RIGID HVAC CO., LTD

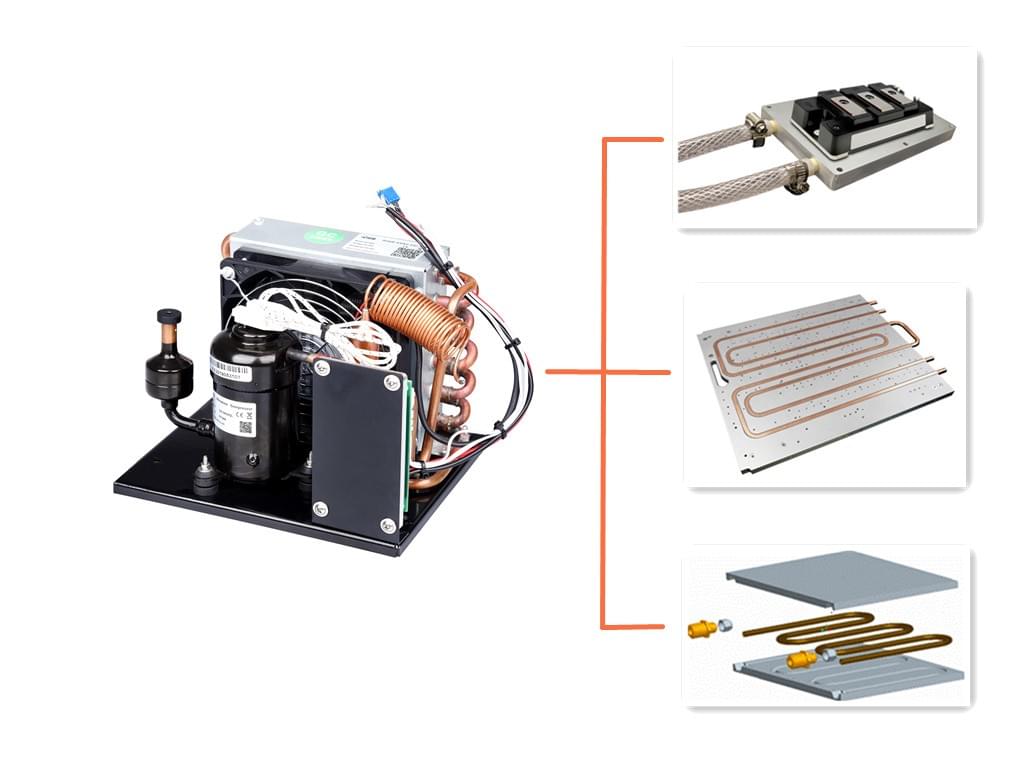

Direct Refrigeration Unit

Direct Cooling Unit—an advanced direct refrigeration solution engineered for superior temperature control across various applications. Whether you're seeking optimal refrigeration performance, efficient electronic cooling, or refrigerator heat dissipation, our Direct Cooling Unit delivers unmatched results.

Some of the leading laser manufacturers are exploring an innovative approach called direct expansion cooling. In this method, the refrigerant flows directly through the cold plate, propelled by the compressor. This approach offers several advantages, including the elimination of a liquid recirculating pump, fluid reservoir, tubing, and connectors—common sources of failures and leaks.

The efficiency is significantly enhanced by eliminating losses associated with cooling a liquid, resulting in energy savings (8 times less than thermoelectric coolers and 2 times less than liquid chillers). Data from our laboratory, the cooling capacity for direct refrigerant is 25% greater than that of a liquid chiller at 25 degrees Celsius. The system is simplified, enhancing reliability and reducing the overall size of the cooling system.

DV1910

Capacity: 450W (1,535Btu)

- 12V DC

- 3.5 kgs/7.7lbs

- Refrigerant: R134A

- Working Amps: 1~8A, (Max 10A)

- 190x160x138 mm (7.48x6.3x5.43 inch)

- The drive board is included.

DV1920

Capacity: 450W (1,535Btu)

- 24V DC

- 3.5 kgs/7.7lbs

- Refrigerant: R134A

- Working Amps: 1~7A, (Max 8.5A)

- 190x160x138 mm (7.48x6.3x5.43 inch)

- The drive board is included.

DV1930

Capacity: 450W (1,535Btu)

- 48V DC

- 3.5 kgs/7.7lbs

- Refrigerant: R134A

- Working Amps: 1~4A, (Max 7.5A)

- 190x160x138 mm (7.48x6.3x5.43 inch)

- The drive board is included.

DV3220

Capacity: 550W (1,876Btu)

- 24V DC

- 4.0 kgs/8.8lbs

- Refrigerant: R134A

- Working Amps: 1~10.3A, (Max 12.5A)

- 190*190*182mm (7.48x7.48x7.17inch)

- Drive board is included

DV2820

Capacity: ≥500W to 700W (2,387Btu)

- 24V DC

- 4.0 kgs/8.8lbs

- Refrigerant: R134A

- Twin-cylinder mini compressor

- Working Amps: 1~8.3A, (Max 12A)

- 190*190*182mm (7.4 x 6.2 x 5.9" inch)

- Drive board is included

- LED display (optional)

DV2820-T

Capacity: ≥500W to 700W (2,387Btu)

- 24V DC

- 4.0 kgs/8.8lbs

- Refrigerant: R290

- Twin-cylinder mini compressor

- Working Amps: 1~8.3A, (Max 12A)

- 190*190*182mm (7.4 x 6.2 x 5.9" inch)

- Drive board is included

- LED display (optional)

Direct Expansion Refrigeration System Cycle

RIGID HVAC specializes in providing highly efficient and reliable refrigerated cooling systems. We have developed the world's smallest rotary compressor and offer custom solutions for various industries, including food, laser, medical, industrial, battery, electric vehicles, and military applications.

Notable products include AlphaCooler, designed for driver body cooling in racing and motorcycles, and compact Liquid Chiller, a core component for liquid refrigeration systems.

RIGID also excels in direct expansion cooling, simplifying system configurations, and maximizing efficiency, particularly in laser, semiconductor, and medical device applications. RIGID company's expertise and proven track record highlight its commitment to delivering compact, efficient, and durable cooling solutions.

DX System Cooling Cycle

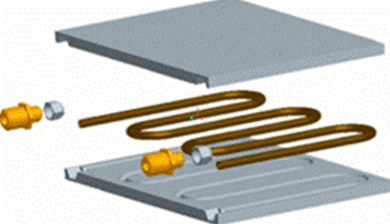

Direct refrigeration systems operate by directly connecting the customer's evaporator. The evaporator, placed in the area to be cooled, cools the space by expanding the refrigerant in its coil and absorbing heat from the surroundings.

Examples of systems using this approach include mini-refrigerators, cooling for laboratory equipment, precision instrument cooling, and equipment that needs direct refrigerant cooling packages.

Direct Cooling Features

- 40% greater cooling capacity.

- Maintenance-free and factory-sealed.

- Improved efficiency and energy savings.

- Refrigerant flows directly through the cold plate.

- Smaller and lighter than traditional liquid chiller systems.

- Ideal for laser, semiconductor, and medical device applications.

- No need for pumps, reservoirs, or tubing, reducing potential failures and leaks.

- Simplified system for high reliability (mean time between failures > 90,000 hours).

Advantages of Direct Refrigeration System

Easy to install, Ease to test, Ultra-compact size, Minimum ceiling or wall space needed.

Low installation costs

Reduced install expenses, No worry of maintenance.

Sine Wave Drive Borad

Ease to test, adjust and balance the system.

Brushless DC Rotary Compressor

Battery or dc power supply, Low energy consumption.

Tiny Size & Smallest Footprint

Easy to integrate into user devices, low noise level.

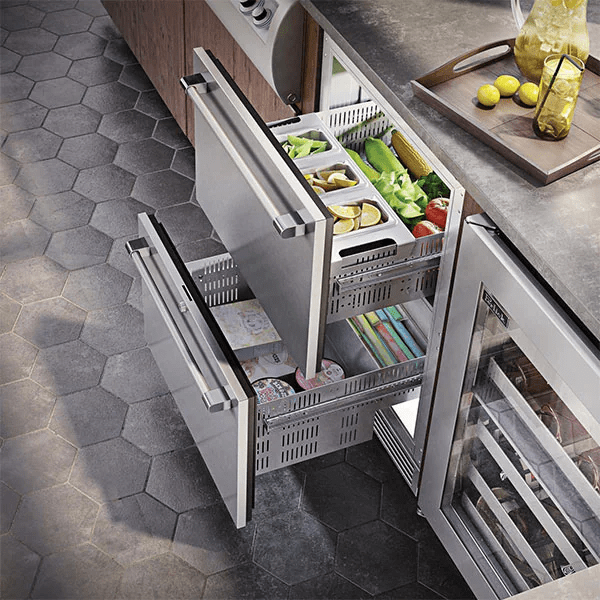

Direct Expansion Evaporator System Applications

The RIGID Direct Expansion Evaporator System comprises miniature refrigeration modules cooled directly by refrigerants, leveraging RIGID's technology for a highly compact cooling solution.

These mini direct expansion systems easily integrate into compact, quiet, reliable, and cost-effective final solutions. Users have the flexibility to incorporate expanded cold plates directly into our expansion systems, enabling tailored cooling or precise temperature control for specific spaces.

RIGID's direct expansion systems find applications in various fields, such as mini-fridges, industrial settings, medical facilities, scientific laboratories, lasers, instruments, and other scenarios requiring active thermal management. The system, with a directly mounted cold plate, allows for precise temperature control with an accuracy of +/-0.5°C.

Thanks to RIGID's mini compressor, these systems can be exceptionally compact, making them ideal for high heat flux applications in electronics cooling, batteries, laboratory cold plates, and more.

Custom Refrigerator

Beverage Cooler

Outdoor Freezer

Outdoor Refrigerator

Electronics Battery

Cold Plate Cooling

Precise Instrument

Laboratory Equipments

Online Store

Buy nowDirect Refrigeration DV3820 (24V)$600.00 - $710.00

Buy nowDirect Refrigeration DV3820 (24V)$600.00 - $710.00 Buy nowDirect Refrigeration DV3830 (48V)$600.00 - $710.00

Buy nowDirect Refrigeration DV3830 (48V)$600.00 - $710.00 Buy nowDirect Refrigeration DV2820-T (24V, R290)$500.00 - $590.00

Buy nowDirect Refrigeration DV2820-T (24V, R290)$500.00 - $590.00 Buy nowDirect Refrigeration DV2820 (24V, R134A)$480.00 - $570.00

Buy nowDirect Refrigeration DV2820 (24V, R134A)$480.00 - $570.00 Buy nowDirect Refrigeration DV3220 (24V, R134A)$460.00 - $550.00

Buy nowDirect Refrigeration DV3220 (24V, R134A)$460.00 - $550.00 Buy nowDirect Refrigeration DV1930 (48V, R134A)$410.00 - $500.00

Buy nowDirect Refrigeration DV1930 (48V, R134A)$410.00 - $500.00 Buy nowDirect Refrigeration DV1920 (24V, R134A)$400.00 - $490.00

Buy nowDirect Refrigeration DV1920 (24V, R134A)$400.00 - $490.00 Buy nowDirect Refrigeration DV1910 (12V, R134A)$390.00 - $480.00

Buy nowDirect Refrigeration DV1910 (12V, R134A)$390.00 - $480.00Contact Us

We have our own R&D department and manufacturing facilities. Thereby, we control the complete process from the first idea to the delivery of finished cooling products to customers. If you don’t see what you are looking for in our product lineup, do not hesitate to talk to us about your system. Apart from standard cooling systems, RIGID also provides custom solutions. We have developed solutions for medical devices, life science, laboratory, electronics, laser, Lithium battery, and electric vehicle customers. We can design a miniature cooling system to meet the requirements of your application. To learn more, go to our Design & OEM page. Or, please contact us for a free evaluation of your application.

FAQ

Direct Refrigeration System Frequently Asked Questions

1. What is direct expansion system?

2. What is direct expansion evaporation mechanical engineering?

3. What is expansion system?

4. How does a direct expansion system work?

5. What is the difference between indirect and direct cooling system?

6. What is the difference between DX system and chilled water system?

7. What is the main function of an expansion valve or capillary?

8. How many types of RIGID HVAC refrigeration systems?

Specifications Download PDF

Miniature compressor

Miniature compressor

Miniature compressor

Miniature compressor

Twin-cylinder compressor

Twin-cylinder compressor

Certificates | Download | Contact Us | Our History | Return & Exchange

RIGID Technology * © Copyright 2010-2023 * RIGID HVAC * RIGID Cooling * All rights reserved.