RIGID specializes in a miniature cooling technique called vapor compression. Vapor compression cooling makes use of the unique characteristics of refrigerants to pump heat from a low temperature to a high temperature through the use of refrigerants. Systems that use vapor compression use the thermodynamics of refrigerants to cool components. Heat is absorbed from its source and is redirected to an external environment that's warmer (usually the ambient environment).

As an active thermal management method, vapor compression cooling systems produce sub-ambient cooling. Vapor compression refrigeration systems are highly efficient ways to perform active thermal management by using appropriate refrigerants, compressors, and heat exchangers.

RIGID’s miniature compressor vapor compression units have been successfully applied to many electronics and medical devices. RIGID compact water chillers are used to cool electronics mounted inside customer's systems. RIGID miniature chillers are 5 times lighter, 4 times more energy efficient, and half the size of thermoelectric based systems.

If that seems interesting and you’d like to know more about RIGID’s products, you are in the right place. Here is a short overview of the compression cooling and miniature circulating cooling systems for active thermal management. Check out different solutions, and don’t hesitate to contact us if you have any questions!

1.

Mini Compressor – Vapor Compression Refrigeration

RIGID put years of hard work into developing a revolutionary solution in miniature dc compressor vapor compression technology. The mini compressors RIGID designed are the result of this research. Their main advantage is that they have exellent cooling capacity, and at the same time. to keep the noise at an impressively low level . Additionally, the system features low vibration, which contributes to lowering the noise.

The compressor is a crucial part of our refrigerating system. Therefore, this component was meant to be as miniature as possible. Several years of trying led us to design a breakthrough mini rotary compressor. The biggest advantages of our rotary compressor include:

● A compact size

● Surprising lightweight

● An efficient performance that compares with bigger units

We like to think of our compressors as “true power in small packaging.” This micro DC unit is perfect for portable and compact cooling machines. Although it already delivers consistent performance, our experts keep improving the compressor. The current fifth-generation implements the sine wave drive board. We patented this approach as we believe it’s crucial to impressive performance.

What Are the Main Features of the Miniature BLDC Rotary Compressors?

At RIGID, customers have always been the top priority. That’s why we came up with a solution that will meet each client’s needs. Our BLDC compressors are available with different cooling capacities. It starts at 100W or 240Btu if you are looking for the smallest possible solution. If you prefer more power, our compressors are ready to deliver up to 550W to 800W, or 2,800Btu of cooling capacity with voltages available 12V, 24V and 48V DC.

You are in complete control of the device. Our cooling systems come with a drive board, which makes it easy to adjust the desired speed. The velocity can vary from 2,000RPM to 6,500RPM, and it all depends on your needs.

Our compressors can use 12V, 24V, or 48V DC. It’s also possible to convert it to AC by using the right kit. This incredible versatility made this portable cooling system extremely popular. It’s possible to use it for various applications. That includes a laser hair removal cooling system, as well as other medical, military, and similar purposes. You can put the device on the countertop as it takes a minimum footprint on it. It’s also excellent to use on the go. The compact size contributes to impressive portability.

RIGID mini rotary compressor is extremely efficient, which is possible because it uses the R134A refrigerant. If your market requested natural refriigerant R290, RIGID has the right miniature meets your demand - QX2802VDL-T. The total weight of the R290 mini compressor doesn’t exceed 720 grams, which is around 2.87 pounds. Our experts implemented a twin-cylinders setup under standard ASHRAE requirements.

And here is the best part – the total energy consumption is surprisingly low. You’ll find that it utilizes 40% less energy than other systems. While we are discussing that, let’s mention the noise reduction is around 5dB(A). That’s an impressive advancement compared to the previously used system. It ensures the compressor is quiet and efficient, which means its activity won’t disrupt others.

These mini compressors can operate at temperatures up to 55℃ (130℉). That makes them the perfect cooling solution in outdoor environments. You can use it for automotive purposes to reduce and maintain optimal temperatures.

The best part is that RIGID’s compressors can deliver excellent performance and optimal thermal management while maintaining impressive lightness. The compressor that weighs 1.5 pounds can have a 30% better performance than a unit that weighs six times as much.

2. Micro DC Aircon – Air Circulating Systems

RIGID Micro DC Aircon removes heat from the air which is circulated through the system to cool the heat source. They are especially applied to critical applications where space and weight are important to them. It is widely used for compact and confined space cooling. DC Air conditioning systems are ideal for cooling bulk heat loads where minimal modification to the system is desired. The mini compressor air conditioner provides an excellent cooling solution where size/space/efficiency are important factors.

The idea of a micro DC air circulating system is simple. It removes the heat from the device to cool it down. The hot air that gets removed from the product circulates through our unit. Thanks to the circulation, it becomes cooler when it returns to the device. That ensures the overall temperature of your product goes down. It’s the perfect option that works well as a CO2 laser cooling system and has many other applications.

Here is the overview of the main characteristics offered by the Micro DC Aircon systems:

- Voltage. RIGID ensures that you can pick the desired voltage option from 12V, 24V, and 48V adjustments. The DC voltage ensures you utilize minimum energy without requiring converters.

- Weight. The weight varies from around ten to twelve pounds. This is a small difference between the least and most powerful options. It’s worth noting that even the settings with the fewest wattage offer efficient performance.

- Size. The size of our micro DC aircon is 350x260x180 millimeters. Yes, you are not wrong; that means the entire unit is incredibly small!

All variations use the R134A coolant, and they operate with an airflow rate of 28.3CFM at the cold air outlet. You can adjust the desired heat transfer rate, and the unit will exceed all expectations when it comes to managing the target temperature.

What Are the Main Advantages of the Micro DC Aircon?

We already mentioned that the device is light and compact. However, that’s not the only advantage. Here are the other benefits you get with our micro DC aircon unit:

- Easy to install. There’s no need for drilling because the mounting process is simple.

- Powered by electrics. There’s no need to worry about the fuel, and there’s no maintenance involved.

- An eco-friendly solution. There won’t be any CO2 emissions to the atmosphere, which means you’ll show responsibility to the environment.

- Maintaining the desired temperature. The cooling temperature can be anywhere from 5C to 30C.

- Minimal noise. The product is surprisingly quiet and has lower noise levels than other units.

RIGID doesn’t use converters to transfer AC to DC. Instead, our micro DC aircon solutions are powered by DC. That means they are efficient and enable incredible fuel savings. The best part is that you’ll save while ensuring optimal performance. Our eco-friendly systems don’t require any oil. That minimizes the hassle around maintenance and ensures your company shows responsibility for the environment.

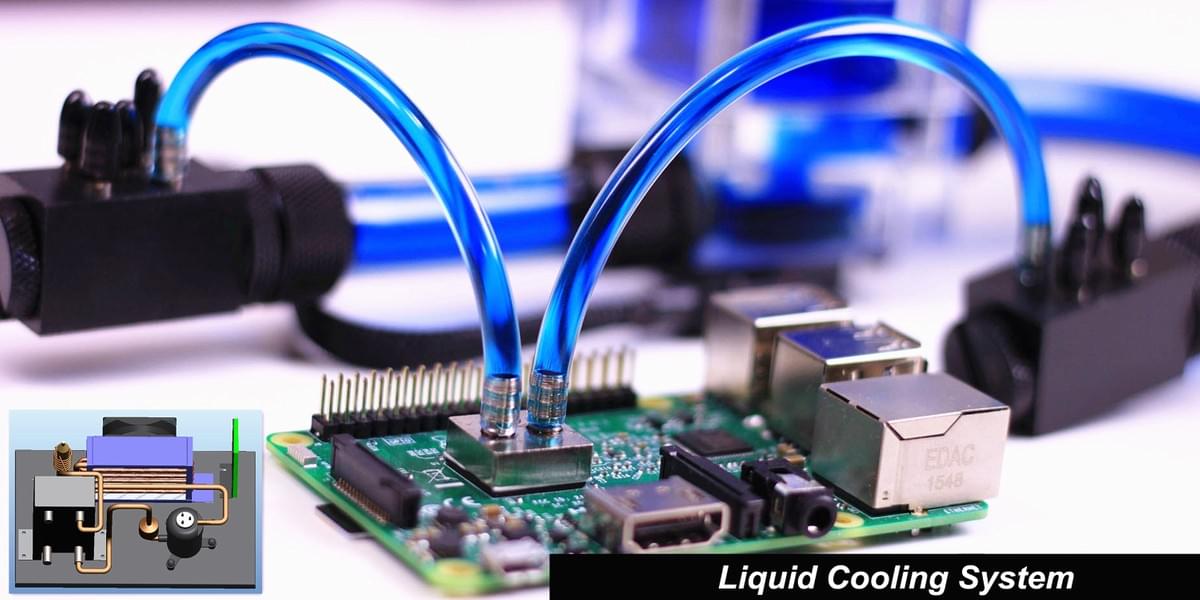

3. Small Cooling Systems – Liquid Circulating Systems

RIGID has been developing compact cooling systems for almost a decade. During that time, we’ve maintained a super quality and performance of our products. Our team did that because we have an impressive dedication to innovation. A portion of our revenue goes to the research department to develop new solutions and implement fresh technologies in our circulating systems.

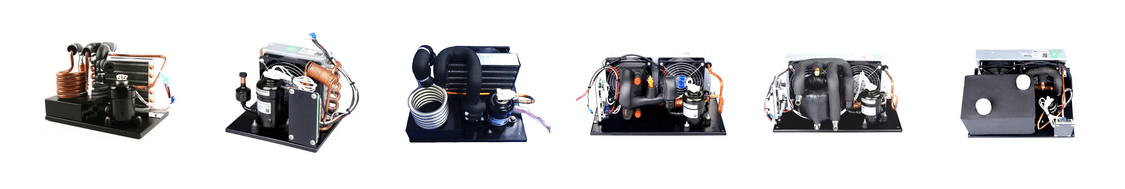

Our standard cooling systems include:

You’ll be more than happy with our liquid circulation systems. Once again, our idea was to design a compact product for various applications. That includes a laser cutter cooling system but also other applications across different industries.

What’s the Working Process of a Liquid Circulating System?

The idea is simple, and it all starts with an intuitive design. The fluid goes into a single pipe. Our mini water chiller is in charge of cooling the liquid. they utilize a refrigeration cycle that lets them remove heat from various liquids and release it into the atmosphere. In a chilling system, their use precedes directing the chilled liquid/coolant to a heat exchanger, process equipment, or other liquids.

The system requires an external pump but managed to keep a compact size. It also has an impressive capacity and surprising efficiency. It can lower the heat level significantly while maintaining a consistent temperature. It’s perfect for active thermal management, where you need to keep the heat at the same level for a long time.

It’s possible to use the device as part of your chilling system. Alternatively, it’s even possible to integrate RIGID’s liquid circulation system into your setup. That means they can become a part of your product. The increase in weight and size will be only minimal, and the cooling benefits will exceed all your expectations.

Here is a quick overview of the available liquid chillers:

● Plate liquid chillers. In part of the heat exchanger between refrigerant and liquid, it is fin-tube heat exchanger.These use a plate and frame heat exchanger.

● Coaxial liquid chiller. In part of the heat exchanger between refrigerant and liquid, it is double layer pipe heat exchanger.

● Stainless steel liquid cooler. This is an excellent option for portable and compact chilling. You often find it in a laser diode cooling system and many other applications.

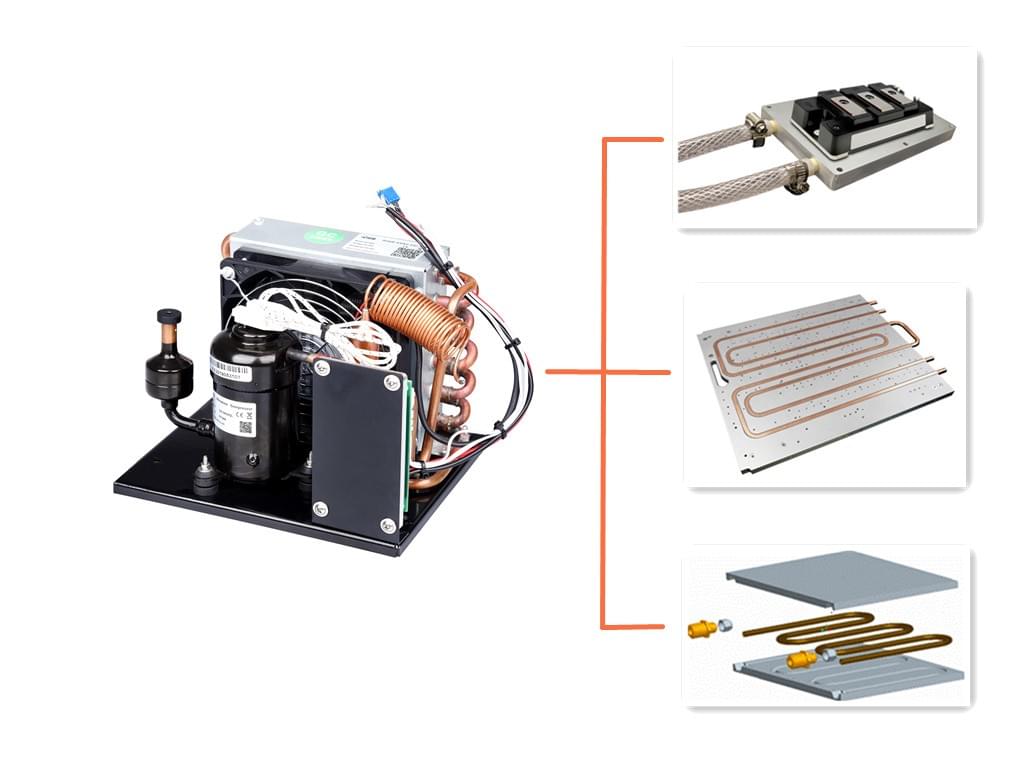

4. DC Condensing Unit – Direct Expansion Systems

The main difference between this unit and others is that it features direct expansion. This is a subsystem that doesn’t come with an evaporator. Its components are the R134A coolant, filler drier, driver board, expansion valve, radiator and condenser, and other parts.

Our DC Condensing Unit is unique because it comes without an evaporator. Instead, you have the freedom to customize the cold plate to your requirements. Please note that we can adjust the system to fit your needs. Our engineers have years of experience and are ready to design a laser cooling water system that will meet your expectations to the smallest detail.

Versatility is the biggest advantage of our systems that directly integrate into your products. That ensures maximum customization and allows tailoring to your requirements. Inserting the cooling system perfectly into your device is imperative for many applications. If you have a precision instrument like a laser, you’ll appreciate mounting the evaporator directly to the product’s module or cold plate.

Apart from the ease of installation, our condensing unit puts complete control in your hands. You can use our patented drive board to adjust the speed to identify optimal performance. That allows you to control the temperature with incredible precision. As with all other cooling solutions, you can pick from multiple voltage options. Our DC condensing unit is compact and light, which means its weight won’t go over 5.5 pounds. That means it will fit your requirements perfectly!

What You Get If You Choose RIGID

It was in 2010 when we launched miniature dc compressor under the name RIGID. Our idea was to revolutionize the Chinese market and offer a new refrigeration solution that combines performance and compact size.

In 2016, we established the RIGID brand and began working on our first DC compressor. Our experts spent years working on innovative solutions. That’s how we finally managed to develop the world’s smallest cooling solutions. Today, you can pick from various options, and our team is ready to customize a compact cooling system to any application you might require.

● Our team always works with you from day one. We’ll listen to your requirements carefully. Based on that, we can suggest and develop the most suitable small cooling systems for your applications.

● We are ready to deliver around the world. Our experts have a short turnaround time for any cooling systems we design. We are ready to send our devices to any location in the world, and we’ll make sure they arrive as soon as possible!

● We are always offering superb quality at competitive prices. At RIGID, we always use top-quality components in our products. That ensures maximum value for the money and impressive durability. At the same time, we strive to offer competitive prices that will suit your budget.

Are you interested in a cooling solution for your application? Feel free to contact our experts to start working on your chilling system today. You can place an online order or get in touch to ask any questions about our products!