Introduction

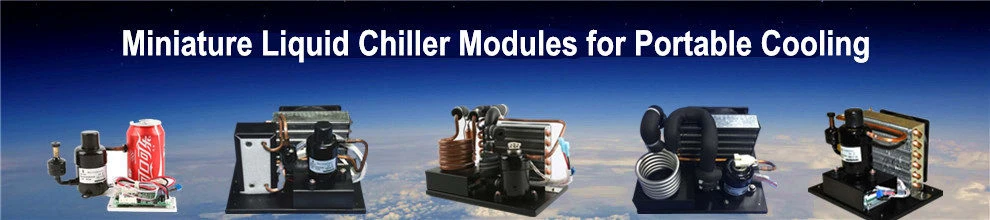

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

In a world where efficiency and sustainability are at the forefront of industrial operations, understanding the importance of chiller units becomes paramount. These units, specifically designed to cool fluids in various applications, play a crucial role in maintaining optimal temperatures for processes and equipment. As industries evolve, so does the technology behind water cooler units, making it essential to stay updated on innovations like those offered by RIGID.

Understanding the Importance of Chiller Units

Chiller units are indispensable in many sectors, from manufacturing to food processing. They regulate temperatures effectively, ensuring that machinery operates smoothly and that products remain at safe temperatures during storage or transport. Without reliable industrial water chillers, businesses would face significant risks of equipment failure and product spoilage.

The Role of Water Coolers in Industry

Water coolers are not just your average office appliances; they serve as vital components in industrial settings as well. By providing efficient cooling solutions for various processes, these systems help maintain productivity while minimizing energy consumption. When it comes to cooling options, many wonder: Are water coolers better than AC? The answer often depends on specific needs and applications; however, water-cooled chillers generally offer superior efficiency for large-scale operations.

Exploring the RIGID Advantage

Their micro and miniaturized designs make them perfect for various applications without compromising performance or energy efficiency. By incorporating advanced technology into their water-cooled chillers, RIGID provides solutions that not only enhance operational effectiveness but also contribute positively to environmental sustainability.

What is a Commercial Chiller Unit

Essentially, a commercial chiller unit is an essential piece of equipment used to remove heat from liquids via vaporization and condensation processes. These units are crucial for maintaining optimal temperatures in various applications, ranging from food processing to chemical manufacturing.

Definition and Function

A commercial chiller unit serves the primary function of regulating temperature by circulating chilled water or other fluids through systems that require cooling. This process not only enhances efficiency but also ensures that machinery operates within safe temperature limits, thereby prolonging equipment life. So, what is a water cooling unit? It’s essentially the backbone of many industrial operations, providing consistent and reliable cooling.

Water coolers have become increasingly popular in various industries due to their ability to maintain specific temperature requirements efficiently. Unlike traditional air conditioning systems that cool air directly, industrial water chillers focus on cooling fluids, which can then be used for multiple applications such as HVAC systems or process cooling. This distinction leads many to ponder: Are water coolers better than AC? The answer often lies in the specific needs of the facility and the efficiency required.

Types of Commercial Chiller Units

Commercial chiller units come in several types tailored for different applications and operational needs. The most common types include air-cooled chillers, water-cooled chillers, and absorption chillers—each with its unique advantages and ideal uses. Water-cooled chillers are particularly favored in larger installations because they utilize water from an external source for heat exchange, making them highly efficient for extensive cooling needs.

Air-cooled chillers are another popular choice; they draw ambient air over condenser coils to dissipate heat but may not be as efficient as their water-cooled counterparts in larger setups. Additionally, absorption chillers use heat sources like natural gas or steam instead of electricity—an excellent option where energy costs vary significantly or where waste heat recovery is feasible. Each type has its place depending on factors like available space and desired efficiency levels.

Working Mechanism

The working mechanism of a commercial chiller unit involves a refrigeration cycle that consists of four main processes: evaporation, compression, condensation, and expansion. Initially, refrigerant absorbs heat during evaporation inside the evaporator coil; this liquid refrigerant then turns into gas as it absorbs heat from the chilled fluid circulating through the system. Next up is compression: this gaseous refrigerant enters the compressor where it's pressurized before moving into the condenser.

In the condenser stage, this high-pressure gas releases its absorbed heat into a secondary medium (usually water), transforming back into liquid form through condensation—a perfect example of thermodynamics at work! Finally, this liquid refrigerant flows back into an expansion valve where its pressure drops before re-entering the evaporator coil to repeat the cycle again seamlessly. Understanding these mechanics helps users appreciate why investing in high-quality industrial water chillers can lead to significant long-term benefits.

Benefits of Industrial Water Chillers

Industrial water chillers are the unsung heroes of temperature control, providing an array of benefits that go beyond mere cooling. They play a pivotal role in enhancing efficiency and performance across various applications, ensuring that operations run smoothly and effectively. By understanding the advantages of these systems, businesses can make informed decisions regarding their cooling needs.

Enhanced Efficiency and Performance

When it comes to optimizing operational efficiency, a water cooler unit is hard to beat. These units are designed to provide consistent temperature control, which is crucial in processes like manufacturing and food production where precision matters. With robust performance metrics, industrial water chillers ensure that equipment runs at peak efficiency while minimizing energy consumption.

Moreover, the advanced technology behind water-cooled chillers allows for rapid cooling response times, making them ideal for environments with fluctuating thermal loads. This responsiveness not only enhances overall productivity but also helps maintain product quality by preventing overheating or temperature spikes. In essence, investing in a reliable water cooler unit translates directly into improved operational performance.

Long-Term Cost Savings

One of the most appealing aspects of industrial water chillers is their potential for long-term cost savings. While the initial investment may seem daunting compared to traditional air conditioning systems, the energy efficiency and reduced operational costs quickly offset this expense. Water-cooled chillers often consume significantly less electricity than conventional AC units, leading to lower utility bills over time.

Additionally, these systems require less maintenance due to their durable construction and efficient design—meaning fewer repair costs and downtime for businesses relying on consistent cooling solutions. When you weigh these long-term savings against initial costs, it's clear that choosing a high-quality water cooler unit can be a financially savvy decision for any industrial operation.

Environmental Sustainability

In today’s eco-conscious world, environmental sustainability is more important than ever—and industrial water chillers rise to meet this challenge head-on. Unlike traditional air conditioning systems that rely heavily on refrigerants with high global warming potential (GWP), many modern water-cooled chillers utilize environmentally friendly refrigerants or operate with minimal emissions altogether. This shift not only reduces your carbon footprint but also aligns your business with global sustainability goals.

Furthermore, because they use less energy than standard AC units while providing superior cooling capabilities, these systems contribute positively to reducing overall greenhouse gas emissions from industrial facilities. Embracing an efficient water cooler unit not only makes good business sense but also showcases your commitment to protecting our planet for future generations.

Choosing the Right Water Cooler Unit

Selecting the right water cooler unit is crucial for optimizing your cooling needs, especially in an industrial setting. With various options available, understanding what to look for can make a significant difference in performance and efficiency. In this section, we’ll explore key features, how to assess cooling capacity, and considerations regarding space and installation.

Key Features to Look For

When evaluating a water cooler unit, it’s essential to prioritize certain features that can enhance its functionality. Look for units equipped with advanced temperature control systems that allow precise adjustments; this ensures optimal cooling performance tailored to your specific needs. Additionally, energy efficiency ratings should be considered—units with higher ratings not only save on electricity bills but also contribute to environmental sustainability.

Another feature worth noting is the ease of maintenance; a water cooler unit designed for simple access allows for routine checks without hassle. Furthermore, consider models that offer noise reduction technology; quieter units are particularly beneficial in settings where a peaceful environment is paramount. Lastly, pay attention to warranty options and customer support services offered by manufacturers—these can provide peace of mind as you invest in your industrial water chillers.

Assessing Cooling Capacity

Understanding cooling capacity is vital when selecting a suitable water cooler unit for your facility. The cooling capacity is typically measured in tons or BTUs (British Thermal Units), indicating how effectively the unit can remove heat from a given space over time. To determine the appropriate capacity needed, consider factors such as the size of the area being cooled and any heat-generating equipment present.

You might wonder: What is a water cooling unit? Essentially, it refers to systems designed specifically for cooling purposes using chilled water circulated through coils or other mechanisms. For larger industrial applications, you may need multiple units working together or more powerful models like water-cooled chillers that efficiently handle substantial loads without breaking a sweat.

It’s also important to factor in seasonal variations; some areas experience extreme temperatures that require higher capacities during peak seasons. Therefore, consulting with professionals who understand these dynamics can help ensure you choose an industrial water chiller capable of meeting both current and future demands seamlessly.

Considering Space and Installation Needs

Before committing to any specific model of a water cooler unit, evaluate your available space carefully—this step often gets overlooked but is critical for optimal operation! Measure not just the floor space but also ceiling height if you're considering larger systems like commercial chillers which might need additional clearance for ventilation or maintenance access.

Moreover, installation requirements vary between different types of units; some may necessitate additional plumbing or electrical work while others could be more straightforward plug-and-play designs. Understanding these nuances will help avoid unexpected costs down the line when integrating new equipment into existing setups.

Finally, think about long-term flexibility: If you anticipate growth or changes in operational needs over time (and let’s face it—who doesn’t?), opting for modular designs could be advantageous as they allow easy scalability without major renovations later on.

Spotlight on RIGID Compressors

Innovative Micro & Miniaturized Designs

RIGID's approach to compressor design emphasizes compactness without sacrificing performance, making them ideal for various applications in industrial settings. These micro and miniaturized designs allow for easier integration into existing systems while ensuring maximum cooling capacity is maintained. As businesses seek solutions that save space and enhance efficiency, these innovations position RIGID as a leader in the water cooler unit market.

Reliability and Noise Reduction

One of the standout features of RIGID compressors is their reliability; they are built to withstand rigorous industrial environments while maintaining optimal performance over time. Additionally, these compressors are designed with noise reduction technology that minimizes operational sounds, creating a more pleasant working environment compared to traditional systems. This focus on quiet operation raises an essential question: Are water coolers better than AC? With RIGID’s advancements, many industries find that water-cooled chillers offer superior reliability and quieter operation than conventional air conditioning units.

Energy Efficiency Benefits

Energy efficiency is at the forefront of modern industrial practices, and RIGID compressors deliver impressive savings on energy consumption for water-cooled chillers. By utilizing advanced engineering techniques, these compressors ensure that every kilowatt hour is maximized for cooling output rather than wasted as heat or noise. As businesses increasingly prioritize environmental sustainability alongside cost savings, investing in efficient water cooler units like those from RIGID becomes an attractive option.

Maintenance Tips for Longevity

Maintaining your water cooler unit is crucial for its longevity and optimal performance. Regular upkeep not only extends the life of your Industrial Water Chillers but also ensures that they operate efficiently, ultimately saving you money in the long run. Here are some essential maintenance tips to keep your water cooling unit in top shape.

Routine Checks and Balancing

Routine checks are the backbone of any effective maintenance plan for a water cooler unit. Start with inspecting the coolant levels, as low levels can compromise cooling efficiency and lead to potential overheating issues. Additionally, regularly clean or replace filters to avoid dust buildup, which can hinder airflow and reduce performance.

Balancing the system is equally important; ensure that all components are functioning harmoniously together. This includes checking for any unusual noises or vibrations that might indicate an imbalance or malfunction within your Industrial Water Chillers. By performing these routine checks, you'll not only enhance the lifespan of your water cooling unit but also improve its overall efficiency.

Common Issues and Solutions

Even with diligent care, you may encounter common issues with your water cooler unit over time. One frequent problem is inconsistent cooling; if you notice fluctuations in temperature, it might be due to a refrigerant leak or a faulty thermostat. Addressing these issues promptly can prevent further damage and costly repairs.

Another common concern is excessive noise coming from your Industrial Water Chillers; this could signal loose components or worn-out parts. Tightening screws or replacing damaged parts can often resolve this issue without needing professional help. However, if problems persist despite troubleshooting efforts, it’s best to consult an expert who understands what a water cooling unit requires.

Importance of Professional Servicing

While routine maintenance is essential, nothing beats the expertise of professional servicing when it comes to ensuring the longevity of your water cooler unit. Trained technicians possess specialized knowledge about various models of Industrial Water Chillers and can spot potential problems before they escalate into major repairs. They also have access to advanced tools that allow for thorough inspections and effective solutions.

Moreover, professional servicing typically includes comprehensive cleaning processes that go beyond what regular maintenance entails—think deep-cleaning coils and inspecting electrical connections! This level of care helps maintain energy efficiency levels that keep operating costs down while extending equipment life significantly. So remember: investing in professional servicing isn’t just smart—it’s necessary for keeping your water cooling unit running like new.

Conclusion

In wrapping up our exploration of commercial chiller units, it’s essential to highlight the myriad benefits they offer. These units are not just about keeping things cool; they enhance efficiency, provide long-term cost savings, and contribute to environmental sustainability. Whether you're considering a water cooler unit for industrial applications or simply curious about what is a water cooling unit?, understanding these advantages can make all the difference in your decision-making process.

Recap of Commercial Chiller Unit Benefits

To recap, commercial chiller units serve as vital components in various industries, ensuring optimal temperature control for processes and equipment. They significantly improve operational efficiency while reducing energy costs over time. Plus, with their ability to minimize environmental impact, investing in industrial water chillers is a smart move for businesses aiming for sustainability.

The Future of Water Cooling Technology

Looking ahead, the future of water cooling technology appears promising and innovative. With advancements in design and efficiency—particularly in water-cooled chillers—we can expect even better performance from these systems. As industries evolve and demand increases for eco-friendly solutions, the evolution of water cooler units will likely lead the way toward smarter cooling technologies that prioritize both performance and sustainability.

Making an Informed Decision

Consider factors like capacity requirements and installation space when evaluating your options among various water cooler units available on the market today. Ultimately, whether you’re pondering if are water coolers better than AC? or simply seeking reliable industrial solutions, understanding your specific needs will guide you toward the perfect choice.