The World's Smallest DC Condensing Unit

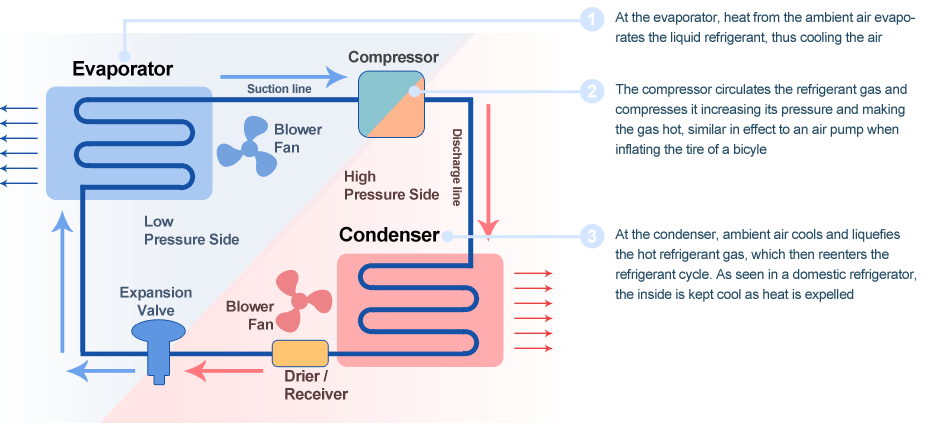

Have you heard of DC Condensing Unit? It is also known as a direct expansion system, which eliminates the use of a secondary coolant loop and uses the refrigerant to directly cool the desired payload via a loop like copper tubes, heat exchanger or cold plate.

A direct expansion system enables the most compactly designed refrigerant system. The concept provides an efficient and elegant cooling system for various applications.

If you choose direct cooling, you do not have to use a water reservoir, a pump, and cooling. Instead, you get a simple but powerful cooling system - RIGID DC Condensing Unit.

DC condensing unit designed by RIGID comes with three different compressors – 12V, 24V, and 48V. The strength you choose will depend on your desired application. The exact power may vary depending on the compressor you use.

In this article, we will check the list of 8 quick solutions to get FAST cooling from RIGID direct refrigeration systems. Take a look at the suggestions and discover the versatility and high potential of these products.

8 Quick Solutions to Get Fast Direct Cooling

1. Cooling in Electric Vehicle Charging Stations

Electric vehicles are the latest trend in the global market. They are eco-friendly solution, and an energy-efficient way to drive from point A to point B.

Each electric vehicle must use a battery. If you want optimal performance from the vehicle, you need to ensure that your battery pack is in excellent shape. That is where a direct expansion cooling system can help.

The batteries in electric vehicles can heat up quickly, especially if you are going at high speeds, or traveling long distances. You don’t want to risk ending on the side of the road having to call someone to tow your vehicle.

Instead, you can ensure that your batteries are working smoothly by keeping them cool. You can do that with a direct refrigeration system, such as the one provided by RIGID.

Since these batteries can be powerful, they may need a lot to cool down. That is why you might need more than one compressor to secure optimal cooling.

It is something to keep in mind, but you can always contact the manufacturer of your DC condensing unit, and ask for the right level of power.

You have the option to use multiple compressors, but only one evaporator and condenser. That saves a considerate amount of space, which can be particularly important in compact vehicles.

Now, you may think that two compressors can’t exactly make a compact system, but you are wrong. The truth is that using two compressors for your direct expansion cooling may result in taking less space than when using a single big compressor.

The direct refrigeration cooling system will perform well under the temperatures that can go as high as 40C.

Regardless of the high heat, the solution will keep your batteries cold at the desired temperature (the recommended surface temp is around 10C).

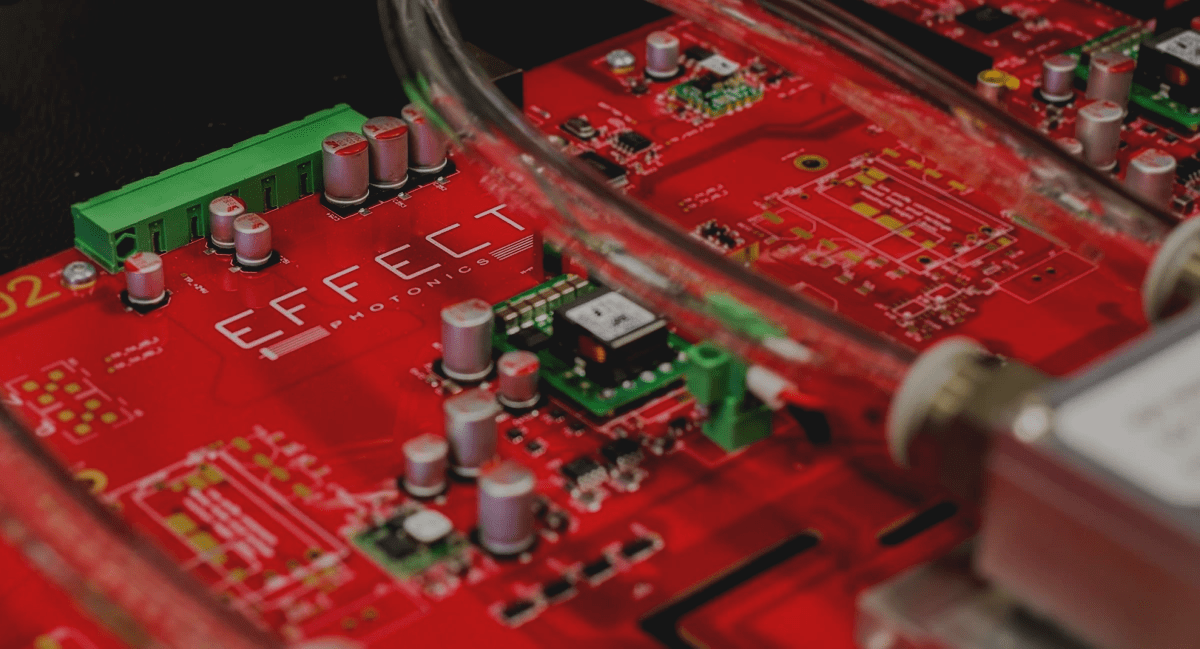

2. Photonics Effective Cooling

For those that haven’t heard of photonics mast, here is a quick overview of this product. It is a sensor that submarines use instead of a periscope.

The photonics mast does all the same things, but it doesn’t require a tube. It has many advantages over a traditional periscope, including more dimensional and locational freedom.

A photonics mast requires a direct compact cooling solution due too its limited size. That is why designers need to get creative when creating a system that will work.

RIGID is ready to design and deliver custom solutions completely tailored to your needs.

For example, photonics masts are high-power devices, and they need a powerful but compact direct refrigeration cooling.

The company can design not only a customized compressor, but also a specific evaporator and condenser. You can get rid of the heat by transferring it into the air or the water.

It may be interesting to discuss the condenser more. Tubes made of stainless steel are a necessity, but they could be embedded with cast aluminum.

The seawater can circulate through the passages, and it won’t disrupt the DC condensing unit to do its job of removing high heat flux from the device.

3. Stem Cell Cooling and Freezing Processing

Cell processing is something that you do in specialized laboratories. It is a very sensitive process that requires having the right equipment and ensuring everything works flawlessly.

That includes keeping the fluids cool at their optimal temperatures.

In some cases, you need to reduce these temperatures to about 2-3C and keep them unchanged for hours. That is hard to do without a direct expansion cooling system.

Additionally, the solution needs to be designed to follow the requirements of the cell processing application in your lab.

Some lab experts try to use a thermoelectric solution, but it is not nearly as reliable, and cannot produce results like a direct compact cooling system.

All the testing was in favor of DC Condensing Units, which can cool the fluid down quickly, and get it ready for any testing you want to perform.

Since cell processing requires a customized solution, the communication between the client and the company is essential. The client should pinpoint all the desires they have from the system.

As long as they have clear expectations, reliable companies like RIGID won’t have a problem tailoring their DC condensing unit to those specific needs.

4. Laboratory Applications

Direct DC Cooling Unit for Portable laboratory cooler box

Since we are mentioning laboratory use of direct refrigeration systems, let’s mention some other applications.

For example, lab experts use different types of chemicals when they are working. And even when they are not in the lab or using the chemicals, those substances require proper maintenance.

Depending on the chemical, you may need to keep them in a cool environment. What would you say about using a cold plate that you can use to chill any chemicals or substances you want?

It works like this – the manufacturer designs a compact cooling system by following all desired and requirements set by the client.

Thanks to Rigid miniature rotary compressor technology, the solution has a form that is aesthetically pleasing, which means you can place it on any countertop surface in the lab.

The dimensions of the cold plate, as well as its power, are following what the client specified. That enables them to put any chemicals, substances, and anything else of the surface.

As long as what they place is in glassware, the direct expansion cooling will cool it down to the desired temperature. Once the chemical reaches that temperature, the plate will maintain it within 0.4C.

If you think about it, it is a very convenient solution. You may be keeping most of these chemicals in a freezer or another room.

But when you need them in the middle of a project, it may be a hassle to go to another room to get them. Not to mention that you might affect the experiment results.

Thanks to the cold plate, you can prepare all the substances and keep their temperature at the desired level. Once you need them, you will be able to use them instantly as they will be within your reach.

5. Phased-Array Antenna

Improved detection sensitivity of phased array radars thanks to cryotechnology

A phased-array antenna is another interesting and creative solution where direct refrigeration cooling can do an impressive job.

Depending on how the system is designed, even military applications can use it.

These direct expansion systems would include multiple cold plates (you can even go up to four or six) to ensure optimal cooling.

The reason why we need to many plates is the high heat flux and extreme ambient temperatures where phased-array antennas may be used.

Depending on your needs, multiple cold plates can ensure 500-600W of cooling. They can maintain excellent performance even when the heat reaches 50C.

Since it is a direct expansion cooling system, it handles the product itself and helps to cool it down by removing high heat flux from its surface.

It is possible to use these multiple cold plates for mass production. However, the manufacturer will probably suggest designing a prototype first.

That way, you can test the unit in the field, and make the necessary adjustment before you resort to mass-scale manufacturing.

6. Keep Your Hot Laser Cool

How about using a direct refrigeration system that can provide the required level of cooling in regular ambient conditions?

In most cases, you won’t operate laser modules in environments with temperatures higher than 35C, which implies that these solutions can do a more than an adequate job.

When it comes to cold plates used for a laser, you should think about two crucial considerations. The first one is that you need a direct expansion cooling solution to reach and maintain the desired temperature.

The temperature maintenance needs to be as precise as possible, or it could affect the performance of the application. That is why the best manufacturers out there can maintain temperatures within +/- 0.4C.

The second consideration is spacing requirements and the integration with the system. Your laser module will have specific requirements in terms of size and space.

It would also be silly not the consider the potential price of the entire projects. That is why you should stick to experienced companies with reliable DC condensing units, such as RIGID.

You can rest assured that they will be capable of delivering a solution that will meet your needs.

7. Multiple Laser Cooling Solution

It works by freezing the fat cells from specific parts of the body

Do you have a laser module that needs cooling down?

How about leaving the idea of chilling a single laser module for a second?

Here is another intriguing way of using a direct expansion unit, and it also has to do with lasers.

Let’s imagine that you have multiple laser modules with high power and various loads of heat. In those situations, you can maintain the required surface thermal control.

That precision is what you get by using a DC condensing unit which generates a standardized level of heat from all modules.

The main idea of this solution lies in its uniformness, and even distribution of temperature is imperative.

It is not easy to achieve that goal, especially if you are dealing with the challenge of designing a direct expansion subsystem in a confined space.

If you are looking for a customized solution similar to this, you want to work only with industry experts.

Although this is an excellent and useful subsystem, it can be a challenge to design it. That is why you need someone experienced working on the project.

8. Semiconductor Test Industry Application

Air Cooled and Water Cooled Chillers for Semiconductor Industry Application

Here is another area where you can use a DC condensing unit for your cooling requirements.

You have the option of working with companies like RIGID to develop a high heat flux solution that can deliver the required cooling to a point load for this industry.

A customized direct expansion solution can handle operation in temperatures that go below zero, and down to -30C.

The main benefit of this option is that you can build it into your application, and it wouldn’t take a lot of additional space.

The heat load can be of various power, but considering the size and the application, the experts recommend sticking to around 150W maximum.

The entire idea is to deliver a simple and direct compact cooling system that will be an affordable solution. Since a single unit aims to be a low-cost option, you can consider using this subsystem for commercial products on a massive scale.

Why Should You Consider RIGID DC Condensing Unit?

Now that we have seen all these solutions for fast direct cooling, you want to ensure reliable results. It is why you need a solution n that you can rely on at all times.

RIGID designed a DC condensing unit that can fit any application perfectly. Whether you are looking for a portable or stationary solution, we can design it for you.

We are proud of the fact that our cooling products have a minimal footprint. They are also light and quiet in operation, which means you don’t have to worry about noise.

The performance is unmatchable, and the thermal control our direct compact cooling systems can achieve has the highest level of precision.

We care about our customers, and that is why we make sure to listen to all your requests and desires.

Our team has the skills and experience to turn those wishes into reality, and the DC condensing unit equipment is a crucial part of how we manage to do that.

If you are looking for a customized direct cooling solution, do not hesitate to give us a call today, and learn more about high-quality RIGID products!