Introduction

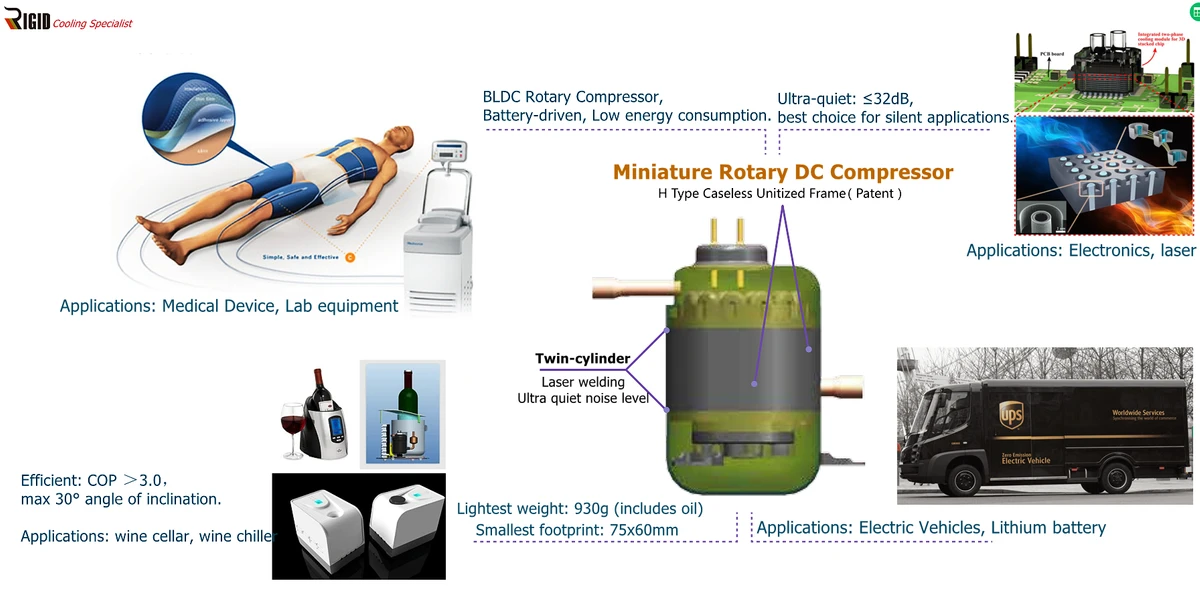

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

Refrigeration condensing units are essential components in cooling systems, providing the necessary heat transfer to keep products and equipment at optimal temperatures. When choosing the right unit, key considerations include size, capacity, and energy efficiency. Exploring different types of condensing units can help businesses find the best fit for their specific refrigeration needs.

Understanding Refrigeration Condensing Units

Refrigeration condensing units are vital in maintaining the proper temperature for various applications, from food storage to industrial processes. These units work by removing heat from the refrigerant vapor and converting it back into a liquid state through compression and condensation.

Key Considerations in Choosing the Right Unit

Selecting the right refrigeration condensing unit involves evaluating factors such as cooling capacity, energy efficiency, and compatibility with existing systems. It's crucial to consider the specific requirements of the application to ensure optimal performance and cost-effectiveness.

Exploring Different Types of Condensing Units

There are various types of refrigeration condensing units available, including air-cooled, water-cooled, and remote condensing units. Each type has its advantages and limitations, making it important for businesses to understand their options before making a decision.

What is a Refrigeration Condensing Unit?

Definition and Functionality

A refrigeration condensing unit is a key component in a cooling system that helps to remove heat from the system. It consists of a compressor, condenser, fan, and various controls, all housed in a single unit. The functionality of the unit lies in its ability to compress and condense refrigerant vapor into liquid, releasing heat in the process.

The compressor is responsible for increasing the pressure and temperature of the refrigerant vapor, while the condenser facilitates the transfer of heat from the refrigerant to the surrounding environment. The fan helps to dissipate this heat by blowing air over the condenser coils, allowing the refrigerant to release its heat energy. The controls in the unit regulate the operation of the compressor and fan to ensure optimal performance and energy efficiency.

Components and Working Mechanism

The main components of a refrigeration condensing unit include the compressor, condenser coil, fan motor, and controls. The compressor is responsible for pressurizing the refrigerant gas, which is then condensed into liquid by the condenser coil. The fan motor helps to dissipate heat from the coil, while the controls ensure proper functioning of the unit.

The compressor plays a crucial role in the refrigeration condensing unit by pressurizing the refrigerant gas, allowing it to circulate through the system. As the gas travels through the compressor, it becomes hot and high-pressure, ready to release its heat in the condenser coil. This process is essential for maintaining the proper temperature inside the cooling system and ensuring efficient operation.

Importance in Cooling Systems

Refrigeration condensing units play a crucial role in maintaining optimum temperatures in various cooling systems such as commercial refrigerators, freezers, air conditioning units, and industrial cooling equipment. They are essential for removing heat from the system and ensuring efficient cooling operations.

Refrigeration condensing units are also crucial for preserving the quality and safety of perishable goods in commercial refrigeration and freezer systems. By maintaining consistent and optimal temperatures, these units help to prevent food spoilage and ensure that products remain fresh for consumers. In addition, they play a vital role in reducing energy consumption and operational costs, making them an indispensable component of any modern cooling system.

Differences Between a Condenser and a Condensing Unit

When it comes to refrigeration systems, the terms condenser and condensing unit are often used interchangeably, leading to confusion. A condenser is a component within a refrigeration system that removes heat from the system, while a condensing unit is the entire assembly that includes the condenser, compressor, and other necessary components for heat exchange.

Clearing the Confusion

The confusion between condensers and condensing units stems from their interconnected roles in refrigeration systems. A condenser is responsible for converting high-pressure gas into liquid refrigerant, while a condensing unit encompasses not only the condenser but also the compressor and other vital parts needed for cooling processes.

The key variance between a condenser and a condensing unit lies in their functions within the refrigeration system. While the condenser is solely responsible for converting high-pressure gas into liquid refrigerant, the condensing unit encompasses a broader range of components, including the compressor and other essential parts required for the cooling process. This distinction is crucial in understanding the roles each component plays in maintaining an efficient and effective refrigeration system.

Identifying Key Variances

The key variance between a condenser and a condensing unit lies in their scope of function within refrigeration systems. While both play crucial roles in heat exchange, the condensing unit operates as an integrated system with multiple components working together to facilitate cooling processes.

The condensing unit typically includes a compressor, condenser coil, and fan, all housed within a single unit. This integrated design allows for more efficient operation and easier installation compared to a standalone condenser. Additionally, the condensing unit often comes pre-wired and pre-charged with refrigerant, simplifying the setup process for technicians.

Impact on Refrigeration Systems

Understanding the differences between a condenser and a condensing unit is essential for selecting the right equipment for specific refrigeration needs. The choice between these components can significantly impact the efficiency and performance of refrigeration systems, making it crucial to differentiate their roles accurately. Condensing units are responsible for both heating and cooling functions, providing a versatile solution for various temperature control requirements. This dual functionality makes them an attractive option for businesses looking to streamline their refrigeration systems and maximize energy efficiency.

Heat and Cool: The Functionality of Condensing Units

Refrigeration condensing units are known for their dual functionality, capable of both heating and cooling. This versatility makes them a valuable asset in various industries, allowing for precise temperature regulation in different applications. Whether it's maintaining the ideal temperature in a pharmaceutical storage facility or providing consistent cooling in a food processing plant, condensing units offer reliable performance across the board.

Dual Functionality Explained

The dual functionality of refrigeration condensing units stems from their ability to both remove heat from an enclosed space, thereby cooling it, and release heat into an area to warm it up. This makes them suitable for a wide range of applications, from commercial refrigeration to industrial heating systems. The flexibility of these units allows businesses to streamline their operations by utilizing one system for both heating and cooling needs, maximizing efficiency and cost-effectiveness.

Furthermore, the dual functionality of refrigeration condensing units allows for precise temperature regulation, ensuring that the enclosed space remains at the desired temperature at all times. This level of control is especially beneficial for businesses that require consistent and stable temperatures for their products or processes, such as pharmaceutical companies or food manufacturers. By having a single system that can both cool and heat, businesses can avoid the need for multiple units or complex HVAC systems, simplifying maintenance and reducing potential points of failure.

Advantages in Temperature Regulation

One of the key advantages of condensing units lies in their precise temperature regulation capabilities. By effectively controlling the temperature within a given space, these units ensure optimal conditions for preserving perishable goods, maintaining equipment functionality, and creating comfortable environments for workers or customers. This level of control is essential across industries such as food and beverage, pharmaceuticals, hospitality, and manufacturing.

Applications in Various Industries

Refrigeration condensing units find application across a broad spectrum of industries due to their adaptability and reliability. From walk-in coolers at grocery stores to climate-controlled storage facilities for medical supplies, these units play a critical role in preserving products and protecting equipment. Additionally, they are widely used in HVAC systems for commercial buildings and industrial facilities where consistent temperature control is essential for operational efficiency.

Dry Cooler vs. Condensing Unit: Which is Right for You?

When it comes to choosing between a dry cooler and a refrigeration condensing unit, it's essential to understand the contrasting features and benefits of each. A dry cooler is an air-cooled heat exchanger that uses ambient air to cool the refrigerant, making it ideal for outdoor installations. On the other hand, a condensing unit combines the condenser and compressor in a single package, providing a compact and efficient solution for indoor applications.

Contrasting Features and Benefits

Dry coolers are known for their energy efficiency and low operating costs, making them a popular choice for large-scale industrial cooling systems. They require minimal maintenance and are suitable for areas with ample outdoor space. In contrast, condensing units offer a space-saving design and can be easily integrated into existing refrigeration systems, making them ideal for commercial and residential applications where space is limited.

Matching Units to Specific Needs

When selecting between a dry cooler and a condensing unit, it's crucial to match the units to specific cooling requirements. Dry coolers excel in applications where high heat rejection is necessary, such as data centers or industrial process cooling. On the other hand, condensing units are well-suited for small-scale refrigeration needs in supermarkets, restaurants, or convenience stores.

Dry coolers are an excellent choice for applications that require high heat rejection, as they are able to efficiently dissipate large amounts of heat. This makes them ideal for use in data centers where cooling is essential to prevent equipment overheating and potential damage. Additionally, dry coolers are well-suited for industrial process cooling, where precise temperature control is necessary to maintain production efficiency.

Optimizing Energy Efficiency

Both dry coolers and condensing units offer energy-efficient solutions for cooling needs. However, the choice between the two depends on factors such as available space, environmental conditions, and specific cooling demands. By carefully evaluating these factors, businesses can optimize energy efficiency while meeting their unique refrigeration requirements.

When considering the choice between dry coolers and condensing units, businesses must also take into account the maintenance requirements of each option. While dry coolers are generally low-maintenance, condensing units may require more frequent upkeep to ensure optimal performance. By factoring in maintenance needs, businesses can make a decision that aligns with their capacity for ongoing maintenance and upkeep.

Condensing Units and Packaged Systems

Understanding Packaged Refrigeration Solutions

Packaged refrigeration solutions are complete systems that include a refrigeration condensing unit, evaporator, and other necessary components in one package. These systems are pre-engineered and factory-assembled, making installation and maintenance easier for businesses in need of reliable cooling solutions.

Benefits and Limitations

The benefits of packaged refrigeration solutions include reduced installation time, simplified maintenance, and improved system efficiency. However, these systems may have limitations in terms of flexibility for customization to specific needs or space constraints in certain applications.

Integration with Other Refrigeration Components

Packaged refrigeration solutions can be seamlessly integrated with other refrigeration components such as compressors, condensers, and controls to create a comprehensive cooling system tailored to the specific requirements of a business. This integration ensures optimal performance and energy efficiency.

Conclusion

Refrigeration condensing units are essential for maintaining optimal temperatures in various industries. Understanding the difference between a condenser and a condensing unit is crucial in making the right choice for your cooling needs. RIGID offers innovative solutions for custom refrigeration systems, ensuring energy efficiency and temperature regulation.

Making the Right Choice for Your Cooling Needs

When choosing a refrigeration condensing unit, consider factors such as size, capacity, and energy efficiency to meet your specific cooling requirements. It's important to understand the functionality of condensing units and how they impact refrigeration systems in order to make an informed decision that aligns with your business goals.

Partnering with RIGID for Innovative Solutions

RIGID is a pioneer in micro cooling technology, offering superior design and uncompromising quality in mini compressors and small chillers. By partnering with RIGID, businesses can benefit from custom-made refrigeration solutions that optimize energy efficiency and enhance competitiveness in the market.

Advancing Your Business with Custom Refrigeration Systems

Condensing units play a crucial role in packaged refrigeration systems, offering benefits such as space optimization and ease of installation. RIGID's focus on client budgets and custom-made solutions ensures that businesses can advance their operations with efficient and reliable refrigeration systems tailored to their specific requirements.