Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

When it comes to commercial cooling systems, water chillers are a popular choice for many businesses. A water chiller system is designed to remove heat from the air and circulate chilled water through a closed-loop system, providing efficient cooling for various applications. But do water chillers use a lot of electricity? Let's explore the ins and outs of these systems and find out.

What are Commercial Water Chillers?

Commercial Water Chillers are refrigeration systems that use water as a cooling medium to provide chilled water for industrial and commercial facilities. These systems are essential for maintaining optimal temperatures in large-scale operations such as manufacturing plants, data centers, and hospitals.

How does a water chiller system work?

A water chiller system works by removing heat from the air using refrigeration cycles to cool down the circulating water. The chilled water is then pumped through pipes to various heat exchangers or coils where it absorbs heat from the surrounding environment, effectively cooling the space.

Do water chillers use a lot of electricity?

Water chillers can be energy-intensive, especially if they are not designed for efficiency. However, advancements in technology have led to more energy-efficient options such as Water Cooled Chillers and Liquid Chiller Systems that offer superior performance while minimizing electricity consumption.

Understanding Water Chiller Systems

When it comes to commercial water chillers, there are two main types of systems: air-cooled and water-cooled chillers. Water cooled chillers use water to absorb heat from the chiller's compressor, while air-cooled chillers use air to remove heat from the refrigerant. Both systems have their own advantages and are suitable for different applications.

Types of Water Cooled Chillers

Water cooled chillers can be further classified into two types: open loop and closed loop systems. Open loop systems use water from a natural source, such as a lake or river, to cool the refrigerant before returning it to the chiller. Closed loop systems, on the other hand, recirculate the same water within the system to cool the refrigerant.

Water cooled chillers are an efficient and cost-effective way to cool large buildings and industrial facilities. Open loop systems are advantageous for their ability to use natural water sources, which can be more energy-efficient and environmentally friendly. On the other hand, closed loop systems offer greater control over the water quality and temperature, making them suitable for applications where consistent cooling is essential. Both types of water cooled chillers have their own unique benefits, allowing businesses to choose the system that best fits their specific needs.

Benefits of Liquid Chiller Systems

Liquid chiller systems offer several benefits for commercial use. They provide consistent cooling performance, are more energy efficient than air-cooled systems, and are ideal for applications that require precise temperature control. Additionally, liquid chiller systems have a longer lifespan and require less maintenance compared to air-cooled alternatives.

Liquid chiller systems also offer the advantage of being quieter than air-cooled systems, making them a more suitable choice for environments where noise levels need to be kept to a minimum. This can be particularly beneficial in office settings or residential buildings where a peaceful atmosphere is essential. Additionally, liquid chiller systems are less susceptible to fluctuations in ambient air temperature, ensuring that they can maintain consistent cooling performance regardless of external conditions. This reliability can be crucial for businesses that rely on uninterrupted cooling for their operations.

Efficiency of Water Cooled Chiller System

Water cooled chiller systems are known for their high efficiency in cooling large commercial spaces. These systems consume less electricity than air-cooled chillers due to their reliance on water as a cooling medium. The efficiency of water cooled chiller systems also contributes to cost savings and reduced environmental impact, making them an attractive choice for businesses looking to improve their sustainability efforts.

Water cooled chiller systems are not only efficient in cooling large commercial spaces, but they also offer greater flexibility in installation. These systems can be placed indoors or outdoors, allowing businesses to make the most of their available space. Additionally, water cooled chiller systems are known for their reliability and longevity, providing consistent cooling performance over time.

Choosing the Right Water Chiller System

When choosing a water chiller system for commercial use, several factors need to be considered. The size and cooling capacity of the system must match the specific requirements of the application. Additionally, energy efficiency and maintenance requirements are crucial to ensure long-term cost-effectiveness.

Factors to Consider for Commercial Use

Commercial water chillers need to be tailored to the unique demands of different industries. Whether it's for food processing, medical equipment, or industrial machinery, the chiller system must meet specific temperature and cooling requirements. It's essential to consider factors such as space limitations, noise levels, and environmental regulations when selecting a water chiller system.

When selecting a water chiller system for commercial use, it's important to take into account the energy efficiency of the equipment. The cost of operation can be significantly impacted by the energy consumption of the chiller, so choosing a system with high energy efficiency can lead to long-term cost savings. Additionally, considering the ease of maintenance and serviceability of the chiller is crucial to minimize downtime and ensure continuous operation.

RIGID's Superior Design and Uncompromising Quality

RIGID stands out in the industry with its superior design and uncompromising quality in mini compressor innovation. Their innovative approach allows for compact cooling systems that are both efficient and reliable. RIGID's commitment to excellence ensures that their water chiller systems are built to last, providing businesses with a dependable solution for their cooling needs.

RIGID's mini compressor innovation doesn't just stop at superior design and uncompromising quality. Their commitment to pushing the boundaries of technology and engineering has led to the development of custom-made refrigeration solutions that cater to specific industry needs. Whether it's for medical, automotive, or food and beverage applications, RIGID's expertise in creating tailored cooling systems sets them apart as a leader in the industry.

Custom-Made Refrigeration Solutions

One of the key advantages of choosing RIGID is their ability to provide custom-made refrigeration solutions. They work closely with clients to understand their specific requirements and develop tailored chiller systems that meet their needs precisely. This level of customization ensures that businesses can optimize their cooling processes while staying within budget constraints.

Furthermore, RIGID's custom-made refrigeration solutions are designed to be energy-efficient, helping businesses reduce their overall operating costs. By tailoring the chiller systems to the specific needs of each client, RIGID ensures that they are not overspending on unnecessary cooling capacity. This cost-efficiency is a key advantage for businesses looking to streamline their operations and maximize their bottom line.

The Cost-Efficiency of Water Chiller Systems

When it comes to commercial water chiller systems, the impact on budget and competitiveness is a crucial consideration for businesses. The initial investment in a high-quality water chiller system may seem significant, but the long-term cost savings and competitive edge it provides can be substantial. By choosing an efficient and reliable water chiller system, businesses can minimize operational costs and gain an advantage in their industry.

Impact on Budget and Competitiveness

Commercial water chillers play a vital role in maintaining the optimal temperature for various industrial processes, ensuring product quality and efficiency. Investing in a top-of-the-line water chiller system may require a significant upfront cost, but the long-term benefits far outweigh the initial investment. By enhancing productivity, reducing downtime, and minimizing maintenance expenses, a high-quality water chiller system can positively impact a company's budget and overall competitiveness.

Energy Efficiency and Savings

One of the key factors that contribute to the cost-efficiency of water chiller systems is their energy efficiency. High-performance liquid chiller systems are designed to minimize energy consumption while delivering superior cooling capabilities. This results in substantial cost savings on electricity bills for businesses, making them more financially sustainable in the long run.

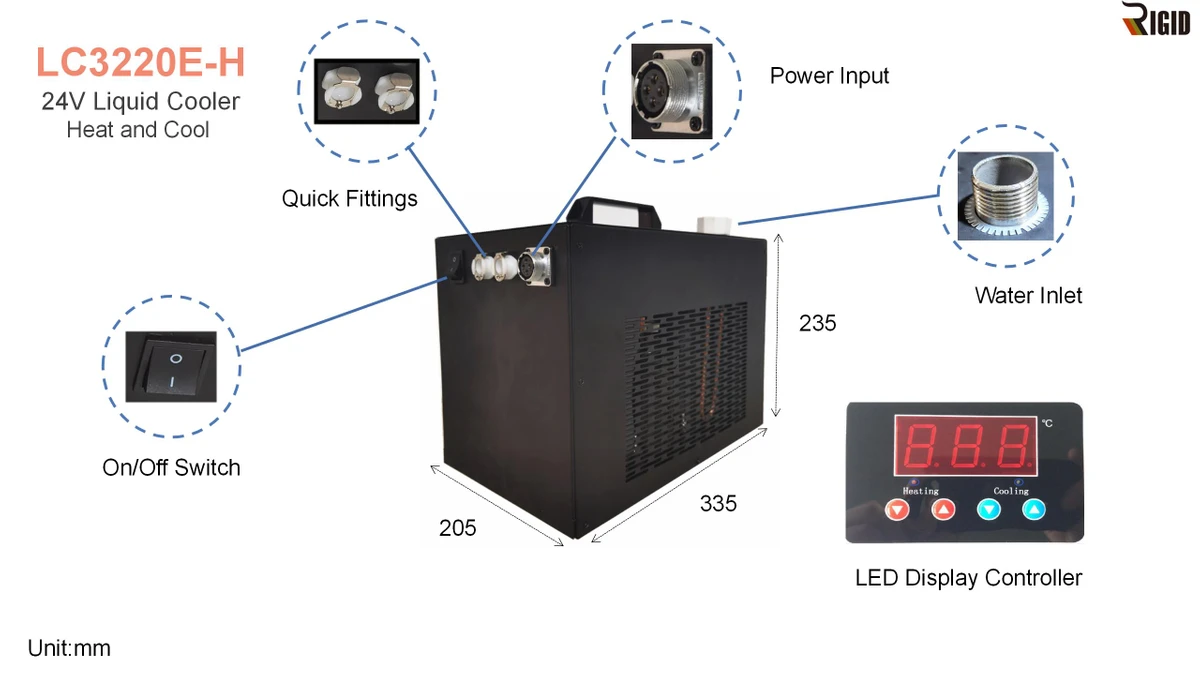

RIGID's Mini Compressor Innovation

RIGID's mini compressor innovation has revolutionized the commercial water chiller industry by offering compact yet powerful cooling solutions that are highly energy-efficient. With RIGID's miniature cooling systems, businesses can enjoy significant savings on operational costs while maintaining exceptional performance. This innovative technology not only reduces electricity consumption but also enhances the overall cost-efficiency of water chiller systems.

Maintenance and Longevity

Importance of Regular Maintenance

Regular maintenance also helps to maintain the safety of the water chiller system, as regular inspections can identify and address any potential hazards or issues before they escalate into major problems. This proactive approach can help businesses avoid costly repairs and potential liabilities associated with equipment malfunctions. Additionally, by keeping the system well-maintained, businesses can ensure that it complies with industry regulations and standards, providing peace of mind for both employees and customers.

Durability of RIGID's Micro Cooling Systems

RIGID's micro cooling systems are designed with durability in mind, using high-quality materials and innovative technology to withstand heavy usage in commercial settings. The superior design and uncompromising quality of RIGID's mini compressors ensure long-term reliability, making them an ideal choice for businesses looking for sustainable cooling solutions.

RIGID's commitment to durability extends beyond just the materials used in their micro cooling systems. Their rigorous testing and quality control processes ensure that each unit is built to last, even in the most demanding commercial environments. This attention to detail not only enhances the lifespan of the cooling systems but also minimizes maintenance and repair costs for businesses, providing a cost-effective and reliable solution for their cooling needs.

Extending the Lifespan of Water Chiller Systems

By investing in RIGID's micro cooling systems, businesses can significantly extend the lifespan of their water chiller systems. The advanced engineering and precision manufacturing of RIGID's products result in reduced wear and tear, leading to fewer replacements and maintenance costs over time. Additionally, the energy efficiency of these micro cooling systems helps businesses save on operational costs, making them a cost-effective long-term investment. Furthermore, RIGID's commitment to innovation means that businesses can stay ahead of the curve with cutting-edge technology that enhances the performance and longevity of their water chiller systems.

The Future of Commercial Water Chiller Systems

As the demand for energy-efficient and cost-effective cooling solutions continues to grow, advancements in micro refrigeration technology are shaping the future of water chiller systems. Manufacturers like RIGID are leading the way with innovative mini compressor designs that cater to the evolving needs of commercial industries.

Advancements in Micro Refrigeration Technology

The continuous development of micro refrigeration technology has revolutionized the efficiency and performance of water chiller systems. RIGID's mini compressor innovation has played a pivotal role in enhancing the functionality and adaptability of these systems, making them more suitable for various commercial applications.

Meeting Specific Requirements

With businesses having diverse cooling needs, water chiller systems must be able to meet specific requirements effectively. RIGID's superior design and uncompromising quality ensure that their miniature cooling systems are customizable, providing tailored solutions that cater to the unique demands of different industries.

RIGID's commitment to meeting specific requirements doesn't stop at customization. Their water chiller systems are also designed to be energy-efficient, helping businesses reduce their carbon footprint and lower operating costs. By providing tailored solutions that not only meet cooling needs but also contribute to sustainability efforts, RIGID sets itself apart as a forward-thinking partner for businesses in various industries.

RIGID's Growing List of Satisfied Clients

RIGID's commitment to excellence has resulted in a growing list of satisfied clients who have experienced the benefits of their innovative cooling solutions. From small businesses to large corporations, RIGID's reputation as a pioneer in the micro cooling industry is reflected in their ability to deliver reliable and efficient water chiller systems that exceed expectations.

Furthermore, RIGID's dedication to customer satisfaction is evident in their personalized approach to every client's unique cooling needs. Their team of experienced professionals takes the time to understand each client's specific requirements and provide tailored solutions that address their challenges effectively. This level of attention to detail and customer care has solidified RIGID's reputation as a trusted partner in the industry, earning them repeat business and referrals from their satisfied clients.

Conclusion

RIGID's Pioneer Role in the Micro Cooling Industry

As a leader in mini compressor innovation, RIGID has revolutionized the micro cooling industry with its superior design and uncompromising quality. With a focus on custom-made refrigeration solutions and meeting specific requirements, RIGID has built a growing list of satisfied clients in the B2B sector.

The Versatility of Miniature Cooling Systems

RIGID's miniature cooling systems, including small chillers and direct cooling solutions, offer unparalleled versatility for commercial water chiller systems. These innovative solutions cater to various B2B applications, ensuring cost-efficiency and competitiveness for businesses.

The Ongoing Evolution of Water Chiller Systems

As technology continues to advance, water chiller systems are evolving rapidly to meet the changing needs of commercial users. RIGID remains at the forefront of this evolution, capturing new technologies in mobile and compact cooling systems to provide cutting-edge solutions for B2B clients.