a and oil and ready to use. It allows end users to adapt to the coolant fittings for ultimate flexibility.

RIGID liquid chiller module is world’s lightest weight and very compact footprint. It particularly designed for small liquid circulatory cooling, such as laser manufacturers, laboratory, hospital lab, large end users and system integrators.

RIGID patent mini dc compressor drives the refrigerant directly through the heat exchangers. This concept eliminates the need for a water cooling loop (water pump, reservoir and associated tubing) resulting in a greatly simplified cooling system.

WHY RIGID DEVELOP LIQUID CHILLER MODULE?

To meet the growing demand of small cooling systems, RIGID has developed compact liquid chiller modules for several customers. At first, these compact cooling modules are used for portable and compact water chiller and small device cooling.

Later, They are widely used in medical, aesthetic, laboratory, military who expressed a need for a compact, lightweight liquid chiller, which would meet the environmental stresses of the harshest environments while still provided sufficient cooling or heating. The system has both heating and cooling capabilities and circulates thermally regulated (+/- 0.5°C) coolant to a customer cold plate or heat exchanger.

The system has a built-in pump and reservoir to circulate the coolant, which allows system to function without the use of a fill kit. The system also has a communication port which allows the user to monitor the system performance and choose the operating temperature.

The compact design gives the user flexibility to design this chiller into their system or have is reside as a separate unit. Also, the cold plate, which ultimately removes heat from the payload, can exist remotely from the chiller and can be designed as appropriate.

The chiller has been designed to meet the requirements of mobile applications where it may besubjected to shock, vibration, and a variety of environmental conditions.

HOW MANY TYPES OF RIGID SMALL COOLING UNITS?

There are 5 types of RIGID small cooling units, they are:

- Coil type liquid chiller

- Plate type liquid chiller

- Coaxial typle liuqid chiller

- DC Condensing unit

- Micro DC Aircon unit

RIGID supplies compact, reliable vapor compression cooling systems, specializing in applications where compact size and reliability are key parameters. We provide custom engineered or standard solutions to meet your small cooling requirements.

RIGID LIQUID CHILLER MODULE (LCM) PARAMETERS

RIGID Liquid Chiller Modules feature refrigerant delivered directly to a liquid loop. minimzing part count and maximizing thermal efficiency.

- DC pumps and reservoirs

- 100-550 Watts of cooling

- Liquid temperature ranges: 25°C to -20°C

- Temperature control

- Efficient isothermal heat transfer

- 4x to 6x more efficient than thermoelectrics

- Hermetically sealed system - no water leaks

- >90,000 hour MTBF

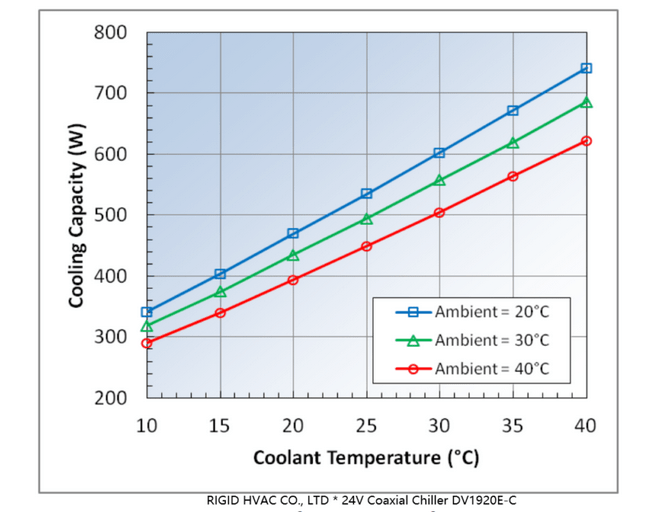

RIGID SMALL COOLING SYSTEM CAPACITY

Cooling Capacity

This is usually defined as the specified nominal cooling capacity at normal working conditions of the system in watts, according to evaporating and condensing temperatures. The capacity is determined by the mass flow rate of refrigerant, which depends on the condensing unit compressor’s displacement, RPM, and volumetric efficiency. RIGID compact liquid chiller module refrigeration capacity ranges from 30W to 250W.

Refrigerant Type

Refrigerant selection can be made on the basis of availability, performance, and ecological considerations. RIGID liquid chiller module has been verified for use with R134a refrigerant.

RIGID SMALL COOLING SYSTEM OTHER SPECIFICATIONS

Ambient Temperature

RIGID liquid chiller modules are usually intended for indoor use, and a minimum of +5ºC is required in order for proper lubrication. In 2017, RIGID has successfully developed T-tropical series mini compressor, which is able to work in 52 degree ambient temperature.

Electrical Power Available

RIGID liquid chiller modules are used in mobile or portable refrigeration systems. Its DC power is produced by batteries, fuel cells, vehicle alternators, solar panels, or from an AC inverter power supply. The compressor must be selected for use according to the DC voltage available. RIGID compressors are available in 12V, 24V and 48V versions.

Size and Cooling

RIGID liquid chiller modules are extremely small, high-performance for end users direct refrigeration devices. Its size is only 7.85x6.3x6.7 inch and weighting only 6.6 lbs. Current models produce as much as 30W to 250W.

RIGID SMALL COOLING SYSTEM WORKING PRINCIPLE

RIGID Small Cooling Systems deliver coolant to a secondary evaporator or heat exchange. The small chiller systems offer ultimate high thermal performance and ultimate flexibility.

- 100 to 550 W of cooling

- 0.1°C temperature control

- 4x to 6x more efficient than thermoelectrics

- Stand alone or integrated solutions

- Customized service is available

- >90,000 hours MTBF

HOW RIGID SMALL COOLING SYSTEM WORK?

RIGID liquid chiller systems offer high heat transfer rates because the R134a refrigerant has a high thermal conductivity and heat-absorption capacity. Our liquid chiller systems are quite compact because of our patent miniature dc compressor. The mini compressor circulates R134A refrigerant which takes away heat from heat source dramatically.

RIGID liquid chillers are ideal for cooling high heat flux components and in applications where a solution must be rugged and reliable. It is also a better cooling solution for small liquid cooling where space and weight are critical fators.

WHY CHOOSE RIGID LIQUID CHILLER MODULE?

Rigid circulatory liquid chiller modules are self-contained high-efficient refrigeration compressor with R134A coolant, smallest condenser and evaporator, filter drier and driver board etc. All these refrigeration parts are all well integrated in one unit, sophisticated design by our skilled engineers. It serves as a source of chilled water for circulation through the water pipes, and the unit has smallest footprint and weight make it portability.

- Extremely small

- Extraordinary cooling performance

- Available for 12V, 24, 48V DC power supply

- Compact design providing reliable results to cooling and refrigeration

- Small & light weight configuration is ideal for small refrigeration application

- Variable speed dc compressor operate in battery, vehicle or solar power

RIGID LIQUID CHILLER MODULE FOR BODY COOLING

RIGID compact & mobile cooling chiller module (also named Liquid Chiller Module), is also used for extreme hot environment and confined space, besides small cooling devices and equipment. After more than 8 years experience for small dc refrigeration system. RIGID has successfully engineered and developed sophisticated cooling systems to handle OEM and ODM project.

In 2017, RIGID introduced a powerful and compact plate type liquid chiller, which meets market's need for personal cooling in the race car industry. Temperatures on the track can reach over 60°C (140°F) and the drivers need to operate their car precisely in these extreme conditions. The size of RIGID's compressor keeps the cooling system lightweight. The efficiency of a vapor-compression solution, yields a great advantage over thermo-electric personal cooling systems.

FAQ

Liquid Chiller Modules

1. What’s the size & weight of each liquid chiller?

2. MOQ for custom liquid chiller?

3. Are chillers pre-charged of refrigerant?

4. How do I refill refrigerant later?

5. What’s the liquid chiller cooling capacity?

6. What applications suit the liquid chillers?

7. How do I control the liquid chiller?

8. Can I monitor temperatures?

9. What refrigerant is used in liquid chiller?

10. What oil is used in liquid chiller?

11. How do I adjust flow rate of liquid chiller?

12. Can the chiller be used for laser cooling?

13. What’s the liquid chiller power input?

14. How quiet is the liquid chiller?

15. How do I install the chiller?

16. Do you provide OEM branding?

17. Can the liquid chiller be run on batteries?

18. What is the lifespan of liquid chiller?

19. How do I buy samples?

20. What if I need extra cooling power?

FAQ

RIGID COMPACT LIQUID CHILLER REFRIGERATION COOLING SYSTEM

1. How To Design A Cooling System?

2. How Liquid Chiller Module (LCM) Work?

3. Could Rigid Liquid Chiller be used in an embedded application?

4. How Liquid Chiller Cool A Lithium-ion (Li-ion) battery?

5. Why Use Compressor Vapor Compression?

6. Can I Request Custom Refrigeration System?

7. Water chiller spec sheets and price?

Standard Products and Custom Solutions

Established in 2010, RIGID is the manufacturer who's behind many popular brands in the US. RIGID's vision is to set the benchmark standard for the micro cooling industry. We are a China manufacturer and supplier of compact cooling systems, working in close cooperation with the leading United States and European manufacturers of Air-conditioning & Refrigeration.

In addition to offering standard products including Micro DC Aircon (ruggedized air conditioner modules for compact and confined space cooling), Liquid Chiller Modules (battery-driven compact refrigeration systems that our customers integrate into their applications), and DC Condensing Units (world's small direct cooling units used by customers in small freezer, medical, laser, and electronics cooling). RIGID also custom design or modify refrigeration systems for most customers' specific applications.

Let our engineering team develop the perfect cooling solution for you!

Certificates | Download | Contact Us | Our History | Return & Exchange

RIGID Technology * © Copyright 2010-2025 * RIGID Cooling * All rights reserved.