RIGID HVAC CO., LTD

Coaxial Liquid Chiller

Coaxial Type Liquid Chiller - Compact battery driven core cooling unit

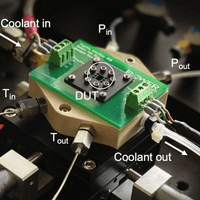

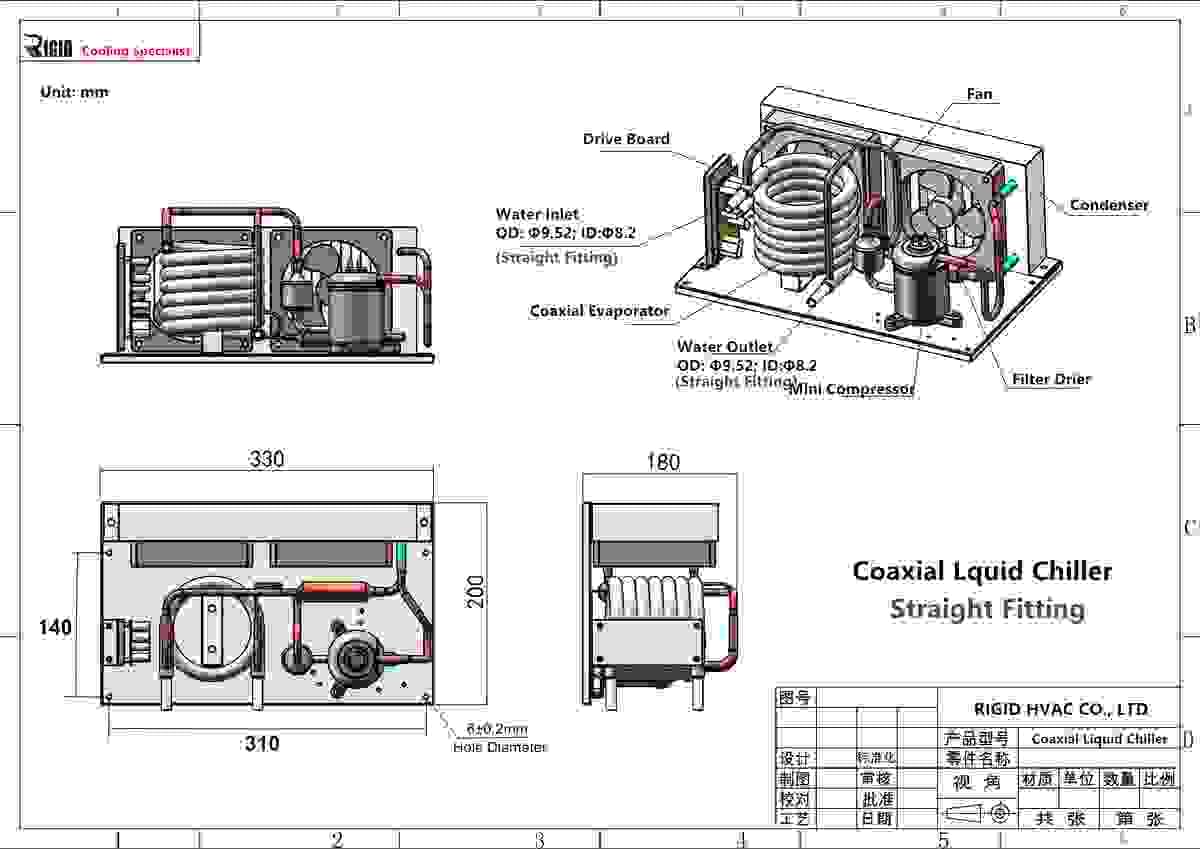

RIGID’s Coaxial Liquid Chiller is a compact, battery-driven cooling powerhouse designed for next-generation thermal control. Built with a coaxial stainless steel heat exchanger, this innovative unit delivers exceptional heat transfer efficiency and durability in the smallest footprint. Weighing only 5 kg (11 lbs) and measuring 330×200×150 mm, it’s ideal for equipment and devices where space, weight, and efficiency are critical.

Powered by a 12V/24V/48V DC rotary compressor, the Coaxial Liquid Chiller provides 100W~550W cooling capacity using eco-friendly R134a refrigerant. Its closed-loop design ensures clean, reliable, and consistent performance across diverse applications such as EV battery cooling, medical devices, laser systems, hydroponics, and personal microclimate cooling.

Engineered for easy OEM integration, users can connect their control to RIGID’s PCB for variable-speed control and peak performance. With customizable configurations and energy-efficient operation, the RIGID Coaxial Liquid Chiller is redefining precision cooling for compact, high-demand systems worldwide.

Coaxial Liquid Chiller

- Weight: 5 kg / 11 lbs

- Refrigerant: R134a / R290

- Voltage: 12V / 24V / 48V DC

- Cooling Capacity: 100W ~ 550W

- Dimensions: 330 × 200 × 150 mm

- Operation: Continuous 24/7 duty

- System Type: Closed-loop liquid chiller

- Cooling Mode: Circulatory water glycal refrigeration subsystem

- Control: External control board via RIGID driver board

- Evaporator Type: Coaxial Stainless Steel Heat Exchanger

Coaxial Liquid Chiller Models

External Drawing

coaxial liquid chiller, compact liquid chiller system, DC compressor chiller, miniature water chiller, OEM cooling module, portable refrigeration system, coaxial stainless steel heat exchanger, 12V 24V 48V liquid chiller, R134a micro chiller, battery-powered cooling unit.

Key Features

Easy to install, compact, Micro-channel condenser, Copper Antimicrobial Evaporator Coils and more.

High-Efficiency Coaxial Heat Exchanger

Features a stainless steel tube-in-tube design that provides exceptional heat transfer performance, corrosion resistance, and long service life. Ensures stable and continuous cooling even under demanding thermal loads.

Compact & Lightweight Design

At only 5 kg (11 lbs) and external size 330×200×150 mm, this all-in-one micro chiller delivers powerful cooling capacity (100W–550W) in a miniature footprint, ideal for portable and space-constrained applications.

DC-Powered & Energy Efficient

Runs on 12V / 24V / 48V DC, perfectly for battery-driven and mobile applications. The brushless DC compressor ensures low power consumption, quiet operation, and long lifespan.

OEM & Customizable Integration

Engineered for easy integration into OEM systems, supports modular customization, allowing engineers to tailor the system to their precise cooling requirements.

Stainless Steel Exchanger Water Chiller – The World’s Smallest Cooling System

The Coaxial Liquid Chiller System is a circulatory refrigeration subsystem. It uses a miniature DC rotary compressor (12V/24V/48V) charged with R134a refrigerant to extract heat from the circulating liquid via a coaxial stainless steel evaporator.

The system includes:

- DC Compressor

- Micro-channel Condenser

- Coaxial Evaporator (heat exchanger)

- Expansion Valve or Capillary Tube

- Electronic Driver Board (PCB)

Liquid flows through the coaxial coil, where heat is absorbed by the refrigerant and expelled through the condenser. The result is a steady flow of chilled liquid, maintaining precise temperature control in a self-contained, closed-loop design.

Key Features:

- Compact & Lightweight: Only 330×200×150 mm, 5 kg (11 lbs) – ideal for portable and embedded systems.

- Flexible Power Options: Operates on 12V / 24V / 48V DC, perfect for battery or mobile power environments.

- High Cooling Efficiency: 100W to 550W cooling capacity using eco-friendly R134a refrigerant.

- Coaxial Heat Exchanger: Stainless steel tube-in-tube design offers superior heat transfer and corrosion resistance.

- Closed-Loop System: Prevents contamination and ensures continuous, stable cooling for mission-critical use.

- Variable Speed DC Compressor: Users can fine-tune cooling output through RIGID’s smart driver board.

- Energy Efficient & Quiet Operation: Brushless DC motor ensures high efficiency, low vibration, and long service life.

- OEM & ODM Ready: Fully customizable micro chiller system for your specific application or device integration.

Application

RIGID Coaxial Liquid Chiller is purpose-built for modern, high-performance devices that demand compact yet reliable temperature control. It’s widely used in:

- Medical Equipment: Laser therapy, cryotherapy, aesthetic machines, and diagnostic systems.

- EV Battery Cooling: Thermal management for electric vehicles, drones, and battery packs.

- Laser Cooling Systems: Keep high-power laser optics and diode modules at stable operating temperatures.

- Hydroponics & Brewing: Maintains nutrient or fermentation temperature stability for optimized results.

- Personal & Wearable Cooling: Perfect for microclimate systems, such as racing suits or firefighter gear.

- Electronics & Computer Cooling: Prevents overheating in embedded systems, CPUs, or control panels.

- Industrial Applications: Suitable for welding equipment, sensors, and laboratory instruments requiring precision temperature control.

Whether it’s for medical precision, industrial reliability, or portable innovation, the Coaxial Chiller delivers powerful refrigeration results in the smallest form factor.

Why Choose RIGID

RIGID is a global leader in miniature DC compressor technology and innovative compact cooling systems. We specialize in custom thermal solutions designed to integrate directly into your equipment - reducing size, weight, and cost while maintaining performance.

Every project is unique - and so is your cooling challenge.

RIGID offers custom-built coaxial chiller modules to meet your specific needs, including:- Custom cooling capacity or voltage

- Specialized evaporator materials (stainless steel, copper, or titanium)

- Integration-ready mechanical design

- Advanced temperature control and monitoring options

Our R&D team works closely with clients to provide tailor-made cooling systems that balance size, performance, and cost for their exact application.

Standard Products and Custom Solutions

RIGID is China’s leading miniature DC compressor and micro cooling system innovator.

We specialize in developing compact, energy-efficient, and high-performance cooling modules for OEM and ODM clients worldwide.Our advantages include:

- Over a decade of R&D in micro refrigeration technology

- Complete in-house manufacturing for superior quality control

- Custom engineering support for integration and prototyping

- Global clients in medical, industrial, and clean-tech sectors

At RIGID, we don’t just sell cooling systems - we deliver precision-engineered thermal solutions that empower your innovations.

Online Store

Buy nowCoaxial Liquid Chiller DV2820E-C-T (R290)$600.00

Buy nowCoaxial Liquid Chiller DV2820E-C-T (R290)$600.00 Buy nowCoaxial Liquid Chiller DV2820E-C (R134a)$580.00

Buy nowCoaxial Liquid Chiller DV2820E-C (R134a)$580.00 Buy nowCoaxial Liquid Chiller DV3220E-C (24V)$560.00

Buy nowCoaxial Liquid Chiller DV3220E-C (24V)$560.00 Buy nowCoaxial Liquid Chiller DV1930E-C (48V)$510.00

Buy nowCoaxial Liquid Chiller DV1930E-C (48V)$510.00 Buy nowCoaxial Liquid Chiller DV1920E-C (24V)$500.00

Buy nowCoaxial Liquid Chiller DV1920E-C (24V)$500.00 Buy nowCoaxial Liquid Chiller DV1910E-C (12V)$490.00

Buy nowCoaxial Liquid Chiller DV1910E-C (12V)$490.00Designed for Integration

The Coaxial-C Liquid Chiller Module is an OEM-ready subsystem, allowing engineers to integrate cooling directly into their equipment.

Users can easily connect their control board to RIGID’s included DC compressor driver board to manage compressor speed, optimize energy usage, and achieve the exact cooling output required.FAQ

Looking for a compact, battery-powered liquid chiller for your device or system?

RIGID offers ready-to-use standard modules and custom-engineered solutions designed to fit your exact needs.1. What is a Coaxial Liquid Chiller?

2. What makes RIGID’s Coaxial Liquid Chiller different?

3. How does a coaxial heat exchanger work in a liquid chiller?

4. What are the key features of the RIGID Coaxial Chiller?

5. What refrigerant is used in RIGID’s Coaxial Liquid Chiller?

6. What industries use the Coaxial Liquid Chiller?

7. Is the Coaxial Chiller suitable for mobile or battery-powered systems?

8. How much cooling capacity does it deliver?

9. What are the benefits of a coaxial chiller design?

10. How heavy and compact is the RIGID Coaxial Chiller?

11. Can the chiller run continuously?

12. How is the chiller controlled?

13. What makes the Coaxial-C model ideal for OEM integration?

14. Can RIGID customize the chiller for my application?

15. Is the Coaxial Liquid Chiller energy-efficient?

16. Can it cool both water and glycol mixtures?

17. What are the advantages of using a DC compressor in liquid cooling?

18. What are common applications for the Coaxial Liquid Chiller?

19. Can it withstand harsh environments or high pressures?

20. How can I purchase or get technical support for RIGID chillers?

Certificates | Download | Contact Us | Our History | Return & Exchange

RIGID Technology * © Copyright 2010-2025 * RIGID Cooling * All rights reserved.