Liquid Nitrogen Generator Stirling Cooler Setup

RIGID R&D team is currently approaching the fulfillment of one of the company's long-standing ambitions, which is to create a cryocooler device capable of producing liquid nitrogen from ambient air. The reason for this ambition comes from the demand of customers and market. The approach RIGID engineers took to achieve this goal is described below.

Assuming you are reading this on Earth, the composition of the atmosphere is approximately 78% nitrogen, 21% oxygen, and 1% argon and other gases. By cooling the air to a temperature range between 77 K (the boiling point of nitrogen) and 90 K (the boiling point of oxygen), the air will begin to condense into a liquid mixture of nitrogen and oxygen. After 3 years of unremitting effort, RIGID technology has developed an excellent piece of thermodynamic equipment known as a Stirling cycle cryocooler RS100 Pro K77 (-196℃).

* The Picture below is Complete Kit Stirling Cryocooler- RS100 Pro K77.

The new developed Stirling cycle refrigerator, also known as a cryocooler, which can reduce the temperature of an object to approximately 77 Kelvin, or -196℃ degrees Celcius (-320℉ degrees Fahrenheit) below zero. Use safe and environmentally friendly oxygen as the refrigerating medium, internationally advanced free piston Stirling technology, wide humidity zone, accurate temperature control of ±0.1℃, small size and easy to carry, very suitable for miniaturized deep-low temperature transportation applications.

This Cryocooler RS100 Pro K77 uses helium as the refrigeration medium, so it is a green product. It is small in size, light in weight, and easy to carry. It is widely used in fields that require precise temperature control.

Furthermore, The Stirling Cycle is a noteworthy mechanism due to its closed cycle nature, whereby the internal working gas (helium) of the Cryogenerator does not come into direct contact with the fluid to be cooled, but only through the heat flow via the heat-exchanger wall.

This approach effectively prevents the contamination of both the customer's process and the working gas of Stirling Cycle, culminating in sustained operating periods and prolonged service life.

Free Piston Stirling Cryocooler Working Process

RIGID Stirling cryocooler is a type of ULTRA-LOW temperature refrigeration system. It uses a piston and a displacer to compress and expand Helium gas to cool an object. The Stirling cryocooler consists of a compressor, a regenerator, a displacer, and a cold heat exchanger. The compressor compresses the helium gas and heats it.

The hot helium gas then flows through the regenerator, which is a porous material that acts as a heat exchanger. The regenerator transfers heat from the helium gas to the environment.

The cooled helium gas then flows through the displacer, which moves up and down in the cryocooler. As the displacer moves up, it pushes the cooled helium gas through the cold heat exchanger, which cools the laboratory automated equipment.

The cold helium gas then flows back through the regenerator, which absorbs heat from the environment and heats the helium gas.

The heated helium gas then flows back into the compressor and the cycle begins again.

FPSC Stirling Cryocooler Main Applications

Nowadays, FPSC (Free-Piston Stirling Cryocooler) technology is widely used to provide ultra-low temperature cooling for a variety of applications, including scientific research, medical equipment, and military systems. Some of the major applications of FPSC Stirling Cryocoolers are:

- Infrared Detectors: FPSC Stirling Cryocoolers are used to cool infrared detectors in thermal imaging cameras and other applications. Cooling the detector to cryogenic temperatures improves the sensitivity and resolution of the images produced by the detector.

- Medical applications: FPSC Stirling cryocoolers are used in medical equipment such as MRI machines and cryosurgery systems. The cryocoolers are used to cool the magnets in the MRI machines and to cool the surgical probes in the cryosurgery systems.

- Aerospace and Defense: FPSC Stirling cryocoolers are used in a variety of aerospace and defense applications, including satellite systems, missile guidance systems, and military electronics. The cryocoolers are used to cool the electronics and other components in these systems, which can improve their performance and reliability.

- Research: FPSC Stirling cryocoolers are used in scientific research applications such as superconductivity research, particle physics research, and astrophysics research. The cryocoolers are used to cool the equipment and samples used in these experiments to cryogenic temperatures.

- Lab Automatic Device: The Stirling cryocooler can achieve very low temperatures, typically in the range of 77 to100 Kelvin, making it suitable for cooling lab automatic devices that require cryogenic temperatures. It is also very efficient and can provide cooling without the need for external cooling fluids.

RIGID Stirling Cooler, which differs from a compressor, is a cooling system that continuously repeats gas compression and adiabatic expansion and uses naturally occurring helium gas as the refrigerant. Most importantly, it has the smallest footprint and very light-weight, whole system just 2.2kgs/4.85lbs.

RIGID FPSC Stirling Cryocooler Features

RIGID Stirling engine technology is breakthrough in Small and Deep Freezing. Temperature down to -99℃ in just a few minutes.

- Oil-Free, Ultra Quiet, Vibration-Free;

- Smallest & Lightest, 2.0kgs (only 1/5 weight of normal compressor);

- For liquid freezing application, 30% at least energy savings;

- For air cooled application, 50% at least energy savings;

- MagLev technology better reduce system redundancy.

Apart from Cryocooler RS100 Pro K77, RIGID also supplies Cryocooler FPSC-RS100 Plus. It adopts standard KF50 flande, which is processed by vacuum brazing equipment to ensure the effective connection between your devices or equipment and the vacuum dewar under high vacuum conditions, which broadens the application field.

Today, RIGID's FPSC Stirling Cryocoolers provide a reliable, efficient and compact solution for cooling a wide range of applications to cryogenic temperatures.

RIGID is the miniature compressor innovation leader in China. We keep looking for novel solutions in compact & portable refrigeration technology.

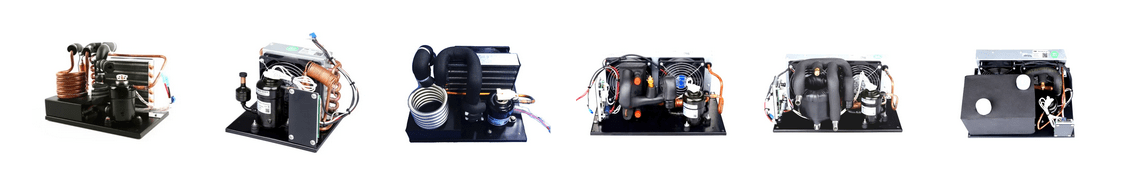

Our product lines include Mini Compressors, Air Cooling, Liquid Cooling, and Direct Refrigerant micro-cooling systems. Products are widely used in commercial, industrial, and personal refrigeration applications, and tiny liquid cycle refrigeration devices. The qualification of most products has met the technical and quality standards of Germany, the U.S., the UK, and Asian countries.

With nearly 12 years of persistent endeavors of our people, RIGID has established a whole set of management systems and has passed ISO9001:2008 International Quality Management System, and has gained CCC, CE, RoHS, and UL certificates.

Today Rigid has helped many companies and startups upgrade their devices with the latest micro cooling technology.