FPSC (Free Piston Stirling Cooler) is a new type of completely cfc-free, high efficiency, energy saving and environmental protection Cooler, which uses a small amount of helium as the coolant.

The brief mechanism is that the cylinder (fin) protruding from the main body is cooled by heat exchange, which is a process of repeated cycle of compression, and the stainless steel piston in the main body is constantly moving up and down, resulting in gas explosion.

If you want to cool an object through the FPSC, make sure the FPSC's thermal receiver is capable of heat exchanging, and the object will be cooled by the cooler through the heat exchange.

The cold part (evaporator), under the condition of 25 ℃ environment of no-load temperature, its temperature is able to reach - 80 ℃ in 2 minutes, very impressive!

There are two pistons (pistons and balancing float) in the top compression chamber, which is filled with helium gas.

The piston is driven by a linear motor, which sends helium gas to the balancing float (80 hz). The temperature difference is controlled at 80 degrees Celsius.

Above the balancing float is the expansion space, between the balancing float and the piston is the compression space, and the annular space around the balancing float is helium gas flow channel.

In the flow passage, the cold side fin is in the expansion space, while and the heat sink is in the compression space. In the middle of cold fin and heat sink is generator.

The role of the regenerator is to exchange the heat of the helium, store the heat, and transfer the heat back to the helium.

Pic. 1, Stirling Cooler Engine Working Principle

Rigid is the miniature compressor innovation leader in China. We keep looking for novel solutions in compact & portable cooling system, we are creative and capture new technologies.

Since 2016, RIGID Technology explored ultra freezing solution, mainly in order to develop free-piston Stirling cycle coolers for pharmaceutical, bio-tech and home refrigerator applications.

These systems, apart from being significantly more efficient than regular vapor-compression refrigerators, have the added advantage of:

- Ultra compact

- Light weight

- Portable

- Efficient

Free Piston Stirling Cooler use helium as the working fluid (and not the HFC refrigerants such as R134a, having a Global Warming Potential of 1,300).

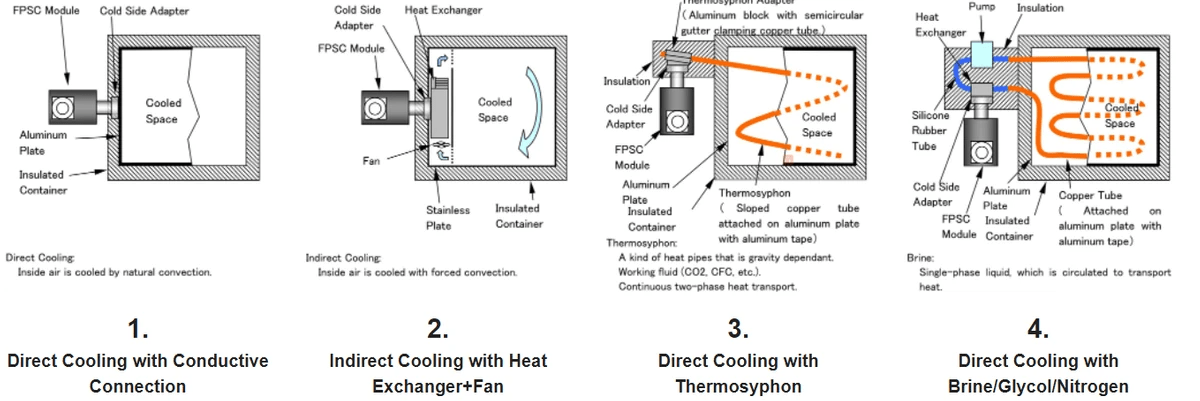

Pic. 3, A schematic diagram followed is shown below

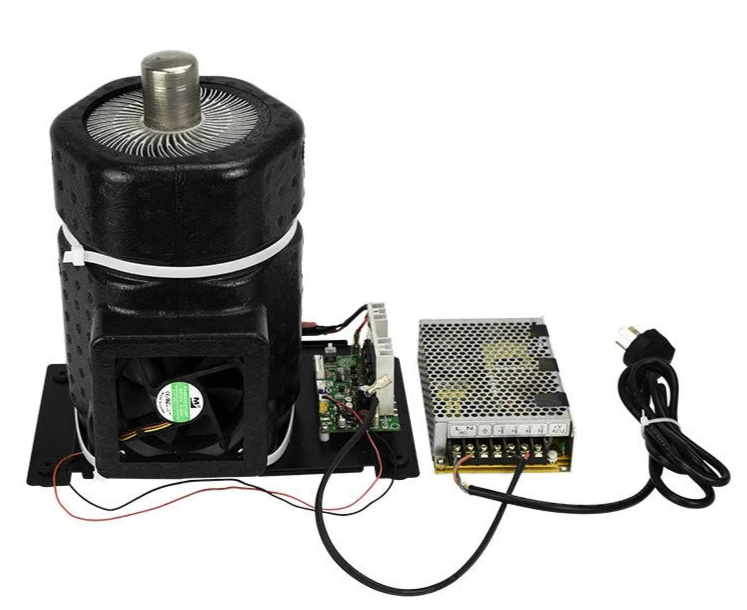

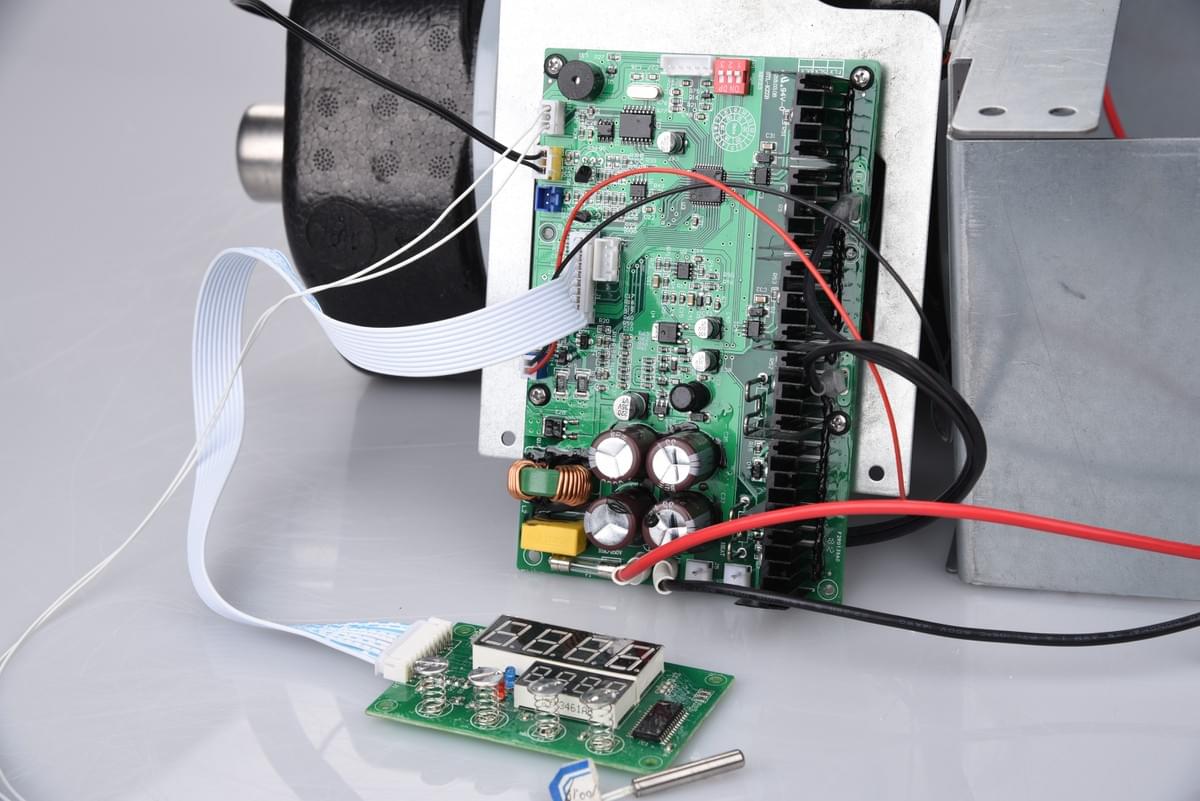

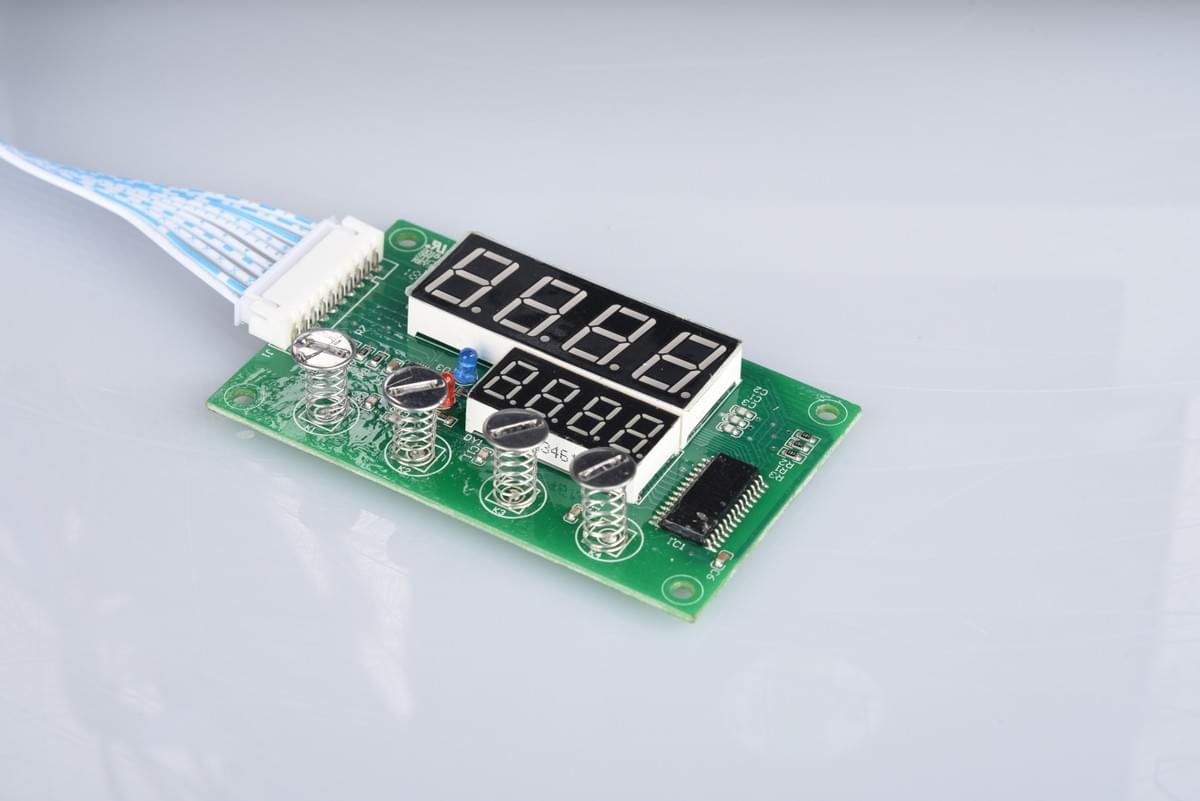

RIGID FPSC Free Piston Stirling Cooler

FPSC also is a kind of Magnetic Levitation Compressor (MagLev solution). But it is even more efficient chiller compressor, low energy cost and consumption.

FPSC offers quieter, more efficient cooling due to its ability to reduce friction, and operates at variable speeds.

FPSC is also named Stirling crycooler, its working noise is quite quiet, as low as 48dB.

This quiet operation makes Stirling crycooler ideal for sound sensitive environments, such as lab, hospital, schools, performance halls, museum etc.

Besides, micro-Stirling cryocooler can be extensively applied in many territories, like pharmaceutical, Bio-tec, electronic components, deep freezer, chemical, energy, foods and logistic etc.

It adopts helium as coolant, MagLev technology. Advantages are shown as below:

- Oil-Free, Ultra Quiet, Vibration-Free

- Smallest & Lightest, 2.0kgs (only 1/5 weight of normal compressor)

- For liquid freezing application, 30% at least energy savings

- For air cooled application, 50% at least energy savings

- MagLev technology better reduce system redundancy

It achieved energy savings of 42% compare to thermoelectric based coolers.

Since no oil is used in Stirling cooler, it eliminates additional material and labor costs, and potential joint leaks associated with oil return.

As Stirling cryocooler with two opposite pistons driven linearly, it provides typical full load performance and superior part load performance.

RIGID's Free Piston Stirling Cooler is the result of over 10 years of technical leadership, innovation and evolution in miniature dc compressor technology.

The Stirling Cooler is cost effective, low in vibration, and extremely efficient. In fact, you will not find a more efficient cryocooler on the market.

Since they require no maintenance, our customers can expect many years of high-performance, trouble-free fast cooling.

FPSC Stirling Cooler Application Principles

Application Examples

RIGID ULT Stirling Cold Solutions Are Trusted in a Variety of Applications.

RIGID Stirling Coolers not only are the most environmentally sustainable ultra-low temperature (ULT) coolers on the market, but they are also the most cost-effective with the lowest life cycle costs. You can benefit from breakthrough Stirling cooler technology without compromising cooling performance across the entire research organization with your devices or equipment.

FPSC, Free Piston Stirling Coolers, are the complete CFC free system, using natural Helium gas. It is small, portable, and it is widely used for precise temperature control for under -160℃ max.

Here's a video of RIGID FPSC beta test. It will normally reach -160°C, however since the ball of ice is covering the entire regenerator section, we notice that the temperature has risen to -114°C.