Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

In the world of temperature control, a recirculating water chiller plays a pivotal role in ensuring that various processes maintain optimal thermal conditions. This laboratory equipment is designed to circulate chilled water, providing precise temperature regulation essential for experiments, manufacturing processes, and medical applications. Whether you're operating a small water chiller or an industrial water chiller, understanding how these systems work can significantly enhance efficiency and effectiveness.

What is a Recirculating Water Chiller

A recirculating water chiller is an advanced cooling system that removes heat from one or more sources and transfers it to the environment through a cycle of evaporation and condensation. This type of chilling solution continuously circulates coolant, ensuring that temperatures remain stable across different applications. With its ability to provide consistent cooling, the laboratory recirculating chiller has become indispensable in research labs and industrial settings alike.

Importance of Precision Temperature Control

Precision temperature control is critical in many fields, from scientific research to manufacturing processes. Fluctuations in temperature can lead to inconsistent results or compromised product quality; hence, using a reliable recirculating chiller can mitigate these risks effectively. By maintaining exact temperatures within specified ranges, these chillers help ensure the integrity of sensitive experiments and production lines.

Applications Across Various Industries

Recirculating chillers find their applications across diverse industries due to their versatility and reliability. In scientific laboratories, they are used for cooling equipment like lasers and reactors; in industrial settings, they facilitate processes such as injection molding or chemical processing; while in medical technology, they assist with maintaining optimal conditions for diagnostic equipment or bioreactors. The adaptability of both small water chillers and larger industrial models makes them essential tools across these sectors.

Understanding Recirculating Water Chillers

Recirculating water chillers are essential pieces of laboratory equipment that provide precise temperature control for various applications. They work by circulating chilled water through a system, maintaining a stable temperature for processes that require it. Understanding how these units function and their key components can help users select the right recirculating chiller for their specific needs.

Definition and Functionality

A recirculating water chiller is a closed-loop cooling system designed to remove heat from equipment or processes while maintaining a desired temperature range. These chillers utilize a refrigeration cycle to cool water, which is then circulated through the connected equipment. Their functionality is crucial in environments where consistent temperatures are necessary, such as in laboratories, industrial settings, and medical technology.

By using a recirculating chiller, facilities can achieve enhanced process control and reliability in their operations. This technology not only ensures optimal performance but also minimizes the risk of overheating sensitive laboratory equipment or industrial machinery. In essence, these chillers serve as the unsung heroes of temperature regulation.

Key Components Explained

Understanding the key components of a recirculating water chiller can provide insights into its operation and maintenance requirements. The primary elements include the compressor, condenser, evaporator, expansion valve, and reservoir tank. Each component plays a vital role in ensuring that the chilling process runs smoothly and efficiently.

The compressor is responsible for compressing refrigerant gas to raise its pressure and temperature before it enters the condenser. The condenser then dissipates heat from this gas into the environment while converting it back into liquid form. The evaporator absorbs heat from the circulating water before returning it to the reservoir tank for continuous cooling—making this cycle critical for any laboratory recirculating chiller's effectiveness.

Differences Between Models

Industrial water chillers typically have larger capacities compared to small water chillers designed for more compact setups like laboratories or smaller production lines. Additionally, some models may offer advanced features such as digital controls or energy-saving modes.

The differences also extend to cooling capacities—larger systems may be necessary for high-demand industrial applications while smaller units might suffice in research labs where space is limited yet precision is paramount. Furthermore, customization options allow users to tailor features according to their unique requirements; thus making it essential to evaluate each model based on intended use cases.

Benefits of Using Recirculating Chillers

Recirculating chillers are becoming increasingly popular in both laboratory and industrial settings due to their numerous advantages. These systems not only provide precise temperature control but also enhance overall operational efficiency. Let's explore some key benefits of using a recirculating water chiller, particularly focusing on energy efficiency, process control, and reliability.

Energy Efficiency Insights

One of the standout features of a recirculating water chiller is its energy efficiency. These systems are designed to minimize energy consumption while maintaining optimal cooling performance, making them an eco-friendly choice for laboratory equipment and industrial applications alike. By efficiently managing heat loads, a laboratory recirculating chiller can significantly reduce operational costs over time.

Moreover, advancements in technology have led to the development of mini compressors that further enhance the energy-saving capabilities of small water chillers. This means that even compact models can deliver impressive cooling power without guzzling electricity. As industries strive for sustainability, choosing an energy-efficient industrial water chiller becomes not just a smart choice but a necessary one.

Enhanced Process Control

Precision is paramount in many processes within scientific research and industrial operations; this is where enhanced process control offered by recirculating chillers comes into play. By providing stable and consistent temperatures, these chillers ensure that experiments and manufacturing processes remain unaffected by temperature fluctuations. This level of control translates into better quality results and increased productivity across various applications.

In addition to stability, modern laboratory recirculating chillers often come equipped with advanced monitoring systems that allow users to track performance metrics in real-time. This capability enables quick adjustments based on specific needs or unexpected changes in conditions, ensuring that your processes run smoothly without interruptions. Ultimately, enhanced process control empowers users to achieve their goals efficiently while maintaining high standards.

Reliability in Laboratory Equipment

Reliability is another critical benefit of using recirculating chillers in laboratory settings or industrial environments where precision matters most. A well-designed recirculating water chiller can operate continuously under demanding conditions without compromising performance or safety standards. This reliability ensures that your valuable experiments or production lines remain uninterrupted—no one wants to deal with unexpected equipment failures!

Furthermore, many manufacturers focus on building robust systems with long lifespans and minimal maintenance requirements for their small water chillers and larger models alike. Investing in reliable laboratory equipment like a quality recirculating chiller means fewer headaches down the road when it comes to repairs or replacements—allowing you to concentrate on what truly matters: your work!

Applications of Recirculating Chillers

Recirculating chillers are versatile tools that find their way into various sectors, demonstrating their importance in maintaining precise temperatures. From scientific research to industrial applications and medical technology, these devices play a crucial role in ensuring optimal performance and reliability. Let’s dive into the specific applications of recirculating water chillers across different fields.

Role in Scientific Research

In the realm of scientific research, precision is paramount, and laboratory equipment often relies on stable temperature conditions to yield accurate results. Laboratory recirculating chillers provide consistent cooling for sensitive experiments, ensuring that reactions occur under controlled conditions. Whether it's maintaining the temperature of samples or cooling down equipment during lengthy procedures, a reliable recirculating chiller is an indispensable asset for researchers.

Moreover, many laboratories utilize small water chillers for tasks that require less cooling capacity but still demand accuracy. These compact units can easily fit into tight spaces without compromising performance, allowing scientists to focus on their work rather than worrying about temperature fluctuations. With advancements in technology, modern laboratory recirculating chillers offer enhanced features such as digital controls and remote monitoring to further streamline research processes.

Use in Industrial Settings

Industrial settings also benefit significantly from the implementation of industrial water chillers designed to handle larger-scale operations. These powerful machines are essential for cooling machinery during manufacturing processes where excessive heat can lead to equipment failure or product defects. By integrating a recirculating water chiller into production lines, industries can maintain optimal temperatures and improve overall efficiency.

Furthermore, companies involved in chemical processing often rely on these systems to regulate temperature-sensitive reactions that could otherwise result in hazardous situations if left unchecked. The ability of industrial water chillers to provide continuous cooling ensures safety while maximizing productivity across various manufacturing environments. As industries evolve towards more sustainable practices, energy-efficient models are becoming increasingly popular among manufacturers looking to reduce operational costs.

Contribution to Medical Technology

In the field of medical technology, precision cannot be compromised; hence the use of laboratory recirculating chillers is vital for numerous applications ranging from diagnostics to therapeutic treatments. For instance, these systems help maintain the integrity of biological samples by providing stable temperatures during storage and transport—an essential factor for accurate test results and patient safety.

Additionally, small water chillers are often employed in medical devices such as lasers or imaging machines where overheating could affect performance or patient outcomes. The integration of efficient recirculating water chillers not only enhances device reliability but also contributes significantly to advancements in healthcare technologies by ensuring optimal operating conditions at all times. As medical technology continues evolving towards more sophisticated solutions, the role of chilling systems remains critical for innovation and effectiveness.

RIGID’s Innovation in Chilling Solutions

When it comes to cutting-edge temperature control, RIGID stands out with its innovative approach to recirculating water chillers. Their technology not only meets the demands of various industries but also elevates the performance of laboratory equipment. By focusing on efficiency and reliability, RIGID has carved a niche for itself in the competitive landscape of industrial water chillers.

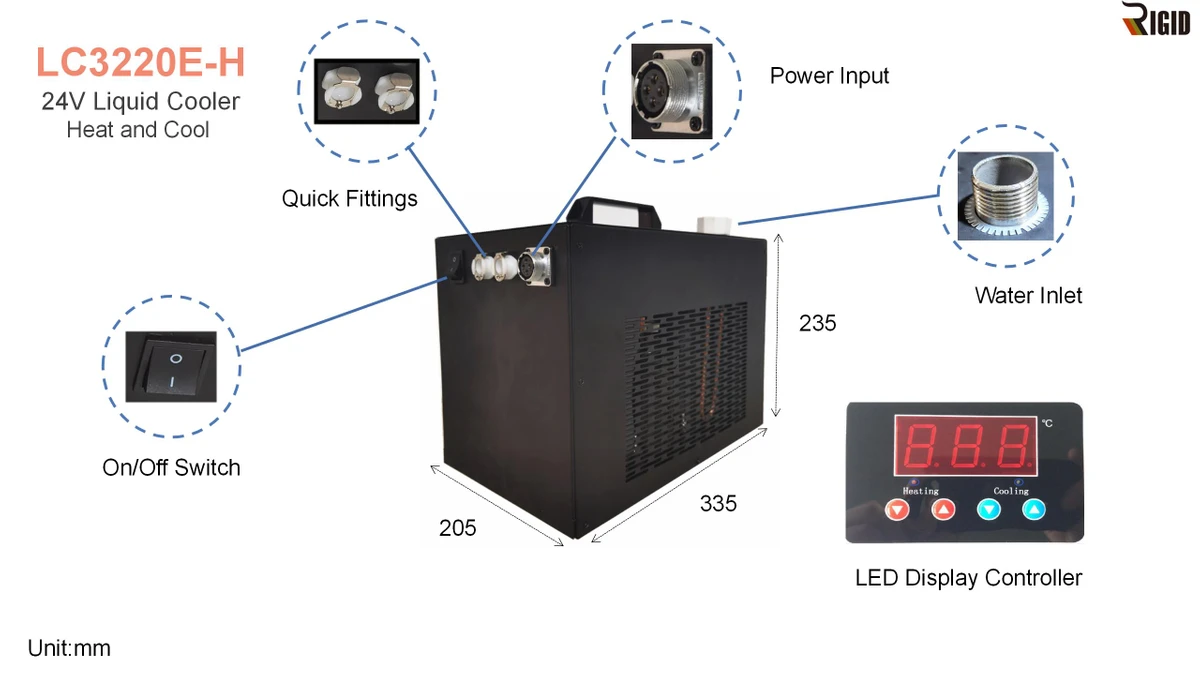

Overview of RIGID’s Technology

RIGID's technology integrates advanced cooling mechanisms that enhance the functionality of recirculating chillers. Their systems are designed with precision engineering, ensuring optimal temperature stability for sensitive applications in laboratories and industrial settings alike. With features like real-time monitoring and automated controls, RIGID’s laboratory recirculating chillers offer unmatched performance and ease of use.

The emphasis on energy efficiency is evident in their design, which minimizes power consumption while maximizing cooling output. This innovation not only contributes to cost savings but also supports environmentally sustainable practices across industries. Furthermore, RIGID's commitment to continuous improvement ensures that their products remain at the forefront of chilling solutions.

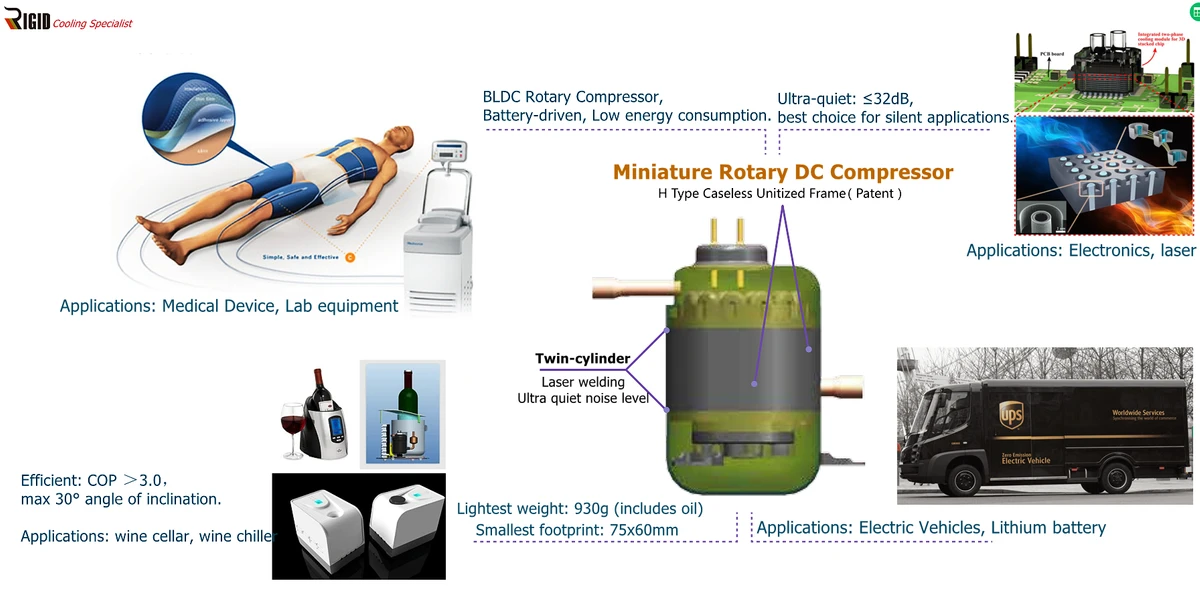

Advantages of Mini Compressors

One standout feature of RIGID’s offerings is their use of mini compressors in their recirculating water chiller models. These compact units deliver impressive cooling capabilities without taking up excessive space—ideal for settings where every inch counts, such as laboratories or small industrial facilities. The mini compressors are designed to operate quietly and efficiently, making them perfect for environments where noise reduction is a priority.

In addition to saving space, these compressors enhance energy efficiency by optimizing power usage during operation. Users can enjoy precise temperature control without worrying about skyrocketing energy bills—a win-win situation! The lightweight design also facilitates easier installation and maintenance compared to traditional larger units.

Client-Centric Customization

RIGID understands that no two applications are alike; hence they offer client-centric customization options for their small water chiller models. This flexibility allows businesses to tailor their chilling solutions according to specific requirements—be it size constraints or unique temperature needs—ensuring optimal performance every time. Customers can choose from various configurations and features that best suit their operational demands.

By engaging directly with clients during the design process, RIGID ensures that each laboratory recirculating chiller is built with precision tailored to individual specifications. This personalized approach fosters long-term relationships and trust between RIGID and its clientele while delivering reliable results consistently across diverse applications. Ultimately, this commitment to customization sets RIGID apart from competitors in the realm of industrial water chillers.

Choosing the Right Chiller for Your Needs

Selecting the perfect recirculating water chiller can feel like navigating a maze, especially with so many options on the market. To ensure you choose the right unit for your specific requirements, it's essential to consider several key factors that will affect performance and efficiency. From temperature ranges to cooling capacities, each aspect plays a crucial role in optimizing your laboratory equipment or industrial setup.

Factors to Consider

When choosing a recirculating chiller, start by assessing your cooling needs—this includes understanding the temperature range required for your applications. Different processes may demand varying levels of precision; some might need a Laboratory Recirculating Chiller that maintains temperatures within fractions of a degree, while others may be more lenient. Additionally, consider the flow rate and volume of fluid you’ll be circulating; these factors directly impact how effectively an Industrial water chiller can manage heat loads.

Another vital consideration is energy efficiency. Look for models that offer high energy ratings to reduce operational costs over time—an important factor if you're using multiple chillers or running them continuously in an industrial setting. Furthermore, think about maintenance requirements; some Small Water Chillers are designed with user-friendly features that simplify upkeep and minimize downtime.

Lastly, pay attention to compatibility with existing systems and equipment. Ensure that the selected recirculating water chiller integrates seamlessly into your current setup without requiring extensive modifications or additional components. This compatibility will save you time and money in both installation and future upgrades.

Comparing Industrial Water Chillers

When it comes to Industrial water chillers, comparing different models can help pinpoint which one best suits your needs. Start by evaluating their cooling capacities—these units often come with varying BTU ratings that indicate how much heat they can remove from processes per hour. A higher BTU rating typically means better performance under demanding conditions but may also lead to increased costs.

Next, consider the construction quality and materials used in manufacturing these chillers; robust designs often translate into longer lifespans and reduced maintenance issues down the line. Additionally, look at noise levels during operation—some high-performance models might produce more sound than desirable in sensitive environments like laboratories or medical facilities.

Don’t forget about technological advancements! Many modern recirculating chillers now feature digital controls and connectivity options, allowing for remote monitoring and control via smartphones or computers—a game-changer for busy professionals managing multiple units across various locations.

Recommendations for Small Water Chillers

For those needing compact solutions without sacrificing performance, Small Water Chillers are ideal candidates worth considering. These units are particularly suitable for laboratory settings where space is at a premium yet precision is paramount—think benchtop applications requiring consistent temperature control without excessive bulkiness.

When selecting a Small Water Chiller, prioritize models known for their reliability and user-friendly interfaces; features such as easy-to-read displays can make adjustments straightforward even during hectic lab sessions. Brands offering customizable options are also beneficial since they allow you to tailor specifications according to unique project requirements.

Lastly, don’t overlook customer reviews! Feedback from other users can provide invaluable insights into performance under real-world conditions—helping you make an informed decision when investing in laboratory equipment designed specifically for efficient cooling solutions.

Conclusion

In summary, recirculating water chillers play a pivotal role in numerous applications, providing essential temperature control for various processes. Their benefits include energy efficiency, enhanced process control, and reliability as laboratory equipment. As industries continue to evolve, the demand for effective cooling solutions like the recirculating chiller will only grow.

Summary of Recirculating Chiller Benefits

Recirculating chillers offer a multitude of advantages that are crucial for both laboratory and industrial settings. The energy efficiency of these systems not only reduces operational costs but also minimizes environmental impact—an increasingly important factor today. Moreover, their reliability ensures consistent performance in critical applications, making them indispensable pieces of laboratory equipment.

Future Trends in Temperature Control

Looking ahead, we can anticipate exciting innovations in temperature control technologies related to recirculating water chillers. Advancements such as smart monitoring systems and IoT integration are set to revolutionize how we manage cooling processes and optimize energy use. Additionally, the trend toward miniaturization may lead to more compact designs in small water chillers that maintain high performance without sacrificing space.

Final Thoughts on Selecting Laboratory Equipment

When selecting laboratory equipment like a laboratory recirculating chiller or an industrial water chiller, it's vital to consider specific needs and application requirements carefully. Factors such as cooling capacity, energy consumption, and maintenance should guide your decision-making process to ensure optimal performance. Ultimately, investing in the right chilling solution will enhance productivity and reliability across various scientific and industrial endeavors.