Introduction

In the ever-evolving world of HVAC technology, horizontal rotary compressors have carved out a significant niche, becoming a go-to choice for various cooling systems. These compressors offer unique advantages that set them apart from traditional options, making them particularly appealing for applications in refrigeration and heat pumps. Understanding how these machines work and where they excel can help consumers make informed decisions when considering which compressor best fits their needs.

Understanding Horizontal Rotary Compressors

Horizontal rotary compressors operate on a simple yet effective principle: they compress refrigerant using rotating elements within a cylindrical housing. This design enhances efficiency by minimizing energy loss during operation, making horizontal rotary compressors an attractive option for both residential and commercial applications. By leveraging advanced engineering techniques, these compressors achieve high performance with reduced noise levels, setting the stage for their widespread adoption.

Key Advantages for Cooling Systems

One of the standout features of horizontal rotary compressors is their compact size combined with powerful output capabilities. This makes them ideal for installations where space is at a premium but performance cannot be compromised. Additionally, they are known for their reliability and longevity, which translates to lower maintenance costs over time—an essential factor when evaluating options like Which is better, a rotary or scroll compressor?

Applications in Refrigeration and Heat Pumps

Horizontal compressors find extensive use in various applications, particularly in refrigeration systems and water source heat pumps. Their ability to efficiently manage temperature control makes them suitable for both residential setups and larger commercial environments alike. Moreover, case studies highlighting the effectiveness of horizontal compressors demonstrate their versatility across different sectors—proving that they are not just another option but often the best choice available today.

The Inner Workings of Horizontal Rotary Compressors

Horizontal rotary compressors are marvels of engineering, designed to deliver efficient cooling solutions across various applications. Their unique design allows for compact installations, making them ideal for both residential and commercial use. Understanding how these compressors operate efficiently provides valuable insights into their advantages over other types.

How They Operate Efficiently

Horizontal rotary compressors function by using a rotating mechanism to compress refrigerant gas, which is then circulated through the cooling system. This process is characterized by its low energy consumption and high efficiency, making it a popular choice among users seeking reliable performance. The continuous rotation helps maintain consistent pressure levels, ensuring optimal cooling capacity without unnecessary energy waste.

In addition to their operational efficiency, horizontal rotary compressors also excel in noise reduction due to their design. Unlike some other compressor types that can be quite loud during operation, these compressors tend to run more quietly, providing a better experience in both residential and commercial settings. The combination of efficient operation and reduced noise makes them an attractive option for anyone considering which compressor is better: a rotary or scroll compressor?

Comparing with Other Compressor Types

When comparing horizontal rotary compressors with other types like scroll or inverter compressors, it’s essential to weigh the benefits and drawbacks of each design. While scroll compressors are known for their smooth operation and compact size, horizontal rotary compressors often provide higher efficiency at varying load conditions—making them versatile across different applications. Additionally, when discussing which compressor is better—a rotary or an inverter—it’s important to consider factors such as initial cost versus long-term operational savings.

For instance, while inverter compressors can offer variable speed control leading to energy savings under certain conditions, horizontal rotary compressors typically have lower maintenance requirements and longer lifespans due to their robust construction. This durability means they can be an excellent choice for applications requiring consistent performance over time without frequent servicing interruptions. Ultimately, the decision may come down to specific needs—whether it's quiet operation or energy efficiency you're after.

Rigid Design and Engineering

The rigid design of horizontal rotary compressors plays a crucial role in their overall performance and reliability. Built with high-quality materials that withstand varying pressures and temperatures, these units are engineered for longevity in demanding environments such as water source heat pumps or industrial refrigeration systems. The engineering behind these machines emphasizes not only durability but also ease of maintenance—a critical factor for many users when selecting between options like horizontal compressors for water source heat pumps.

Moreover, leading manufacturers focus on innovative designs that enhance the efficiency of horizontal rotary compressors while reducing their environmental impact through lower refrigerant leakage rates and improved energy consumption profiles. When choosing a Horizontal Rotary Compressor Manufacturer, it's vital to consider those who prioritize advanced technology alongside sustainable practices in their production processes—and who have proven track records in reliability.

Horizontal Rotary Compressor vs. Scroll Compressor

Which is Better, a Rotary or Scroll Compressor?

The choice between a horizontal rotary compressor and a scroll compressor often hinges on performance requirements and efficiency needs. Horizontal rotary compressors excel in robustness and compact design, making them ideal for applications like water source heat pumps where space may be limited. On the other hand, scroll compressors are celebrated for their quiet operation and smooth flow of refrigerant, appealing to those prioritizing noise reduction in residential settings.

However, while both types have their merits, it's crucial to evaluate your specific requirements before deciding which compressor fits best. For instance, if you need something that can handle high pressures with excellent reliability over time, the horizontal rotary compressor might take the crown. Ultimately, understanding your application will help clarify whether you should lean toward a rotary or scroll solution.

Performance Metrics and Efficiency

When comparing performance metrics between horizontal rotary compressors and scroll compressors, several factors come into play: energy consumption, cooling capacity, and operational longevity are just some of them. Horizontal rotary compressors typically offer higher efficiency ratings under heavy loads due to their robust construction and design philosophy tailored for durability. In contrast, while scroll compressors may shine in quieter operations with lower energy usage during light loads, they can struggle when faced with more demanding tasks.

Efficiency also varies based on application suitability; for example, horizontal compressors for water source heat pumps provide excellent performance in environments requiring consistent cooling or heating cycles. Furthermore, many manufacturers focus on improving these metrics through advanced engineering techniques—so it's worth researching different models before making your decision!

Application Suitability

Application suitability is another critical factor when determining whether a horizontal rotary compressor or a scroll compressor is right for you. For industrial settings needing reliable cooling solutions under varying conditions—such as commercial refrigeration—a horizontal rotary compressor often proves superior due to its ability to maintain performance across diverse loads efficiently. Conversely, if you're looking at residential air conditioning systems where noise levels need consideration without sacrificing too much power output—scroll compressors could be more fitting.

Additionally, think about future needs: if you're planning on expanding your setup or integrating new technologies like inverter systems later down the line—consider how well each option adapts to those changes! As always with such decisions involving technology investments: consult reputable sources or even reach out directly to trusted manufacturers specializing in horizontal rotary compressors for tailored advice.

Selecting the Right Compressor for Your Needs

Choosing the right compressor can feel like navigating a maze of options, but understanding your specific needs can simplify the process immensely. Whether you’re leaning towards a horizontal rotary compressor or an inverter model, each has its unique advantages tailored to different applications. In this section, we’ll explore the nuances between rotary and inverter compressors, key factors to consider in your selection, and how specific applications influence your choice.

Rotary vs. Inverter: Making the Choice

A horizontal rotary compressor typically offers robust performance with fewer moving parts, which translates to lower maintenance costs and increased reliability over time. On the other hand, inverters provide variable speed options that enhance energy efficiency by adjusting output based on demand—ideal for fluctuating cooling needs.

So, which is better—a rotary or scroll compressor? While scroll compressors are known for their quiet operation and compact size, horizontal rotary compressors excel in high-capacity applications where durability is paramount. Ultimately, your decision should hinge on factors such as energy efficiency goals, application demands, and budget constraints.

Key Factors to Consider

Selecting the right compressor extends beyond just brand names; several critical factors come into play when making your choice. First off is capacity; ensure that whichever model you choose meets or exceeds the cooling requirements of your space without overspending on unnecessary power output. Additionally, consider energy efficiency ratings—compressors with higher ratings can lead to significant savings over time.

Another crucial factor is noise levels; if you're installing a unit in a residential area or near workspaces, opting for quieter models may be advantageous—this is where horizontal rotary compressors often shine due to their solid design that minimizes vibrations. Finally, don't overlook compatibility with existing systems; ensuring that your chosen model integrates seamlessly with current infrastructure can save you headaches down the line.

Role of Applications in Selection

The application plays a pivotal role in determining which type of compressor will best suit your needs—especially when considering options like horizontal compressors for water source heat pumps. These specialized units are designed specifically for efficient heat transfer in environments where water temperature fluctuates seasonally or based on usage patterns. Understanding how these compressors interact with various systems helps narrow down choices significantly.

For instance, if you're focusing on residential versus commercial applications, you'll find different requirements influencing performance expectations and sizing considerations significantly. Horizontal rotary compressors might be more suited for commercial settings due to their ability to handle larger loads efficiently while providing reliable service over extended periods compared to smaller-scale inverter models typically used in homes.

In conclusion, selecting between a horizontal rotary compressor and an inverter requires thoughtful consideration of application-specific needs alongside key performance metrics such as energy efficiency and noise levels—all while keeping future maintenance costs at bay!

Applications of Horizontal Compressors in Heat Pumps

Horizontal rotary compressors are increasingly becoming the go-to choice for heat pump applications, particularly in water source systems. Their design allows for efficient operation and adaptability, making them suitable for various environments and climates. As energy efficiency becomes a priority, understanding how horizontal compressors fit into heat pump technology is essential.

Horizontal Compressors for Water Source Heat Pumps

Water source heat pumps leverage the stable temperature of underground water to provide heating and cooling efficiently. Horizontal rotary compressors play a pivotal role in these systems due to their ability to handle variable loads while maintaining high efficiency. With their compact design and robust performance, horizontal compressors for water source heat pumps can easily be integrated into residential and commercial setups.

Benefits for Residential and Commercial Use

The advantages of using horizontal rotary compressors extend beyond just efficiency; they also include reduced noise levels and lower maintenance costs. For residential applications, homeowners appreciate the quiet operation during both heating and cooling cycles, enhancing comfort at home. In commercial settings, businesses benefit from the reliability and longevity of these compressors, which translates into lower operational costs over time.

Case Studies of Successful Implementations

Several successful implementations highlight the effectiveness of horizontal rotary compressors in real-world applications. One case involved a multi-family residential complex that opted for a water source heat pump system equipped with horizontal rotary compressors; this led to a 30% reduction in energy bills compared to traditional systems. Another example is a commercial building that utilized these compressors to maintain optimal temperatures year-round while achieving significant energy savings—showing that when it comes down to which is better, a rotary or scroll compressor?, many are leaning towards the former due to its proven track record.

Leading Manufacturers in Horizontal Rotary Compressors

When it comes to horizontal rotary compressors, the choice of manufacturer can significantly influence performance and reliability. The market is filled with various brands, each offering unique features and benefits. Understanding which manufacturers stand out can help you make informed decisions for your cooling systems.

RIGID: Mini Compressor Innovation Leader

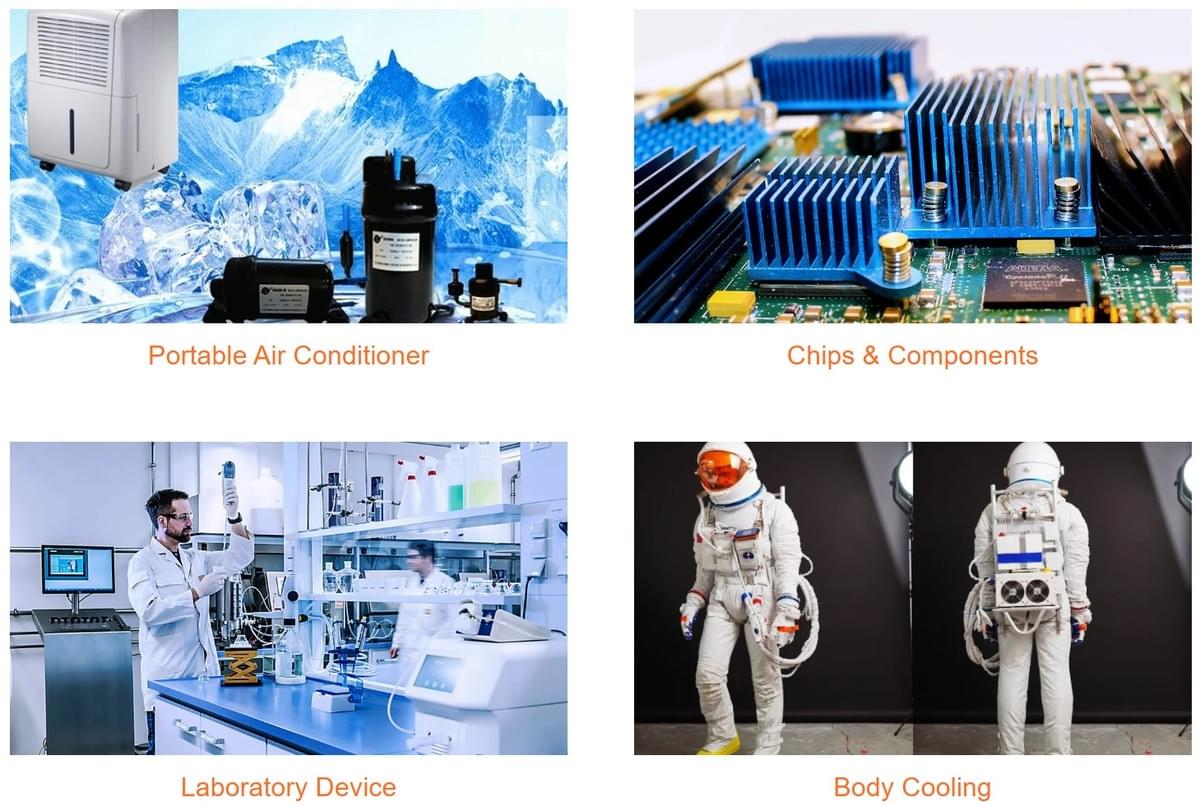

RIGID has established itself as a leader in the mini compressor segment, particularly with its innovative horizontal rotary compressors. Their commitment to efficiency and compact design makes them a favorite among engineers and designers alike. With a focus on cutting-edge technology, RIGID's compressors are tailored for various applications, including horizontal compressors for water source heat pumps.

RIGID’s products are crafted with precision engineering that maximizes performance while minimizing energy consumption. Their range of horizontal rotary compressors is known for reliability and longevity, making them ideal for both residential and commercial use. When considering which compressor is better—a rotary or scroll compressor—RIGID’s offerings often come out on top due to their advanced design features.

Notable Brands in the Market

In addition to RIGID, several other notable brands contribute significantly to the landscape of horizontal rotary compressors. Companies like Daikin, Mitsubishi Electric, and Emerson have made their mark by delivering high-quality products that cater to diverse cooling needs. Each brand brings its unique strengths; for instance, Daikin is renowned for its energy-efficient solutions while Mitsubishi Electric excels in quiet operation.

These manufacturers also provide a variety of options tailored to specific applications such as HVAC systems or refrigeration units. When comparing options like Which compressor is better—a rotary or an inverter? it's essential to review what these brands offer regarding efficiency metrics and application suitability. This way, you can choose the best fit based on your specific requirements.

What to Look for in a Manufacturer

Selecting the right horizontal rotary compressor manufacturer involves more than just looking at product specs; it requires assessing several key factors that ensure quality and performance over time. First off, consider the manufacturer's reputation within the industry—brands with a long history of innovation typically offer reliable products backed by solid warranties.

Next up is customer support; ensure that the manufacturer provides excellent service post-purchase because this can save you from future headaches related to maintenance or troubleshooting issues down the line. Lastly, look into whether they specialize in specific applications—knowing if they produce horizontal compressors for water source heat pumps can be crucial depending on your project needs.

Conclusion

In wrapping up our exploration of horizontal rotary compressors, it’s clear that these machines offer a wealth of benefits for various cooling applications. Their efficiency, compact design, and versatility make them a formidable choice in the realm of refrigeration and heat pumps. When considering whether to opt for a horizontal rotary compressor or explore alternatives like scroll or inverter compressors, the advantages presented here should guide your decision-making process.

Recap of Horizontal Rotary Compressor Benefits

Horizontal rotary compressors stand out due to their exceptional energy efficiency and reliable performance across different environments. They are particularly effective in applications such as water source heat pumps, where consistent cooling is crucial. Additionally, the robust design of these compressors ensures longevity and minimal maintenance, making them an attractive option for both residential and commercial use.

Making Informed Choices for Efficiency

When evaluating which is better—a rotary or scroll compressor—it’s essential to consider specific application needs and performance metrics. Each type has its unique strengths; however, horizontal rotary compressors often deliver superior energy savings over time. Similarly, when pondering which compressor is better—a rotary or an inverter—understanding your operational requirements will lead you to the most efficient solution tailored to your needs.

The Future of Cooling Solutions with RIGID

The future looks bright for horizontal rotary compressors, especially with innovative manufacturers like RIGID pushing the envelope in mini compressor technology. As market demands evolve towards more sustainable solutions, these compressors are likely to play a pivotal role in shaping modern cooling systems. With advancements in engineering and design from leading horizontal rotary compressor manufacturers, we can expect even greater efficiencies and capabilities in years to come.