Have you ever taken your time to imagine that there was a time when the district cooling systems were not around?

What is even hard to imagine is how life would be unbearable without this amazing technological evolution.

Developments, and even most industries would need the entire support of the grid and miss solutions that is provided by waste and renewable heats.

It is no denying that DC condensing units have grown to become so beneficial in the current market.

Therefore, it is important to get it right when handling or choosing the condensing unit to be used in the network.

In addition, when talking about DC condensing units, what comes to mind is none other than the RIGID DC Condensing Units.

Why the RIGID DC Condensing Unit

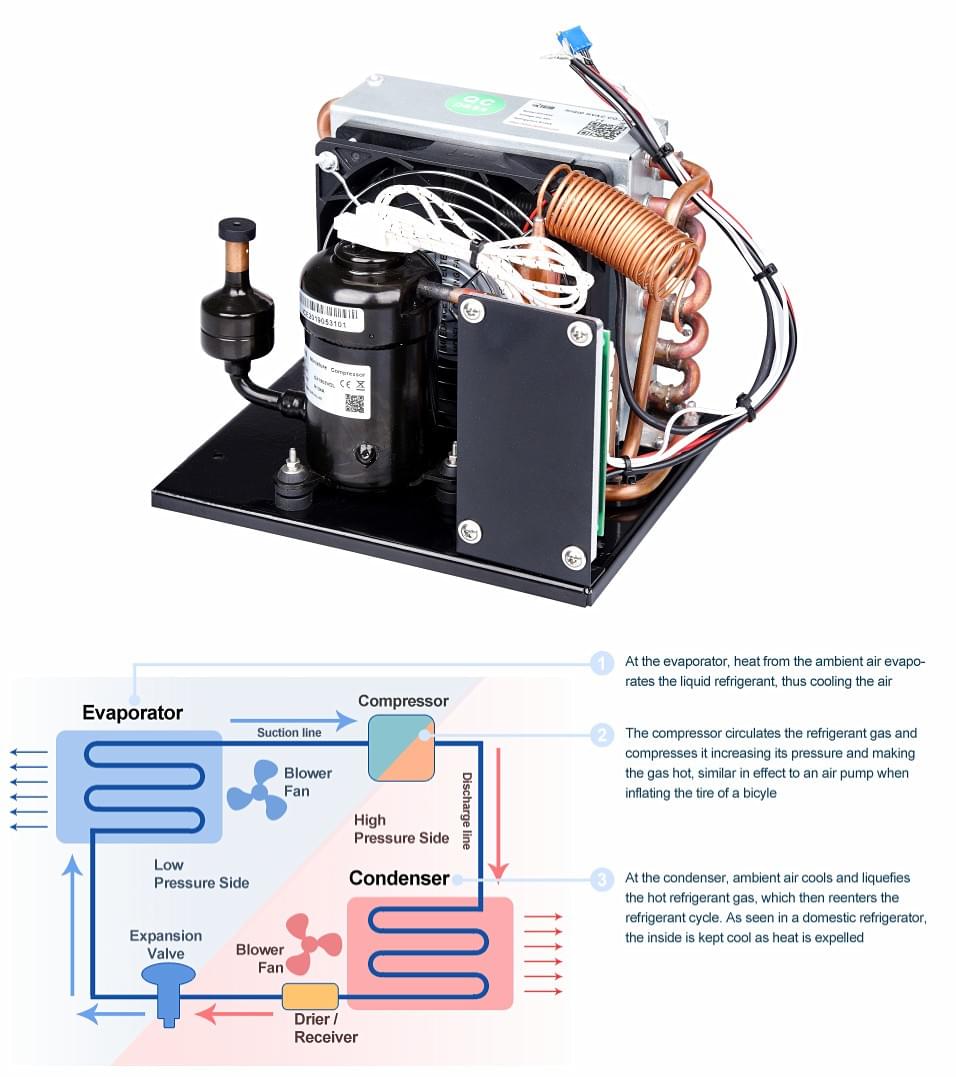

There are a number of things that make up a full district cooling plant. They include electrical substations, TES facilities, cooling towers, pumping stations, as well as the chillers.

There are also other important components such as the systems control, switchgear, piping, and the auxiliary equipment.

One of the integral parts of the system is the condenser cooling, and the provider may opt to offer it with a number of alternatives.

The RIGID DC Condensing Units will always be dependent on three major forms of condensing units, which include evaporative condensers, water-cooled, and air-cooled.

In a normal DC system, a central plant will offer several buildings with cool water through several underground pipework. The heat exchangers will be situated right between the buildings and the distribution network.

Their main purpose is to guide the rejection of heat that always extracted from the chilled water, as well as the heat from the absorption chiller or the vapor compression cycle to ambient the air or to separate the circuit of water.

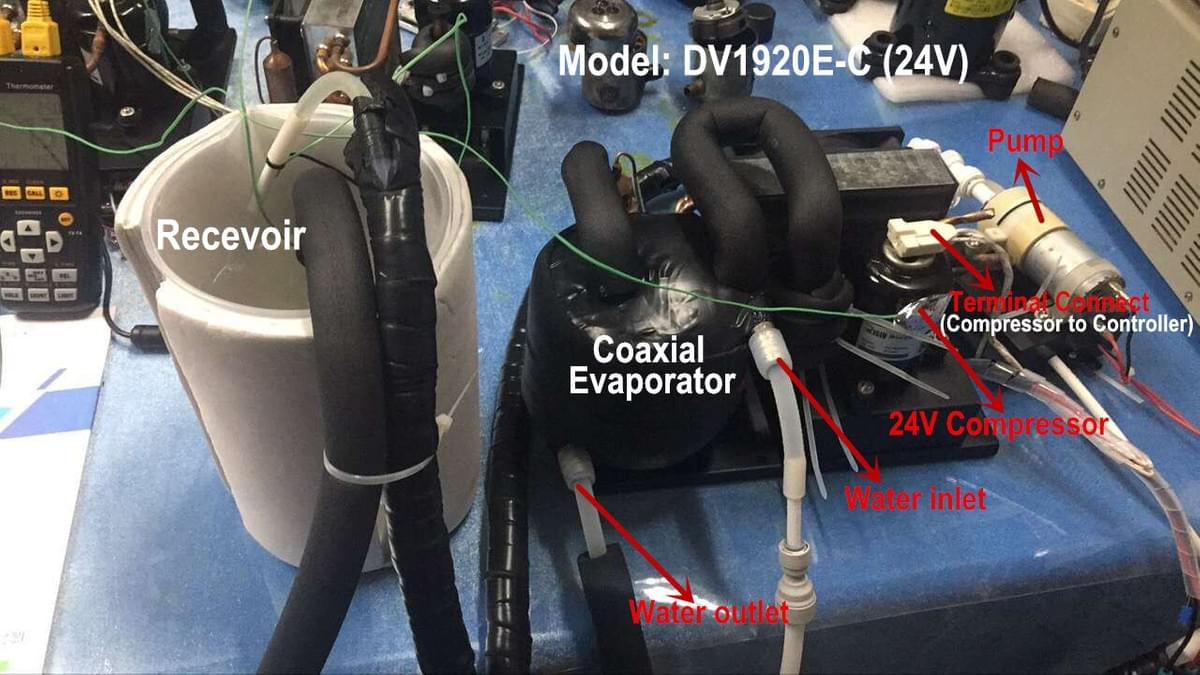

The other name for the DC condensing unit is the direct compact cooling or the direct expansion system.

It provides the highest rates of heat transfer. The condensing units are classified based on the voltage, size, such as the 12-volts, 24-volts, and the 24-volts DC compressor.

The direct refrigeration system uses the R134A coolant, and the system would heat directly at the source of the heat, therefore lowering the component count and the size of the system.

The RIGID DC condensing units also offer direct expansion cooling. It is the work of the compressor to drive the refrigerant directly as it passes via the evaporator.

This particular component will eliminate the use of a water reservoir or a water pump, ultimately brining a simplified cooling system.

These DC condensing units have been designed to directly integrate into the compact system of any user and offer very high heat fluxes at the main source of heat.

How RIGID DC Condensing Unit Works

On the RIGID DC’s cold plate, the refrigerant goes through an isothermal phase change that gives serious tight control temperatures across the entire cold plate.

A number of users would normally prefer a cooling subsystem module that can easily assemble or integrate with their equipment or machine. This is the only way they can attain a smaller cooling solution.

It also has a control board for the end user that can easily connect with the drive board of the RIGID DC Condensing unit to be able to control the speed of the compressor and achieve the best performance that they are looking for.

With an exception of the ordinary chiller units, RIGID DC Condensing Units also personalize or tailor made small modules of cooling to be able to meet the special demands of the customers.

With the mini compressor technology, the RIGID DC Condensing unit is able to provide one of the most compact systems of cooling.

The system can also entirely integrate into a final solution, which is not only affordable and reliable, but also quiet and compact.

There are a number of applications where the miniature direct cooling system can be applied. For example, they can be used in scientific lasers, precise instruments, laser, and medical.

In the scientific lasers, the evaporator is directly mounted to the cold plate of the user’s device.

Get the Best Technology for Direct and Fast Cooling

One of the latest concepts in the market of refrigeration has to be the invention of the DC condensing units.

As noted earlier, these systems are designed for both compact and portable direct expansion use.

It is fully built cooling solution that is designed for refrigerators and reach-in-freezers in both commercial and personal use, and not leaving out the medical refrigeration applications.

In addition to that, it also offers outdoor operations with a number of other benefits that cut across the whole industry.

Its compact and portable concept provides the best flexibility and the pocket size function that it boasts of enable the users to move with it from one place to another.

Due to the fact that it is directly chilled by a R134A coolant, and there is no any other secondary coolant that is needed, the direct compact cooling systems have the best cooling capacity in the whole market.

It is also imperative to note that all the refrigeration parts present in this cooling kit are just minimal parts that just serve the purpose of minimizing its main size.

There are no fans that are needed to circulate the cool air, and the coolant needs no pump to circulate it.

Air or liquid acting a secondary coolant will dictate the additional thermal resistance and they will also add certain heat to the system, and this will lower the capacity of net cooling.

The DC condensing units have been made available in various voltage units such as 12V, 24V, and 48V.

They can also be powered by a solar power, a battery, or just a car battery.

Their main compressor is a BLDC inverter compressor and it has great adjustable speed at 1500 to 6500 rpm, and it is the best for miniature freezer cooling systems as well as applications in small mobile refrigeration systems.

The Ways of Getting Fast Direct Cooling

To some, it might seem like just making the decision to pick any condensing unit in a district cooling system is an easy process.

Unfortunately, that is not true. There are a number of options that should be considered before settling for a particular RIGID DC Condensing Unit.

This implies that the process of picking up the best condensing unit can be very overwhelming, bearing in mind the capital importance of all these devices.

There is too much offered in the world of condensing units, and some may be very important while others may not.

Here are some of the DC condensing units that are on the market today.

1. Water Cooled Condensers

Water-cooled condensers and chillers are specialized heat exchangers. They exchange heat by removing heat from one fluid and transferring it to another fluid. A water-cooled condenser is a heat exchanger that removes heat from refrigerant vapor and transfers it to the water running through it.

Heat that comes from a building or a process and served by a DC condensing system must be handled through either heat rejection or heat recovery.

Alongside the cooling tower, the water-cooled condenser works to ensure there is circulation of heat to the outside parts.

This system is the best for those who are looking for general better efficiencies when it comes to direct compact cooling.

Because the system uses less power, there will always be less costs and consumption of energy. Owing to the minimal weather exposed components, and the high efficiency, these types of direct refrigeration is able to last longer, as long as the maintenance is done in the right manner.

On top of that, the condenser is able to operate in the high temperature zones such as the manufacturing industries.

2. The Air Cooled Condensers

An air cooled condenser (ACC) is a direct dry cooling system where steam is condensed inside air-cooled finned tubes.

The cool ambient air flow outside the finned tubes is what removes heat and defines the functionality of an ACC. In thermal power plants (T), the steam from the turbine exhaust flows into the ACC where condensation occurs.

Then the condensate returns to the boiler (B) in a closed loop. Since the steam coming from the turbine is at a low pressure, the ACC works at a pressure close to a vacuum, and non-condensable gases (G) are removed continuously by an air evacuation unit.

With several advantages that it boasts of, this kind of condenser might not be so applicable in a number of regions that do not have sufficient fresh water.

One of the most attractive elements of these condensers is, the less general maintenance requirement.

The set-up may just demand maintenance just two times in a year, as compared to the air-cooled condensers that would need much attention.

This kind of RIGID DC condenser also offers flexibility for the plant location and plot plan arrangement.

For these reasons and others more, air cooled condensers have continued to become more prevalent in DC condensing units.

For purposes of the level of equal heat transfer, the air-cooled condensers come with more economic advantages when put into comparison to the water-cooled condensers.

There are a number of methods of improvements that can be applied in case the performance dwindles. They include adjusting the tube geometry and enhancing the inner pipe surface.

3. Sea Water Cooled Condenser

For the systems that are stationed close to a sea, using huge amounts of water to reject heat is a cost effective and viable option.

The method is very eco-friendly, and not forgetting the fact that it also saves the energy.

However, the dire need to make this technology work best in tough sea conditions implies that the implication of the initial cost can be a huge challenge.

4. Types of DC Condensing Units Based on Voltage

This direct compact cooling system has been designed with a cooling capacity of 500 to 1,600Btu.

In addition to that, this direct refrigeration system is also made up of the four basic components of the great R134A cooling system, an evaporator, an expansion valve or the capillary, a micro channel condenser, as well as a small DC compressor.

It is the work of the compressors to drive the refrigerant through the main evaporator directly. This is a brand new concept that has been designed to be used in the compact and portable direct DC condensing units.

First, it is important to take note that this particular direct expansion unit has the same configuration as that of the 12 DC cooling system.

DV3220-24V is definitely the most powerful DC condensing system, and it has a cooling capacity of more than 360 watts.

This type of direct compact cooling system boasts of a cooling capacity of 500Btu to 1,230 Btu. Its main BLDC compressors will always drive the refrigerant directly through the evaporator.

Just as it is with the 12V direct expansion system, this new concept is also designed for the compact and portable refrigeration applications.

The other name for this direct compact cooling system is the 48-volt recirculating chiller.

Even though it has the tiniest working current, this compressor cooling has the same configuration as just that of the 12-volt condensing unit. This direct refrigeration system has a cooling capacity of 500Btu to 1,600 Btu.

Just as it is with the 24-volt DC condensing Unit, the BLDC compressors of this system drive the refrigerant through the main evaporator directly.

It is also the best system for both compact and portable direct refrigeration applications.

Reduce Costs in Cooling with RIGID DC Condensing Units

With the amazing DC refrigeration systems for cars, portable boxes, trucks, motorbikes, vans, boats, and others, you will definitely transcend the barriers for mobile refrigeration.

The amazing performance of the DC condensing units will help in various industries such as telecommunication, medical, and food.

In areas where battery power is relied upon for up to 16 hours in a day, the DC condensing units can greatly help.

It is important to note that the compressors will always cool the battery and therefore optimize their life lasting.

With this amazing feature, you will be able to secure your signal and even save your general costs of replacements and maintenance.

Since the battery is one of the biggest issues, these DC condensing units will enable you to achieve the following;

- You will be able to create a cooling system that can work with batteries, wind turbines, and solar cells, without having to look for conversion to the alternating current.

- Enjoy the services of an energy efficient DC condensing unit with a high COP.

- On top of all that, you will simplify the design of the general system and make sure that there is maximum performance.

It is also important to note that all the DC condensing units are designed with an electronic control unit with a speed control that is in-built as well as a thermostat signal.

Other components that are found in this system are a thermal protection, a fan speed control, a safety against the destructive battery discharge and an electronic thermostat as well as a fan speed control on some models through the PC software.

These condensing units have been built with the sole purpose of offering standard-setting innovation in the cooling and refrigeration space.

By combining reliability and an outstanding efficiency, these systems offer valuable savings, without regarding the operating conditions or the applications.

With these condensing units that have been customized for both personal and industrial use, some of the benefits that the users stand to enjoy include the following;

- Extreme durability

- Standard and Eco design full compliance

- They are easy to install, and they will ensure an easy and fast installation even on a limited space

- They come with a broad operational array – They work on a wide range of evaporating temperatures

- They have been designed with a pre-assembled power cord – 60 Hz models

- They have dual frequency

- They are also UL recognized – 60 Hz models

Beyond the Evidence of RIGID DC Condensing Units

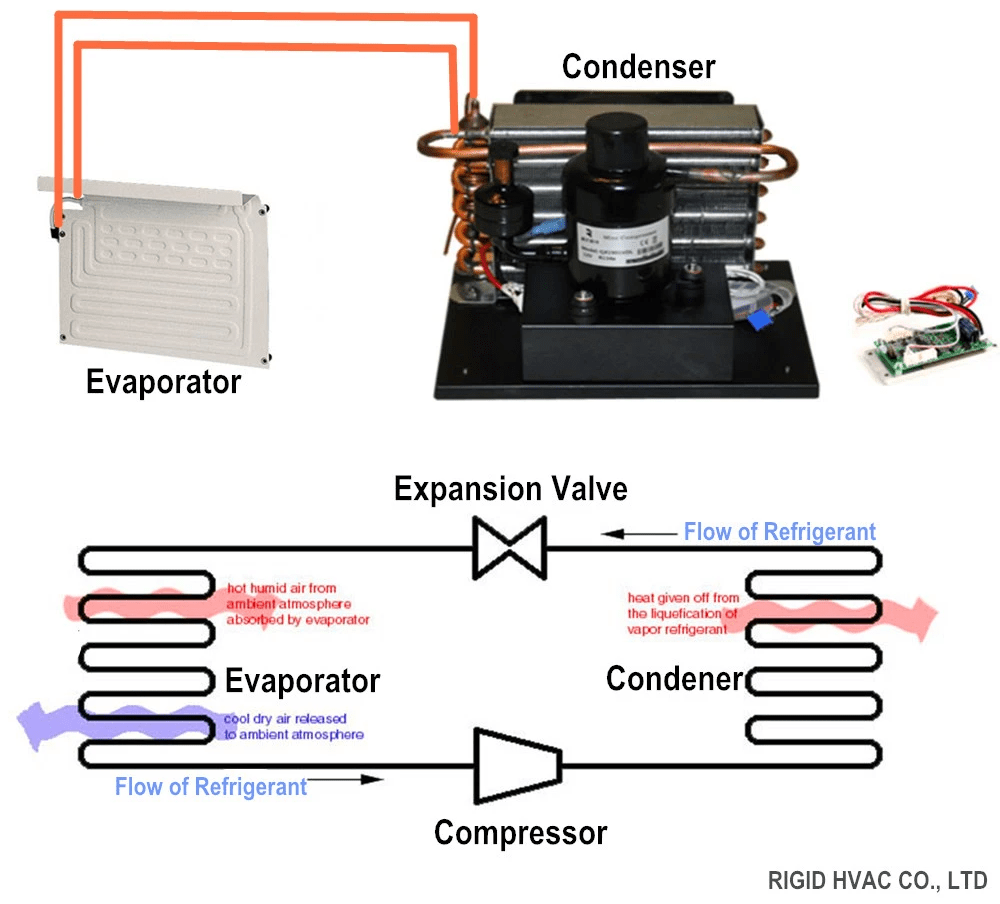

As noted earlier, the RIGID DC condensing unit is a direct expansion subsystem that does not come with the evaporator.

It is made up of micro DC compressor of various voltage units such as 12V, 24V, as well as the 48V.

On top of that, it also comes with a R134A coolant, the tiniest condenser, and the radiator in the whole market, a capillary or an expansion valve, and a filter drier. It also has a number of refrigeration parts and the driver board.

The RIGID DC condensing unit was developed to satisfy the growing market who is searching for the best vapor-compression refrigeration cycle; in addition to being able to meet their demands for small cooling devices.

The primary goal of the RIGID DC Condensing unit is to create the most compact cooling system that has even been created in the whole market.

Since it uses the micro-refrigeration compressor, it is able to eliminate any possible need of a secondary coolant loop.

This kind of configuration allows the tiny DC cooling unit to cool directly the desired device or equipment through a cold plate.

RIGID DC Condensing Units do not supply the evaporator, or the cold plate as they are always referred.

The cold plate can always be tailor made by the end users to be able to adapt to their preferences or budget.

It is also very important to note that RIGID still welcome personalize orders from various customers and users.

The engineers who are part of this whole project are not only easy going, but will also be willing to work with the customers directly so that they can customize their compact cooling system just as requested.

The future is bright and technology advances daily. It is a fact that all the condensing technology used for DC condensing comes with a fair share of demerits and merits.

Nevertheless, despite all that, any of the units could be the best as long as they serve the needs for space, cost, efficiency, the size of the refrigeration plant, as well as the mode of operation.

All in all, RIGID DC Condensing units appear to be the best for both commercial and personal use.