Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

In the realm of scientific research and industrial applications, maintaining precise temperature control is crucial for achieving accurate results. This is where laboratory recirculating chillers come into play, offering a reliable solution to regulate temperatures in various settings. These sophisticated chiller systems are designed to provide consistent cooling, ensuring that experiments and processes run smoothly without the risk of overheating.

Understanding Laboratory Recirculating Chillers

A laboratory recirculating chiller is an advanced cooling system that circulates coolant through a closed-loop system to maintain desired temperatures in laboratory environments. Unlike traditional chillers, which may rely on ambient air or other methods for cooling, these specialized water chiller systems utilize a continuous flow of chilled liquid to remove heat efficiently. The result is enhanced thermal stability, which is essential for sensitive experiments and equipment.

The Importance of Temperature Control

Temperature control in laboratories cannot be overstated; it directly impacts the quality and reliability of experimental outcomes. Fluctuations in temperature can lead to inconsistent results or even compromise sensitive materials during testing processes. Thus, utilizing an efficient water cooled chiller or industrial water chiller ensures that precise temperatures are maintained throughout experiments, contributing to better data accuracy and reproducibility.

Applications of Laboratory Chillers

Laboratory chillers find applications across diverse fields including pharmaceuticals, biotechnology, chemical processing, and more. In pharmaceutical labs, for instance, maintaining specific temperatures during drug formulation is vital for efficacy and safety testing. Similarly, in chemical processing industries, water chiller systems are employed to cool reaction vessels or condensers effectively—showcasing their versatility and importance across multiple sectors.

What is a Laboratory Recirculating Chiller?

When it comes to maintaining precise temperatures in laboratory environments, a laboratory recirculating chiller is an essential piece of equipment. This sophisticated chiller system circulates coolant through various apparatuses, ensuring that experiments and processes remain at optimal temperatures. Understanding its definition and functionality is the first step in appreciating how these systems contribute to scientific success.

Definition and Functionality

A laboratory recirculating chiller is designed specifically to cool liquids used in various laboratory applications. It functions by removing heat from a fluid and transferring it to the surrounding environment, effectively keeping the temperature stable within the desired range. This capability makes it indispensable for tasks such as cooling reaction vessels, maintaining sample integrity, or even supporting other equipment like centrifuges or lasers.

Components of a Chiller System

A typical chiller system comprises several key components that work together seamlessly to achieve effective cooling. These include a compressor, evaporator, condenser, expansion valve, and a reservoir for the coolant—often water in water chiller systems. Each component plays a vital role; for instance, the compressor pressurizes the refrigerant while the evaporator absorbs heat from the liquid being cooled.

How Recirculating Chillers Work

Recirculating chillers operate on principles similar to traditional refrigeration but are tailored for industrial water chillers or laboratory settings. The process begins with the coolant circulating through an evaporator where it absorbs heat from the liquid being cooled—this causes it to evaporate into gas form. The compressor then takes this gas and compresses it, raising its pressure and temperature before moving it into the condenser where it's cooled down back into liquid form before returning to complete the cycle again.

Types of Recirculating Chillers

When it comes to laboratory recirculating chillers, understanding the different types available is crucial for selecting the right chiller system for your specific needs. The primary distinction lies between water chillers and air chillers, each offering unique advantages depending on the application. Let’s dive into these types and how they fit into the broader landscape of laboratory cooling solutions.

Water Chillers vs. Air Chillers

Water chillers are often favored in laboratory settings due to their superior cooling efficiency and temperature stability compared to air chillers. While air chillers use ambient air to cool equipment, water chillers circulate chilled water through a closed-loop system, allowing for more precise temperature control essential for sensitive experiments. In environments where consistent cooling is paramount, such as chemical processing or biotechnology labs, water chiller systems shine as the go-to choice.

On the flip side, air chillers have their place in scenarios where space is limited or where portability is key. They tend to be easier to install since they don’t require plumbing considerations like water cooled chillers do. However, when high-performance cooling is non-negotiable, particularly in industrial applications, laboratory professionals often find themselves gravitating towards robust water chiller systems.

Ultimately, both options serve critical roles in maintaining optimal conditions within laboratories; however, understanding their differences can significantly impact operational efficiency and effectiveness in various applications.

Industrial Water Chillers Overview

Industrial water chillers are heavy-duty versions of standard laboratory recirculating chillers designed to handle larger volumes and more demanding cooling tasks. These systems are engineered for continuous operation and can maintain low temperatures even under high loads — making them indispensable in industries like pharmaceuticals and manufacturing where precision is critical. With capabilities that extend beyond typical lab settings, industrial water chillers ensure that processes remain stable without overheating.

One of the standout features of industrial water chiller systems is their ability to integrate with other equipment seamlessly; whether it's a laser cutter or a large-scale fermentation tank, these units provide reliable cooling support across various applications. Moreover, many modern industrial models come equipped with advanced monitoring technologies that allow users to track performance metrics easily — ensuring that any potential issues can be addressed before they escalate into costly downtime.

In summary, when looking at options for high-demand environments requiring consistent temperature control over prolonged periods, investing in an industrial water chiller proves beneficial not just for performance but also for peace of mind.

Key Features of Water Cooled Chillers

Water cooled chillers boast several key features that make them particularly effective within laboratory settings and beyond. For starters, they typically offer higher energy efficiency compared to their air counterparts due to reduced reliance on compressor power when utilizing chilled water from an external source or reservoir. This translates into lower operating costs over time — an attractive proposition for budget-conscious laboratories aiming for sustainability without sacrificing performance.

Another notable feature is their enhanced heat exchange capabilities; these units utilize evaporators designed specifically for optimal thermal transfer rates which help maintain steady temperatures even during peak usage times in busy labs or production facilities. This reliability ensures experiments yield consistent results without interruptions caused by fluctuating temperatures — a crucial aspect when working with sensitive materials or reactions.

Lastly, many modern water cooled chiller systems come outfitted with user-friendly interfaces that allow operators easy access to essential data such as flow rates and temperature readings at a glance — simplifying monitoring efforts while enhancing overall operational efficiency within any lab environment.

Benefits of Using a Laboratory Chiller

Laboratory recirculating chillers are essential tools that provide numerous advantages for scientific research and industrial applications. Their ability to maintain consistent temperatures enhances experimental precision, while their energy-efficient designs contribute to cost savings. Let's delve into some of the key benefits that make these chiller systems indispensable in laboratory settings.

Enhanced Precision and Stability

One of the primary benefits of using a laboratory chiller is its capability to deliver enhanced precision and stability in temperature control. Whether you’re working with sensitive materials or conducting intricate experiments, maintaining a stable temperature is crucial for obtaining accurate results. Water chiller systems, particularly industrial water chillers, excel at providing this level of consistency by continuously circulating coolant through the system, ensuring that your processes remain unaffected by external temperature fluctuations.

Moreover, laboratory recirculating chillers can be finely tuned to meet specific temperature requirements, allowing researchers to achieve optimal conditions for their experiments. This level of control not only minimizes variability but also enhances reproducibility across different trials or studies. As a result, scientists can focus on their work without worrying about unexpected thermal shifts that could compromise their findings.

Energy Efficiency in Chilling Systems

Energy efficiency is another significant advantage offered by modern laboratory chillers. Many water cooled chillers are designed with advanced technologies that minimize energy consumption while maximizing cooling performance. By optimizing the chilling process, these systems reduce operational costs and contribute to a more sustainable laboratory environment.

Additionally, energy-efficient chiller systems often come equipped with smart features such as variable speed compressors and programmable controls that allow users to adjust cooling based on real-time needs. This adaptability not only saves energy but also prolongs the lifespan of the equipment by reducing wear and tear on components. Consequently, laboratories can enjoy both reduced utility bills and an environmentally friendly approach to temperature management.

Cost-Effective Solutions for Laboratories

Investing in a laboratory recirculating chiller can lead to long-term cost savings for any research facility or industrial application. While the initial purchase may seem substantial, the durability and efficiency of water chiller systems often translate into lower maintenance costs over time compared to less reliable cooling options. Furthermore, many manufacturers offer warranties and support services that enhance the value proposition of investing in high-quality equipment like industrial water chillers.

Moreover, when considering downtime due to equipment failure or inadequate cooling solutions, it becomes clear how critical reliable chilling systems are for maintaining productivity in laboratories. A well-functioning water cooled chiller ensures continuous operation without interruptions caused by overheating or equipment malfunctions—ultimately saving time and money in research endeavors. Thus, choosing an efficient laboratory chiller not only provides immediate benefits but also serves as a strategic investment for future success.

Choosing the Right Chiller System

Selecting the right laboratory recirculating chiller is crucial for ensuring optimal performance in various applications. With numerous options available, it's essential to consider factors like cooling capacity, energy efficiency, and maintenance requirements. Understanding these elements will help you make an informed decision that aligns with your laboratory's specific needs.

Factors to Consider in Selection

When choosing a chiller system, start by assessing the cooling requirements of your equipment and processes. Different applications may require varying temperatures and flow rates, so understanding your specific needs is paramount. Additionally, consider the space available for installation; some water chiller systems are more compact than others, making them suitable for smaller labs.

Energy efficiency is another critical factor that can significantly impact operational costs over time. Opting for a high-efficiency water cooled chiller can lead to substantial savings on electricity bills while also reducing your laboratory's carbon footprint. Lastly, don’t overlook maintenance requirements; selecting a model that’s easy to service can save you time and hassle in the long run.

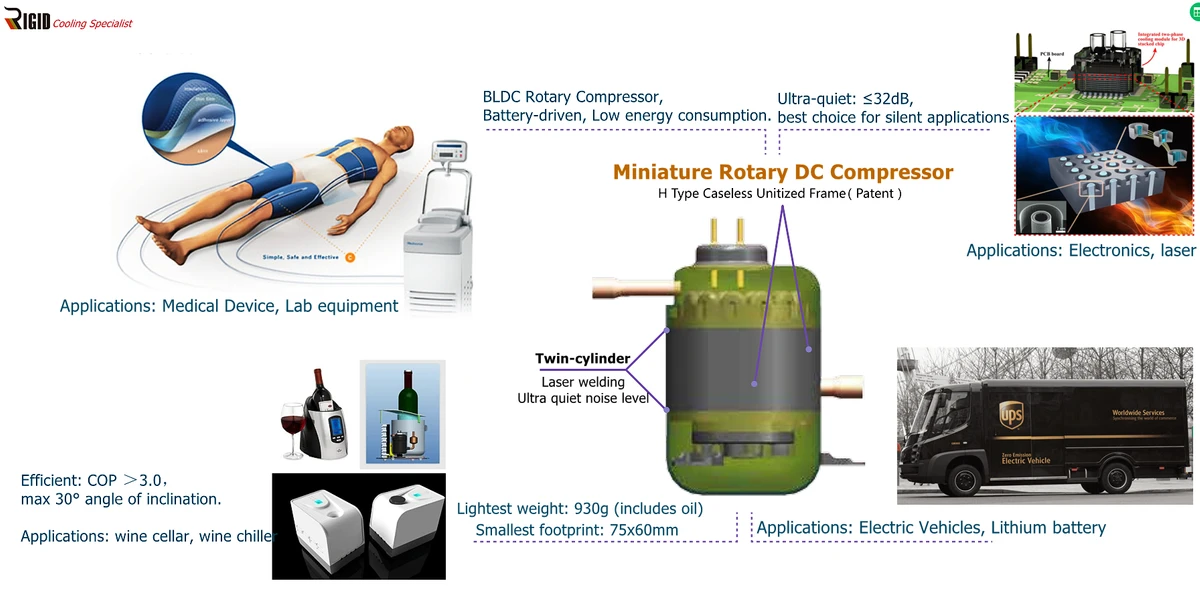

RIGID’s Offerings in Mini Compressors

RIGID provides an impressive range of mini compressors tailored specifically for laboratory recirculating chillers. These compact units are designed to deliver reliable cooling performance without taking up too much space in your lab environment. With robust construction and innovative technology, RIGID’s mini compressors ensure consistent temperature control across various applications.

One standout feature of RIGID's offerings is their energy-efficient design, which helps laboratories save on operating costs while maintaining optimal performance levels. Additionally, these mini compressors are compatible with both water chillers and industrial water chillers, providing flexibility based on your specific requirements. By choosing RIGID's products, you're investing in quality solutions that cater to diverse laboratory environments.

Customization Options for Specific Needs

Every laboratory has unique cooling requirements; thus, customization options are vital when selecting a recirculating chiller system. RIGID understands this need and offers tailored solutions that address specific temperature ranges and flow rates required by different applications. Whether you require a specialized water cooled chiller or modifications to fit existing setups seamlessly, RIGID has you covered.

Moreover, customization extends beyond technical specifications; aesthetic considerations can also play a role in integrating new equipment into your lab environment effectively. With options ranging from color choices to housing designs that align with existing lab decor, you can find a solution that meets both functional and visual criteria seamlessly. Ultimately, having access to customized solutions ensures that your laboratory operates efficiently while meeting all necessary compliance standards.

Maintenance Tips for Laboratory Chillers

Maintaining your laboratory recirculating chiller is crucial for ensuring its longevity and optimal performance. Regular upkeep can prevent costly downtimes and ensure that your chiller system operates efficiently. Here are some essential maintenance tips to keep your water chiller running smoothly.

Routine Maintenance Best Practices

Routine maintenance best practices for water chiller systems involve regular inspections, cleaning, and component checks. Start by ensuring that the condenser coils are clean and free from debris, which can hinder heat exchange efficiency in your industrial water chiller. Additionally, checking the coolant levels regularly is essential; low coolant can lead to overheating and decreased performance of your laboratory chiller.

Another key aspect of routine maintenance is monitoring the temperature settings to ensure they remain within the desired range for optimal cooling. It’s also wise to replace any worn-out filters promptly, as clogged filters can restrict airflow and decrease the efficiency of your water cooled chiller. By adhering to these practices, you’ll enhance the reliability of your recirculating chillers while minimizing unexpected breakdowns.

Troubleshooting Common Issues

Even with diligent maintenance, issues may arise with your laboratory recirculating chiller that require troubleshooting skills. One common problem is inadequate cooling; if temperatures are not reaching expected levels, check for refrigerant leaks or blockages in the system's flow path. This could indicate a need for repairs or adjustments within the water chiller systems.

Another frequent issue involves unusual noises coming from the industrial water chiller; these sounds could signal mechanical problems such as faulty pumps or loose components. It's important to address these noises promptly to avoid further complications down the line with your laboratory chiller's operation. Lastly, keep an eye out for error codes displayed on digital control panels—these codes often provide insight into specific malfunctions that require attention.

Importance of Professional Support

While routine maintenance and troubleshooting can resolve many issues with a water cooled chiller, professional support plays a vital role in maintaining peak performance over time. Expert technicians have specialized knowledge about various types of recirculating chillers and can quickly diagnose complex problems that may elude untrained eyes. They also have access to advanced tools and replacement parts necessary for effective repairs on industrial water chillers.

Moreover, engaging professionals ensures that any preventive measures taken align with manufacturer guidelines—this helps maintain warranties while extending the lifespan of your equipment significantly. Regular professional servicing not only enhances reliability but also optimizes energy efficiency across all aspects of laboratory cooling needs—keeping costs manageable in an ever-demanding lab environment.

Conclusion

In summary, laboratory recirculating chillers are indispensable tools for maintaining precise temperature control in various laboratory environments. These chiller systems enhance the stability of experiments, ensuring that results are reliable and reproducible. With options like water chillers and industrial water chillers, laboratories can find solutions tailored to their specific needs.

Recap of Chiller System Benefits

The benefits of using a laboratory chiller extend beyond mere temperature regulation; they include enhanced precision, energy efficiency, and cost-effectiveness. A well-functioning chiller system reduces the risk of thermal fluctuations that could compromise experimental integrity. Furthermore, water cooled chillers contribute to lower operational costs by utilizing efficient cooling methods that minimize energy consumption.

Future Trends in Laboratory Chillers

Looking ahead, the future of laboratory recirculating chillers is poised for innovation with advancements in technology and sustainability practices. Expect to see more energy-efficient designs and smart technologies that allow for better monitoring and control of temperature settings in water chiller systems. Moreover, as industries push for greener solutions, eco-friendly refrigerants will likely become a standard feature in modern industrial water chillers.

Why Choose RIGID for Your Cooling Needs

When it comes to selecting a reliable partner for your cooling requirements, RIGID stands out with its commitment to quality and customization in laboratory chiller options. Their range of products includes state-of-the-art water cooled chillers designed to meet diverse application needs without compromising performance or efficiency. Choosing RIGID means investing in durable solutions backed by professional support—ensuring your laboratory operates at optimal levels.