RIGID HVAC CO., LTD

Free Piston Stirling Cryocooler

FPSC (Free Piston Stirling Cryocooler) is a new type of completely CFC-free, high-efficiency, energy-saving, and environmental protection Cooler, which uses a small amount of helium as the coolant.

FPSC also is a kind of Magnetic Levitation Compressor (MagLev solution). But it is an even more efficient chiller compressor, with low energy cost, and consumption. It is small and portable, and it is widely used for precise temperature control for under -170℃ maximum.

RIGID, one of the leading Chinese companies in terms of innovation, designed a Free-Piston Stirling cooler – FPSC. The unit takes the entire product to a whole new level where it can save a lot of energy and significantly improve efficiency. The default version of Stirling coolers includes pistons, heat exchangers, and compression spaces. But we see technological advancements in all industries, such as Biotech, Pharmaceutical, Food, Energy, Chemical, Medical, Bio-Science, logistics, and Metrology.

RIGID Free-Piston Stirling Cryocooler is a game-changer for next-generation ultra-deep freezing! Read More...

Product Models

Stirling Cooler, which we refer to as the FPSC (Free Piston Stirling Cooler). RIGID has prepared a product lineup of Stirling Coolers that can cool air temp to 30℃ ~ -160℃ using helium gas as the refrigerant. The Stirling Cooler, which differs from a compressor, is a cooling system that continuously repeats gas compression and adiabatic expansion and uses naturally occurring helium gas as the refrigerant.

Helium is a very safe gas that is entirely harmless to our global environment. The typical use of our Stirling Cooler is in portable freezers, and refrigerators, but we are also developing a product lineup for use in laboratory equipment and in medical devices used for low-temperature distribution of goods.

Capacity: 40W

Input Power: 12V

N.W: 2.2kg (4.8lbs)Coolant: Helium=2.5g

Size: ODФ86mm x Length260mm

Working Condition: 0℃~+60℃(32℉~140℉)

Installation: Any direction is workableTemperature Sensor of Controller: -1℃ to -99℃

Temp Range in Cold Fin (Cold part): -100℃~ 0℃

Capacity: 80W

Input Power: 24V

N.W: 2.2kg (4.8lbs)Coolant: Helium=3.0 g

Size: ODФ86mm x Length270mm

Working Condition: 0℃~+60℃ (32℉~140℉)Installation: Any direction is workable

Temperature Sensor of Controller: -1℃ to -99℃

Temp Range in Cold Fin (Cold part): -140℃~ 0℃Capacity: 100W

N.W: 4.0kg (8.8lbs)

Coolant: Helium=3.0g

12V~30V DC Power Supply

External Size: 132mm×132mmx336mm (LxWxH)

Working Condition: 0℃~+60℃ (32℉~140℉)

Installation: Any direction is workable

Temperature Sensor of Controller: 0℃ to -140℃

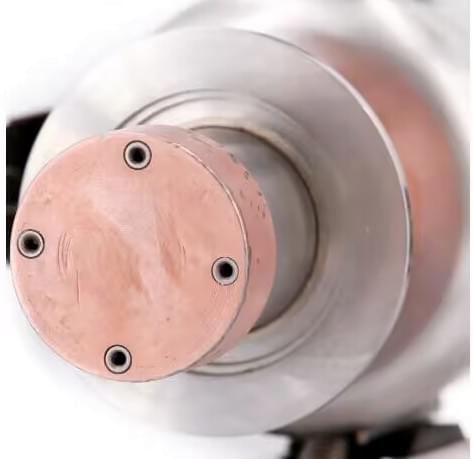

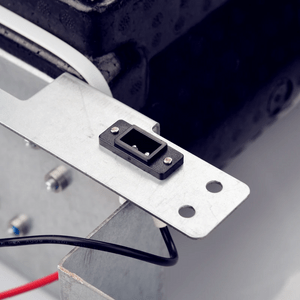

Temp Range in Cold Fin (Cold part): -160℃ ~0℃FPSC Cryocooler Parts

KF50 Flange

Cold Adapter

Cold Adapter

St. St. Cold Head

Copper Cold Head

Copper Cold Head

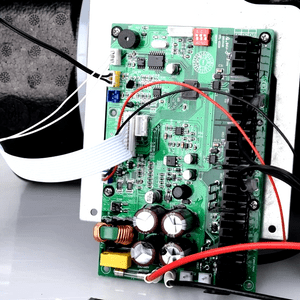

FPSC Cryocooler & PCB

Premium Technology with the lowest total cost of ownership!

Cooling Performance Curve

Using safe and environmentally friendly Helium gas as the refrigerant. With the international advanced Free-piston Stirling technology, RIGID Stirling Coolers have a minimum temperature that can be controlled to -160℃, ±0.1℃. Furthermore, the Cryocooler has the smallest footprints, which is very suitable for deep, and fast low-temperature transportation and cold chain logistics.

Cryocooler Applications

To cool air in a compact and confined area!

1Direct Cooling with Conductive Connection

Cooling Efficiency - Limited:

The aluminum plate has uneven cooling, resulting in a relatively high thermal resistance between the aluminum plate and the inside air. This limits the effective cooling volume.

Impact of Frost - Minimal:

When the aluminum plate surface is covered with frost, the surface area exposed to the inside air doesn't decrease significantly.

Other Considerations:

Vibration from the FPSC can directly transfer to the insulated container and aluminum plate, potentially causing noise issues.

2Indirect Cooling with Heat Exchanger+Fan

Cooling Efficiency - Optimal:

The thermal resistance between the cold side of the FPSC and the heat exchanger is minimal. Additionally, the thermal resistance within the air is also low.

Impact of Frost on Cooling - Significant:

When frost accumulates, it blocks the airflow, reducing the exposed surface area of the finned plate to the inside air. This results in a decrease in cooling performance.

Other Considerations:

1. It's important to choose a fan motor that can operate efficiently at the desired working temperature.

2. The heat generated by the fan motor contributes an extra heat load, potentially lowering the overall cooling performance.

3Direct Cooling with Thermosyphon

Cooling Efficiency - Improved:

The aluminum plate is cooled more evenly compared to "1". Thanks to two-phase heat transport, there's minimal thermal resistance between the aluminum plate and FPSC.

Impact of Frost on Cooling - Minimal:

Even when the aluminum plate surface is covered with frost, the exposed surface area to the inside air remains largely unchanged.

Other Considerations:

1. It's important to identify and have the right working fluid ready for the desired operating temperature.

2. Make sure to have the necessary equipment for charging the working fluid.

4Direct Cooling with Brine/Glycol/Nitrogen

Cooling Efficiency - Improved:

A copper tube is attached to the aluminum plate with more flexibility than in "3". This results in more uniform cooling compared to "3", although it does lead to a slightly higher thermal resistance.

Impact of Frost on Cooling - Minimal:

Even when the aluminum plate surface is covered with frost, the exposed surface area to the inside air remains largely unchanged.

Other Considerations:

1. Make sure to have suitable brine and a pump ready for the desired operating or storage temperature.

2. The heat from the pump motor contributes extra heat, potentially reducing the overall cooling performance.

3. Take precautions to prevent potential brine leakage.

Key Features

A Game-Changer For Next-Generation Deep Freezing - State Of The Art!

Evaporating Temp Below -99 ℃

Temperature down to -99℃ in few mins. It's suitable for strict temperature control. Depending on the heat mass, cooling capacity and speed can be fine-tuned.

Temperature Below -160 ℃

No OIL, No CFC.

It adopts helium as coolant, MagLev technology. It can reach maximum ultra deep temp -160℃ (only RS100), with 50% energy savings.

Most Compact & Lightweight

RIGID stirling cooler can be installed on various applications, especially for portable equipment because of its compactness and lightweight.

Completed & Integrated

RIGID Stirling cooler, drive board, temperature control and fan are integrated in one unit. You can install it into your system or equipment as it is.

Zero Maintenance & Less Engineering

Integrated configuration, no solder joints, which greatly improves reliability while reducing after-sales maintenance.

Long Continuous Operation

Stirling convertor sets achieves 14-Year continuous operation milestone, record-breaking power convertor.

Refrigerant CFC Free & Oil Free

Freon or other substitutes have been completely eliminated. No need oil operation, no wear, low failure rate.

All-Round Installation Available

Installation angle is not required, can be 360° rotation. Shock resistant, less vibration, ultra low working noise.

APPLICATIONS

RIGID ULT Stirling Cold Solutions Are Trusted in a Variety of Applications.

RIGID Stirling Coolers not only are the most environmentally sustainable ultra-low temperature (ULT) coolers on the market, but they are also the most cost-effective with the lowest life cycle costs. You can benefit from breakthrough Stirling cooler technology without compromising cooling performance across the entire research organization with your devices or equipment.

Military & Aerospace

Medical & Laboratory

Bio-tech Pharma

Semiconductor

Vaccine Transportation

Smart Cold Chain

Portable Freezer

X-Ray Machines

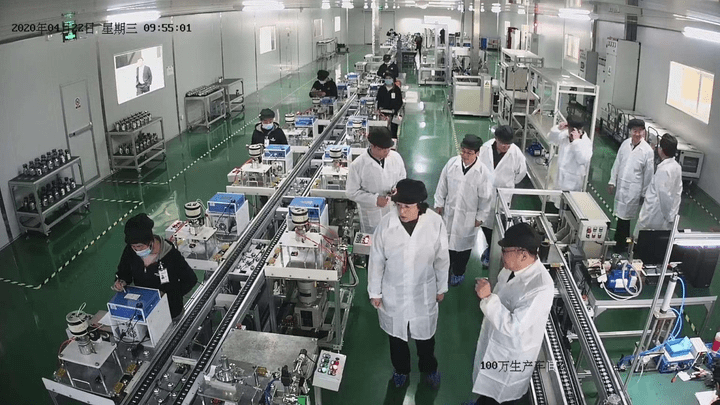

Stirling Cooler Factory

Stirling technology has been used in military and aerospace fields for more than 20 years.

However, due to its high price, it has not been used in the mass market, and there are not many related application products.

After 3 years of efforts, RIGID engaged with a China researchinstitue and has successfully launched a series of affordable quality products for deep freezing.

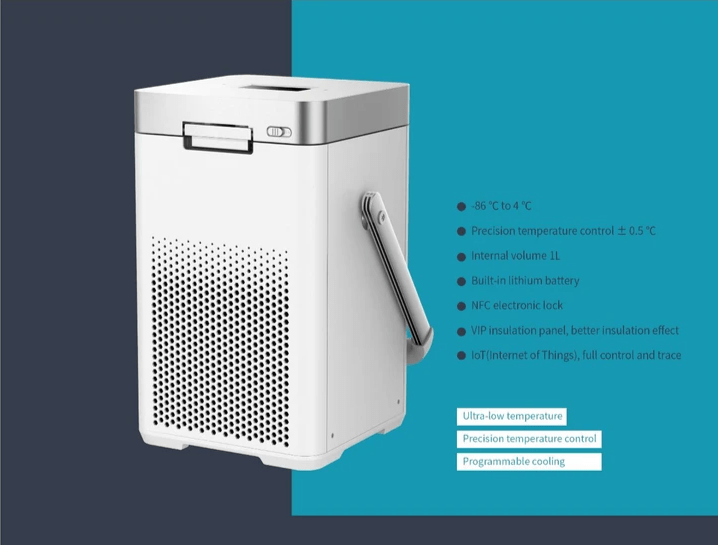

-86℃ Stirling Freezer

Model: CPF01L86

Temperature -86℃ and portable freezer. Best choice for vaccine and drug transportation and storage.

Our R&D Team

Ultra-low Transportable Cryogenic Freezers are specifically designed for Vaccine and drug transportation and storage.

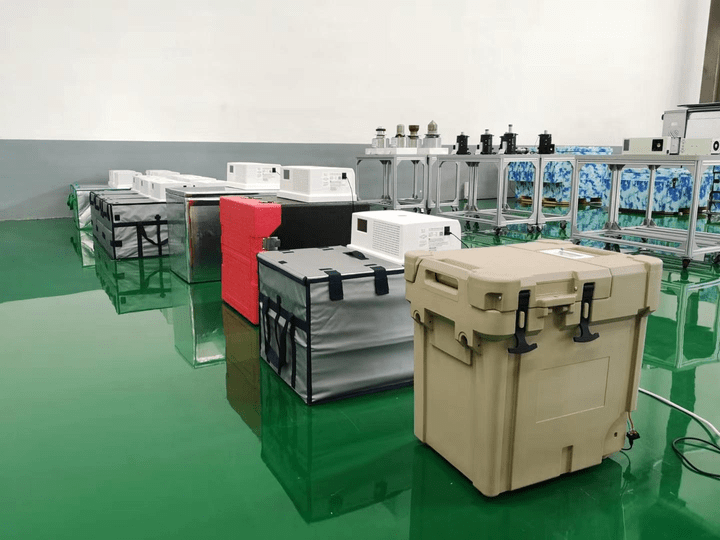

Stirling Power Freezer

Freezers For all kinds of vaccines.

Covid-19 Vaccine Freezer Storage and Transportation.

Set the temperature you need from 8℃ to -80℃.

Vaccine Freezer

RIGID Can Provide Off-the-Shelf Products Designed And Produce By Us And Our Partners.

- CONTACT US

For further information contact Rigid Stirling today!

Stirling Cryocooler FAQ

1. What's Free Piston Stirling Cooler (FPSC)?

2. How does a Stirling Cooler work?

3. What's Stirling engine used for?

4. How cold can RIGID Stirling Cooler get?

5. Which gas is used in Stirling Cooler?

6. What's the main part of Stirling Cooler?

7. How do I control a Stirling Cooler?

8. How long can a Stirling Cooler run?

9. What do I need besides the Stirling cryocooler?

10. What maintenance Stirling Cooler is required?

11. What's Stirling Cooler input power?

12. Where can I buy Stirling Cooler?

13. Can I use the system in a vacuum?

14. Are there any special mounting requirements for RIGID Stirling Cooler?

15. Can I get a custom cold tip or evaporator?

Certificates | Download | Contact Us | Our History | Return & Exchange

RIGID Technology * © Copyright 2010-2023 * RIGID HVAC * RIGID Cooling * All rights reserved.