Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems!"

Laser chillers play a crucial role in maximizing the performance and efficiency of laser systems. These powerful cooling devices ensure optimal chilling, which directly impacts the overall system performance. In this article, we will explore the importance of powerful laser chillers and how they enhance system performance. We will also introduce RIGID's reliable liquid chiller for laser systems, a cutting-edge solution designed to meet the cooling needs of various industries.

The Importance of Powerful Laser Chillers

Powerful laser chillers are essential for maintaining the stability and reliability of laser systems. Laser technology generates a significant amount of heat during operation, which can negatively impact system performance if not properly managed. Laser chillers effectively dissipate this heat, ensuring that lasers operate within their specified temperature range.

How Optimal Chilling Enhances System Performance

Optimal chilling is crucial for enhancing system performance in several ways. Firstly, it helps maintain consistent laser output power and stability, which is essential for applications such as cutting, engraving, and welding. Secondly, it protects sensitive components from overheating, reducing the risk of damage or downtime. Lastly, optimal chilling improves overall efficiency by minimizing energy consumption and reducing operating costs.

RIGID's Reliable Liquid Chiller for Laser Systems

RIGID Technology is an innovative leader in miniature refrigerated compressor solutions based in China. With extensive research and development capabilities, RIGID has developed a range of high-quality laser chillers to meet the diverse cooling needs of different industries. Their products are known for their reliability, efficiency, and customized design options.

Understanding Laser Chillers

Laser chillers are essential components in laser systems that help maintain optimal operating temperatures for improved performance and longevity. These specialized cooling systems ensure that lasers operate within their specified temperature ranges, preventing overheating and potential damage.

What Are Laser Chillers?

Laser chillers are compact refrigeration units designed to cool the laser medium or optics of a laser system. They use a closed-loop liquid cooling system to remove heat generated during laser operation. By circulating chilled liquid, usually water or a coolant mixture, through the laser components, they effectively dissipate heat and maintain stable operating temperatures.

Key Components of a Laser Chiller System

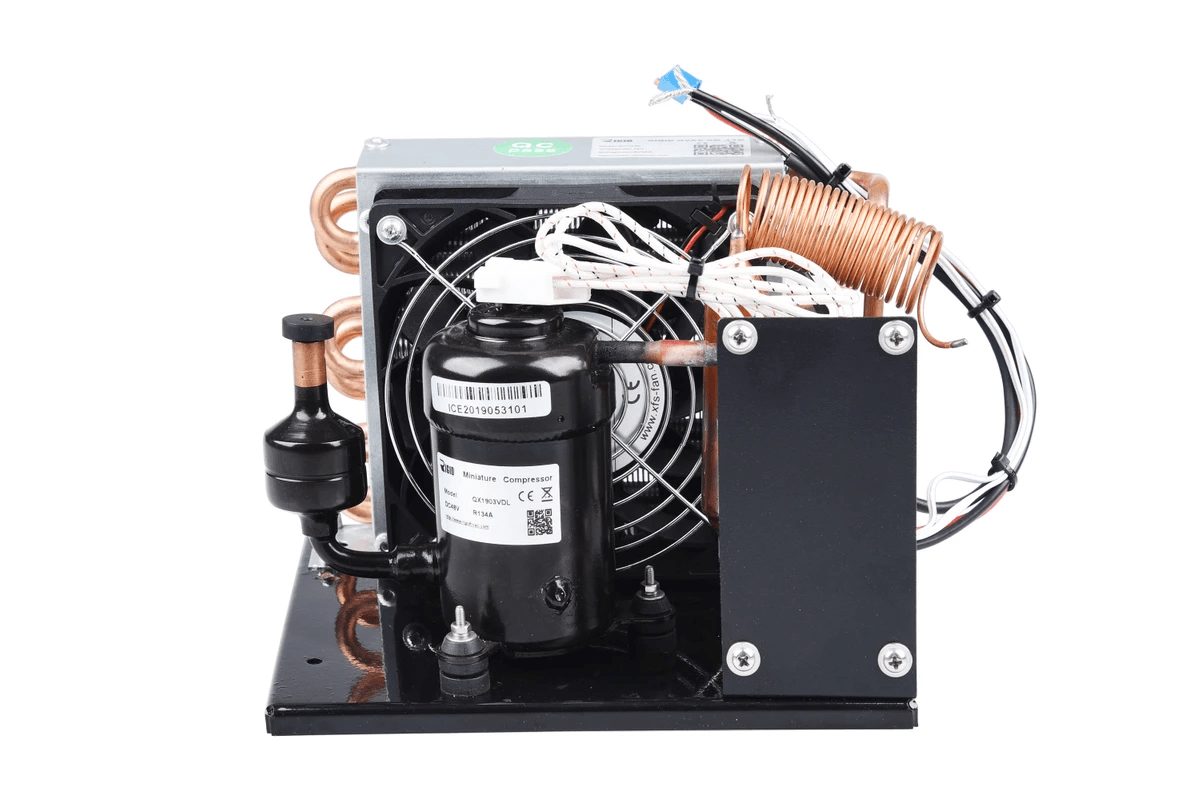

A typical laser chiller system consists of several key components working together to achieve efficient cooling. These include a compressor, condenser, evaporator, expansion valve, and pump. The compressor pressurizes the refrigerant gas, while the condenser releases heat from the compressed gas to the surrounding environment. The cooled refrigerant then flows through the evaporator where it absorbs heat from the laser system before returning to the compressor via the expansion valve.

The Role of Industrial Chillers in Laser Cooling

Industrial chillers play a crucial role in laser cooling as they provide precise temperature control and stability required for optimal laser performance. They remove excess heat generated by lasers during operation and maintain consistent temperatures within tight tolerances. This ensures that lasers operate at their peak efficiency while minimizing thermal stress on critical components such as diodes, mirrors, or fiber optics.

RIGID Technology specializes in designing advanced micro refrigeration systems specifically tailored for laser chiller applications. Their miniature compressors offer compactness without compromising performance, making them ideal for space-limited laser systems. With their expertise in customized design and research and development, RIGID Technology provides reliable cooling solutions that enhance the performance and longevity of laser systems.

Benefits of Using Laser Chillers

Laser chillers offer a range of benefits that can greatly enhance the performance and efficiency of laser systems. By investing in a reliable laser chiller, users can experience improved laser performance and stability, protection against overheating and downtime, as well as enhanced efficiency and cost savings.

Enhanced Laser Performance and Stability

Laser chillers play a crucial role in maintaining optimal operating temperatures for laser systems. By providing precise cooling capabilities, they ensure that lasers operate at their peak performance levels consistently. The stable temperature control offered by laser chillers helps to minimize fluctuations that can negatively impact the accuracy and quality of laser outputs.

Protection Against Overheating and Downtime

Overheating is a significant concern when it comes to laser systems. Excessive heat can lead to damage to sensitive components, reduced lifespan of lasers, and even system failure. Laser chillers effectively dissipate heat generated during operation, preventing overheating issues that could result in costly downtime or repairs.

Improved Efficiency and Cost Savings

Efficiency is crucial in any industrial setting, including laser systems. Laser chillers optimize system performance by maintaining consistent cooling temperatures, resulting in improved energy efficiency. This not only reduces energy consumption but also leads to cost savings over time.

Investing in reliable laser chillers from RIGID Technology offers additional advantages such as micro-sized designs for space-saving installations, customized solutions tailored to specific needs, and cutting-edge technology developed through extensive research and development efforts.

Choosing the Right Laser Chiller

When it comes to selecting a laser chiller, there are several important factors to consider. First and foremost, you need to assess your specific cooling requirements and the size of your laser system. Understanding the cooling capacity needed for your particular application is crucial in ensuring optimal performance and longevity of your laser equipment.

Additionally, evaluating the energy efficiency of a chiller is essential for minimizing operational costs and reducing environmental impact. Look for laser chillers that are equipped with advanced technologies, such as variable speed compressors and intelligent control systems, which can significantly improve energy efficiency.

Furthermore, it is vital to explore different types of laser chillers available in the market. The most common types include air-cooled chillers and water-cooled chillers. Air-cooled chillers are suitable for applications where water availability or quality is limited. On the other hand, water-cooled chillers offer higher cooling capacities and are ideal for industrial environments where heat dissipation is critical.

When considering different options, RIGID's Laser Chillers stand out as top contenders due to their innovative design and exceptional performance. RIGID Technology specializes in developing customized cooling solutions that cater specifically to the needs of laser systems.

By investing in RIGID's Laser Chillers, you can benefit from their micro-sized refrigerated compressors that provide superior cooling power while maintaining a compact footprint. These miniature compressors are designed using cutting-edge technology developed through extensive research and development efforts.

Moreover, RIGID's Laser Chillers offer mobile capabilities, allowing for flexible installation options within your facility. This feature enables you to optimize space utilization while ensuring efficient cooling of your laser equipment.

RIGID's Liquid Chiller for Laser Systems

RIGID Technology is at the forefront of innovation in the field of laser chillers, offering a comprehensive product line that meets the diverse needs of laser systems. With their Micro, Miniature, Mobile, and Customized designs, RIGID provides cutting-edge solutions for all types of laser cooling requirements.

Overview of RIGID's Laser Chiller Product Line

RIGID's laser chiller product line encompasses a wide range of options to cater to various industrial applications. From compact systems suitable for small-scale operations to powerful units designed for high-performance lasers, RIGID has it all.

Their Micro series offers miniature laser chillers that are perfect for space-constrained environments. These compact units deliver efficient cooling while taking up minimal space in your setup.

For larger applications, the Miniature series provides enhanced cooling capabilities without sacrificing portability. These chiller units are designed to be easily transported and installed wherever they are needed.

RIGID also offers Mobile laser chillers that are ideal for on-the-go cooling needs. Whether you're conducting research in different locations or require temporary cooling solutions, these mobile units ensure reliable performance wherever you go.

Lastly, RIGID's Customized designs allow you to tailor your chiller system according to your specific requirements. Their team of experts in Research and Development can work closely with you to create a personalized solution that perfectly suits your needs.

Cutting-Edge Features and Innovative Technology

RIGID's laser chillers incorporate state-of-the-art technology and cutting-edge features to ensure optimal performance and reliability. Their advanced compressor technology guarantees efficient cooling while minimizing energy consumption.

These chiller systems also feature intelligent temperature control mechanisms that maintain precise temperature levels throughout operation. This helps protect delicate laser components from overheating and ensures consistent performance over extended periods.

Testimonials from Satisfied Customers

RIGID's commitment to excellence and customer satisfaction is evident in the positive feedback they receive from their customers. Here are a few testimonials from satisfied users of RIGID's laser chillers:

1. We have been using RIGID's laser chiller for our CO2 laser system, and we couldn't be happier with its performance. It keeps our laser cool even during prolonged use, allowing us to achieve precise and consistent results. - John D., Laser System Manufacturer.

2. The mobility of RIGID's laser chiller has been a game-changer for our research team. We can easily transport it to different locations without compromising on cooling efficiency. It has truly revolutionized our fieldwork. - Sarah M., Research Scientist.

3. RIGID's customized laser chiller perfectly matched our unique cooling requirements. Their team worked closely with us to design a solution that met all our specifications, resulting in improved system performance and reliability. - David L., Industrial Laser User.

With their extensive product line, innovative technology, and satisfied customer base, RIGID Technology is undoubtedly the go-to choice for all your laser chiller needs.

Installation and Maintenance Tips

Proper Installation Procedures for Laser Chillers

When installing laser chillers, it is crucial to follow proper procedures to ensure optimal performance and longevity. Begin by selecting a suitable location that provides adequate ventilation and access for maintenance. Position the chiller on a stable surface to prevent vibrations that could affect laser system operation. Connect the chiller to the laser system using compatible hoses or pipes, ensuring proper alignment and secure connections. It is also important to check for any leaks before starting the system.

To avoid potential damage, it is recommended to use a power conditioner or surge protector to protect the chiller from electrical surges or fluctuations. Additionally, ensure that the power supply meets the required voltage specifications of the chiller.

Regular Maintenance and Cleaning Guidelines

Regular maintenance is essential for keeping laser chillers in optimal condition and extending their lifespan. One crucial aspect of maintenance is cleaning the chiller regularly to remove any dust or debris that may accumulate on its surfaces or components.

Start by disconnecting power sources and allowing sufficient time for the chiller to cool down before cleaning. Use a soft cloth or brush to gently remove dust from external surfaces, being careful not to damage any sensitive parts.

For internal cleaning, refer to the manufacturer's guidelines for specific instructions on how to clean filters, coils, and other components. Ensure that all cleaning agents used are compatible with the materials of construction in your specific chiller model.

Troubleshooting Common Chiller Issues

Despite proper installation and maintenance practices, occasional issues may arise with laser chillers. Here are some common problems you may encounter along with possible solutions:

1. Insufficient cooling: If your chiller is not providing adequate cooling, check the coolant levels and ensure that the chiller is receiving sufficient power supply. If the issue persists, contact a qualified technician for further diagnosis.

2. Noisy operation: Excessive noise from your chiller could indicate loose components or an issue with the compressor. Check for loose screws or bolts and tighten them if necessary. If the noise continues, consult a professional for assistance.

3. Leaks: If you notice any leaks from your chiller, immediately shut off the power supply and inspect hoses, fittings, and seals for damage or improper connections. Replace any faulty parts and test for leaks before restarting the system.

Remember to always refer to the manufacturer's guidelines and seek professional assistance if needed when troubleshooting chiller issues.

Conclusion

Take Your Laser System Performance to the Next Level

By investing in powerful laser chillers, you can significantly enhance the performance of your laser system. These chillers play a crucial role in maintaining optimal temperatures for laser cooling, ensuring stable and reliable operation. RIGID's innovative liquid chiller for laser systems is designed to meet the unique cooling needs of industrial lasers, providing exceptional performance and efficiency.

Harness the Power of RIGID's Laser Chiller Technology

RIGID Technology is at the forefront of miniature refrigerated compressor innovation in China. With their expertise in mobile and compact cooling systems, they have developed cutting-edge laser chillers that deliver superior performance and reliability. Their products are designed with precision and undergo rigorous research and development to provide customized solutions for various laser applications.

Invest in Reliable Cooling Solutions for Long-Term Success

Choosing the right laser chiller is crucial for long-term success. Factors such as cooling capacity, energy efficiency, and type of chiller should be carefully considered before making a decision. RIGID's liquid chiller for laser systems offers a wide range of features and advanced technology to ensure optimal cooling performance, protecting your investment from overheating and downtime.

With proper installation procedures, regular maintenance, and troubleshooting guidelines, you can maximize the lifespan of your laser chiller system. By following these best practices, you can ensure that your laser system operates at its peak performance while minimizing costly repairs or replacements.