RIGID HVAC CO., LTD

Miniature

24V DC Compressor

Micro Size, Silent Performance — Variable Speed DC Inverter Compressors Built for Efficiency.

24V Mini Compressor

The RIGID 24V miniature refrigeration DC compressor represents a major breakthrough in vapor compression technology. With ultra-low noise and minimal vibration, this compact rotary compressor is the most significant advancement in miniature cooling systems in over a century.

Designed for efficiency and mobility, RIGID mini DC compressors are ideal for a wide range of thermal management applications, including compact refrigeration units, water coolers, medical cooling systems, micro air conditioners, and direct electronic cooling. Their small footprint and lightweight construction make them perfect for portable, mobile, and space-limited environments.

Built for performance, RIGID’s rotary variable-speed mini compressors deliver cooling capacities from 100W to 700W (up to 2,387 BTU/h). They are powered by a driver board that enables precise temperature control through variable speed (2,000 to 6,500rpm) using a square wave signal.

Trusted by engineers and innovators worldwide, RIGID continues to lead the industry in compact cooling systems for mobile and off-grid refrigeration and air conditioning applications.

Features

RIGID Mini Compressor Provides Unparalleled Performance!

Smallest Footprint

Super compact size: 2.3 x 3.07 inch.

Lightest Weight

720 grams only (Including Refrigerator oil).

Sine Wave Drive Borad

Variable Speeds ranging from 2,000 to 6,000rpm.

Brushless DC Rotary Compressor

Battery or dc power supply, Low energy consumption.

1.4cc Mini Compressor

QX1402VDL

Nominal Capacity: 300W (1,023Btu)

- 24V DC

- 720g /1.6lbs

- Refrigerant: HFC-134a

- Size: 82 x 56 mm (High x Diameter)

- Working amps: 1~7A, (Max. 8.5A)

- Compressor type: Brushless DC Motor

- Variable speed drive:(2,000~6,000rpm)

- Drive board: ACRC-DB1510

1.9cc Mini Compressor

QX1902VDL

Nominal Capacity: 450W (1,535Btu)

- 24V DC

- 720g /1.6lbs

- Refrigerant: HFC-134a

- Size: 82 x 56 mm (High x Diameter)

- Working amps: 1~7A, (Max. 8.5A)

- Compressor type: Brushless DC Motor

- Variable speed drive:(2,000~6,000rpm)

- Drive board: ACRC-DB1510

1.9cc Tropical Compressor

QX1902VDL-T

Nominal Capacity: 455W (1,552Btu)

- 24V DC

- 900g /1.98lbs

- Refrigerant: HFC-134a

- Size: 92 x 71 mm (High x Diameter)

- Working amps: 1~8.2A, (Max. 15A)

- Compressor type: Brushless DC Motor

- Variable speed drive:(2,000~6,500rpm)

- Drive board: ACRC-DB1510

3.2cc Mini Compressor

QX3202VDL

Nominal Capacity: 550W (1,876Btu)

- 24V DC

- 2260g /4.98lbs

- Refrigerant: HFC-134a

- Size: 112.5 x 73 mm (High x Diameter)

- Working amps: 1~10.3A (Max. 12.5A)

- Compressor type: Brushless DC Motor

- Variable speed drive:(2,000~4,500rpm)

- Drive board: ACRC‐DB3010

2.0cc Mini Compressor

QX2002VDL

Nominal Capacity: 525W (1,790Btu)

- 24V DC

- 810g /1.79lbs

- Refrigerant: R134a / R290

- Cylinder Number: Single pump

- Size: 88.5 x 53.5 mm (High x Diameter)

- Working Amps: 1~5.2A, (Max.10A)

- Drive board (2,700~6,300rpm)

- Display Panel included

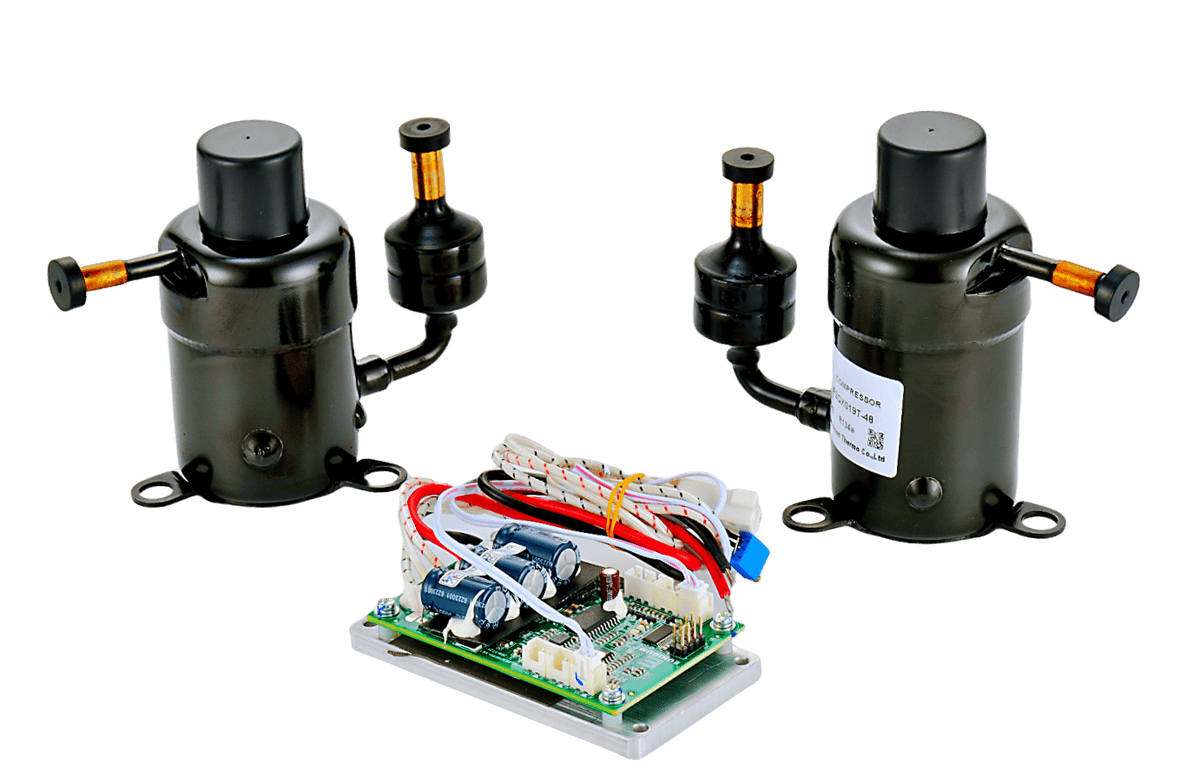

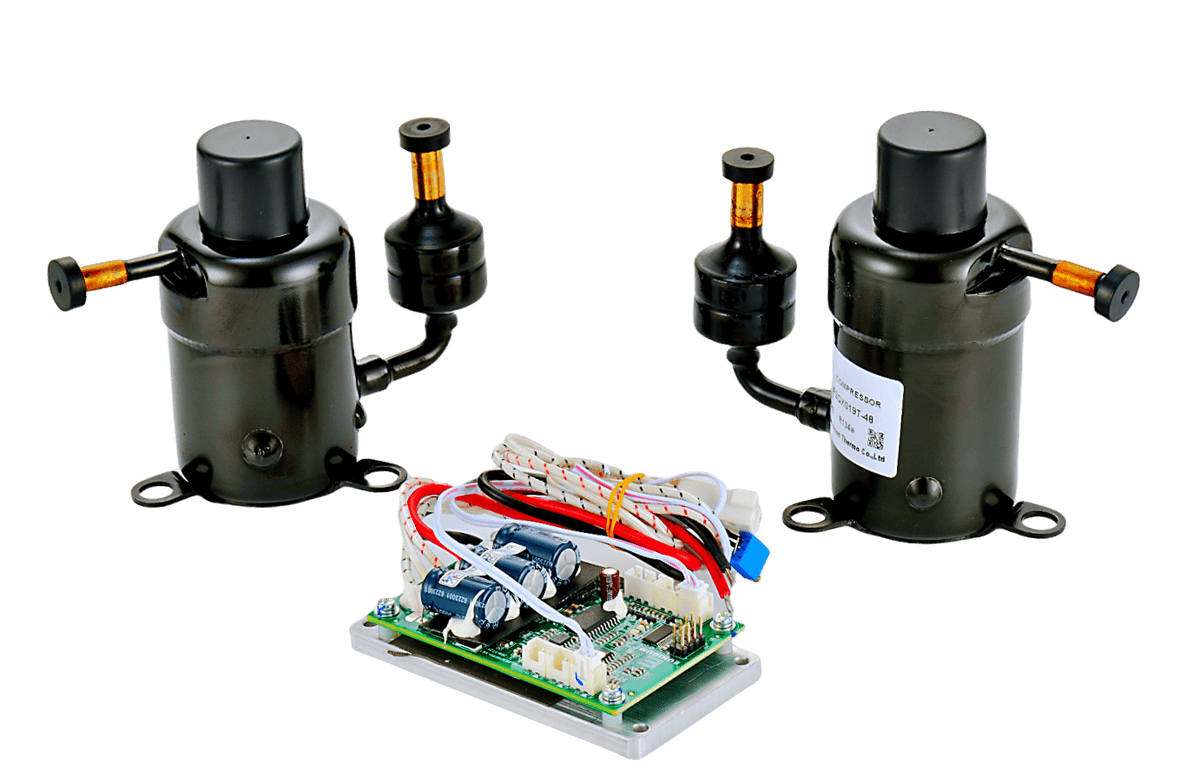

2.8cc Mini Compressor

QX2802VDL

Nominal Capacity: 700W (2,387Btu)

- 24V DC

- 1.3kgs /2.87lbs

- Refrigerant: R134a / R290

- Cylinder Number: 2 pumps

- Size: 130 x 61 mm (High x Diameter)

- Working Amps: 1~8.3A, (Max.12A)

- Drive board (1,800~4,500rpm)

- Display Panel included

3.8cc Mini Compressor

QX3802VDL

Nominal Capacity: 700W (2,387Btu)

- 24V DC

- 1.6kgs /3.53lbs

- Refrigerant: R134a / R290

- Cylinder Number: 2 pumps

- Size: 145 x 64 mm (High x Diameter)

- Working Amps: 1~12A, (Max.18A)

- Drive board (1,800~6,000rpm)

- Display Panel included

Compact Power for Mobile and Off-Grid Cooling

The Mini Compressor Provides Unparalleled Performance!

Compact. Quiet. High-Performance.

RIGID’s 24V DC Compressors redefine miniature cooling with a cutting-edge twin-cylinder rotary design and brushless DC motor. Engineered for mobile and compact refrigeration systems, these compressors deliver outstanding cooling capacity with up to 40% less noise and significantly reduced vibration.

Lightweight and space-saving, RIGID 24V compressors are built for efficiency and durability. With variable-speed inverter control, they offer precise temperature management and intelligent load adaptation—making them the ideal solution for applications where power, silence, and space matter most.

✅ Ideal Applications Include:

- Portable air conditioning and refrigerators

- Telecom cabinet and battery cooling

- Marine cooling boxes and photonic chillers

- Seat coolers, compact dryers, and small-scale appliances

- Vehicle and transport A/C systems (even with the engine off)

Quiet Inverter Compressor

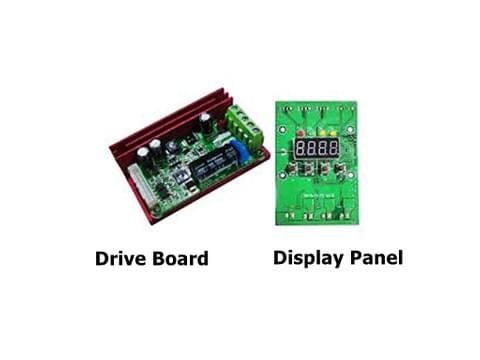

Drive Board&Display Panel

Single vs Twin Cylinders

Twin Cylinder QX2802VDL

24V Mini Compressor Performance Curve

Model: QX1902VDL

24V Mini Compressor

- Voltage: 24V DC

- Refrigerant R134a

- Net Weight: 1.6 lbs / 0.72kgs

- Motor Type: Variable Speed Motor

- Capacity: 100~455W (1550Btu)

- Small compressor for heating & cooling

24V Mini Compressor Features

- Low installation costs

- Lightweight & small size

- Low energy consumption

- Low operating noise (45dB)

- Fully hermetic, No maintenance

- Battery, solar power, DC power run

- World’s smallest DC 24V compressor

- Apply to HBP, MBP & LBP applications

- Applications: Heating, Cooling, and Refrigeration.

🌡️ High Performance at Speeds

Backed by real-world data, the performance curves show strong cooling capacity and consistent mass flow across a wide range of evaporation temperatures and speeds (3,000–5,000 RPM), even under demanding conditions (condensing temp: 54.4°C).

🔋 Flexible Power Options

Whether powered by battery, solar, vehicle, or grid (via AC-DC converter), the QX19 is built for versatility. Its low power input and silent operation make it a perfect match for portable freezers, medical cooling units, mobile fridges, and compact electronics thermal management.

📊 Smart and Reliable

From -25°C to +20°C evaporator temps, the QX19 ensures optimized input power and high nominal capacity, ensuring energy-saving cooling on the go.

Easy Integration with Your System for Advanced Control

Integrating RIGID’s drive board (PCB) and optional display panel into your system is simple - perfect for users who need advanced functions or want to control the compressor using their own software.

The motor drive board enables variable-speed operation, allowing you to adjust the cooling capacity by changing the compressor speed. It accepts a 0–5V DC analog control signal to regulate speed precisely.

- Minimum speed: 2,000 RPM (when control voltage is 0.7V or lower)

- Maximum speed: 6,000 RPM (at 4.5V or higher)

- Between 0.7V and 4.5V, the speed control is linear and can be calculated using the formula: S = 1132 × V + 1408

- Where S = compressor speed in RPM, and V = control voltage in VDC.

This flexible setup gives you smooth and reliable control, making it easy to customize cooling performance based on your specific application requirements.

Motor Features & Applications

RIGID mini 12V DC compressors have the size, weight, and durability that make them well-suited to small or portable applications, including:

- Small Cooling

- Medical Device

- Beverage Cooling

- Small Refrigerators

- EV/RV Battery Cooling

- Portable Heat Pumps

- Electronic Components

- Mini-Chilled Water Systems

- Portable DC Air Conditioner

- Electronics Cooling Systems

- Aesthetic & Medicine Device

- Telecommunications Cooling

- Portable Mini Cooling Systems

- Miniature Refrigeration/Freezer Systems

- Thermally-Controlled Shipping Containers

- Portable and Small Cooling Applications

- Automotive (Electric Vehicle, Vessel, Helicopter)

Contact Us

Any Messages From You Will Receive Our Prompt Reply In 1h.

Online Store

Buy nowTwin Cylinder Compressor QX2802VDL (24V, R134A)$290.00 - $300.00

Buy nowTwin Cylinder Compressor QX2802VDL (24V, R134A)$290.00 - $300.00 Buy nowTwin Cylinder Compressor QX2802VDL-T (24V, R290)$320.00 - $330.00

Buy nowTwin Cylinder Compressor QX2802VDL-T (24V, R290)$320.00 - $330.00 Buy nowTwin Cylinder Compressor QX3802VDL (24V, R134A)$350.00 - $360.00

Buy nowTwin Cylinder Compressor QX3802VDL (24V, R134A)$350.00 - $360.00 Buy nowTwin Cylinder Compressor QX3802VDL-T (24V, R290)$380.00 - $390.00

Buy nowTwin Cylinder Compressor QX3802VDL-T (24V, R290)$380.00 - $390.00 Buy nowTwin Cylinder Compressor QX3803VDL (48V, R134A)$350.00 - $360.00

Buy nowTwin Cylinder Compressor QX3803VDL (48V, R134A)$350.00 - $360.00 Buy nowTwin Cylinder Compressor QX3803VDL-T (48V, R290)$380.00 - $390.00

Buy nowTwin Cylinder Compressor QX3803VDL-T (48V, R290)$380.00 - $390.00 Buy now7.5cc Horizontal DC Compressor$410.00 - $420.00

Buy now7.5cc Horizontal DC Compressor$410.00 - $420.00 Buy now9.6cc Horizontal DC Compressor$430.00 - $440.00

Buy now9.6cc Horizontal DC Compressor$430.00 - $440.00 Buy now15.0cc Horizontal DC Compressor$450.00 - $460.00

Buy now15.0cc Horizontal DC Compressor$450.00 - $460.00 Buy nowHorizontal Compressor QH3802VDL (24V, R134a)$380.00

Buy nowHorizontal Compressor QH3802VDL (24V, R134a)$380.00 Buy nowHorizontal Compressor QH2802VDL (24V, R134a)$320.00

Buy nowHorizontal Compressor QH2802VDL (24V, R134a)$320.00 Buy nowMini Compressor QX1901VDL (12V)$210.00

Buy nowMini Compressor QX1901VDL (12V)$210.00 Buy nowMini Compressor QX1902VDL (24V)$220.00 - $250.00

Buy nowMini Compressor QX1902VDL (24V)$220.00 - $250.00 Buy nowMini Compressor QX1903VDL (48V)$230.00

Buy nowMini Compressor QX1903VDL (48V)$230.00 Buy nowMini Compressor QX3202VDL (24V)$290.00

Buy nowMini Compressor QX3202VDL (24V)$290.00 Buy nowMini Compressor QX2002VDL (24V)$260.00

Buy nowMini Compressor QX2002VDL (24V)$260.00 Buy nowMini Compressor QX3002VDL (24V)$290.00

Buy nowMini Compressor QX3002VDL (24V)$290.00 Buy nowMini Compressor QX3003VDL (48V)$300.00

Buy nowMini Compressor QX3003VDL (48V)$300.00 Buy nowHigh-Power Mini Compressor QX8848VDL (48V)$410.00 - $500.00

Buy nowHigh-Power Mini Compressor QX8848VDL (48V)$410.00 - $500.00FAQ

RIGID Mini 24V Compressors – Powering the Future of Miniature Refrigeration.

1. What is RIGID mini 24V compressor?

2. What makes RIGID’s 24V mini compressor different?

3. What is the operating voltage of the 24V DC compressor?

4. What is 24V DC compressor cooling capacity range?

5. What refrigerant is 24V DC compressor used?

6. Does the 24V mini compressor support variable-speed control?

7. How is 24V DC compressor speed controlled?

8. Is the 24V DC compressor noisy?

9. Does the 24V DC compressor vibrate much?

10. Is the cooling performance consistent across temperature ranges?

11. Can I run the mini compressor off a battery?

12. Can 24V DC compressor be powered using AC electricity?

13. Does RIGID provide a driver board for the compressor?

14. Can I connect the compressor to my microcontroller or PLC?

15. What is the average power consumption of 24V DC compressor?

16. What are the main applications of a 24V mini compressor?

17. Is 24V DC compressor suitable for use in RVs or trucks?

18. Can 24V DC compressor be used for telecom battery cooling?

19. Can I use 24V compressor in a compact dryer or chiller?

20. Is customization available for special applications?

Standard Products and Custom Solutions

Established in 2010, RIGID is the manufacturer who's behind many popular brands in the US. RIGID's vision is to set the benchmark standard for the micro cooling industry. We are a China manufacturer and supplier of compact cooling systems, working in close cooperation with the leading United States and European manufacturers of Air-conditioning & Refrigeration.

In addition to offering standard products including Micro DC Aircon (ruggedized air conditioner modules for compact and confined space cooling), Liquid Chiller Modules (battery-driven compact refrigeration systems that our customers integrate into their applications), and DC Condensing Units (world's small direct cooling units used by customers in small freezer, medical, laser, and electronics cooling). RIGID also custom design or modify refrigeration systems for most customers' specific applications.

Let our engineering team develop the perfect cooling solution for you!

Certificates | Download | Contact Us | Our History | Return & Exchange

RIGID Technology * © Copyright 2010-2025 * RIGID Cooling * All rights reserved.