Precision Thermal Control for Analytical, Biotech & Aerospace Applications

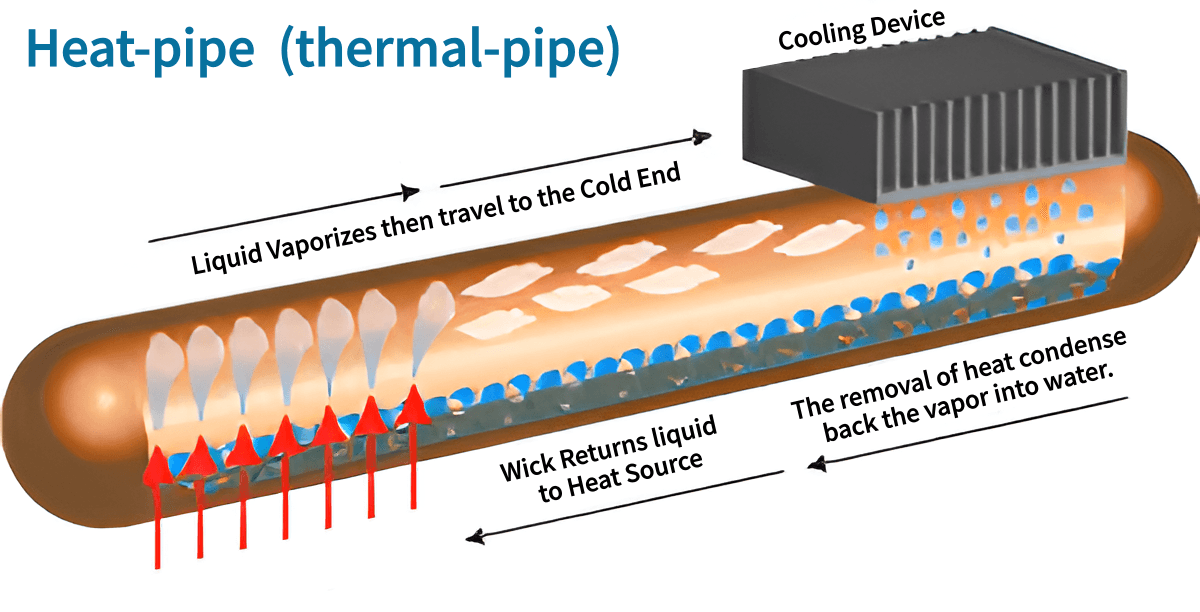

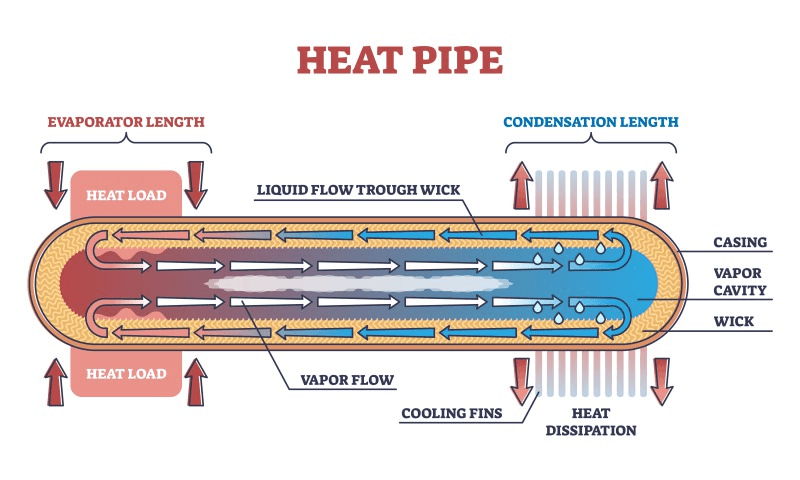

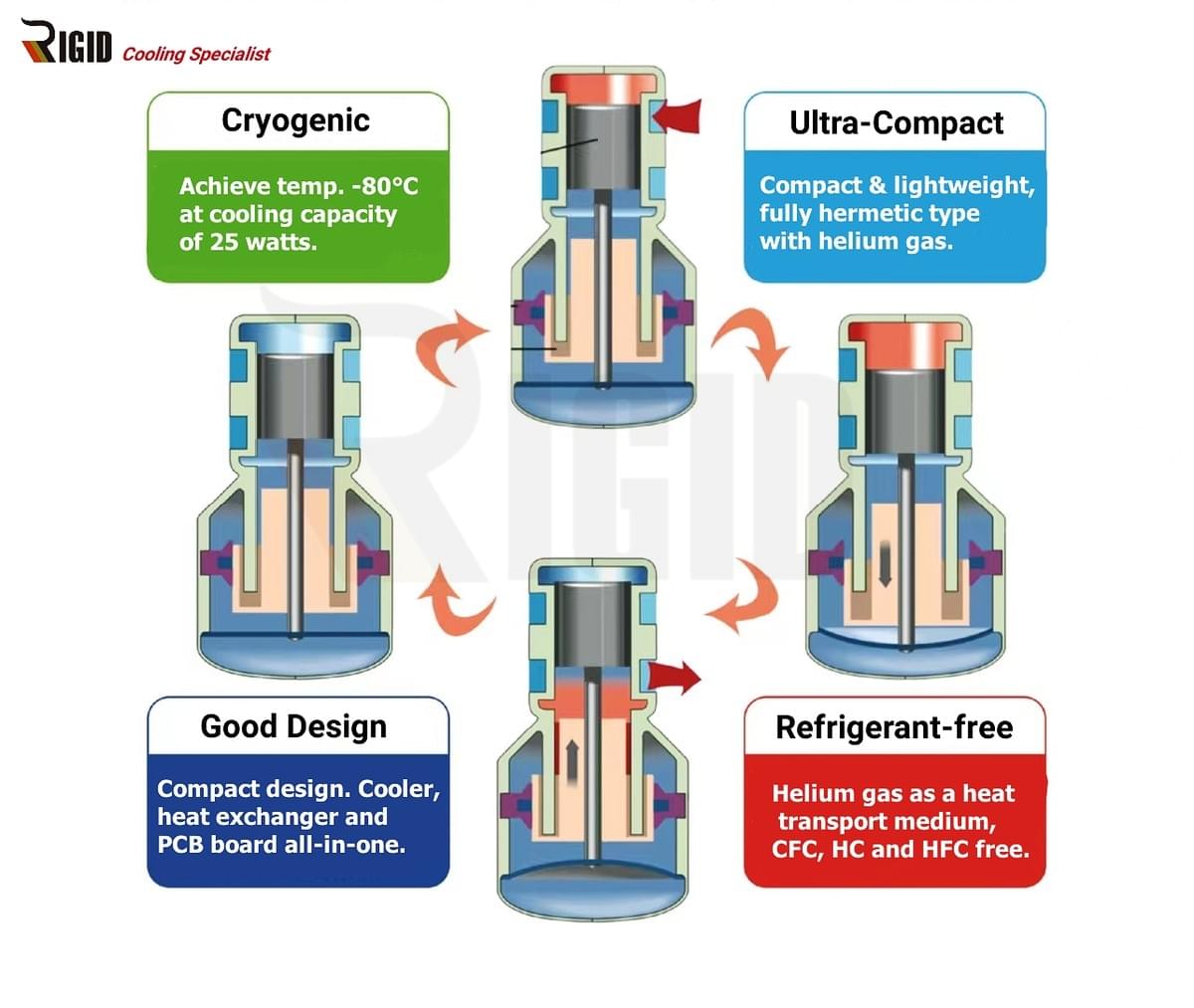

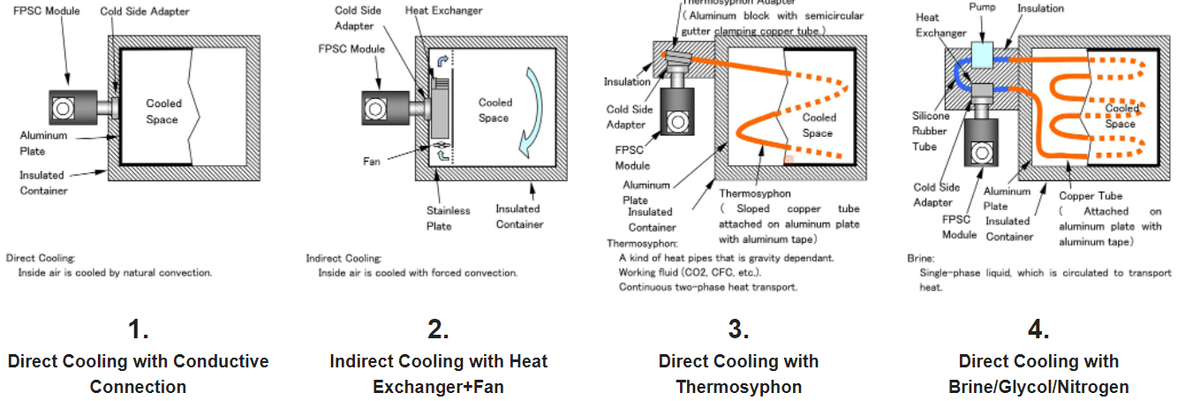

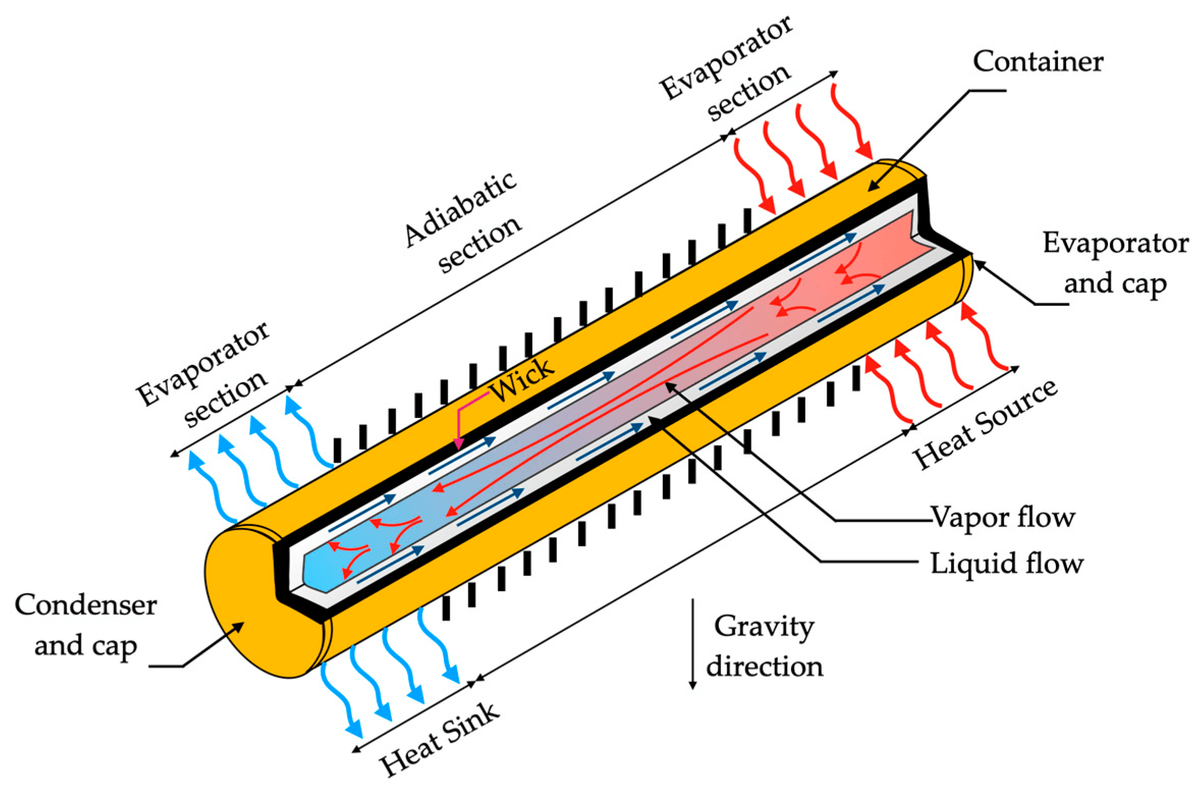

FPSC Stirling Cryocoolers with integrated Heat Pipe and Diode Heat Pipe technology deliver ultra-efficient, passive heat transport with near-zero temperature loss. Designed for environments where direct cooling is impractical, these systems enable remote heat rejection, thermal isolation, and unidirectional heat flow, making them ideal for mission-critical and precision applications.

Why Heat Pipe–Integrated Stirling Cryocoolers?

Near-isothermal heat transfer (≈1 °C gradient, independent of distance)

- Passive, vibration-free, and maintenance-free operation.

- Optional diode heat pipe to prevent reverse heat flow.

- Supports compact system layouts and sealed environments.

- Proven performance in cryogenic and high-temperature conditions.

1. Analytical Instruments Cooling Solutions

Precision Thermal Stability for High-Sensitivity Measurements

Analytical instruments require extreme thermal stability to maintain accuracy, repeatability, and signal integrity. FPSC Stirling Cryocoolers combined with heat pipe technology provide controlled cooling for sensitive detectors and optics while relocating heat rejection away from measurement zones.

Typical Applications

- Mass spectrometers

- Spectroscopy systems (IR, Raman, UV-Vis)

- X-ray and neutron detectors

- Semiconductor metrology tools

Key Benefits

- Eliminates thermal drift and noise

- Allows compact, vibration-sensitive instrument design

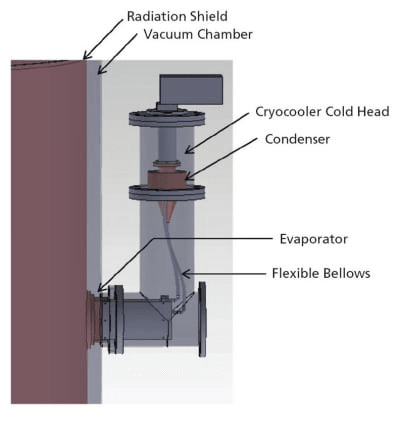

- Enables remote condenser placement outside sealed chambers

2. Biotechnology & Life Sciences Cooling

Reliable Cooling for Biological Samples & Medical Devices

In biotechnology and medical applications, temperature accuracy and system reliability are critical. Heat pipe-assisted Stirling Cryocoolers provide clean, silent, and stable cooling without airflow contamination or mechanical vibration.

Typical Applications

- PCR and DNA amplification systems

- Biochemical analyzers

- Medical imaging detectors

- Bio-sample storage and preservation

Key Benefits

- Maintains precise temperature control for sensitive samples

- No airflow disturbance or particle contamination

- High reliability for continuous laboratory operation

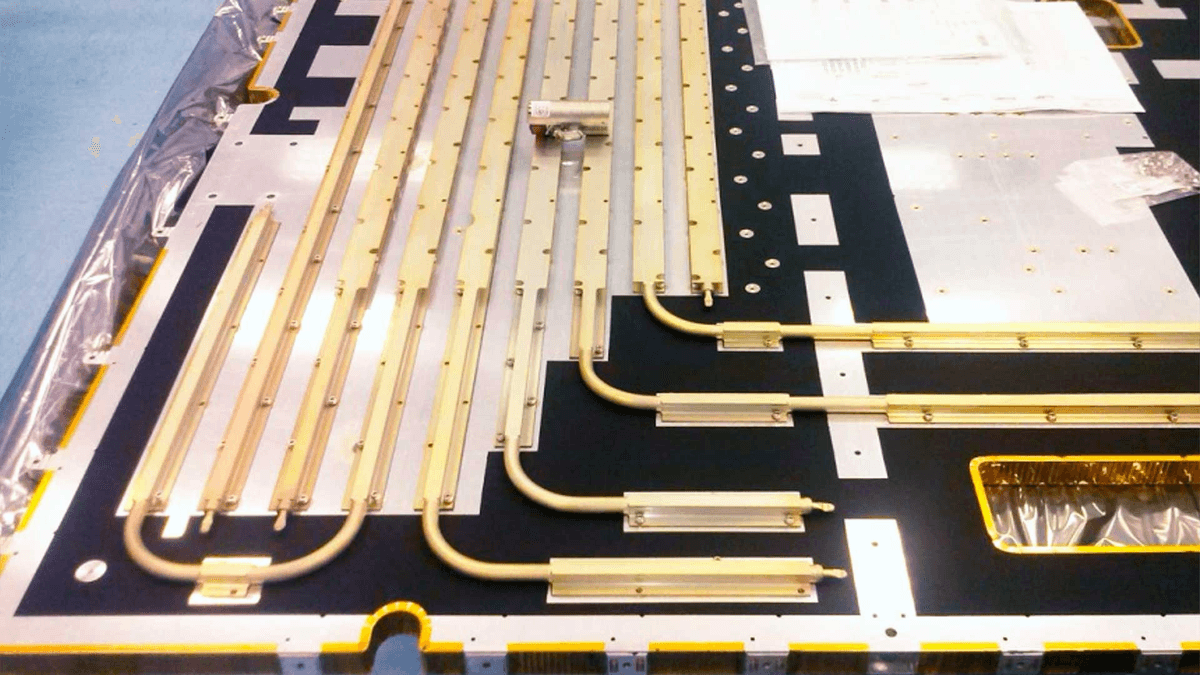

3. Aerospace & Space Systems Thermal Management

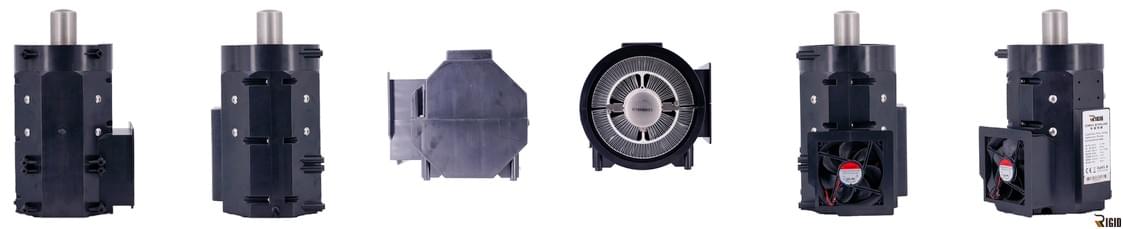

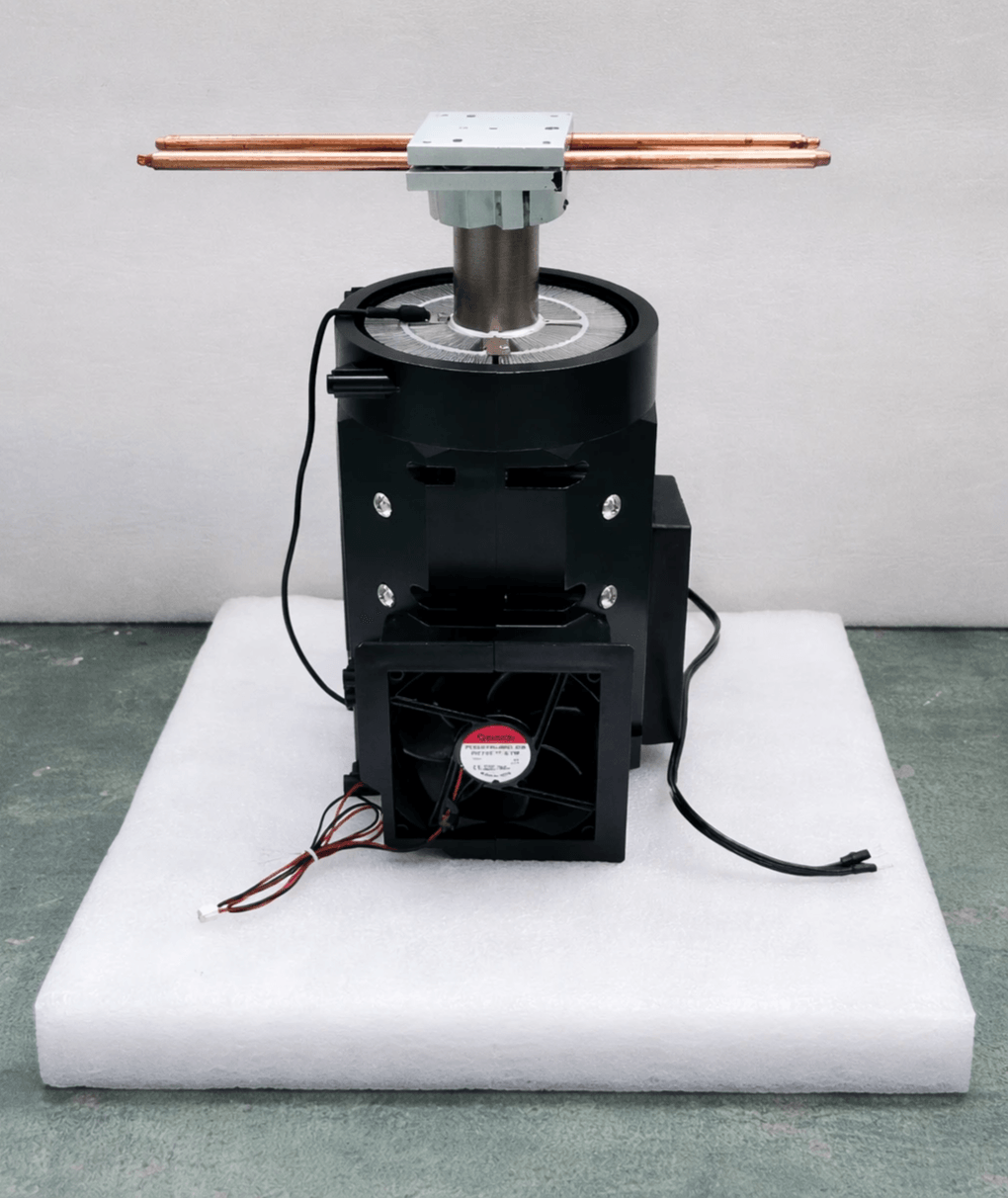

FPSC Stirling Cryocooler with Heat Pipe (Model name: RS100)

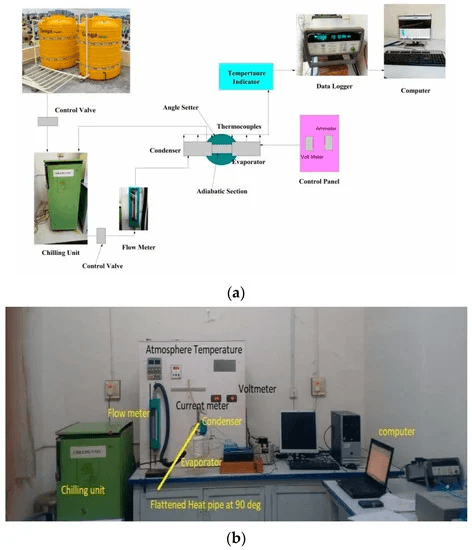

FPSC Cryocooler Working Principle - Cryogenic ultra-low freezing in minutes.

Mission-Critical Thermal Control in Extreme Environments

Aerospace systems face extreme thermal gradients, vacuum conditions, and limited power availability. FPSC Stirling Cryocoolers with diode heat pipe technology ensure controlled, unidirectional heat transfer and thermal protection in harsh environments.

Typical Applications

- Spaceborne infrared sensors

- Avionics and payload cooling

- Satellite thermal control systems

- Planetary landers and deep-space probes

Key Benefits

- Prevents reverse heat flow during thermal cycling

- Enables remote heat rejection in confined spacecraft structures

- Proven compatibility with alkali-metal heat pipes for high temperatures

Diode Heat Pipe Advantage for Critical Systems

- Blocks reverse heat flow automatically

- Protects cold-sensitive components

- Enhances system survivability during shutdown or thermal reversal

- Ideal for aerospace, cryogenic, and precision instrumentation

Why Choose FPSC Stirling Cryocooler Solutions?

- Modular integration with heat pipe or diode heat pipe architectures

- Customizable for temperature range, orientation, and environment

- Long service life with zero maintenance

- Trusted solution for scientific, biomedical, and aerospace OEMs

Talk to Our Thermal Engineering Team

Need application-specific optimization? We support OEM customization, system simulation, and integration guidance. Feel free to contact us, email quinn@rigidhvac.com