Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

In an era where environmental consciousness is at the forefront, the need for greening compressor cooling has never been more pressing. The refrigeration industry is responsible for a significant portion of greenhouse gas emissions, prompting a shift towards sustainable practices and technologies. By embracing greener alternatives, we can reduce our carbon footprint while still meeting the demands of modern cooling systems.

The Need for Greening Compressor Cooling

The growing awareness of climate change and its impacts has necessitated urgent action in various sectors, including refrigeration. Traditional refrigerants often have high Global Warming Potential (GWP), contributing to atmospheric warming and environmental degradation. To address this challenge, industries must focus on greening compressor cooling through innovative technologies that minimize harmful emissions while maintaining efficiency.

The Role of Green Gases in Refrigeration

Green gases play a pivotal role in transforming refrigeration practices by offering effective alternatives to conventional refrigerants. These substances are designed to have low GWP, making them more environmentally friendly choices for compressor cooling systems. As businesses increasingly adopt these green gases, they not only comply with regulations but also enhance their sustainability credentials.

Understanding Global Warming Potential of Refrigerants

Understanding the Global Warming Potential (GWP) of refrigerant gases is critical for evaluating their environmental impact. GWP measures how much heat a greenhouse gas traps in the atmosphere over a specified time compared to carbon dioxide; thus, selecting low-GWP options is essential for greening compressor cooling efforts. By prioritizing refrigerants with lower GWP values, companies can significantly contribute to global climate goals while enjoying operational efficiencies.

Key Technologies for Compressor Cooling with Green Gases

In the quest for greening compressor cooling, innovative technologies are transforming the refrigeration landscape. These advancements not only reduce the environmental impact of cooling systems but also enhance their efficiency and performance. By focusing on key technologies for compressor cooling with green gases, companies can significantly lower their Global Warming Potential (GWP) while meeting the demands of modern applications.

Advances in Refrigeration Technology

Refrigeration technology has witnessed remarkable advancements aimed at reducing reliance on traditional refrigerants with high GWP. New systems utilize low-GWP refrigerants that are both effective and environmentally friendly, paving the way for sustainable cooling solutions. Furthermore, these innovations improve energy efficiency, which is crucial in minimizing the overall carbon footprint associated with compressor power supply.

The integration of smart technology into refrigeration systems has also played a pivotal role in optimizing performance. With advanced sensors and data analytics, these systems can adapt to varying load conditions and external temperatures, ensuring optimal energy usage at all times. This not only contributes to greening compressor cooling but also enhances system longevity and reliability.

Innovations by RIGID in Compact Cooling Systems

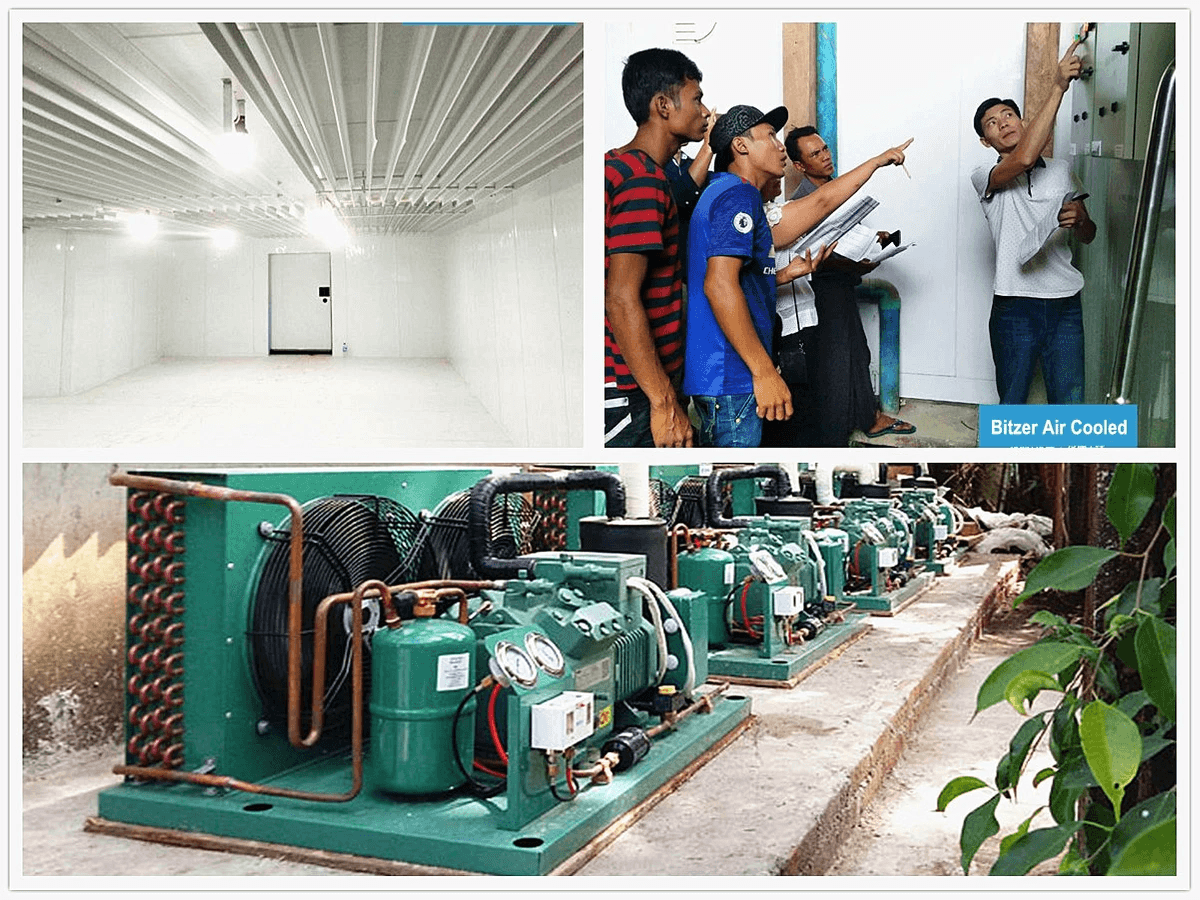

RIGID has been at the forefront of developing compact cooling systems that prioritize both size and sustainability—an essential combination in today’s market. Their innovative designs utilize cutting-edge materials and engineering principles to create highly efficient compressors that consume less energy while delivering superior performance. This focus on compactness aligns perfectly with global efforts toward greening compressor cooling initiatives.

Additionally, RIGID's commitment to integrating low-GWP refrigerants into their products showcases their dedication to reducing environmental impact without compromising effectiveness. By designing systems that are both space-efficient and environmentally responsible, RIGID sets a benchmark for other manufacturers aiming to innovate within this sector. Their contributions demonstrate how combining compactness and sustainability can lead to significant advancements in refrigeration technology.

Sustainable Materials in Compressor Design

The use of sustainable materials is an essential aspect of modern compressor design aimed at enhancing efficiency while minimizing environmental harm. By selecting recyclable or biodegradable components, manufacturers can significantly lower the ecological footprint associated with production and disposal processes of compressors used in greening compressor cooling applications. This thoughtful approach not only helps reduce waste but also aligns with broader sustainability goals across industries.

Moreover, incorporating sustainable materials often leads to improved thermal conductivity and durability within compressor units, further enhancing performance metrics such as energy efficiency and lifespan—key factors when considering compressor power supply dynamics as well as overall system effectiveness. As companies increasingly prioritize eco-friendly practices, adopting sustainable materials becomes a competitive advantage that resonates well with consumers who value corporate responsibility.

In conclusion, leveraging key technologies for compressor cooling with green gases is vital for achieving a more sustainable future in refrigeration practices worldwide. By embracing advances in refrigeration technology, innovations from leading companies like RIGID, and prioritizing sustainable materials in design processes, stakeholders can contribute significantly toward lowering GWP while ensuring efficient operations across diverse applications.

Combining Compactness and Sustainability

In the quest for greening compressor cooling, achieving a balance between compactness and sustainability is crucial. As industries strive to reduce their carbon footprints, the demand for smaller, more efficient cooling systems has skyrocketed. The challenge lies in ensuring that these compact designs do not compromise environmental integrity or energy efficiency.

The Balance of Size and Environmental Impact

When designing refrigeration systems, the size of the compressor plays a pivotal role in determining its overall environmental impact. Smaller systems often utilize less energy, thereby reducing their Global Warming Potential (GWP) when using green gases as refrigerants. However, compressing technology into a smaller footprint must be done thoughtfully to avoid sacrificing performance or safety measures associated with sustainable refrigerants.

Moreover, optimizing compressor power supply dynamics is essential for maintaining efficiency while minimizing waste. This involves integrating advanced technologies that enhance energy efficiency without enlarging equipment size. By finding this delicate balance between compactness and environmental responsibility, companies can contribute significantly to greening compressor cooling efforts.

RIGID's Approach to Efficient Design

RIGID stands at the forefront of innovations in compressor design that prioritize both compactness and sustainability. Their approach involves utilizing cutting-edge materials and manufacturing techniques that minimize waste while maximizing performance. By focusing on lightweight yet durable components, RIGID ensures that their systems are not only efficient but also environmentally friendly.

Additionally, RIGID's commitment to incorporating green gases with low GWP into their products reinforces their dedication to sustainable refrigeration solutions. Their designs emphasize energy-efficient operations that align with modern standards for safety measures in air cargo applications involving sustainable refrigerants. This strategic alignment enables RIGID to lead the way in greening compressor cooling while setting benchmarks for others in the industry.

Case Studies on Miniature Cooling Systems

Examining case studies of miniature cooling systems sheds light on successful implementations of compact yet sustainable technology in real-world scenarios. One notable example is a portable refrigeration unit developed by RIGID specifically for medical transport, which utilizes green gases with low GWP while maintaining an impressively small profile. This system not only meets stringent safety measures but also highlights how innovation can effectively address both size constraints and environmental concerns.

Another case study involves a food preservation solution designed for remote locations where traditional power sources are scarce; it integrates renewable energy sources alongside its compact design principles to ensure optimal operation without excessive emissions or waste generation. These examples illustrate how combining compactness and sustainability can yield practical solutions that contribute positively towards greening compressor cooling initiatives across various sectors.

Through these endeavors, RIGID continues to pave the way toward a future where refrigeration technology not only meets market demands but also aligns with global sustainability goals—truly embodying what it means to be at the intersection of innovation and environmental responsibility.

Compressor Power Supply Dynamics

In the quest for greening compressor cooling, understanding the dynamics of compressor power supply is crucial. The efficiency of refrigeration systems not only impacts energy consumption but also plays a significant role in reducing the Global Warming Potential (GWP) of refrigerant gases. By optimizing power supply strategies, we can enhance sustainability while maintaining performance.

Energy Efficiency in Refrigeration Systems

Energy efficiency is the cornerstone of modern refrigeration systems, particularly when it comes to greening compressor cooling. Advanced technologies such as variable speed drives and high-efficiency compressors have emerged, allowing systems to operate at optimal levels while consuming less energy. This not only reduces operational costs but also minimizes the environmental impact associated with traditional refrigerants that have high GWP.

Moreover, energy-efficient designs help in mitigating climate change by lowering greenhouse gas emissions from refrigeration units. By focusing on improving energy efficiency across various applications, companies can significantly contribute to a more sustainable future in compressor cooling technology. The integration of these advancements aligns perfectly with the broader goal of combining compactness and sustainability in refrigeration solutions.

Integration of Renewable Energy Sources

The integration of renewable energy sources into compressor power supply systems represents a significant leap forward for greening compressor cooling initiatives. Solar panels, wind turbines, and other renewable technologies can provide clean energy to power refrigeration units, drastically reducing reliance on fossil fuels and minimizing their carbon footprint. This shift not only enhances the sustainability profile of refrigeration systems but also ensures that they operate efficiently without contributing to global warming.

As renewable energy technologies continue to advance and become more accessible, their incorporation into compressor power supplies will likely become standard practice in many industries. Companies like RIGID are already exploring innovative ways to harness these green energies for their compact cooling solutions, further solidifying their commitment to environmentally friendly practices. The synergy between renewable sources and advanced refrigeration technology paves the way for a more sustainable future.

The Future of Compressor Power Solutions

Looking ahead, the future of compressor power solutions promises exciting developments aimed at enhancing both efficiency and sustainability in greening compressor cooling efforts. Emerging technologies such as smart grids and AI-driven analytics are set to revolutionize how we manage energy consumption within refrigeration systems by optimizing performance based on real-time data analysis. Such advancements will enable companies to make informed decisions regarding their energy use while minimizing waste.

Additionally, ongoing research into alternative refrigerants with lower GWP will play a pivotal role in shaping the next generation of compressors that are both powerful and eco-friendly. As industries adapt to stricter regulations surrounding refrigerant use and environmental impact, embracing innovative power supply solutions will be essential for compliance as well as competitiveness in the market landscape focused on sustainable practices.

The combination of these trends heralds an era where greening compressor cooling is not just an aspiration but a reality that benefits both businesses and our planet alike.

Safety Measures and Air Cargo with Sustainable Refrigerants

In the pursuit of greening compressor cooling technologies, safety measures become paramount, especially when dealing with sustainable refrigerants. The transition to green gases, while beneficial for the environment, introduces various risks that must be thoroughly understood and mitigated. Awareness of these risks is essential for ensuring safe operations in air cargo and refrigeration systems.

Understanding the Risks of Green Gases

Green gases may significantly lower the Global Warming Potential (GWP) of refrigerant gases compared to their traditional counterparts, but they are not without their hazards. Some green refrigerants can be flammable or toxic at certain concentrations, making it crucial to understand their properties before use. Additionally, improper handling can lead to leaks or accidents that jeopardize both personnel safety and environmental integrity.

Protocols for Safe Handling and Transportation

To ensure safe handling and transportation of sustainable refrigerants, robust protocols must be established. This includes training personnel on the specific characteristics of each refrigerant used in greening compressor cooling applications. Furthermore, implementing strict guidelines for storage conditions—such as temperature controls and leak detection systems—can minimize risks associated with transporting these substances in air cargo operations.

Best Practices for Air Cargo Operations

Air cargo operations involving sustainable refrigerants require adherence to best practices that prioritize safety while maintaining efficiency. This includes using specially designed containers that are compatible with green gases and ensuring proper labeling to inform handlers of potential hazards. Regular audits and compliance checks should also be conducted to align with evolving regulations surrounding the use of sustainable materials in compressor power supply systems.

Navigating Regulatory Challenges

The landscape of refrigerant use is constantly evolving, and navigating the regulatory challenges associated with greening compressor cooling can be daunting. Governments worldwide are implementing stricter regulations to mitigate the impact of refrigerants on global warming potential (GWP). Companies in the refrigeration industry must stay informed about these regulations to ensure compliance while embracing Key Technologies for Compressor Cooling with Green Gases.

Global Regulations on Refrigerant Use

Global regulations surrounding refrigerant use are becoming increasingly stringent as awareness of climate change rises. The Montreal Protocol and its amendments have set a precedent for phasing out high-GWP gases, pushing industries towards greener alternatives. This shift not only encourages the adoption of sustainable practices but also aligns with the goals of combining compactness and sustainability in refrigeration technology.

The Impact of Policy Changes on the Industry

Recent policy changes have had a significant impact on how companies approach compressor power supply dynamics and their overall operational strategies. For instance, stricter limits on GWP have led many manufacturers to invest heavily in research and development to create innovative systems that utilize low-GWP refrigerants. As a result, businesses that adapt quickly to these changes not only comply with regulations but also gain a competitive edge in an increasingly eco-conscious market.

Compliance Strategies for Companies

To effectively navigate regulatory challenges, companies must adopt proactive compliance strategies that align with global standards while promoting greening compressor cooling initiatives. This includes conducting regular audits of their refrigeration systems to ensure they meet current regulations and investing in training programs for employees on safety measures related to sustainable refrigerants. By fostering a culture of compliance and innovation, organizations can successfully balance their operational needs with environmental responsibilities.

Conclusion

In the rapidly evolving landscape of refrigeration, embracing sustainable practices is no longer just an option; it’s a necessity. As we have explored throughout this discussion, greening compressor cooling through the adoption of innovative technologies and sustainable materials positions the industry for a brighter, more environmentally friendly future. By prioritizing eco-conscious approaches, we can mitigate the detrimental effects of traditional refrigerants and contribute to global efforts against climate change.

Embracing the Future of Refrigeration

The future of refrigeration lies in our ability to adapt and innovate while reducing our carbon footprint. Key technologies for compressor cooling with green gases are paving the way for systems that not only perform efficiently but also align with environmental standards. By understanding and addressing the Global Warming Potential (GWP) of refrigerant gases, we can implement solutions that prioritize both performance and sustainability.

The Competitive Edge of Sustainable Cooling

Businesses that integrate sustainable cooling solutions gain a competitive edge in today’s eco-conscious market. Combining compactness and sustainability allows companies to offer products that meet consumer demands without compromising on efficiency or environmental responsibility. As energy efficiency becomes increasingly important, organizations focusing on these principles will likely outperform their competitors who cling to outdated practices.

RIGID's Contribution to Greening Compressor Cooling

RIGID stands at the forefront of this transformation by championing innovations in compressor design and power supply dynamics. Their commitment to safety measures and air cargo with sustainable refrigerants demonstrates a holistic approach to greening compressor cooling while ensuring compliance with global regulations. With RIGID leading by example, other companies are encouraged to adopt similar strategies that emphasize sustainability as both a business imperative and an ethical obligation.