Introduction

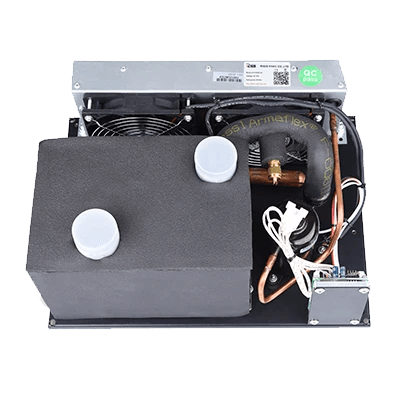

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

These vital components play a crucial role in maintaining optimal temperatures and ensuring that meat stays fresh for longer periods. Understanding how these systems work and their significance in cold storage can make all the difference for businesses relying on meat preservation.

Importance of Walk In Freezer Condensers

A walk in freezer condenser is essential for any operation that requires reliable cold storage solutions. It not only helps maintain low temperatures but also ensures energy efficiency, which translates into cost savings over time. Investing in a high-quality condenser is a strategic move that can enhance operational efficiency and product quality.

Understanding Meat Cold Storage Needs

The specific needs of meat cold storage are unique compared to other perishable items, making it essential to understand these requirements thoroughly. Factors such as temperature control, humidity levels, and air circulation are paramount for preserving freshness and preventing spoilage. A well-functioning walk in freezer condenser paired with an evaporator is vital for creating the ideal environment for meat storage.

Choosing the Right Equipment

Selecting the right equipment involves more than just picking any available model; it requires careful consideration of various factors including size, capacity, and efficiency ratings. The combination of a walk in freezer compressor with an appropriate condenser ensures that your cold storage system operates at peak performance. With so many options on the market, understanding what works best for your specific needs is key to making an informed decision.

Key Components of a Walk In Freezer

Each part plays a vital role in maintaining the necessary temperatures for meat storage, ensuring that your products remain fresh and safe. From the walk in freezer condenser to the evaporator and compressor, these components work together like a well-rehearsed orchestra.

Walk In Freezer Condenser Functionality

The walk in freezer condenser is often considered the heart of the cooling system. It’s responsible for expelling heat absorbed from inside the freezer, allowing it to maintain low temperatures effectively. By compressing refrigerant gas into a liquid state, the walk in freezer condenser ensures that your meats stay frozen while preventing any unwanted temperature fluctuations.

In essence, this component takes on the heat exchange process with finesse. As hot refrigerant gas passes through coils within the condenser, it releases heat into the surrounding air, transforming back into a liquid form. This cycle is crucial because it sets up the next phase of cooling within your walk-in freezer system.

Understanding how your walk in freezer condenser operates can help you troubleshoot issues before they escalate into costly repairs or product loss. Regular maintenance checks ensure that this vital component functions efficiently, keeping your meat storage at optimal conditions.

Walk In Freezer Evaporator Explained

Next up is the evaporator—a key player alongside your walk in freezer condenser and compressor! The evaporator absorbs heat from inside the freezer space by turning refrigerant back into gas as it circulates through its coils. This process cools down air within your unit, making sure that everything remains at safe temperatures for meat storage.

As warm air enters through vents or fans, it passes over these cold coils filled with refrigerant. The result? A drop in temperature that helps preserve quality and safety standards for all stored meats. Without an efficient evaporator working hand-in-hand with your walk in freezer condenser, you’d be facing some serious thawing troubles!

Regularly checking and cleaning your evaporator coils can greatly improve efficiency and extend its lifespan—saving you time and money down the road! So don’t overlook this critical component; after all, it’s what keeps those steaks nice and frosty.

Role of the Walk In Freezer Compressor

Finally, let’s talk about another essential element: the walk in freezer compressor! Often referred to as the workhorse, this component compresses refrigerant gas from low pressure to high pressure before sending it off to both the condenser and evaporator systems. Essentially, without a functioning compressor, neither your walk in freezer condenser nor evaporator would be able to do their jobs effectively.

The compressor acts like a pump that regulates refrigerant flow throughout your cold storage unit while maintaining optimal pressure levels—ensuring consistent cooling performance at all times! When choosing equipment for meat cold storage needs, selecting a reliable compressor should be high on your list of priorities.

In summary, understanding how each part works—including how they interact with one another—can lead to better decision-making when investing in or maintaining a walk-in freezer system. Keeping an eye on these components will help you avoid unexpected breakdowns while ensuring top-notch preservation standards for all stored meats!

How Walk In Freezer Condensers Work

Understanding how a walk in freezer condenser operates is crucial for anyone involved in meat storage. The efficiency and effectiveness of this equipment directly impact the quality and safety of stored products. Let's break down the cooling process, heat exchange mechanisms, and why efficient design matters.

Cooling Process Overview

The cooling process of a walk in freezer condenser begins with the compressor, which compresses refrigerant gas into a high-pressure state. This gas then travels through the condenser coils, where it releases heat to the outside environment, transforming into a liquid state. Once cooled, this liquid refrigerant flows to the evaporator unit inside the freezer, where it absorbs heat from the meat storage area before returning to the compressor to repeat the cycle.

An efficient walk in freezer condenser ensures that this cycle runs smoothly and consistently. By maintaining optimal temperatures, it helps preserve meat quality while preventing spoilage or bacterial growth. Understanding this cycle is essential for selecting and maintaining your cold storage system effectively.

Heat Exchange Mechanism

The heat exchange mechanism within a walk in freezer condenser is where all the magic happens—well, not actual magic but some impressive science! As refrigerant flows through coils inside both the condenser and evaporator units, it absorbs and releases heat efficiently due to differences in pressure and temperature. This process allows for effective cooling while minimizing energy consumption.

In essence, as warm air from inside your walk-in freezer comes into contact with cold evaporator coils, it cools down rapidly before circulating back into your storage space. The role of both the walk in freezer condenser and evaporator is vital here; they work hand-in-hand to ensure that your meat stays at safe temperatures without excessive energy expenditure. Understanding this mechanism can help you appreciate why regular maintenance is essential for optimal performance.

Importance of Efficient Design

Efficient design is paramount when considering a walk in freezer condenser system because it directly affects performance and operating costs. High-quality condensers are engineered to maximize heat exchange while minimizing energy usage—this means lower electricity bills! An efficient design also translates into less wear on components like compressors, leading to longer lifespans for your equipment.

Moreover, an efficiently designed system can adapt better to fluctuating demands—like when you receive a large shipment of meat or need extra cooling during peak seasons. This adaptability not only enhances performance but also ensures that you are meeting health standards without breaking a sweat (or your budget). Investing in an efficient walk in freezer condenser isn't just smart; it's essential for anyone serious about meat cold storage.

Selecting the Best Condenser for Meat Storage

The efficiency of your walk in freezer condenser and evaporator system can significantly impact both the quality of your stored products and your operating costs. Additionally, understanding the specific needs of your meat storage operation will help narrow down your choices.

Factors to Consider

First and foremost, consider the size and capacity of the walk in freezer condenser you need. The amount of meat you plan to store will dictate not only the size but also the power requirements of both the condenser and compressor. Energy efficiency is another crucial factor; choosing a model with high energy ratings can lead to substantial savings over time while ensuring that your meat remains at optimal temperatures.

Next, think about environmental conditions where your walk in freezer will operate. If it’s located in an area with fluctuating temperatures or humidity levels, you'll want a condenser designed to handle those challenges effectively. Lastly, don’t overlook maintenance ease; some models allow for simpler access to components like filters and coils, making routine checks less of a hassle.

Comparing Brands and Specifications

When comparing brands and specifications for walk in freezer condensers, it's essential to look beyond just price tags. Different manufacturers offer various features that may cater better to specific needs—such as noise levels, durability against corrosion, or advanced technology integrations like smart monitoring systems. Reading reviews from other users can provide insights into real-world performance that specifications alone might not reveal.

Another aspect worth considering is warranty offerings; robust warranties often indicate manufacturer confidence in their products' longevity and reliability. Pay attention to compatibility between different components as well—your chosen walk in freezer condenser should seamlessly integrate with its corresponding evaporator and compressor for optimal performance. Ultimately, investing time into comparing these elements will ensure you make an informed decision that aligns with your business's unique demands.

Maintenance Tips for Walk In Freezer Systems

Neglecting routine checks can lead to costly repairs and spoilage of stored goods, especially meat products that require precise temperature control. Understanding how to care for these components can save you both time and money in the long run.

Routine Checks You Can’t Ignore

Regular maintenance checks should be part of your routine if you want your walk-in freezer condenser and evaporator to function efficiently. Start by inspecting the condenser coils for dirt or debris; clean them as needed to maintain airflow and cooling efficiency. Don't forget about checking the compressor for any unusual noises or vibrations, as these can indicate underlying issues that need immediate attention.

Additionally, monitor the temperature settings regularly. If you notice fluctuations outside of the ideal range for meat storage, it could signal a problem with either the walk-in freezer compressor or evaporator that needs addressing before it affects your inventory. Keeping an eye on door seals is also essential; worn seals can let warm air in, making your system work harder than necessary.

Troubleshooting Common Issues

If your walk-in freezer isn’t performing optimally, troubleshooting common issues is a smart first step before calling in professionals. One frequent issue involves inadequate cooling; this could stem from a malfunctioning walk-in freezer condenser or evaporator. Check for ice buildup on the evaporator coils—this might indicate airflow problems or refrigerant issues that require prompt resolution.

Another common problem is excessive noise coming from the compressor; this could suggest mechanical failure or improper installation. Make sure all components are securely mounted and free from obstructions that might create noise. Lastly, if you notice water pooling around your unit, inspect drainage lines for clogs or blockages—it’s often an easy fix but can lead to significant problems if left unattended.

Importance of Professional Servicing

While routine checks and troubleshooting are vital parts of maintenance, professional servicing cannot be overlooked when it comes to complex systems like a walk-in freezer condenser setup. Trained technicians have specialized knowledge about all components—including compressors and evaporators—and can identify potential issues before they escalate into major problems. They also have access to tools and equipment necessary for thorough inspections that go beyond what untrained eyes might catch.

Investing in professional servicing not only enhances performance but also extends the lifespan of your cold storage system significantly—saving you money over time on repairs and energy costs associated with inefficient operation. Moreover, regular professional check-ups often come with warranties on parts replaced during service visits which adds another layer of financial protection against future breakdowns.

Energy Efficiency in Cold Storage

In today's environmentally conscious world, energy efficiency in cold storage is more than just a trend; it's a necessity. Utilizing energy-efficient systems can significantly reduce operational costs while also minimizing the carbon footprint associated with meat storage. This is especially important for businesses looking to optimize their budget without compromising on quality or safety.

Benefits of Energy-Efficient Systems

Energy-efficient systems, such as advanced walk in freezer condensers, offer numerous advantages that extend beyond mere savings on utility bills. By consuming less energy, these systems contribute to a more sustainable operation and can enhance the lifespan of essential components like the walk in freezer compressor and evaporator. Furthermore, businesses that invest in efficient cooling solutions often experience fewer breakdowns and lower maintenance costs over time.

RIGID’s Innovations for Better Efficiency

RIGID has been at the forefront of developing innovative technologies aimed at improving the efficiency of walk in freezer condensers and related systems. Their cutting-edge designs incorporate smart sensors and advanced heat exchange mechanisms that make use of energy more effectively than traditional models. By focusing on optimizing both the walk in freezer condenser and evaporator performance, RIGID ensures that your cold storage needs are met with minimal environmental impact.

Impact on Operating Costs

The financial implications of choosing an energy-efficient walk in freezer condenser cannot be overstated; reduced energy consumption directly translates to lower operating costs for businesses involved in meat storage. Additionally, when paired with an efficient walk in freezer compressor, these systems can lead to substantial savings over time—often recouping initial investments within a few years through decreased utility expenses. Ultimately, this financial advantage allows businesses not only to thrive but also to reinvest those savings into other critical areas.

Conclusion

In the world of meat storage, the role of a high-quality walk in freezer condenser cannot be overstated. These systems are essential for maintaining optimal temperatures and ensuring that meat products remain fresh and safe for consumption. Investing in a reliable walk in freezer condenser and evaporator setup not only protects your inventory but also enhances operational efficiency.

Benefits of Using Quality Condensers

These condensers ensure consistent cooling performance, which is crucial for preventing spoilage and maintaining product quality. Moreover, they often come equipped with advanced features that optimize energy use, translating into lower operating costs over time.

Custom Solutions for Unique Needs

Every business has its own unique requirements when it comes to meat cold storage, which is why custom solutions are invaluable. A tailored walk in freezer compressor setup can be designed to meet specific temperature ranges and space constraints while maximizing efficiency. By working with professionals who understand your needs, you can create a cold storage solution that perfectly fits your operation’s demands.

The Future of Meat Cold Storage Technology

As technology continues to evolve, the future of meat cold storage looks promising with innovations aimed at enhancing efficiency and sustainability. New advancements in walk in freezer condenser designs are emerging, incorporating smart technology that allows for real-time monitoring and adjustments based on inventory needs. This not only improves product safety but also paves the way for greener practices within the industry.