RIGID HVAC CO., LTD

Direct Expansion System

Direct expansion (DX) cooling eliminates the need for a secondary coolant loop. Instead, the refrigerant itself directly absorbs and removes heat from the target surface, such as a cold plate or evaporator, for faster and more efficient thermal transfer.

In recent years, direct expansion systems have rapidly gained popularity in the refrigeration and HVAC industries. Their simple construction, compact design, and easy integration into user equipment make them an ideal choice for modern cooling applications. Because DX systems eliminate extensive ductwork, pumps, and coolant piping, installation becomes faster, cleaner, and far more cost-effective.

The RIGID DX evaporator system takes this technology even further. Designed for precision and simplicity, it connects directly to the user’s evaporator or cold plate, providing direct refrigerant-to-surface cooling. Without the need for circulating air or liquid coolants, the system uses fewer components and avoids unnecessary energy losses.

By removing pumps, and secondary coolant loops, RIGID Direct Expansion Cooling System minimizes thermal resistance and prevents additional heat buildup, delivering higher net cooling capacity, improved reliability, and superior energy efficiency in a compact, easy-to-install package.

Smarter Cooling. Simpler Design. Reliable Performance.

High-pressure liquid refrigerant is directly into the evaporator, compressed by micro compressor, condensed, stored, and expanded. Ideal for lasers, semiconductors, and medical devices.

- 12V / 24V / 48V DC

- Low installation costs.

- Lightweight and small in size.

- Low energy consumption.

- Lower maintenance costs.

- Low operating noise (45dB).

- Can be battery, DC-powered operation

- Easy to test, adjust, and balance the end user's system.

- Individual sections can operate without running the entire system.

Direct Expansion System Models

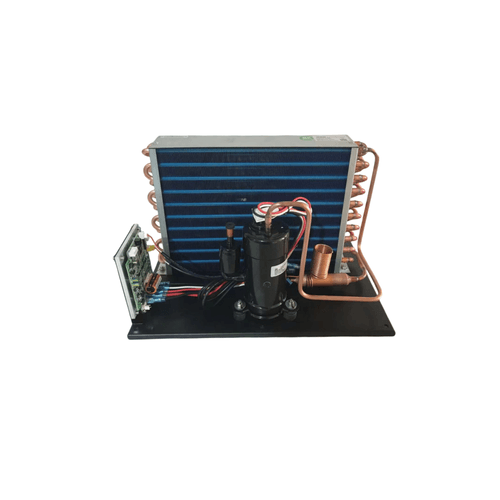

Direct Expansion System, DV2820

Capacity: ≥500W to 700W (2,387Btu)

- 24V DC

- 4.0 kgs/8.8lbs

- Refrigerant: R134A or R290

- Compressor type: Twin-cylinder micro compressor

- Working Amps: 1~8.3A, (Maximum 12A)

- Size: 190*160*180mm (7.5 x 6.3 x 7.0 inch)

- 24V mini compressor to enable peak performance

- Drive board is included

- LED display (optional)

Technical Specification – Direct Expansion (DX) Cooling System

Advantages of Direct Expansion System

Easy to install, Easy to test, Ultra-compact size, Minimum ceiling or wall space needed.

Higher Cooling Efficiency

The refrigerant directly cools the target surface without a secondary loop, heat transfer is faster and more efficient. This minimizes energy loss and delivers up to 40% higher cooling capacity compared to liquid chillers or thermoelectric systems.

Compact and Lightweight Design

The DX system removes pumps, coolant reservoirs, and extensive piping, making the overall system up to 20× smaller and lighter. It’s ideal for space-constrained or portable applications like medical devices, lasers, and battery cooling.

Simplified Installation and Maintenance

With fewer components and no need for coolant circulation, installation is simple and quick. The factory-sealed, maintenance-free design ensures long-term reliability with minimal service requirements.

Energy Savings and Cost Reduction

By eliminating redundant parts such as fans and pumps, the DX system consumes less power and reduces total system cost. It provides energy-efficient cooling with lower operating expenses and an extended product lifespan.

Typical Applications

1. Medical Devices & Laboratory Equipment

The compact DX cooling module delivers precise temperature control for medical analyzers, imaging systems, and portable lab devices. Its low vibration and quiet performance make it ideal for sensitive environments.

2. Laser & Semiconductor Cooling

RIGID’s energy-efficient refrigeration system ensures stable thermal management for laser diodes, semiconductor wafers, and optical instruments, maintaining accuracy and reliability during continuous operation.

3. Battery Thermal Management

The DC-powered cold plate system efficiently regulates battery temperatures in electric vehicles, drones, and power storage units, extending battery life and enhancing safety in compact power systems.

4. Industrial & Electronic Equipment

Perfect for control panels, sensors, and automation devices, the miniature DX system provides targeted cooling that prevents overheating and boosts equipment performance in harsh or confined environments.

5. Scientific & Analytical Instruments

For precision instruments that require stable, low-noise cooling, RIGID’s direct expansion evaporator ensures accurate temperature control without pumps or coolant circulation.

6. Portable & Embedded Cooling Solutions

Compact and lightweight, the DX cooling unit integrates seamlessly into portable refrigerators, wearable medical coolers, or small enclosures where space and power efficiency are critical.

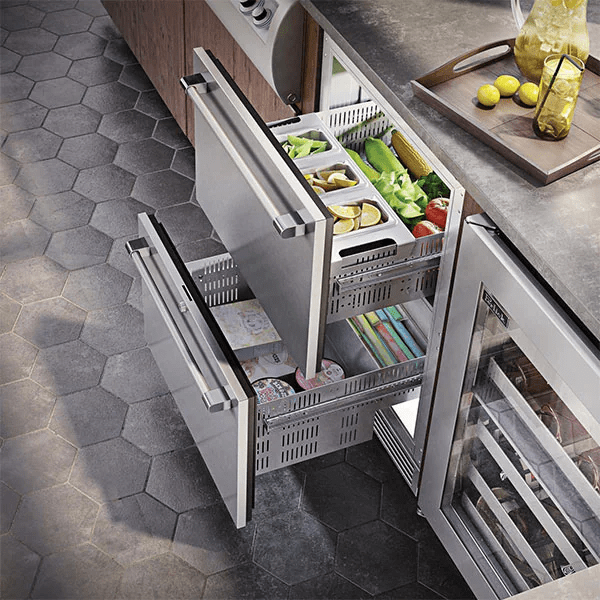

Cold Plate Refrigeration

Beverage Cooler

Outdoor Freezer

Outdoor Refrigerator

Electronics Battery

Cold Plate Cooling

Precise Instrument

Laboratory Equipments

Online Store

Buy nowDirect Refrigeration DV3820 (24V)$600.00 - $710.00

Buy nowDirect Refrigeration DV3820 (24V)$600.00 - $710.00 Buy nowDirect Refrigeration DV3830 (48V)$600.00 - $710.00

Buy nowDirect Refrigeration DV3830 (48V)$600.00 - $710.00 Buy nowDirect Refrigeration DV2820-T (24V, R290)$500.00 - $590.00

Buy nowDirect Refrigeration DV2820-T (24V, R290)$500.00 - $590.00 Buy nowDirect Refrigeration DV2820 (24V, R134A)$480.00 - $570.00

Buy nowDirect Refrigeration DV2820 (24V, R134A)$480.00 - $570.00 Buy nowDirect Refrigeration DV3220 (24V, R134A)$460.00 - $550.00

Buy nowDirect Refrigeration DV3220 (24V, R134A)$460.00 - $550.00 Buy nowDirect Refrigeration DV1930 (48V, R134A)$410.00 - $500.00

Buy nowDirect Refrigeration DV1930 (48V, R134A)$410.00 - $500.00 Buy nowDirect Refrigeration DV1920 (24V, R134A)$400.00 - $490.00

Buy nowDirect Refrigeration DV1920 (24V, R134A)$400.00 - $490.00 Buy nowDirect Refrigeration DV1910 (12V, R134A)$390.00 - $480.00

Buy nowDirect Refrigeration DV1910 (12V, R134A)$390.00 - $480.00Direct Expansion Refrigeration System Cycle

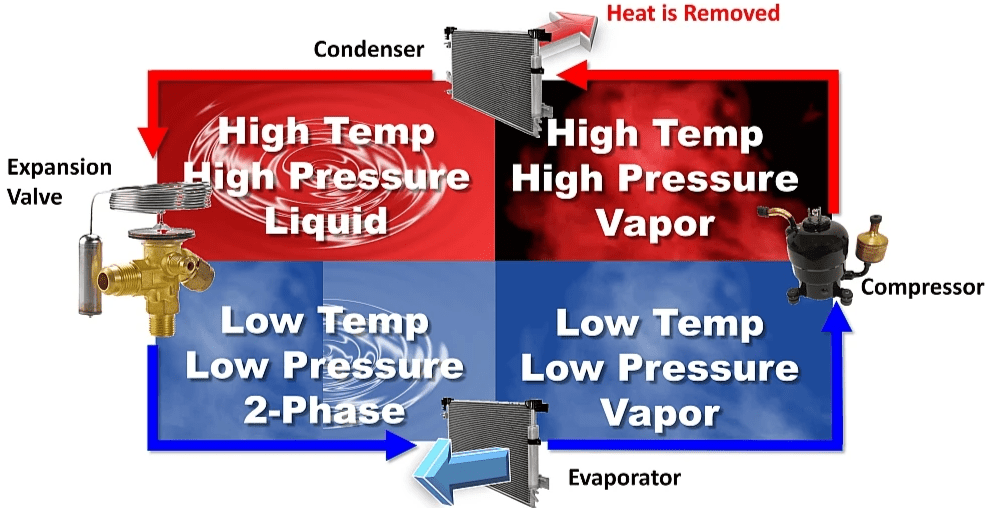

In direct refrigerant cooling, the refrigerant flows directly through the evaporator or customer cold plate, providing immediate and efficient heat transfer. RIGID’s DX expansion evaporator system, circulation is powered by our patented miniature DC compressor, ensuring compact design and high reliability.

This approach eliminates the need for a liquid recirculation pump, water tank, or complex piping—all common sources of leaks, maintenance, and energy loss. Compared to traditional liquid chillers, RIGID’s DX system is up to 20 times smaller and lighter, offering a 45% higher cooling capacity and significantly improved energy efficiency.

With an average lifespan of over 90,000 hours, the sealed, maintenance-free system minimizes downtime and maximizes performance. The simplified architecture prevents fluid leakage, enhances durability, and delivers precise, stable cooling performance.

RIGID’s Direct Expansion Cooling Technology is ideal for lasers, semiconductors, medical devices, and any application where compactness, efficiency, and reliability matter most.

To explore this innovative energy-efficient cooling solution or discuss your project needs, contact RIGID today for a free consultation and technical evaluation.

How Direct Expansion Systems Work

A direct expansion (DX) system connects directly to the customer’s evaporator. The evaporator sits in the space to be cooled, and as the refrigerant expands, it absorbs heat and cools the area efficiently. DX systems are ideal for mini-refrigerators, laboratory equipment, precision instruments, and any application that requires direct refrigerant cooling.

Direct Expansion Cooling System -

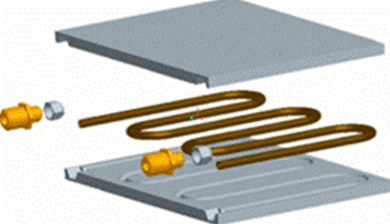

Compact DX Module

The RIGID direct expansion system can be connected to a cold plate, which acts as an evaporator. When the cold plate is placed on the part to be cooled, the cold plate absorbs and disperses heat from the part into the heat transfer fluid. Cold plates are used in a wide range of electronic cooling applications in many process industries.

Specifications Download PDF

450W (1,535Btu)

450W (1,535Btu)

450W (1,535Btu)

550W (1,876Btu)

≥500W to 700W (2,387Btu)

≥500W to 700W (2,387Btu)

Contact Us

The RIGID Direct Expansion (DX) Cooling System offers a powerful combination of efficiency, reliability, and compact design. As a compact DX cooling module, it provides direct refrigerant-to-surface heat exchange, achieving faster cooling performance with minimal energy loss.

Engineered as an energy-efficient refrigeration system, it eliminates bulky pumps, secondary coolant loops, and unnecessary components, reducing power consumption and operating costs.

With its DC-powered cold plate system, RIGID delivers precise temperature control in a lightweight, plug-and-play format, making it the perfect solution for portable, medical, and industrial thermal management applications.

Direct Expansion (DX) Cooling System - FAQ

1. What is a Direct Expansion (DX) Cooling System?

2. How does a DX cooling system work?

3. What are the main advantages of a direct expansion system?

4. What makes RIGID’s DX system different from others?

5. What applications use RIGID DX systems?

6. Can the DX system be powered by batteries?

7. How energy-efficient is the DX cooling system?

8. Does the DX system require maintenance?

9. How precise is the temperature control?

10. Is the system noisy during operation?

11. What refrigerants are used in RIGID DX systems?

12. Can the DX system replace a traditional liquid chiller?

13. What is the lifespan of a RIGID DX cooling module?

14. How compact is the DX system?

15. Does it work in both air-cooled and water-cooled setups?

16. Can the DX system be customized?

17. What industries benefit from DX cooling systems?

18. How does a DX cooling system improve reliability?

19. Are DX systems environmentally friendly?

20. Why choose RIGID for your direct expansion cooling needs?

Standard Products and Custom Solutions

Established in 2010, RIGID is the manufacturer who's behind many popular brands in the US. RIGID's vision is to set the benchmark standard for the micro cooling industry. We are a China manufacturer and supplier of compact cooling systems, working in close cooperation with the leading United States and European manufacturers of Air-conditioning & Refrigeration.

In addition to offering standard products including Micro DC Aircon (ruggedized air conditioner modules for compact and confined space cooling), Liquid Chiller Modules (battery-driven compact refrigeration systems that our customers integrate into their applications), and DC Condensing Units (world's small direct cooling units used by customers in small freezer, medical, laser, and electronics cooling). RIGID also custom design or modify refrigeration systems for most customers' specific applications.

Let our engineering team develop the perfect cooling solution for you!

Certificates | Download | Contact Us | Our History | Return & Exchange

RIGID Technology * © Copyright 2010-2025 * RIGID Cooling * All rights reserved.