Free Piston Stirling Cooler is a kind of Magnetic Levitation Cooler. It is widely used for precise temperature control for under -100℃.

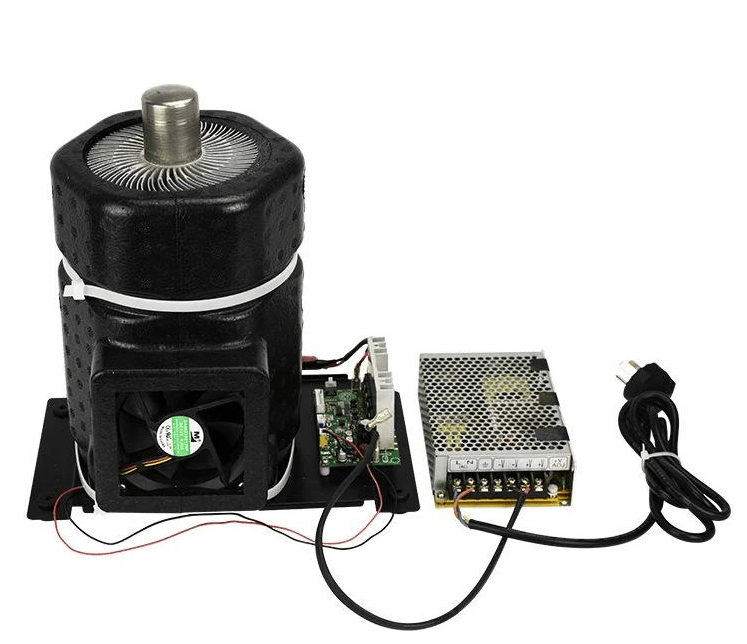

This is the Stirling Cooler, which we refer to as FPSC (Free Piston Stirling Cooler). The default version of Stirling coolers includes pistons, heat exchangers, and compression spaces. But we are seeing the technology advancements in all industries, and Stirling refrigerators aren’t an exception.

The Stirling Cooler use Helium as a gas, which differs from a compressor, is a cooling system continuously repeats gas compression and adiabatic expansion and uses naturally helium gas as the refrigerant. Helium is a very safe gas. It is entirely harmless to our environment.

The typical use of our Stirling Cooler is deep temperature refrigerators, freezers, but RIGID is also developing a product lineup for use in laboratory equipment, and other equipment used for low temperature distribution of goods.

RIGID, one of the leading Chinese companies in terms of innovation, designed a free piston Stirling cooler – FPSC. The unit takes the entire product to a whole new level where it can save a lot of energy and significantly improve efficiency.

Thanks to that, these units are eco-friendly solutions suitable for all those individuals and corporate clients who want to demonstrate their care for the planet. The new cooler doesn’t contain any CFC, and it is interesting to note that the role of coolant was taken by helium. It is even more impressive that FPSCs use doesn’t need a big amount of helium – it is a small quantity that can do the cooling.

What Is a Stirling Cooler?

The Free Piston Stirling Cooler (FPSC) is an elegant, completely sealed heat transfer system that has only two moving parts (a piston and a displacer), and which can use helium as the working fluid without concern about seal leakage.

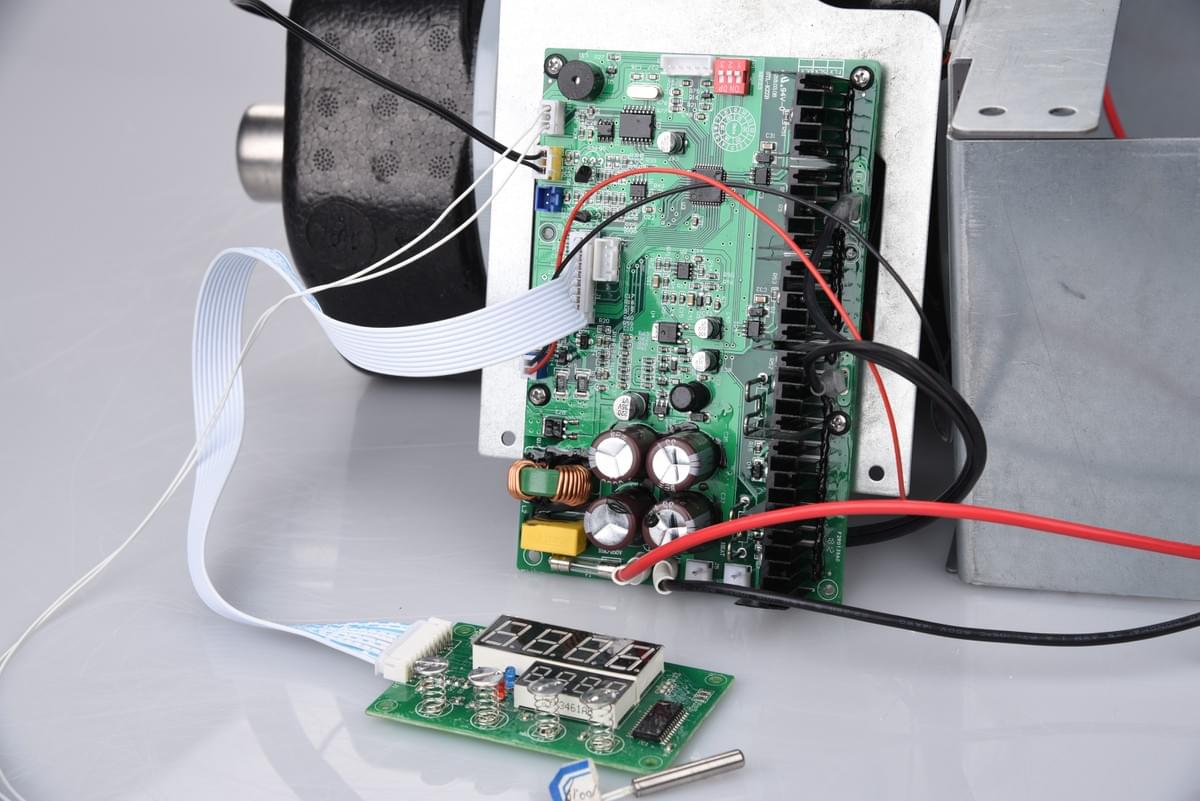

The piston is typically driven by an oscillating magnetic field that is the source of the power needed to drive the refrigeration cycle. The magnetic drive allows the piston to be driven without requiring any seals, gaskets, O-rings, or other compromises to the hermetically sealed system.

Claimed advantages for the system include environmental friendliness, cooling capacity, lightweight, compact size, precise controllability, and high efficiency.

Stirling coolers are nothing but cryocoolers that use a Stirling cycle to work. These cooling systems function as standalone units, and you can find them in various sizes.

In most cases, Stirling coolers are tabletop models that can cool down different objects and items to cryogenic temperatures.

Free piston Stirling coolers use a Stirling engine, which has only two parts that move. The unit has a casing made of stainless steel, and all sensitive components are hermetically sealed inside.

- Biotech/Pharmaceutical – you can use low temperatures for maintaining chemicals and other pharmaceutical products, including vaccines.

- Energy/Chemical – you can create a cryogenic environment and analyze and inspect different chemicals and test reactions of chemicals.

- Metrology – if you need to maintain precise temperature, and keep it at the desired low level, these units are the right choice.

- Foods/Logistics – if you are doing food delivery, you can keep the food refrigerated to maintain its freshness and deliciousness. Additionally, Stirling coolers can be used in portable freezers.

- Medicine/Vaccine - you can use Rigid Stirling Cooler for compact and deep freezer. The lowest maximum temperature can reach minus -100℃.

How Does Free Piston Stirling Cooler Work?

Since Free Piston Stirling Coolers (FPSC) are new and revolutionary units, you are probably wondering how they work. Here is a quick explanation.

You have the main body with a fin or cylinder protruding from it. The product uses a heat exchanger to cool the cylinder down. The heat exchange involves repeating compression cycles.

The main body also contains a piston that moves up and down continuously. The material of choice for these pistons is usually stainless steel. The moving of the piston combined with the compression leads to a gas explosion.

The upper compression chamber of the cooling system contains two pistons and balancing floats. The manufacturer uses helium gas to fill the chamber, and a linear motor to drive the piston.

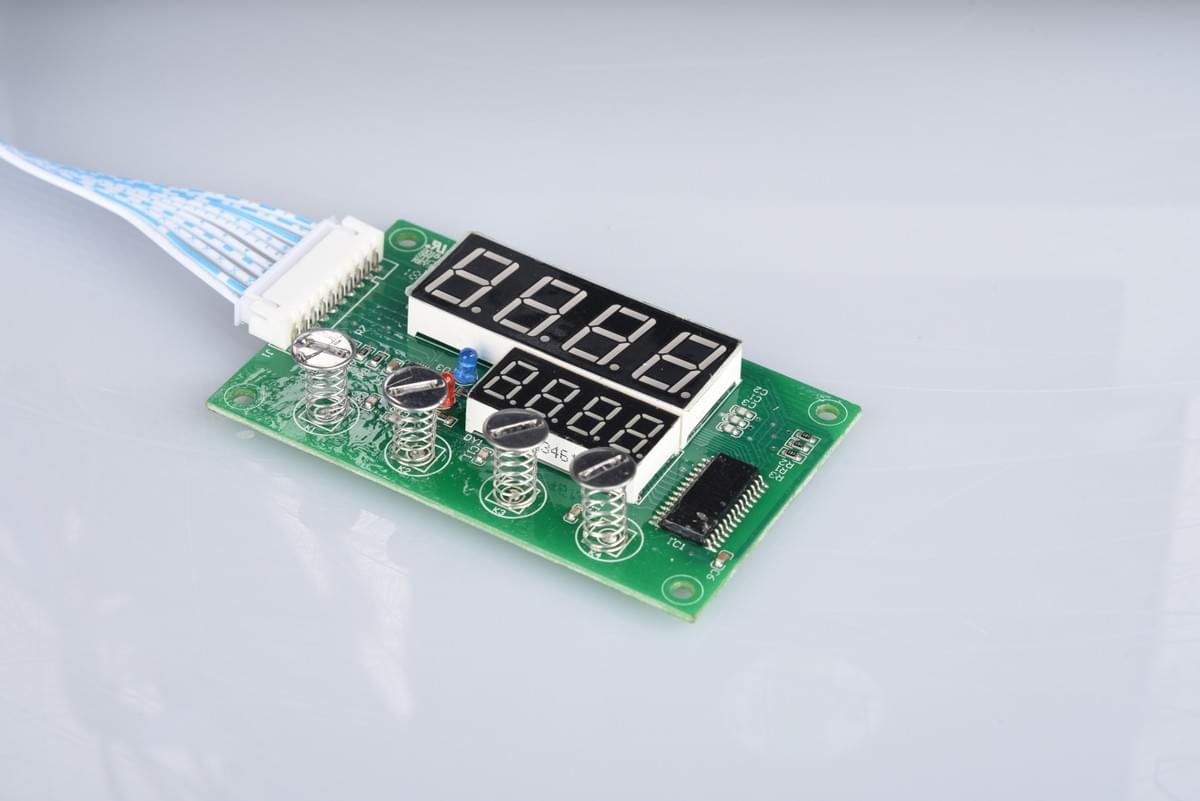

The driving action transfers helium to the 80Hz balancing float. The system can control the difference in temperature at 80C.

You will also find an expansion space on the top of the balancing float. At the same time, compression space is between the piston and the float for balancing. Finally, a helium gas flow channel is the annular space that surrounds the balancing float.

Now, let’s focus on the flow passage. In the expansion space, you will find a cold side cylinder (fin), and the compression space is where the designers put the heat sink. You will also find a regenerator in the space between the heat sink and the cold cylinder fin.

Why would you need a regenerator? The idea is to ensure helium’s heat exchange, as well as capture that heat, store it, and return it to the helium gas.

In case there is something unclear, you can check out the photo above. The picture clearly explains the working principle of a Stirling cooler engine, and you can use it to understand previous paragraphs better.

Here is another photo that can better explain the working principle of a free piston Stirling cooler. It is a 3D image of various components included in the FPSC.

The piston driving frequency is approximately 80Hz. The piston motion creates a pressure differential that drives the displacer.

That differential goes through the refrigerant because it needs to keep a certain phase angle of the displacer to the piston.

In essence, the refrigerant is expanded and compressed by the linear motor that drives the piston. Thanks to that, you have an expansion (cool) space and compression (warm) space. That is the basic explanation of a Stirling cycle.

What makes a free piston Stirling cooler unique? The fact that Rigid added a feature that piston does not have to be physically connected with the displacer. Instead, it has the freedom of moving independently.

Can an FPSC Cool Down Items Effectively?

Are you wondering if the Free Piston Stirling Cooler is capable of cooling items effectively?

The answer is yes, but it is important to make sure that heat exchange is one of the features offered by the product’s thermal receiver. It is the way how FPSCs manage to cool down objects near them.

Now that we established how Stirling coolers cool down objects, let’s talk the effectiveness. It may depend on the unit, but the FPSC designed by Rigid needs only two minutes to reach temperatures as low as -80C. We are talking about an environment where the no-load temperature is 25C.

If you want to see the Free Piston cooler designed by Rigid in action, we suggest checking out this video. It is beta testing of the product where the object that the unit cools down reaches -114C.

Who Is the Company Behind the Free Piston Stirling Cooler?

As early as 8 years ago, RIGID has secret research agent in this deep freezing industry. Ever since day one, the company dedicates maximum effort to come up with innovative miniature compressor solutions. The primary idea behind their unit is innovation.

The company is trying to combine an effective solution designed in a portable and compact package. The idea is to reduce the size of cooling units as much as possible while keeping their performance at the highest level.

Rigid uses modern approaches and technologies and utilizes creativity, skill, and knowledge of its engineers to design unique and customized solutions for many applications. The company searches for an ideal ultra-freezing solution. Thanks to that approach, Rigid managed to come up with FPSC units that have versatile uses.

These units have been designed after more than a decade of innovation, leadership, and evolution in developing miniature DC compressors.

Some of the potential applications of DSPCs include home refrigeration, biotech, and pharmaceutical industries.

Is FPSC a Better Choice Than Compressor Refrigerator?

The short answer is yes, but we always like to explain the issue in detail.

The compact size is the first reason why free piston Stirling coolers are better than cooling systems that utilize vapor compression.

Apart from the small size, you can also expect the system to be lightweight. Thanks to those two characteristics, you will essentially get a portable cooler that you can effortlessly transfer from one location to another.

The overall weight of the complete Stirling Cooler is 4.41 pounds (2 kilograms), which is quite impressive. You can better understand how light this cooling unit is if we tell you that a normal compressor weighs five times as much.

Even if you neglect the obvious sizing advantage, FPSC is better than vapor-compression systems because they are a more efficient solution. Thanks to higher efficiency and better use of energy, they also manage to be eco-friendly.

Additionally, the working fluid of FPSC is helium gas, which is also a positive thing for the environment. Many other cooling solutions utilize R134a and other solutions, which can have a high potential for global warming.

Are Free Piston Stirling Coolers Quiet?

You might think that a cooling system needs to be loud to be efficient. The FPSC designed by Rigid proves that it is possible to deliver efficient cooling while ensuring that the system remains extremely quiet.

The trick lies in operating at different speeds and reducing friction as much as possible. Additionally, the system is vibration-free, which contributes to reducing the noise level.

Are you wondering how much noise you can expect from a free piston Stirling cooler? The estimation is that these systems are as quiet as 48dB, which is quite impressive for a cooling unit.

The low noise level makes the FPSC unit extremely versatile. You can use it in places where you couldn’t imagine to place a cooling system before.

For example, you can place a Stirling cooler in a museum, and it will manage to cool down the objects without disturbing the visitors.

The same applies to hospitals where you wouldn’t disturb the patients while ensuring optimal temperatures wherever they are needed.

While we are talking versatility and suitability for various industries, we should mention that free piston Stirling coolers are oil-free, which means you won’t get all messy when transporting or cleaning them.

Can a Stirling Cooler Save Money and Energy?

We can’t tell you about the exact money savings because they will depend on the energy cost in your region. However, we can tell you that the testing proved that these units could secure an average 50% energy saving.

You will get a more efficient performance thanks to the magnetic bearings, and that is how the system can deliver those savings.

It is crucial to emphasize that the savings will depend on the application. For example, air cooling can secure the mentioned 50% and even more savings in some cases.

The minimum can be lower for some other applications, such as liquid freezing. If you need to cool down liquids, you can expect to save approximately 30% of energy compared to normal compressors.

That energy efficiency makes FPSCs a far better eco-friendly solution than standard cooling units. On top of that Rigid ensured to use helium gas in Stirling coolers.

Helium has zero potential for global warming, which means that it is not harmful to the environment.

Are Free Piston Stirling Coolers Precise Temp-Control?

You already know that FPSCs are effective. The coolers designed by Rigid are even more effective than the competition because they can cool down an application for up to 80C in only two minutes.

Once the object or item reaches the desired temperature, it is vital to maintain it constantly. That can be particularly vital in laboratories where you need to maintain chemicals, but also for many other applications.

You will be glad to know that Rigid’s FPSC has the capability of temperature control that is precise within +/- 0.1C.

It sounds incredible, but you can rest assured that the cryocooler will maintain the ideal temperature for any application effortlessly.

Are you wondering about the lowest temperature that free piston coolers can achieve? Rigid ensures that the application can be cooled down to -170C if necessary.

What Are Applications for Free Piston Stirling Cooler?

Here are some suggestions of different ways of using FPSCs:

- Direct cooling with conductive connection

- Direct cooling with brine

- Direct cooling with thermosyphon

- Indirect cooling

Now, let’s take a look at some industries where you can use these units:

- Biotech/pharmaceutical – you can use low temperatures for maintaining chemicals and other pharmaceutical products, including vaccines. Freeze drying, preventing byproduct formation, and even cryopreservation are also potential uses of a Stirling cooler.

- Energy/chemical – you can create a cryogenic environment and analyze and inspect different chemicals. You can also use the environment created by FPSCs to test reactions of chemicals.

- Metrology – if you need to maintain precise temperature, and keep it at the desired low level, these units are the right choice.

- Foods/logistics – if you are doing food delivery, you can keep the food refrigerated to maintain its freshness and deliciousness. Additionally, Stirling coolers can be used in portable freezers.

- Vaccine/Medicine - you can use Rigid Stirling Cooler for compact and deep freezer. The maximum lowest temperature can reach minus -100

These applications are merely some suggestions how you can use a free piston Stirling cooler. It is an extremely versatile cooling system that you can use virtually anywhere.

The only important thing is that you need to achieve and maintain an ultra-low temperature of an item, substance, or object. The Stirling cooler will take care of the rest.

Is It Hard to Maintain FPSC?

No, it is not difficult to maintain these cooling units at all. Furthermore, Rigid made maximum effort to ensure the maintenance is effortless.

First of all, FPSC systems are oil-free. That will eliminate the risk of leaks, and make taking care of the unit easier. It also means that free piston Stirling coolers virtually do not require any maintenance.

They are long-term units that will last for years, and during all that time, you don’t have to put it any effort to maintain their longevity. The only thing you should do is to enjoy fast and efficient cooling!

But what if you just don’t like it, send it back to us. 100% refund, simple! It is RIGID guarantee!

Why Choose RIGID Free Piston Stirling Cooler

RIGID Stirling technology is a breakthrough in Small and Deep Freezing. It is widely used for precise temperature control for under -100℃. The future is bright and technology advances daily.

It is a fact that RIGID Stirling Cooler technology used for fast and deep freezing has been very well-received in the global market.

It can be used in an abundant of applications, also a better alternative of miniature dc compressor. Nevertheless, despite all that, any of the units could be the best as long as they serve the needs for space, cost, efficiency, the size of the refrigeration plant, as well as the mode of operation.

All in all, RIGID Free Piston Stirling Cooler is the best for both commercial and personal use.