Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

Understanding Peltier and Compressor Technologies

Peltier coolers operate on the principle of thermoelectricity, utilizing a small electrical current to create a temperature difference across two sides of a semiconductor material. This innovative approach allows for compact designs that can fit into tight spaces, making them ideal for niche applications. On the other hand, compressor-based coolers rely on traditional refrigeration cycles involving refrigerants and mechanical compression, which can offer more robust cooling power in larger setups.

Key Differences in Cooling Methods

The fundamental differences between Peltier vs compressor technologies lie primarily in their operational mechanisms and efficiency levels. While Peltier systems are known for their quiet operation and lack of moving parts, they typically struggle with heat dissipation under heavy loads compared to their compressor counterparts. Conversely, compressor-based coolers excel at providing rapid cooling but may come with higher energy consumption and noise levels—factors worth considering depending on your environment.

The Importance of Choosing the Right Solution

Selecting between Peltier vs compressor technologies isn’t merely a matter of preference; it’s about aligning your choice with your specific application requirements. Whether you need a compact solution for delicate electronics or robust cooling for industrial machinery will heavily influence your decision-making process. Ultimately, understanding both options empowers you to choose wisely—ensuring optimal performance while minimizing costs over time.

Peltier Efficiency

Evaluating Energy Consumption

Energy consumption is a vital factor when comparing Peltier vs compressor technologies. Peltier coolers generally consume less power than their compressor-based counterparts, especially in smaller applications where compactness is essential. However, it's important to note that while they may be more efficient at low loads, their performance can drop significantly under high thermal loads compared to a Compressor-Based Cooler.

Understanding the specifics of energy consumption helps users appreciate the potential savings associated with using a Peltier cooler in suitable applications. For instance, if you’re cooling small electronics or personal spaces, the lower energy draw of thermoelectric systems can lead to reduced electricity bills over time. Nevertheless, if you're considering larger installations or environments requiring sustained cooling power, you might find that compressor-based systems offer better long-term efficiency despite higher initial costs.

Real-World Performance Scenarios

Real-world performance scenarios provide insight into how Peltier efficiency translates into practical applications versus compressor technologies. In small-scale settings like portable coolers or compact refrigeration units, Peltier systems often excel due to their lightweight nature and ease of integration into various designs—perfect for those who prioritize portability without sacrificing too much cooling power. However, as ambient temperatures rise or larger volumes need cooling, many users find themselves leaning towards compressor-based solutions for their superior heat removal capabilities.

In industrial contexts or large facilities where consistent and powerful cooling is required, compressor systems typically dominate due to their ability to maintain steady temperatures even under significant load variations. This stark difference between thermoelectric cooling vs compressor technologies illustrates why choosing the right system hinges on understanding your specific needs and environment requirements—after all, nobody wants an ice cream maker that can't keep up during summer BBQs!

Cost-Effectiveness Analysis

When analyzing cost-effectiveness in the context of Peltier vs compressor options, several factors come into play beyond just initial purchase price. While Peltier coolers may have lower upfront costs and are often easier to install due to fewer moving parts and no refrigerants involved—making them appealing for DIY enthusiasts—they might not always be the most economical choice over time depending on usage patterns and operational demands.

For example, if you frequently need heavy-duty cooling capabilities over extended periods (think server rooms or industrial processes), investing in a Compressor-Based Cooler could yield better results in terms of longevity and reliability despite higher initial costs. Additionally, factoring in maintenance expenses reveals that while compressors may require more upkeep due to mechanical wear-and-tear issues over time; well-maintained compressors can outperform their thermoelectric counterparts significantly when it comes down to overall lifetime costs.

In summary, evaluating cost-effectiveness requires careful consideration of both short-term savings through energy consumption as well as long-term operational viability based on specific application needs—whether you opt for a sleek Peltier cooler or a robust compressor system will ultimately depend on your unique circumstances!

Peltier Cooling Design

Peltier cooling design is an exciting field that showcases the versatility and efficiency of thermoelectric systems. These designs leverage the principles of thermoelectricity to provide effective cooling solutions in various applications, especially when space is at a premium. In this section, we’ll explore the application areas for Peltier systems, their advantages in compact spaces, and the latest innovations driving thermoelectric technology forward.

Application Areas for Peltier Systems

Peltier systems shine in specific application areas where traditional compressor-based cooling may fall short. For instance, they are ideal for small electronic devices like CPUs and GPUs that require precise temperature control without bulky components. Additionally, Peltier coolers find their niche in portable coolers or medical devices where maintaining a stable temperature is crucial—think of those handy little lunchboxes that keep your sandwich fresh!

In contrast to compressor-based coolers that dominate larger industrial setups, Peltier technology excels in compact applications due to its lightweight and small footprint. This makes them particularly suitable for consumer electronics and automotive uses where space is at a premium. As we delve deeper into the world of thermoelectric cooling vs compressor technologies, it’s clear that Peltier systems cater to needs often overlooked by traditional methods.

Advantages in Compact Spaces

First off, these systems operate without moving parts—this means less noise and vibration compared to their compressor counterparts! Moreover, their small size allows for installation in tight areas where conventional compressors simply cannot fit.

Another significant benefit is energy efficiency; with proper design considerations, a Peltier cooler can effectively manage heat dissipation while consuming less power than larger compressors. This aspect becomes increasingly vital as our world leans toward more sustainable practices and energy conservation efforts. Thus, when weighing peltier vs compressor options for confined environments or portable devices, the scales often tip favorably towards thermoelectric solutions.

Innovations in Thermoelectric Applications

The realm of thermoelectric applications has witnessed remarkable innovations recently that bolster the effectiveness of Peltier cooling design further. Advanced materials such as bismuth telluride are being explored to enhance Peltier efficiency; these materials allow for better heat transfer properties while maintaining compactness—a win-win situation! Additionally, researchers are developing hybrid systems that combine both thermoelectric elements with traditional refrigeration methods to maximize performance across various scenarios.

Moreover, smart technology integration has led to intelligent thermal management systems utilizing real-time data analytics to optimize performance dynamically—a feature not typically found in standard compressor-based coolers! As industries continue exploring new avenues within this field, it’s evident that advancements will only expand the potential applications of Peltier technology beyond what we currently envision today.

Compressor-Based Coolers

Overview of Compressor Technology

Compressor technology operates on a straightforward principle: it compresses a gas refrigerant, raising its temperature and pressure before circulating it through coils to release heat outside. This process allows for significant temperature drops inside the cooler, making it ideal for various applications from household refrigerators to large industrial chillers. In contrast to Peltier systems, which rely on electrical current passing through semiconductor materials, compressors can achieve much lower temperatures over larger areas.

The mechanics behind compressor-based coolers involve multiple components including the compressor itself, condenser coils, evaporator coils, and an expansion valve. These elements work together seamlessly to create a continuous cycle of heat absorption and dissipation. While discussing thermoelectric cooling vs compressor systems might highlight some advantages of Peltier efficiency in specific scenarios, it's hard to overlook how well-established compressors handle heavy-duty cooling tasks.

Leading Brands in the Market

In the world of compressor-based coolers, several brands have established themselves as leaders by consistently delivering high-quality products that meet diverse consumer needs. Companies like Frigidaire and Whirlpool dominate household appliance markets with reliable refrigerators and freezers that utilize advanced compressor technology for maximum efficiency. On the commercial side, brands such as Carrier and Trane are synonymous with robust HVAC solutions that keep large facilities climate-controlled year-round.

These brands not only provide effective cooling but also invest in research and development to enhance energy efficiency further while reducing environmental impact—an increasingly important consideration in today's eco-conscious market. By comparing Peltier vs compressor options from these leading manufacturers, consumers can make informed decisions based on performance metrics tailored to their specific needs. The competition among these companies drives innovation forward across both technologies.

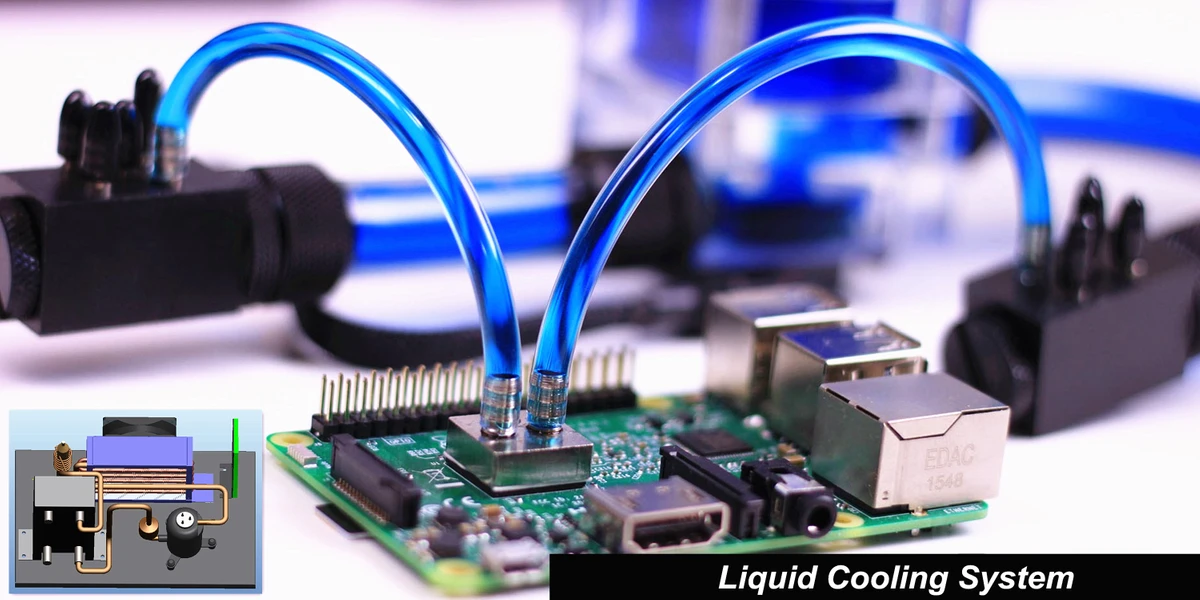

RIGID's Role in the Mini Compressor Space

RIGID has carved out a niche within the mini compressor space by offering compact yet powerful cooling solutions designed for specialized applications like portable coolers or small refrigeration units. Their mini compressors are engineered with precision to provide reliable performance while maintaining energy efficiency—a key factor when considering peltier vs compressor options for smaller setups where space is limited but cooling demands remain high.

By focusing on lightweight designs without compromising on power or effectiveness, RIGID stands out among competitors who may overlook this segment of the market. Their commitment extends beyond just manufacturing; they actively engage with customers to tailor solutions that fit unique operational requirements across various industries—from food service establishments needing consistent refrigeration to outdoor enthusiasts seeking portable chill solutions during adventures.

RIGID’s innovations reflect an understanding that even within miniaturized formats, effective thermoelectric cooling vs compressor capabilities can significantly impact user experience and operational costs over time—making them a strong contender in discussions about future trends in cooling technologies.

Thermoelectric Cooling vs Compressor

Pros and Cons of Each System

Peltier cooling design offers several advantages, including compact size, lightweight nature, and quiet operation. These thermoelectric coolers are perfect for small-scale applications where space is at a premium or noise levels must be kept to a minimum. However, Peltier efficiency often suffers in terms of energy consumption compared to traditional compressor systems that can deliver more powerful cooling over larger areas.

On the flip side, compressor-based coolers are known for their robustness and efficiency in handling larger volumes of air or liquid. They excel in environments that require rapid temperature reduction or consistent cooling over extended periods. The downside? They tend to be bulkier, noisier, and less energy-efficient than their Peltier counterparts when used in smaller applications.

In summary, while Peltier vs compressor technologies each have their merits, the right choice hinges on your specific requirements—whether you prioritize size and silence or power and efficiency.

Suitability for Different Environments

When considering thermoelectric cooling vs compressor systems, it's essential to evaluate where each technology thrives best. Peltier coolers shine in compact spaces such as portable devices, medical equipment, or specialized electronics that demand precision without excessive noise or vibration. Their suitability for niche applications makes them an appealing option for industries that require tailored solutions.

Conversely, compressor-based coolers dominate large facilities like commercial kitchens or industrial settings where high-capacity cooling is necessary. These environments benefit from the robust performance of compressors that can handle significant heat loads efficiently over time. In essence, selecting between Peltier vs compressor solutions boils down to understanding your environment's specific demands—whether it’s portability or sheer power.

Ultimately, recognizing these differences helps guide users toward making informed decisions about which system will best meet their operational needs while maintaining optimal performance.

Long-Term Operational Costs

Cost considerations play a pivotal role when comparing long-term operational expenses associated with Peltier vs compressor technologies. While initial investments may vary significantly between the two systems—Peltier units often being less expensive upfront—their energy efficiency (or lack thereof) can impact overall costs over time. Higher electricity bills associated with running less efficient thermoelectric systems could negate those initial savings.

On the other hand, while compressors may have higher upfront costs due to their complexity and size requirements, they typically offer greater long-term reliability and lower operational costs due to better energy efficiency during continuous use scenarios. This means that although you might spend more initially on a compressor-based cooler system, you could save money in the long run through reduced electricity consumption.

In conclusion, evaluating long-term operational costs is crucial when deciding between thermoelectric cooling vs compressor options; it’s not just about what fits your budget today but also what will keep your wallet happy tomorrow!

Applications in Industry

When it comes to industrial applications, the debate of Peltier vs compressor becomes crucial for decision-makers. Each cooling technology has its unique strengths and weaknesses, which can significantly impact performance based on the specific requirements of an application. Understanding where each method excels can lead to more efficient and effective cooling solutions.

Where Peltier Shines

Peltier cooling design is particularly advantageous in compact or space-constrained environments, where traditional Compressor-Based Coolers might not fit. For instance, in electronic devices or medical equipment that require precise temperature control without bulky components, Peltier coolers are often the preferred choice. Their ability to provide targeted cooling without moving parts also translates into lower maintenance needs and enhanced reliability.

Moreover, Peltier efficiency is impressive in situations where noise reduction is paramount; they operate silently compared to their compressor counterparts. This makes them ideal for applications like portable coolers or small refrigeration units used in laboratories and specialized medical devices. The versatility of Peltier systems allows them to shine brightly in niche markets where traditional cooling methods may falter.

Compressor Dominance in Large Facilities

While Peltier systems have their advantages, compressor-based cooling remains the go-to solution for large-scale operations and facilities that demand high-capacity cooling. In industries like food storage, pharmaceuticals, and manufacturing plants, a Compressor-Based Cooler can deliver consistent performance over extended periods with minimal downtime. These systems excel at handling larger thermal loads efficiently, making them indispensable for industrial applications.

Compressor technology benefits from established infrastructure and widespread availability of parts and service support, which enhances operational reliability for businesses with significant cooling needs. Additionally, advancements in compressor design have led to improved energy efficiency metrics that continue to close the gap with thermoelectric options when considering long-term operational costs. Thus, while the debate between thermoelectric cooling vs compressor rages on, compressors firmly hold their ground in larger facilities.

Custom Solutions by RIGID for Various Industries

RIGID’s commitment to innovation means they offer tailored solutions that cater specifically to different industry requirements—whether it's a sleek Peltier cooler designed for compact electronic enclosures or robust compressor systems built for heavy-duty industrial use. By understanding both Peltier vs compressor dynamics and leveraging their expertise across various sectors such as automotive or telecommunications, RIGID provides optimal designs that meet diverse needs efficiently.

Their custom solutions often integrate advanced technologies that enhance both performance and energy consumption metrics—an essential factor when evaluating Peltier efficiency against traditional compressors. This approach not only ensures compliance with industry standards but also promotes sustainability through eco-friendly practices tailored to each application’s demands. Ultimately, RIGID exemplifies how understanding specific use cases can lead to innovative solutions that bridge the gap between thermoelectric options and conventional compressors.

Environmental Impact

When it comes to the environmental impact of cooling technologies, the debate between Peltier and compressor-based systems is more relevant than ever. Energy efficiency plays a crucial role in determining which system is the better choice for our planet. Both methods have their merits, but understanding their energy consumption and sustainability can help in making an informed decision.

Energy Efficiency Comparisons

Energy efficiency is a hot topic when comparing Peltier vs compressor technologies. Peltier coolers generally consume less energy at lower cooling loads, making them ideal for compact applications where space is limited and efficiency is paramount. However, when tasked with larger cooling demands, compressor-based coolers often outperform their Peltier counterparts due to their ability to manage higher heat loads more effectively.

In real-world scenarios, the efficiency of Peltier systems can vary significantly based on design and application. For instance, a well-designed Peltier cooling system may rival or even exceed the performance of a Compressor-Based Cooler under specific conditions. However, as cooling demands increase or environments become harsher, traditional compressors tend to shine brighter in terms of overall energy usage.

Ultimately, choosing between these two technologies often boils down to specific needs and circumstances. While both have unique advantages, understanding how they stack up against each other in terms of energy consumption will guide you toward selecting the most suitable option for your situation.

Sustainability of Peltier Systems

When discussing sustainability in thermoelectric cooling vs compressor systems, it’s essential to recognize that Peltier technology has some inherent eco-friendly advantages. These systems do not rely on refrigerants that can contribute to greenhouse gas emissions; instead, they utilize electricity directly for cooling purposes. This characteristic makes them particularly appealing from an environmental standpoint.

Moreover, advancements in materials science are enhancing the sustainability of Peltier cooler designs by improving thermoelectric materials' efficiency and reducing waste during production processes. As manufacturers focus on developing greener solutions within this space, we can expect even more eco-friendly innovations that align with global sustainability goals.

However, it's also important to consider that while Peltier systems are generally more sustainable at smaller scales or lower capacities, they may struggle with larger applications where compressors still dominate due to their superior capacity for heat management. Thus, while evaluating sustainability factors like longevity and recyclability becomes crucial when comparing these two technologies.

RIGID's Commitment to Eco-Friendly Practices

RIGID has taken significant strides toward promoting eco-friendly practices within its product lines by focusing on both energy-efficient designs and sustainable manufacturing processes. By integrating advanced thermal management solutions into its Compressor-Based Cooler offerings alongside innovative Peltier cooling designs, RIGID exemplifies a commitment to minimizing environmental impact across various industries.

The company actively seeks out sustainable materials and adheres strictly to regulations governing environmentally friendly production methods—demonstrating that profitability does not need to come at the expense of our planet's health. Furthermore, RIGID continuously invests in research aimed at improving both types of cooling technologies while ensuring they remain accessible and efficient for consumers seeking greener alternatives.

In conclusion, whether you lean towards a peltier cooler or prefer compressor technology depends significantly on your specific needs regarding environmental impact and performance requirements—both options have roles worth considering as we navigate future trends in cooling solutions together.

Conclusion

In the ongoing debate of Peltier vs compressor technologies, it’s clear that both systems have unique strengths and weaknesses. While Peltier coolers offer compact designs and energy-efficient solutions for smaller applications, compressor-based coolers dominate in larger industrial settings where high cooling power is necessary. Ultimately, the choice between these two cooling methods hinges on specific needs, application areas, and environmental considerations.

Final Thoughts on Peltier vs Compressor

When considering Peltier vs compressor systems, one must weigh factors like efficiency, size constraints, and operational costs. Peltier efficiency shines in scenarios where space is limited and energy consumption needs to be kept low. On the other hand, compressor-based cooling excels in environments requiring robust performance over extended periods.

Making an Informed Choice for Cooling Systems

Choosing between a Peltier cooler and a compressor-based cooler isn’t just about immediate needs; it’s also about long-term implications. Understanding the nuances of Peltier cooling design can help you identify if such a system aligns with your goals or if a more traditional approach might serve better in terms of durability and capacity. By analyzing your specific requirements—whether it’s for home use or industrial applications—you can make an informed decision that balances performance with cost-effectiveness.

Future Trends in Cooling Technologies

As we look ahead at future trends in cooling technologies, both thermoelectric cooling vs compressor systems are expected to evolve significantly. Innovations in materials and design will likely enhance the efficiency of both types of systems while reducing their environmental impact. The growing emphasis on sustainability will push manufacturers like RIGID to refine their offerings further—ensuring that whether you opt for a Peltier or compressor solution, you’re making a choice that benefits not just your needs but also our planet.