Introduction

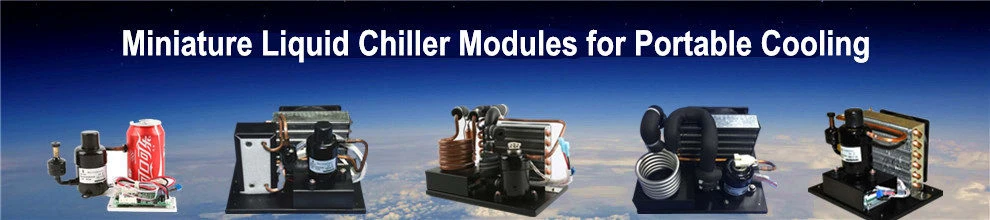

Are you seeking a compact and efficient cooling solution for your needs? Look no further than the innovative world of micro chillers. These small liquid chillers, also known as mini chiller units or miniature cooling systems, are designed to provide powerful cooling in a compact package. Whether you need a mini chiller system for industrial applications or a micro cooling unit for personal use, micro chillers offer the perfect balance of size and performance.

What is a Microchiller?

A micro chiller is a small liquid chiller designed to provide efficient and reliable cooling in a compact package. These mini cooling systems are ideal for applications where space is limited but powerful cooling is essential. With advanced technology and precision engineering, micro chillers deliver exceptional performance while taking up minimal space.

The Benefits of Efficient Cooling Solutions

Efficient cooling solutions provide a range of significant benefits that can enhance both operational performance and environmental responsibility. Here’s a closer look at these advantages:

- Reduced Energy Consumption: Efficient cooling systems are designed to use less energy while delivering the same level of cooling power. This results in lower energy bills and a more cost-effective cooling solution.

- Lower Operating Costs: By consuming less energy and often requiring less maintenance, efficient cooling solutions help reduce overall operating costs. This is particularly beneficial for businesses and residential users seeking to minimize long-term expenses.

- Improved Environmental Sustainability: Efficient cooling solutions contribute to environmental sustainability by lowering greenhouse gas emissions and reducing the overall carbon footprint. This is achieved through reduced energy consumption and environmentally friendly refrigerants.

- Enhanced Cooling Performance: Systems like small chiller units are designed to deliver maximum cooling power with minimal energy usage. This ensures that optimal temperatures are maintained effectively without compromising efficiency.

- Increased Reliability: Efficient systems often incorporate advanced technology and engineering, improving reliability and performance. This means fewer breakdowns and a more consistent cooling experience.

Adopting efficient cooling solutions reduces energy consumption and operating costs, supports environmental sustainability, and enhances overall system performance. Small chiller units, in particular, offer a powerful and eco-friendly option for effective cooling with minimal energy use.

Why RIGID is Your Ultimate Cooling Partner

When it comes to finding the perfect micro chiller for your needs, RIGID is the ultimate partner you can trust. With their expertise in mini compressors and small chillers, direct cooling, and micro DC aircon technology, RIGID offers a wide range of innovative miniature cooling systems to meet any requirement. Their dedication to custom-made refrigeration solutions ensures that every client receives the perfect solution tailored to their specific needs.

Understanding Microchillers

Microchillers are compact cooling systems that provide efficient and reliable cooling in small spaces. These small liquid chillers circulate a coolant through a closed loop, absorbing heat from the surrounding environment and dissipating it elsewhere. This process allows micro chillers to maintain a consistent temperature, making them ideal for various applications.

How Microchillers Work

Microchillers operate using a small chiller unit that contains a compressor, condenser, expansion valve, and evaporator. The compressor pressurizes the refrigerant gas, which then flows to the condenser, releasing heat and turning into a liquid. The liquid refrigerant passes through the expansion valve, causing it to expand and cool down before entering the evaporator to absorb heat from the target area. Finally, the refrigerant returns to the compressor to complete the cycle.

Microchillers are an efficient and cost-effective way to cool small spaces or specific areas within a larger facility. Their compact size makes them easy to install and maintain, saving space and resources. Additionally, they offer precise temperature control, allowing for optimal cooling in targeted areas without affecting the overall temperature of the surrounding environment. This level of control can lead to energy savings and improved comfort for occupants.

Advantages of Using Small Liquid Chillers

Small liquid chillers offer numerous advantages compared to traditional cooling systems, making them an appealing choice for various applications. Here are some key benefits:

- Compact Size: Small liquid chillers' smaller footprint makes them ideal for space-constrained environments. Their compact design allows them to fit into areas where larger systems might be impractical.

- Energy Efficiency: These chillers are designed to operate with high energy efficiency, helping to lower operating costs and reduce overall energy consumption.

- Precise Temperature Control: Small liquid chillers provide accurate and consistent temperature control, which is crucial for applications requiring precise cooling to maintain optimal conditions.

- Quiet Operation: They are engineered for quiet performance, making them suitable for environments where noise levels are a concern, such as office spaces or laboratories.

- Easy Installation and Minimal Maintenance: Small liquid chillers are typically straightforward to install and require minimal maintenance. This ease of use translates to time and cost savings for businesses.

- Modular Design and Scalability: Small liquid chillers' modular nature allows for easy expansion. Additional units can be added as cooling needs grow, offering a flexible and scalable solution without major infrastructure changes.

Small liquid chillers offer a combination of space efficiency, energy savings, precise control, quiet operation, ease of installation, and scalability. These advantages make them a cost-effective and versatile choice for businesses seeking effective cooling solutions while accommodating future growth.

Applications of Miniature Cooling Systems

Miniature cooling systems are used in various industries, such as electronics cooling, medical equipment cooling, laser systems cooling, and more. Their ability to provide targeted and reliable cooling makes them indispensable in maintaining optimal operating conditions for sensitive equipment and processes.

Remember that RIGID specializes in providing innovative miniature cooling solutions like micro DC air conditioners and racing coolers that cater specifically to micro refrigeration and air conditioning needs. With RIGID's expertise in custom-made refrigeration solutions and commitment to client collaboration, you can trust us as your ultimate partner for all your micro chiller requirements!

The Ultimate Guide to Microchiller Maintenance

Tips for Maximizing Efficiency

To ensure your microchiller operates at peak efficiency, consider these practical tips:

1. Regular Cleaning and Maintenance

- Clean Coils: Keep the condenser and evaporator coils clean to promote optimal heat transfer. Accumulated dirt and debris can reduce efficiency and increase energy consumption.

- Check for Leaks: Regularly inspect the system for any leaks and ensure refrigerant levels are adequate. Addressing leaks promptly helps maintain performance and prevents further damage.

2. Monitor Airflow

- Ensure Unobstructed Airflow: Check to make sure no obstructions are blocking the airflow around your micro chiller. Blocked airflow can hinder performance and reduce cooling efficiency.

- Maintain Proper Ventilation: Ensure the area around the chiller is well-ventilated and free from any potential blockages. Proper ventilation is crucial for effective heat dissipation and system efficiency.

3. Regular System Checks

- Inspect Components: Periodically check all components for signs of wear or malfunction. Regular inspections help identify potential issues early and prevent unexpected breakdowns.

- Optimize Settings: Adjust system settings according to operational needs and environmental conditions to ensure efficient performance.

4. Professional Servicing

- Schedule Professional Maintenance: Arrange for routine maintenance by a qualified technician to ensure all aspects of the microchiller are functioning correctly. Professional servicing can enhance the longevity and efficiency of your system.

By following these tips—maintaining clean coils, monitoring airflow, conducting regular system checks, and scheduling professional servicing—you can maximize the efficiency of your microchiller and ensure it operates reliably and effectively.

Common Issues and Troubleshooting

Common issues with small chiller units may include inadequate cooling, unusual noises, or system malfunctions. If you encounter any of these issues, it's important to troubleshoot immediately. Check for blockages in the system, inspect the electrical connections, and ensure that all components are functioning properly.

If you cannot identify and resolve the issues with your small chiller unit, it is essential to seek professional servicing. Regular maintenance and check-ups by qualified technicians can help prevent potential problems and ensure the efficient operation of your chiller unit. By scheduling routine servicing, you can extend the lifespan of your equipment and avoid costly repairs in the future.

Importance of Regular Servicing

Regular servicing of your miniature cooling system is crucial for its longevity and performance. Schedule routine maintenance checks to inspect all components, replace worn-out parts, and ensure the system runs at its optimal capacity. By investing in regular servicing, you can prevent costly repairs and extend the lifespan of your micro cooling unit.

Choosing the Right Microchiller for Your Needs

When selecting a mini chiller unit, several crucial factors must be considered. The size and capacity of the small liquid chiller should match your cooling requirements. Additionally, it's important to assess the miniature cooling system's energy efficiency and noise levels to ensure they align with your needs.

Factors to Consider When Selecting a Mini Chiller Unit

When selecting a mini chiller unit, several critical factors should be considered to ensure you choose the right system. Here’s a comprehensive guide to making an informed decision:

1. Cooling Capacity:

- Determine Needs: Accurately assess the cooling power required for your specific application. Selecting a unit with the appropriate cooling capacity ensures effective performance and prevents system overworking.

2. Energy Efficiency:

- Evaluate Efficiency Ratings: Look for a mini chiller with high energy efficiency ratings. A more efficient unit will save costs over time by reducing energy consumption.

3. Noise Levels:

- Consider Operating Environment: If the mini chiller is used in a noise-sensitive environment, such as an office or laboratory, choose a model with lower noise levels to maintain a comfortable atmosphere.

4. Size and Installation Requirements:

- Check Space Constraints: Ensure the mini chiller unit fits within the available space, considering any physical size restrictions or layout considerations.

- Ease of Installation: Consider the installation requirements, including any special setup needs or complexities. Opt for a unit that simplifies the installation process and fits seamlessly into your existing infrastructure.

5. Maintenance and Serviceability:

- Access to Maintenance: Choose a mini chiller that is easy to maintain and service. Check for accessibility of key components and availability of replacement parts to ensure ongoing reliability.

6. Cost of Ownership:

- Total Cost Analysis: Factor in the initial purchase price and long-term operational costs. A more expensive unit might offer better efficiency and lower operating costs, providing better value over time.

By thoroughly evaluating these factors—cooling capacity, energy efficiency, noise levels, size and installation requirements, maintenance needs, and total cost of ownership—you can select a mini chiller unit that meets your needs effectively and efficiently.

Custom-Made Refrigeration Solutions from RIGID

RIGID offers custom-made refrigeration solutions tailored to meet your unique needs. Whether you require a small chiller unit with specific dimensions or specialized features, RIGID can work with you to design and manufacture a miniature cooling system that perfectly fits your requirements.

RIGID understands that every industry has unique refrigeration needs, so we are committed to providing customized solutions that cater to your specific requirements. Whether you need a compact cooling unit for a medical device or a specialized chiller for a beverage dispenser, RIGID has the expertise to design and manufacture the perfect refrigeration system for your application. Our team will work closely with you to ensure the final product meets your specifications and delivers optimal performance.

Meeting Specific Requirements with Micro Cooling Units

RIGID specializes in meeting specific requirements with its micro cooling units. Whether you need a mini water chiller for industrial applications or a small liquid chiller for medical equipment, RIGID has the expertise and capabilities to deliver customized solutions that precisely meet your needs.

RIGID's custom-made microchillers are designed to enhance your cooling efficiency and optimize the performance of your equipment. With a focus on precision and reliability, our micro cooling units are tailored to meet the specific requirements of your industrial or medical applications. By partnering with RIGID, you can be confident that you will receive a high-quality, custom solution that exceeds your expectations.

RIGID's Innovative Cooling Solutions

RIGID is at the forefront of innovative cooling solutions, offering a range of cutting-edge products to meet clients' diverse needs. Our Mini Compressor Technology is a game-changer in the industry, providing powerful and efficient cooling in a compact and versatile package. Whether it's for small liquid chillers or miniature cooling systems, our mini compressor technology delivers exceptional performance and reliability.

RIGID's commitment to innovation doesn't stop at our Mini Compressor Technology. We also offer a range of advanced control systems that allow for precise and efficient cooling process management. Our smart control solutions enable clients to optimize energy usage, monitor performance, and ensure the longevity of their cooling systems. With RIGID's cutting-edge control technology, clients can have peace of mind knowing that their cooling needs are being met with the highest efficiency and reliability.

RIGID's Mini Compressor Technology

Our mini compressors are also designed with low noise levels in mind, making them suitable for use in noise-sensitive environments such as offices or residential buildings. This feature ensures that the cooling system operates quietly and does not disrupt the surrounding environment, providing occupants a comfortable and peaceful atmosphere. Additionally, the compact design of our mini compressors allows for easy installation in tight spaces, making them an ideal choice for applications where space is limited.

Direct Cooling with Micro DC Aircon

RIGID's Micro DC Aircon provides direct cooling for microchillers and mini chiller systems, delivering efficient and reliable temperature control in confined spaces. This innovative solution is perfect for applications where traditional air conditioning units are not feasible, offering precise cooling for small liquid chillers and miniature cooling systems. With its compact design and powerful performance, Micro DC Aircon is an ideal choice for micro refrigeration and air conditioning.

Furthermore, RIGID's Micro DC Aircon is designed to be energy efficient, helping to reduce operating costs and environmental impact. Its advanced technology allows for precise temperature control, ensuring that microchillers and mini chiller systems can operate at optimal levels without wasting energy. This makes it an ideal choice for businesses looking to minimize their carbon footprint while maintaining reliable equipment cooling.

RIGID's Racing Coolers and Mini Water Chillers

For specialized requirements such as racing coolers or mini water chillers, RIGID offers custom-made refrigeration solutions that deliver exceptional performance in demanding environments. Our racing coolers are designed to withstand extreme conditions while providing reliable cooling for high-performance applications. Likewise, our mini water chillers offer efficient temperature control in compact settings, making them ideal for various microchiller applications.

In addition to their exceptional performance, RIGID's racing coolers and mini water chillers are also known for their durability and reliability. Our custom-made refrigeration solutions are built to last, ensuring they can withstand the rigors of demanding environments without compromising on cooling efficiency. Whether for high-performance racing applications or compact microchiller setups, our products are designed to deliver consistent and precise temperature control, making them the top choice for specialized cooling requirements.

Boosting Competitiveness with Efficient Cooling

RIGID understands the importance of staying competitive in today's fast-paced market, so we offer cutting-edge microchiller solutions to help our clients gain an edge. Our small liquid chillers and mini cooling systems are designed to maximize efficiency while minimizing costs, allowing businesses to stay ahead of the curve.

How RIGID Helps Clients Stay Competitive

With our innovative microchiller technology, RIGID empowers clients to achieve optimal cooling performance without breaking the bank. Our small chiller units and miniature cooling systems are engineered to deliver superior results, giving businesses the advantage they need to outshine their competitors.

Tailoring Solutions to Fit Clients' Budgets

At RIGID, we understand that every business operates within a specific budget. That's why we offer tailored solutions to fit our client's financial constraints without compromising on quality or performance. Our mini chiller systems are designed with cost-effectiveness in mind, ensuring that businesses can achieve efficient cooling without overspending.

Collaboration with Clients for Custom-Made Refrigeration

One key way RIGID boosts competitiveness is through collaboration with clients for custom-made refrigeration solutions. We work closely with businesses to understand their unique needs and requirements, then develop bespoke microchiller systems that address those specific challenges. This collaborative approach ensures that our clients access cutting-edge cooling technology that gives them a competitive advantage.

Take Control of Your Cooling Needs with RIGID

At RIGID, we understand the importance of efficient cooling solutions, so we offer a range of innovative microchillers and small chiller units to meet your specific needs. Whether you're looking for a miniature cooling system, mini chiller system, or small liquid chiller, RIGID covers you with our custom-made refrigeration solutions. Our focus on boosting competitiveness and collaboration with clients ensures that you can confidently take control of your cooling needs.

Enhance Your Cooling Efficiency with RIGID

RIGID's cutting-edge technology in micro chillers and small liquid chillers is designed to enhance cooling efficiency. Our mini compressor technology and direct cooling with micro DC aircon provide superior performance in a compact size, making them ideal for a wide range of applications. With RIGID, you can trust that our innovative solutions will keep your systems running smoothly.

RIGID: Your Trusted Partner for Microchillers

As your trusted partner for microchillers and miniature cooling systems, RIGID is committed to delivering high-quality products that meet your requirements. Our racing coolers and mini water chillers are just a few examples of our innovative solutions for ensuring optimal performance in micro refrigeration and air conditioning applications.

With RIGID as your ultimate cooling partner, you can confidently take control of your cooling needs. Our team works directly with clients to provide custom-made refrigeration solutions tailored to fit their budgets and boost their competitiveness in the market. Trust RIGID to deliver reliable and efficient micro chillers that exceed expectations.