Tiny Water Cooler with Compressor for a Laser Cooling Systems

Lasers have many applications across different industries. They are versatile, but their temperature rises quickly. If they get too hot, they are unusable and could even suffer damage. That’s why it’s necessary to maintain optimal temperatures in laser applications. That’s where a laser cooling system comes into play.

It is known that high-efficiency lasers generate a lot of heat. It is necessary to remove the heat from the system to prevent components from overheating. And water cooling ensures the long-term accuracy of the laser wavelength and thus the ideal laser beam quality. The thermal stress of the laser system is greatly reduced. The compact water cooling units developed by RIGID continuously circulate water to the laser equipment to avoid overheating.

At RIGID, we developed a unique laser cooling system - Direct Expansion System, that utilizes our tiny water cooler. It’s compact but powerful and consistent in maintaining the desired temperature. This guide reveals everything you should know about laser cooling. Check it out to learn more about our systems!

The Importance of Lasers Across Different Industries

You’ll find lasers are versatile and applicable in different industries. Depending on how they are constructed, you can use them for many purposes. Here is a short overview of the branches where laser applications could deliver impressive results!

Science

Scientists across many fields make use of lasers. Here is where they proved themselves useful:

● Spectroscopy. Lasers are a pure light source, and that makes them suitable for various spectroscopy techniques.

● Heat treatments. If you treat surfaces with laser, you can improve their durability and resistance to wear and tear.

● Lunar laser ranging. The scientists added a laser to a large telescope. They calculated how long it took for it to return to Earth to determine the resistance to the Moon.

● Photochemistry. A short pulse of light with a laser system can lead to chemical reactions. It also analyzes them to identify intermediate molecules. That’s convenient in biochemistry to analyze protein functions.

● Laser scanners. You can use lasers in barcode scanners as they are fast in reading the codes.

● Microscopy. Many microscopes use lasers to deliver excellent quality images.

Military

Lasers can help with ranging but also assist with communications and serve as actual weapons. Check out the potential laser uses in the military industry:

● Countermeasures. If someone sends an infrared homing missile, lasers could disorient its heads. Depending on the laser strength, they are capable of helping on the defensive end against powerful weapons.

● Energy weapons. Lasers can serve as classic weapons, and some units can disorient a person.

● Guidance and designators. You can use a laser beam to guide a missile to a vehicle or another target. Target designators are capable of indicating a target and serving as navigators for precision munition.

● A part of firearms. Lasers can improve the targeting when using weapons, such as a rifle or handgun. Most applications use a red diode, although it could also be an IR diode, which you can only use with night vision.

Medicine

Lasers can improve medical treatments and equipment. You can find them in many medical applications, including:

- Eye and refractive surgery. It can be helpful in resolving issues humans might have with their eyes.

- Cosmetic operations. That includes dealing with scars, wrinkles, sunspots, and stretch marks. You can also remove tattoos, hairs, and birthmarks with lasers.

- Laser scalpels. These can assist in urology, gynecological, and other surgical treatments.

- Tumor removal. Lasers can remove tumors without “touching” the body, which is important for the spinal cord and brain.

- Dentistry uses. Many dentists use them to remove caries, whiten teeth, and perform oral surgeries.

Industry and Commerce

Lasers have become an important asset for industrial and commercial applications. They can process materials and micro materials, and the uses include:

- Cutting, drilling, welding, marking, cleaning, and other operations.

- Rangefinders and guidance systems.

- Engraving, printing, using lasers for manufacturing OLED displays.

- Showing subtitles on movies.

- Laser scanners can provide precise measurements.

The entertainment industry uses lasers, too. You often see laser lighting in concerts and other big events. Laser tags are another entertainment activity.

Why Are Laser Cooling Systems Important?

Lasers have dozens of uses across different industries. Regardless of their applications, you want the performance to be at the maximum level. Additionally, it’s necessary to maintain consistent performance. That’s only possible if you have thermal control over the lasers. They can get hot quickly, which affects performance and can lead to damage.

It’s imperative to maintain the optimal temperature of the lasers. That’s why RIGID designed a laser cooling system that combines compact size and excellent performance. It doesn’t take a lot of room, and it’s versatile. Thanks to the small size, you can use it on different devices. The cooling system guarantees precise thermal control.

Main Features of the RIGID Laser Cooling System

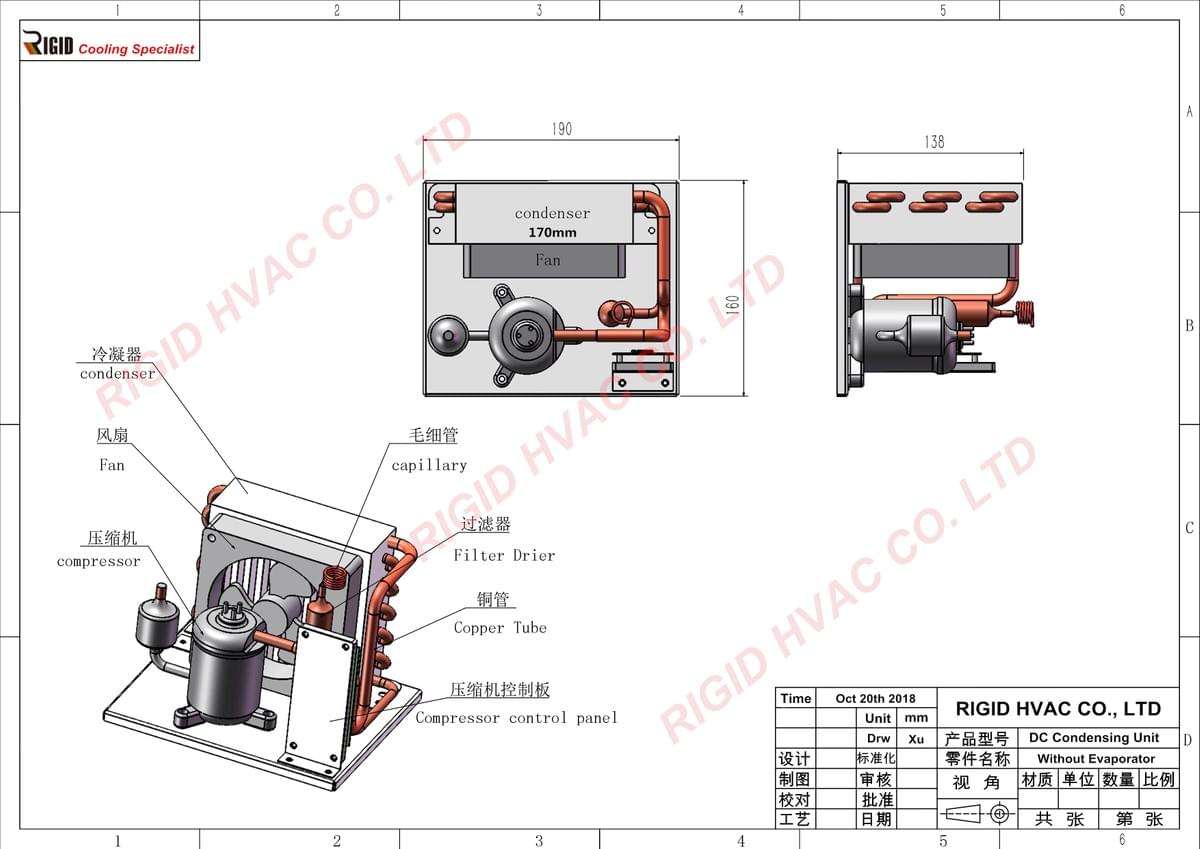

RIGID is an expert in chilling solutions. Our laser cooling water systems have a simple working process. They contain four major parts, including an evaporator, microchannel condenser, small compressor, and an expansion or capillary valve.

The working process is as simple it could get. The first part is absorbing the heat from the device. That’s usually done with a coolant or refrigerant. The cooler creates a cycle by pushing the heat from your product through the chiller. Once it reaches the end of the cycle, it returns cold to your device. It’s a simple cooling process, but it enables efficient cooling. Here are the main features and reasons why you should consider RIGID laser cooling systems!

1.

A Surprisingly Compact Size

The first thing that will surprise you is the extra-small size of our chillers. It always depends on your needs, but our solutions can be as small as 7.48x6.3x5.43 inch (190x160x138mm). That makes it perfect as a laser hair removal cooling system or for any other compact device.

The portable size makes the integration process simple. You can install the component as a part of your product, and it won’t take much room. It will be easy to stay within your desired total product sizes. At the same time, you’ll ensure that the performance remains efficient and in line with your requirements.

It’s worth mentioning that the laser cooling system RIGID creates is suitable for confined spaces. It takes little room, which is why you can use it in restricted areas. The system will maintain exceptional chilling performance by taking as little room as possible.

2.

A Lightweight Product

Your device requires an efficient cooling system, but you also want to maintain it as light as possible. If each kilogram is important to your product, you’ll appreciate RIGID’s CO2 laser cooling system. It weighs up to 2.5 kilograms or up to 5.5 pounds.

Our team will analyze the requirements of your application. Based on that, we’ll give our best to design a chiller that will be as lightweight as possible. We’ll make sure not to add a single pound more than necessary.

3.

High-Quality Construction

While size and weight are important, it all comes down to performance. That’s why RIGID designed the best-performing product while keeping it tiny. We use high-quality components to ensure maximum longevity and durability.

It also secures that your device will perform consistently. You can also count on our helpful customer support. We are there to help you with every step of the process. Our expert staff will answer any questions you have about the chilling solution for your product.

4.

Optimal and Consistent Thermal Control

RIGID Direct Expansion System can be embedded into a DX cold plate to the heat from heat source. It can reduce the temperature by approximately -20 to -25C. Not only will it cool down the temperature to the desired level, but it will maintain impressive consistency. Thanks to the optimal performance, you can expect premium thermal control, which ensures your product works smoothly.

Our cooling systems can also come with a sine wave drive board. The board for speed control can adjust the speed of the compressor. That means you can change the compressor settings to ensure you get just the desired temperature.

5.

Multiple Voltage and Wattage Options

RIGID Direct Expansion System has three different voltage options – 12V, 24V, and 48V. The wattage can vary from 100 to 550W, which gives you plenty of room to find the desired settings for your application. If you don’t need excessive power, you’ll be happy with the most affordable solution. But if you want to maximize the potential of your chiller, you’ll be surprised how much power it can pack in a small size.

6.

Silent Performance and Low Noise Levels

If you use a laser hair removal cooling system, you don’t want it to be too loud. It can be annoying and disrupt you from focusing on using the product. Silent products are always a better user experience. That’s why you want to keep the overall noise levels in your devices as low as possible.

That’s where RIGID cooling systems can help. Our chilling solutions usually have a noise rating of 40dB. Let us only say that’s like you are in a library, which means you can expect the cooler to be very silent. Our solutions use brushless compressors, and that’s the main reason why they manage to maintain this low noise level. If you’d like your product to stay silent while active, our cooling solutions fit that description perfectly.

7.

Designing a Customized Solution for Your Needs

An important feature of the RIGID cooling system is that it can easily be adjusted to fit different applications. The impressive range of customization options ensures that you can get the solution tailored to your product.

Our customized chilling solutions are the best thing you can get on the market. You might have a product that requires maximum power from our laser cooling system. Perhaps you want the smallest possible solution to fit your device without taking unnecessary room. Whichever way you choose, we can deliver the product that perfectly meets your expectations!

What You Should Know About RIGID

RIGID has a long tradition and is famous for its dedication to innovation and excellence. Our main office is in China, and we focus on making affordable and efficient cooling systems. We work closely with European, US, and other relevant experts in refrigeration and cooling.

At RIGID, we start with having a great idea. From there, our research and development section takes over. We invest years in developing a solution that will suit our clients’ needs perfectly.

Our focus is on miniature and compact cooling solutions. That includes a laser cutter cooling system but also solutions for medical, military, and other applications. At RIGID, we strongly believe that our products speak for themselves. That’s why we don’t spend huge amounts on marketing. Instead, we use maximum funds to create impressive products for our customers.

Why You Should Work with RIGID to Design Laser Cooling System

RIGID meets all relevant laws and regulations. Our products are in line with the ISO 9001 international standard. Over the years, we’ve worked with many companies from Europe, Asia, the USA, Russia, and the Middle East.

Customized Solutions for Your Needs

It’s not only about finding a laser diode cooling system. You want a system that suits your requirements. Each product is unique, which is why you’ll benefit from a customized solution for your application.

At RIGID, we begin by discussing your requirements. Our experts analyze your product and come up with the best idea for a cooling solution. We make sure that the chilling system fits your budget and expectations while maintaining a compact size and efficient performance.

Fast Delivery Anywhere in the World

Our team gives its maximum on small and big projects. We make sure to go the extra mile to honor the deadline and finish the order execution on time. That means our clients can expect fast delivery to ensure they begin using their devices as soon as possible. Purchase Online!

Always There for Our Clients

At RIGID, we believe in developing and maintaining a strong relationship with our clients. We begin by listening to your requirements and implementing them in the customized solution. Our team makes sure the prices stay competitive, so you don’t suffer large budget hits. We make sure everything works flawlessly before sending the laser cooling system to your address.

Once you receive the device, you can count on us for technical support. Our experts are there to answer any questions you might have throughout the process.

Do you need a laser cooling system for your equipment? If yes, don’t hesitate to Contact RIGID today! or email us by info@rigidhvac.com