Introduction

In the realm of food preservation and temperature-sensitive goods, refrigeration cold storage plays a pivotal role. It involves maintaining specific temperatures to ensure that perishable items remain fresh and safe for consumption. But what is cold storage refrigeration? This system employs various technologies and methods to create an environment that inhibits spoilage, making it essential for industries ranging from food service to pharmaceuticals.

Efficiency in cold storage is not just a luxury; it's a necessity. With rising energy costs and increasing environmental concerns, optimizing refrigeration systems can lead to significant savings and reduced carbon footprints. Understanding which refrigerant is used in cold storage, along with the right equipment choices, can dramatically enhance operational efficiency while maintaining product integrity.

Several key factors affect the performance of refrigeration cold storage systems. These include the design of industrial cold rooms, the selection of appropriate refrigerants, and effective inventory management practices. By delving into these elements, businesses can unlock innovations that not only improve efficiency but also ensure compliance with health regulations while maximizing profitability.

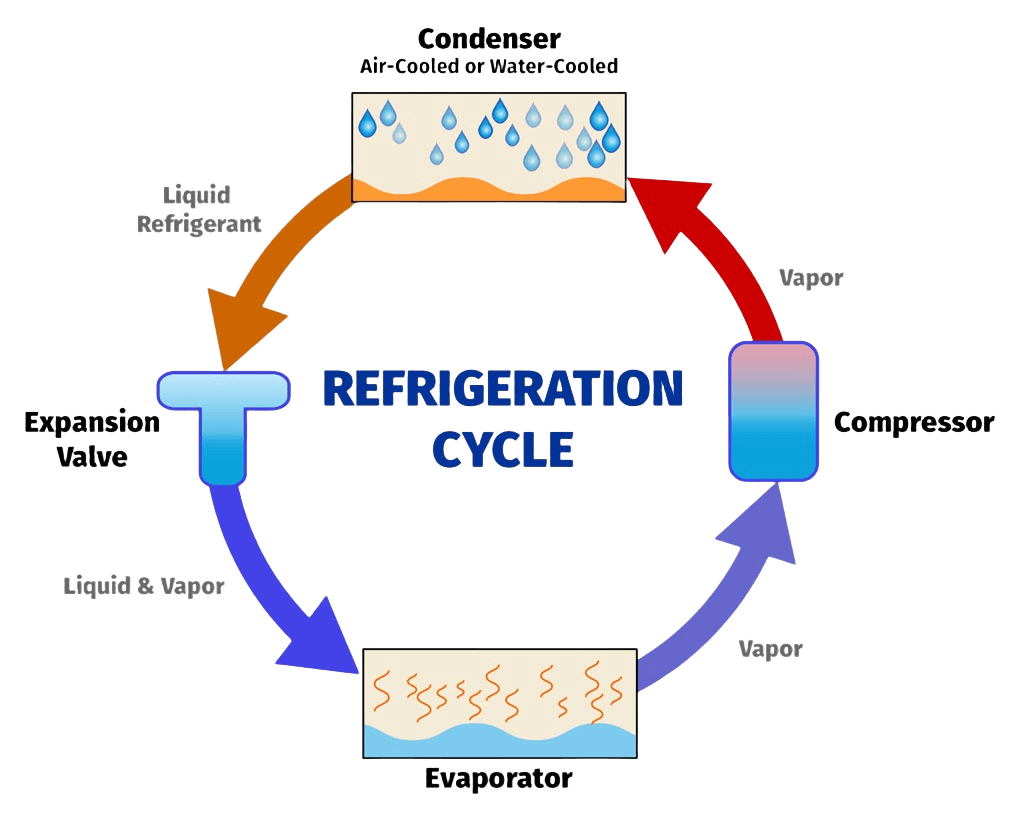

The Refrigeration Cycle Explained

Understanding the refrigeration cycle is crucial for anyone involved in refrigeration cold storage. This process is what keeps your perishable goods fresh and safe, ensuring that they maintain their quality over time. Let’s delve into the basics, key components, and the vital role this cycle plays in maintaining optimal conditions.

Basics of the Refrigeration Cycle

The refrigeration cycle is essentially a heat transfer process that removes heat from a designated area to keep it cool. At its core, it involves four main stages: evaporation, compression, condensation, and expansion. When we ask ourselves, What is cold storage refrigeration? we are referring to this intricate dance of thermodynamics that allows us to store food and pharmaceuticals at safe temperatures.

During evaporation, refrigerant absorbs heat from the environment inside the cold storage unit, turning from liquid to gas. This gas then travels to the compressor where it’s pressurized and heated before moving into the condenser coils outside or on top of your refrigerator. Here again, we see the magic of phase change as it releases heat into the atmosphere and turns back into a liquid—ready to start its journey all over again.

Key Components of Cold Storage Systems

Cold storage systems rely on several key components working together seamlessly for optimal performance. These include compressors, condensers, evaporators, expansion valves, and various types of insulation materials that keep everything running smoothly. If you've ever wondered which refrigerator is used in cold storage applications—industrial refrigerators often serve this purpose due to their robust design and efficiency.

Compressors are like the heart of these systems; they circulate refrigerant through pipes while maintaining pressure levels necessary for effective cooling. Condensers release heat absorbed during evaporation while evaporators facilitate cooling by absorbing heat from stored items in refrigerated spaces like an industrial cold room & equipment setup. Each component plays a critical role in ensuring temperature stability within these environments.

Role in Maintaining Optimal Conditions

Maintaining optimal conditions within a refrigeration cold storage system hinges on understanding how these components interact within the refrigeration cycle framework. For instance, if any part of this cycle fails or operates inefficiently—even slightly—it can lead to temperature fluctuations that compromise stored goods' integrity. Thus arises another question: What is the cold storage method? It's about using these systems effectively to ensure consistent temperatures are maintained throughout.

The design and layout of industrial cold rooms also impact efficiency; improper space utilization can hinder airflow or create hot spots leading to spoilage risks for sensitive products like dairy or meats. Moreover, integrating advanced monitoring technologies ensures real-time tracking of temperatures so operators can swiftly address any deviations before they escalate into larger issues—keeping everything fresh and compliant with safety standards!

In conclusion, understanding how each aspect of the refrigeration cycle contributes to effective cold storage management not only enhances product longevity but also maximizes operational efficiency across industries reliant on temperature-controlled environments.

Choosing the Right Refrigerant

When it comes to refrigeration cold storage, selecting the right refrigerant is crucial for maintaining efficiency and performance. The refrigerant plays a pivotal role in the refrigeration cycle, affecting everything from energy consumption to environmental impact. Understanding what is cold storage refrigeration involves recognizing how these substances interact within cold storage systems.

Types of Refrigerants Used in Cold Storage

In industrial cold rooms and equipment, several types of refrigerants are commonly used, each with its unique properties and applications. Traditional options like R-22 and R-134a have been staples in the industry, but growing concerns about ozone depletion have led to a shift towards more eco-friendly alternatives such as R-410A and natural refrigerants like ammonia or CO2. When asking which refrigerant is used in cold storage today, it’s essential to consider both efficiency and environmental impact.

Environmental Impact and Efficiency

The choice of refrigerant can significantly influence both operational costs and ecological footprint in refrigeration cold storage systems. Many older refrigerants contribute to global warming potential (GWP) and ozone layer depletion, making them less favorable as regulations tighten worldwide. Therefore, understanding which refrigerator is used in cold storage not only involves looking at its cooling capacity but also assessing its environmental impact—an increasingly vital consideration for modern businesses.

RIGID’s Innovations in Refrigerants

RIGID has been at the forefront of developing innovative refrigerants that maximize efficiency while minimizing environmental harm. Their commitment to sustainability means they focus on creating solutions that align with current regulations without compromising performance in industrial cold rooms & equipment. By integrating advanced technology into their products, RIGID ensures that users can enjoy effective refrigeration cold storage without worrying about excessive energy consumption or harmful emissions.

Selecting the Optimal Cold Storage Equipment

When it comes to refrigeration cold storage, choosing the right equipment is crucial for maintaining product quality and operational efficiency. The selection process involves understanding various types of refrigerators and their specific applications in cold storage settings. In this section, we will explore which refrigerator is used in cold storage, provide an overview of industrial cold rooms and their equipment, and emphasize the importance of tailoring equipment to meet unique needs.

Which Refrigerator is Used in Cold Storage?

In refrigeration cold storage, the choice of refrigerator can significantly impact performance and energy consumption. Commonly used systems include walk-in coolers, blast freezers, and reach-in refrigerators, each designed for specific temperature requirements and types of stored products. Understanding what is cold storage refrigeration involves recognizing that different items necessitate different cooling solutions to preserve freshness effectively.

For example, perishable goods like fruits or dairy may require a consistent temperature range that a specialized refrigerator can provide. Additionally, industrial settings often utilize larger systems that can accommodate bulk quantities while ensuring uniform cooling throughout the space. So when asking which refrigerator is used in cold storage? The answer largely depends on the specific needs of the operation.

Industrial Cold Room & Equipments Overview

Industrial cold rooms are essential components within refrigeration cold storage facilities as they create controlled environments suitable for various products. These rooms are equipped with advanced cooling technologies that enable precise temperature management across large spaces. Key equipment includes evaporators, condensers, compressors, and shelving units tailored for efficient airflow and organization.

The design of industrial cold rooms plays a vital role in maximizing space utilization while minimizing energy consumption during operation. Moreover, integrating additional features like humidity control systems can enhance product preservation further by preventing spoilage due to excess moisture or dryness. Understanding these aspects helps businesses select appropriate industrial cold room & equipments that align with their operational goals.

Importance of Tailoring Equipment to Needs

One size does not fit all when it comes to refrigeration cold storage; therefore, tailoring equipment to specific needs is paramount for success. Factors such as product type, volume requirements, and operational processes must be considered during selection to ensure optimal performance. What is the cold storage method? It’s about creating an environment where products remain fresh through careful planning regarding equipment choices.

Selecting customized solutions not only enhances efficiency but also contributes significantly to cost savings over time by reducing energy waste associated with improper sizing or functionality mismatches between products and systems used for preservation purposes. Ultimately, investing time upfront into understanding which refrigerant is used in cold storage alongside other essential considerations ensures long-term benefits for any business relying on effective refrigerated environments.

Implementing Effective Cold Storage Methods

In the realm of refrigeration cold storage, effective methods are paramount for maintaining product quality and safety. Understanding what is cold storage refrigeration? is essential for optimizing processes and ensuring that temperature-sensitive materials remain in peak condition. The right approach can significantly enhance performance, reduce waste, and ultimately save costs.

What is the Cold Storage Method?

The cold storage method refers to the systematic approach of preserving perishable goods at low temperatures to extend their shelf life. This technique relies heavily on the refrigeration cycle, which circulates refrigerants through a closed system to absorb heat from the stored items. By maintaining optimal conditions, this method ensures that products such as food, pharmaceuticals, and chemicals are kept fresh and safe for consumption or use.

Cold storage refrigeration employs specific equipment designed for industrial applications. Understanding which refrigerator is used in cold storage helps businesses select appropriate systems tailored to their unique needs. The effectiveness of these methods hinges on proper equipment selection and maintenance to ensure consistent temperature control throughout the storage environment.

Best Practices for Inventory Management

Effective inventory management plays a crucial role in maximizing efficiency within refrigeration cold storage facilities. Implementing best practices involves regularly monitoring stock levels, conducting routine inspections, and utilizing FIFO (First In First Out) principles to minimize spoilage risks. By keeping track of expiration dates and ensuring proper rotation of products, businesses can optimize their inventory turnover rates while reducing waste.

Another vital aspect of inventory management in industrial cold rooms is accurate labeling and organization of products. Clear labeling helps staff quickly identify items while minimizing retrieval times during busy operations. Additionally, maintaining a clean and organized space contributes significantly to operational efficiency within any cold storage environment.

Lastly, integrating advanced tracking systems can further enhance inventory management practices by providing real-time data on stock levels and conditions within the refrigeration cycle. This technology allows businesses to make informed decisions regarding ordering patterns or necessary adjustments in temperature settings based on demand fluctuations.

Integrating Technology for Enhanced Control

In today's rapidly evolving landscape, integrating technology into refrigeration cold storage operations has become essential for enhancing control over environmental conditions. Automated monitoring systems provide real-time insights into temperature fluctuations, humidity levels, and equipment performance—enabling swift responses before minor issues escalate into costly problems.

Moreover, employing IoT (Internet of Things) solutions allows facilities to connect various components within their industrial cold room & equipment setups seamlessly. These connections facilitate remote access to critical data points through smartphones or computers—empowering managers with tools needed for proactive decision-making regarding maintenance schedules or energy consumption reductions.

Furthermore, smart analytics can help optimize energy usage by analyzing historical data trends related to which refrigerant is used in cold storage applications or how effectively specific equipment performs under varying loads over time. By leveraging these technological advancements strategically within their operations—companies stand poised not only to improve efficiency but also contribute positively towards sustainability goals as well!

Enhancing Efficiency Through Design

In the realm of refrigeration cold storage, design plays a pivotal role in maximizing efficiency and ensuring optimal temperature control. A well-planned layout can significantly impact how effectively space is utilized, which directly correlates to energy consumption and operational costs. By focusing on thoughtful design strategies, businesses can enhance their cold storage capabilities while minimizing waste.

Importance of Proper Layout and Space Utilization

When examining what is cold storage refrigeration?, one must consider the significance of layout and space utilization. A strategic arrangement not only facilitates easy access to inventory but also promotes efficient airflow around stored products, which is crucial for maintaining consistent temperatures. By optimizing the layout, facilities can reduce energy costs while improving overall operational efficiency in an industrial cold room & equipment setting.

Furthermore, proper space utilization helps prevent overcrowding, which can lead to temperature fluctuations that compromise product quality. An effective cold storage method involves designing spaces that are tailored to specific needs—whether it’s for perishable goods or pharmaceuticals—allowing for better management of inventory levels and reducing spoilage rates. Ultimately, a well-thought-out design can transform a basic refrigeration cold storage facility into a highly efficient operation.

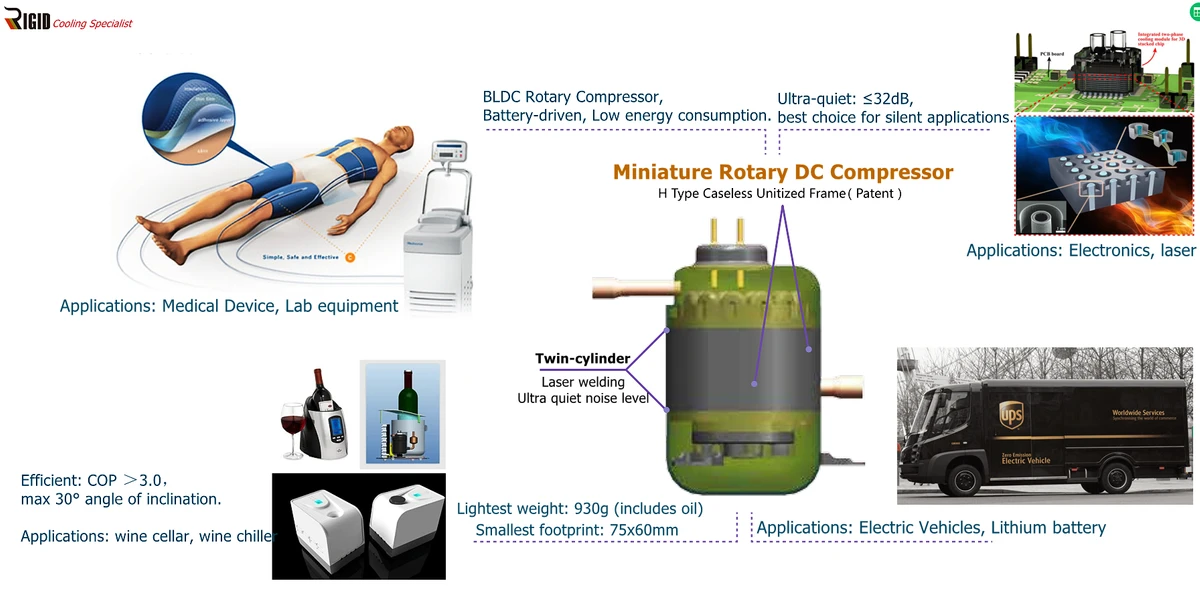

RIGID’s Compact Cooling Solutions

RIGID has taken the lead in providing compact cooling solutions that cater specifically to the demands of modern refrigeration cold storage systems. These innovative designs maximize usable space while ensuring optimal performance through advanced technology integration. With options tailored for various applications, RIGID's solutions address common challenges faced by operators seeking efficient refrigeration methods.

The compact nature of these cooling systems allows for more flexibility in layout design without sacrificing performance or capacity. This adaptability makes it easier to incorporate features such as adjustable shelving or modular units that can be reconfigured as needs change over time. As businesses explore which refrigerator is used in cold storage settings, RIGID stands out with its ability to offer customizable solutions that meet diverse requirements.

Moreover, RIGID continuously invests in research and development to enhance their equipment's efficiency further—a key factor when considering which refrigerant is used in cold storage applications today. Their commitment to sustainability means choosing refrigerants with lower environmental impacts without compromising on performance or reliability.

Advanced Insulation Techniques

In addition to layout and equipment selection, advanced insulation techniques are essential for enhancing efficiency within refrigeration cold storage facilities. Proper insulation minimizes heat transfer between the inside and outside environments—crucial when maintaining stable temperatures during varying external conditions. This aspect not only improves energy efficiency but also extends the life cycle of refrigeration systems by reducing their workload.

Utilizing cutting-edge materials designed specifically for industrial cold rooms ensures that temperature fluctuations are kept at bay while also providing significant cost savings over time due to reduced energy consumption rates. When exploring what is the cold storage method?, it's important to recognize how effective insulation contributes directly to achieving desired temperature ranges consistently throughout stored products' lifecycle.

RIGID employs state-of-the-art insulation materials designed with both durability and thermal resistance in mind—ensuring long-lasting performance even under demanding conditions typical of industrial settings. As companies strive for excellence in their operations, investing in advanced insulation techniques becomes a cornerstone strategy for achieving superior efficiency within their refrigeration cold storage environments.

Conclusion

In wrapping up our exploration of refrigeration cold storage, it's essential to recognize the evolving landscape of this critical industry. With advancements in technology and growing environmental awareness, the future of cold storage refrigeration promises to be more efficient and sustainable. As we look ahead, embracing innovative practices will be key to optimizing performance while minimizing costs.

Future Trends in Refrigeration Cold Storage

The future trends in refrigeration cold storage are likely to revolve around energy efficiency and sustainability. Expect a surge in the use of natural refrigerants as businesses seek alternatives that minimize environmental impact while maintaining effective cooling capabilities. Additionally, smart technology integration will enhance monitoring and control systems, making it easier to manage temperature fluctuations and reduce energy consumption.

Maximizing Cost-Effectiveness with RIGID

Maximizing cost-effectiveness with RIGID involves selecting the right equipment tailored for specific needs within industrial cold rooms & equipment setups. By utilizing advanced insulation techniques and compact cooling solutions, RIGID helps businesses optimize their refrigeration cold storage operations without breaking the bank. Furthermore, investing in efficient refrigerants can lead to significant long-term savings by reducing energy costs associated with maintaining optimal conditions.

The Role of Innovation in Cold Storage Efficiency

Innovation plays a pivotal role in enhancing efficiency within cold storage systems. From developing cutting-edge refrigeration cycles that improve heat exchange processes to designing user-friendly interfaces for managing inventory effectively, technological advancements are reshaping how we think about what is cold storage refrigeration? The continuous evolution of equipment ensures that businesses can adapt quickly to changing market demands while maintaining high standards for quality and safety.