Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

In the realm of advanced technologies, compact cryo cooling systems have emerged as essential components across various industries. These systems not only enhance performance but also enable groundbreaking applications in fields such as superconductivity and quantum computing. As the demand for efficient and reliable cryogenic cooling technologies continues to rise, understanding their significance becomes increasingly vital.

The Importance of Compact Cryo Cooling Systems

Compact cryo cooling systems play a crucial role in ensuring optimal performance for sensitive electronic components and superconducting materials. Their ability to maintain ultra-low temperatures is indispensable for applications that require precision and stability, such as MRI machines, particle accelerators, and space exploration equipment. As industries strive for miniaturization without compromising efficiency, these systems become indispensable allies in pushing technological boundaries.

Advancements in Cryogenic Cooling Technologies

Recent advancements in cryogenic cooling technologies have transformed how we approach temperature management at low levels. Innovations such as miniature compressors and improved thermal insulation techniques have made it possible to design more efficient and compact cryo cooling systems than ever before. These developments not only enhance system performance but also reduce energy consumption, paving the way for more sustainable solutions in various applications.

Overview of RIGID’s Innovations

RIGID is at the forefront of these innovations, continually pushing the envelope with its cutting-edge cryo cooling solutions. By focusing on compact designs that don’t sacrifice power or efficiency, RIGID has established itself as a leader in the field of cryogenic cooling technologies. Their commitment to quality and innovation ensures that clients receive tailored solutions that meet specific needs while maximizing performance across diverse applications.

Understanding Cryo Cooling Principles

To grasp the intricacies of cryo cooling, one must first delve into the scientific principles that govern this fascinating technology. Cryogenic cooling operates primarily on the principles of thermodynamics, where gases are cooled to extremely low temperatures, resulting in a significant reduction in thermal energy. This process is crucial for achieving the ultra-cold environments necessary for various applications, particularly in superconducting materials that exhibit remarkable electrical properties at low temperatures.

The Science Behind Cryogenic Cooling

At its core, cryogenic cooling involves manipulating gas behavior under extreme conditions to achieve desired temperature reductions. When gases are compressed and subsequently allowed to expand rapidly, they absorb heat from their surroundings—a principle known as adiabatic expansion. This phenomenon is central to cryo cooling systems, which utilize specialized refrigerants to efficiently transfer heat away from critical components and maintain optimal operating temperatures.

The science behind cryogenic cooling also encompasses phase changes of substances like helium and nitrogen, which play pivotal roles in creating and sustaining cryogenic environments. These elements can exist as both liquids and gases at low temperatures, allowing for versatile applications across different industries. Understanding these scientific principles not only enhances our knowledge of cryogenic technologies but also informs the development of more efficient cryo cooling systems.

Key Components of Cryo Cooling Systems

Cryo cooling systems are composed of several key components that work harmoniously to achieve effective temperature control. At the heart of any cryogenic system is the compressor, which compresses refrigerants and initiates the cooling cycle by increasing pressure and temperature before expansion occurs. Additionally, heat exchangers play a crucial role by facilitating heat transfer between different mediums within the system.

Another vital component is the expansion valve or device that regulates refrigerant flow into evaporators where it expands rapidly—this rapid expansion leads to lower temperatures essential for maintaining superconducting conditions. Furthermore, insulation materials are employed throughout these systems to minimize thermal losses and enhance overall efficiency during operation. Each component contributes significantly to optimizing performance in various applications reliant on advanced Cryogenic Cooling Technologies.

Applications in Superconducting Elements

The applications of cryo cooling technologies extend far beyond basic refrigeration; they hold transformative potential in fields such as electronics and medical imaging due to their effectiveness with superconducting elements. Superconductors require specific low-temperature conditions to exhibit zero electrical resistance—a phenomenon that can be achieved using advanced cryo cooling systems designed precisely for this purpose. For instance, magnetic resonance imaging (MRI) machines utilize superconducting magnets cooled by liquid helium or nitrogen within specialized cryogenic setups.

Moreover, particle accelerators leverage these technologies extensively; they rely on highly efficient coolers capable of maintaining superconducting magnets at ultra-low temperatures while minimizing energy consumption during operation. The continued advancement in compact designs ensures that even smaller devices can benefit from these powerful capabilities without compromising performance or efficiency—demonstrating how integral cryo cooling has become across diverse scientific disciplines.

RIGID’s Role in Miniature Cooling Solutions

When it comes to miniature cooling solutions, RIGID has carved out a unique niche with its innovative cryo cooling technologies. The company focuses on developing compact, efficient cryo cooling systems that cater to a variety of applications, particularly in the realm of superconducting elements. By leveraging cutting-edge engineering and design principles, RIGID is reshaping the landscape of cryogenic cooling.

Overview of RIGID’s Technologies

RIGID's technologies are at the forefront of advancements in cryogenic cooling systems. Their designs incorporate state-of-the-art components that optimize performance while minimizing size and energy consumption. This commitment to innovation allows RIGID to deliver cooling solutions that are not only effective but also tailored to meet specific client needs across various industries.

Advantages of RIGID’s Cryo Cooling Systems

One of the standout advantages of RIGID’s cryo cooling systems is their remarkable efficiency. These compact systems utilize advanced thermodynamic principles, allowing them to achieve lower temperatures faster than traditional models without compromising reliability. Additionally, their lightweight design makes them ideal for integration into tight spaces where conventional systems would struggle.

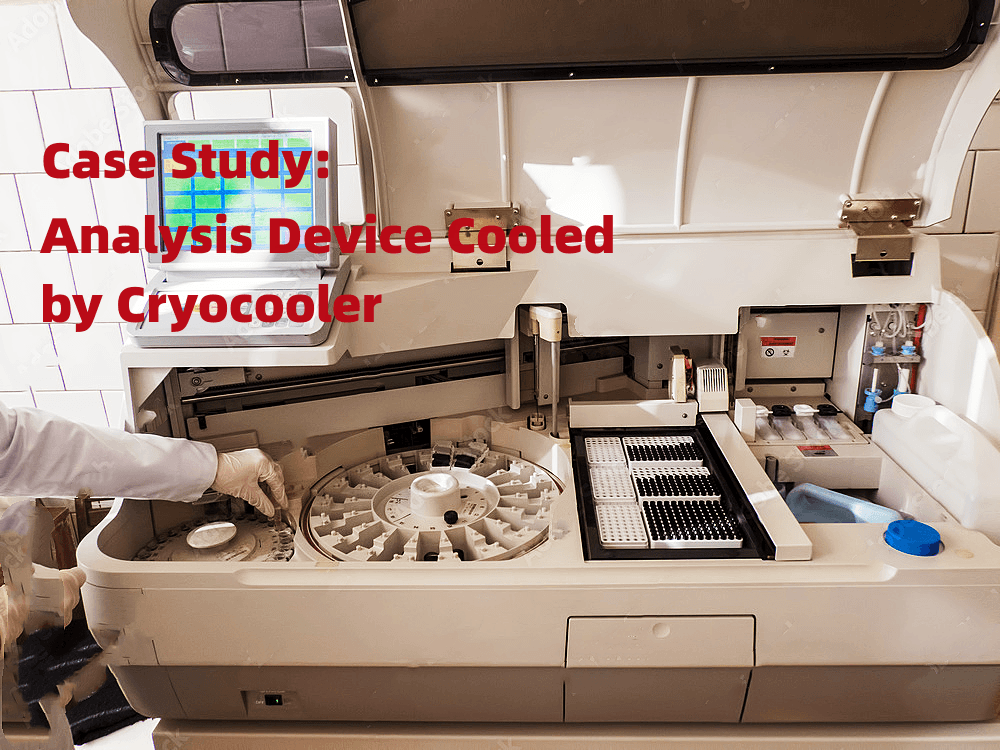

Case Studies Showcasing RIGID’s Impact

RIGID's impact can be seen through various case studies that highlight its successful implementation of cryo cooling solutions across different sectors. For instance, in a project involving superconducting magnets for particle accelerators, RIGID's miniature cryogenic cooling technology significantly improved operational efficiency and reduced downtime during maintenance periods. Another case involved medical imaging equipment where RIGID's compact designs led to enhanced image clarity while saving valuable space in diagnostic facilities.

Comparing Traditional vs. Compact Systems

In the ever-evolving realm of cryogenic cooling technologies, understanding the differences between traditional and compact cryo cooling systems is crucial for making informed decisions. As industries push for smaller, more efficient solutions, compact systems have emerged as game-changers in the field. This section will delve into the efficiency, cost-effectiveness, and performance metrics that set these two approaches apart.

Efficiency of Compact Cryo Cooling Systems

Compact cryo cooling systems are designed with efficiency in mind, leveraging advanced engineering to maximize performance while minimizing size. Unlike traditional systems that often require extensive space and resources, compact designs utilize innovative technologies to achieve superior thermal management with less energy consumption. This efficiency not only translates into lower operational costs but also enhances the overall functionality of superconducting elements that rely on precise temperature control.

Moreover, the integration of miniaturized components in these cryogenic cooling technologies allows for rapid response times and improved temperature stability. By reducing thermal inertia, compact systems can quickly adapt to fluctuating demands without compromising on performance. This agility is particularly beneficial in applications where maintaining optimal temperatures is critical for functionality and longevity.

Cost-Effectiveness of Mini Compressor Designs

When it comes to cost-effectiveness, mini compressor designs shine brightly against their traditional counterparts. The smaller footprint of compact cryo cooling systems means reduced material costs and easier installation processes—factors that significantly lower initial investment requirements for businesses seeking efficient cooling solutions. Additionally, ongoing maintenance expenses are generally minimized due to fewer moving parts and simplified designs.

The economic benefits extend beyond just upfront costs; enhanced energy efficiency leads to substantial savings over time as well. Businesses utilizing these advanced cryogenic cooling technologies can expect lower utility bills while enjoying reliable operation without frequent breakdowns or repairs associated with larger traditional systems. Thus, companies can allocate their resources more effectively while still achieving optimal thermal performance.

Performance Metrics for Superconducting Elements

Performance metrics play a pivotal role in evaluating the effectiveness of any cryo cooling system—compact or traditional—and this is especially true when it comes to superconducting elements that demand precision in temperature control. Compact cryo cooling solutions often outperform conventional models by delivering consistent low temperatures necessary for superconductivity without excessive power draw or heat generation.

Key metrics such as temperature uniformity, response time under load changes, and overall reliability are essential benchmarks when comparing these two types of systems. Compact designs frequently achieve tighter temperature tolerances and faster stabilization times due to their innovative engineering approaches within a smaller package—a distinct advantage when precision matters most in scientific research or high-tech applications involving superconductors.

In summary, while both traditional and compact cryogenic cooling technologies have their merits, it's clear that compact systems offer significant advantages in efficiency, cost-effectiveness, and performance metrics tailored for superconducting elements.

Future Trends in Cryogenic Cooling Technologies

The landscape of cryogenic cooling is evolving rapidly, driven by advancements in technology and an increasing demand for efficiency and customization. As industries explore the potential of superconducting materials and other applications, the focus is shifting towards innovative cryo cooling solutions that can meet diverse needs. This section delves into the future trends shaping cryogenic cooling technologies, highlighting innovations, customization options, and sustainability efforts.

Innovations to Watch in Cryo Cooling

The next wave of innovations in cryo cooling systems promises to revolutionize how we approach temperature management in various applications. Emerging technologies such as magnetic refrigeration and advanced thermoelectric devices are gaining traction due to their potential for higher efficiency and lower energy consumption compared to traditional methods. Furthermore, advancements in materials science are enabling the development of more effective thermal insulators, which could enhance the performance of cryogenic cooling systems across multiple sectors.

In addition to these technological breakthroughs, digital integration is becoming a game-changer in monitoring and controlling cryo cooling systems. With real-time data analytics and IoT capabilities, operators can optimize performance while minimizing energy usage and maintenance costs. As these innovations continue to unfold, they will pave the way for smarter, more efficient cryogenic cooling solutions tailored for specific applications.

The Rise of Customizable Cooling Solutions

As industries increasingly seek tailored solutions for their unique challenges, customizable cryo cooling systems are emerging as a key trend. Manufacturers like RIGID are leading the charge by offering modular designs that can be adapted based on specific requirements—whether it’s size constraints or thermal performance needs. This flexibility allows clients to integrate compact cryo cooling solutions seamlessly into existing setups without compromising on efficiency or effectiveness.

Moreover, customization goes beyond just physical design; it encompasses software integration as well. Advanced control systems enable users to fine-tune their cryogenic cooling operations according to real-time conditions or operational demands. This level of adaptability not only enhances system performance but also significantly reduces downtime—a crucial factor in high-stakes environments like research laboratories or medical facilities.

Sustainability and Environmental Considerations

In today's eco-conscious world, sustainability has become a paramount consideration for all sectors—including those utilizing cryogenic cooling technologies. The industry is witnessing a shift towards refrigerants with lower global warming potential (GWP) as well as energy-efficient designs that minimize carbon footprints while maintaining optimal performance levels in cryo cooling systems. These changes align with global efforts aimed at reducing environmental impact across various industries.

Furthermore, companies are increasingly adopting circular economy principles by designing products that are easier to recycle or repurpose at their end-of-life stage. By focusing on sustainable practices throughout the lifecycle of their products—from production through disposal—manufacturers contribute positively to environmental stewardship while meeting regulatory requirements related to climate change mitigation. In this way, future developments in cryogenic cooling technologies will not only enhance operational efficiencies but also support broader sustainability goals.

Client-Centric Approaches by RIGID

In a world where one-size-fits-all solutions often miss the mark, RIGID stands out with its client-centric approach to cryo cooling systems. Understanding that each application has unique requirements, RIGID excels in delivering customized cryogenic cooling technologies tailored to diverse industries. By prioritizing collaboration and innovation, RIGID ensures that every client receives a solution that maximizes performance and efficiency.

Custom Solutions for Diverse Applications

RIGID recognizes that the landscape of cryo cooling is as varied as its applications—from medical devices to aerospace technologies. This understanding drives the development of custom solutions designed specifically for each client's needs, ensuring optimal performance in even the most demanding environments. Whether it’s a compact cryo cooling system for a portable device or an intricate setup for large-scale research facilities, RIGID’s expertise guarantees precision-engineered solutions.

The flexibility inherent in RIGID's design process allows them to address challenges unique to various sectors effectively. By leveraging advanced materials and innovative engineering techniques, they create cryogenic cooling technologies that not only meet but exceed industry standards. This commitment to customization empowers clients with systems that enhance their operational capabilities while remaining cost-effective.

Partnering with Clients for Optimal Results

At RIGID, collaboration is key; they believe that partnering closely with clients leads to superior outcomes in cryo cooling systems. Engaging clients from initial concept discussions through implementation ensures alignment on goals and expectations, paving the way for successful project execution. This hands-on approach fosters trust and transparency, allowing both parties to navigate challenges together efficiently.

By involving clients throughout the development lifecycle, RIGID can quickly adapt designs based on real-time feedback and evolving requirements. This responsiveness not only enhances product quality but also accelerates time-to-market for critical applications like superconducting elements used in cutting-edge research and technology deployments. Ultimately, this partnership model cultivates long-term relationships built on shared success.

Success Stories: Meeting Specific Requirements

RIGID's portfolio brims with success stories showcasing how tailored cryogenic cooling technologies have transformed client operations across various sectors. One notable example involved developing a specialized mini compressor design for an aerospace client facing stringent weight restrictions without sacrificing performance efficiency in their cryo cooling system. The result? A lightweight solution that seamlessly integrated into their existing framework while significantly enhancing operational capacity.

Another instance highlights how RIGID collaborated with a medical equipment manufacturer needing precise temperature control for sensitive diagnostic tools using advanced superconducting elements—essentially revolutionizing their product line's reliability and accuracy through bespoke designs tailored specifically for their needs. These case studies exemplify how understanding specific requirements leads to innovative solutions that drive industry advancements.

RIGID’s commitment to meeting specific client demands showcases its role as more than just a supplier; they are strategic partners invested in collective success through cutting-edge cryogenic cooling technologies.

Conclusion

In the rapidly evolving realm of superconducting technology, the future looks bright and promising. As we continue to push the boundaries of what’s possible, advancements in cryo cooling systems will play an essential role in enhancing performance and efficiency. The integration of innovative Cryogenic Cooling Technologies is set to redefine industries, paving the way for breakthroughs that were once thought impossible.

The Future of Superconducting Technology

The future of superconducting technology hinges on our ability to harness advanced cryo cooling solutions effectively. As researchers dive deeper into quantum computing and high-energy physics, the demand for efficient and compact cryo cooling systems will only increase. These technologies are not just a trend; they are becoming a necessity for achieving unprecedented levels of performance in various applications.

How Compact Cryo Cooling Systems Enhance Performance

Compact cryo cooling systems are revolutionizing how we approach performance enhancement in superconducting elements. By providing efficient thermal management, these systems ensure optimal operational conditions, which can significantly improve device reliability and longevity. Furthermore, their space-saving designs allow for greater flexibility in application, making them indispensable across multiple sectors from medical imaging to aerospace.

RIGID’s Commitment to Innovation and Quality

At RIGID, innovation isn’t just a buzzword; it’s a core value that drives our commitment to excellence in cryogenic technologies. Our continuous investment in research and development ensures that we stay at the forefront of cryo cooling advancements while maintaining quality standards that our clients can rely on. With each new solution tailored to meet specific needs, RIGID exemplifies what it means to be a leader in compact cryo cooling systems.

[Image description=modern laboratory with advanced cryogenic equipment, engineers working on compact cooling systems, vibrant colors highlighting technology], Image name=cryogenic_laboratory_innovation, Alt tag=Innovative cryo cooling system enhancing superconducting technology performance