Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

Rugged electronics design plays a crucial role in ensuring the reliability and performance of various devices, such as programmable logic controllers (PLCs) and digitel systems. These rugged electronics are designed to withstand harsh environments, including extreme temperatures, vibrations, and moisture. As an expert in designing customized solutions for rugged electronics, RIGID Technology understands the importance of addressing the challenges faced by these devices.

Understanding the Importance of Rugged Electronics Design

Reliable operation is essential for seamless processes and efficient control in industries using PLCs and other electronic systems. Rugged electronics design ensures that these devices can withstand the demanding conditions they are exposed to daily. By incorporating robust components and implementing effective thermal management solutions, RIGID Technology aims to enhance the longevity and performance of rugged electronics.

The Challenges Faced by Rugged Electronics

Due to their operating environments, rugged electronics face numerous challenges. Extreme temperatures can cause overheating or freezing, leading to malfunctions or even permanent damage. Vibrations and shocks can also impact the reliability of these devices, potentially disrupting critical operations. Additionally, exposure to moisture, dust, and corrosive substances poses significant risks to their functionality.

RIGID's Custom Small Cooling Solution

To address the challenges faced by rugged electronics, RIGID Technology offers a custom small cooling solution specifically designed for compact and mobile applications. Our miniature refrigerated compressors provide efficient cooling capabilities while maintaining a small footprint. With our expertise in research and development, we continuously innovate new technologies to ensure optimal performance in even the harshest environments.

The Fundamentals of Rugged Electronics Design

Rugged electronics are specialized devices that withstand harsh and demanding environments and provide reliable performance in extreme conditions. They are commonly used in manufacturing, oil and gas, transportation, and military applications.

When designing rugged electronics, several key considerations must be taken into account. First, the device must operate in various temperatures, from extreme cold to high heat. It should also resist dust, water, and other environmental factors that could damage or disrupt its functionality.

Environmental testing plays a crucial role in validating the design of rugged electronics. Through rigorous testing procedures, manufacturers can ensure that their devices meet the required standards for durability and reliability. This includes subjecting the devices to temperature cycling tests, humidity tests, vibration tests, and shock tests.

By conducting these tests during the design phase, manufacturers can identify any weaknesses or vulnerabilities in their products and make necessary improvements before they reach the market.

Understanding the fundamentals of rugged electronics design is essential for creating reliable and robust devices that can withstand challenging environments. By considering key factors such as temperature resistance and environmental testing validation, manufacturers can ensure that their products meet the highest quality and performance standards.

At RIGID Technology, we specialize in developing customized solutions for rugged electronics through extensive research and development efforts. Our miniature compressors and micro DC aircon systems are designed to provide efficient cooling solutions for compact mobile applications. With our expertise in miniature refrigerated compressor innovation, we are committed to delivering cutting-edge solutions that meet the unique needs of our customers in various industries.

Enhancing Reliability in Rugged Electronics

Rugged electronics, such as programmable logic controllers (PLCs), are designed to withstand harsh environments and provide reliable operation in demanding applications. To ensure longevity and durability, choosing robust components that can withstand the rigors of rugged use is crucial.

Choosing Robust Components for Longevity

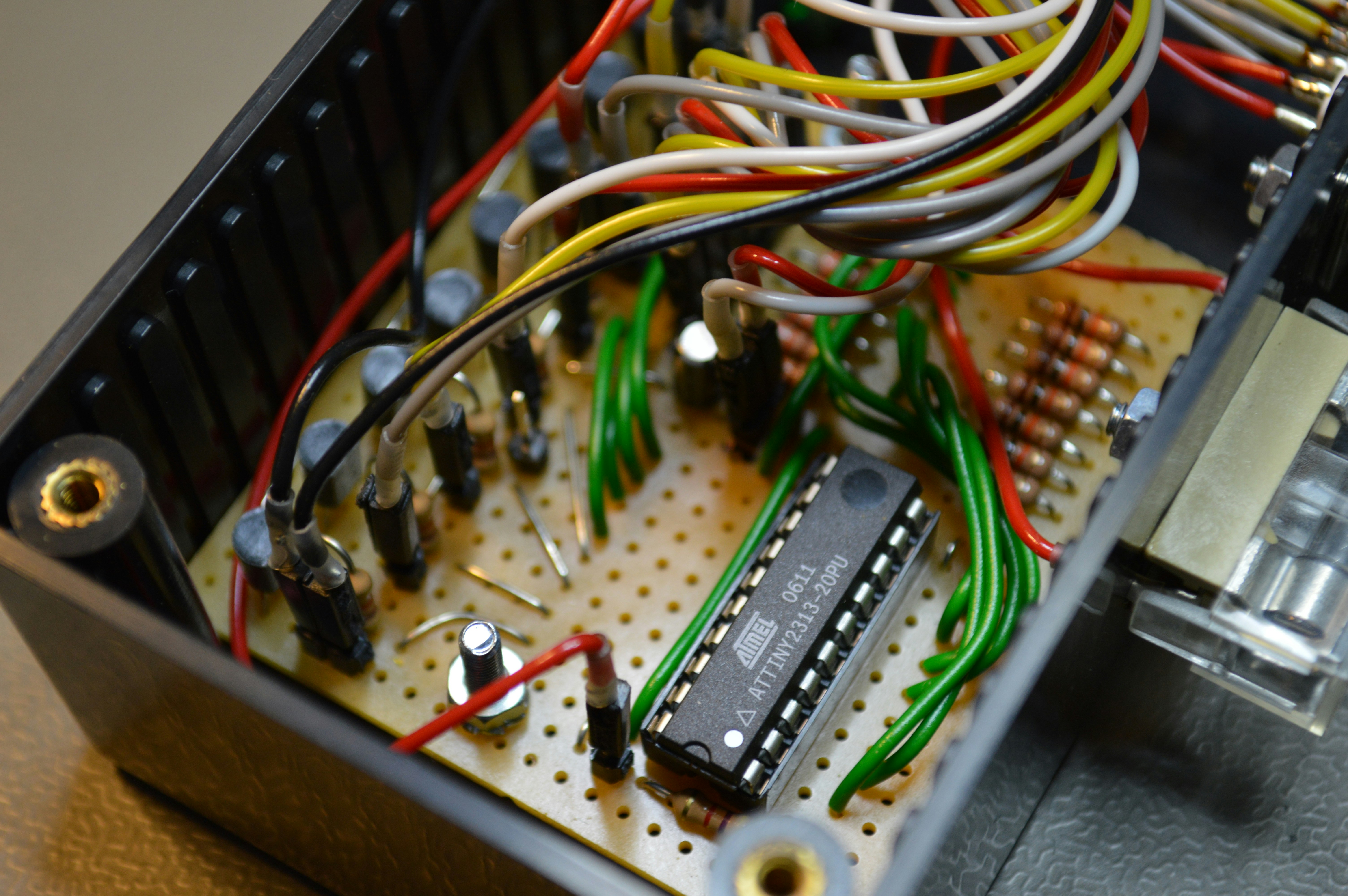

When designing rugged electronics, selecting high-quality components is essential for long-term reliability. Components specifically designed for rugged environments, such as those offered by RIGID Technology, can withstand extreme temperatures, vibrations, and shocks. These components undergo rigorous testing to ensure their durability and performance under challenging conditions.

Manufacturers can minimize the risk of failure and downtime in rugged electronic systems by choosing robust components. This increases the equipment's lifespan, reduces maintenance costs, and improves overall productivity.

Implementing Effective Thermal Management Solutions with RIGID's Miniature Cooling Systems

Another critical aspect of enhancing reliability in rugged electronics is effective thermal management. Excessive heat can significantly impact the performance and lifespan of electronic components. RIGID's miniature cooling systems are designed to efficiently dissipate heat from compact spaces, ensuring optimal operating temperatures even in challenging environments.

By implementing these advanced cooling solutions, manufacturers can prevent overheating issues that may lead to component failures or reduced performance. This ultimately enhances the reliability and longevity of rugged electronic systems.

Understanding Vibration and Shock Resistance

When deployed in harsh environments or mobile applications, rugged electronic devices often face significant vibrations and shocks. Understanding how these factors affect the performance of electronic components is crucial for ensuring reliability.

RIGID Technology specializes in developing vibration- and shock-resistant solutions for rugged electronics. Their expertise lies in designing products that can withstand high vibration levels without compromising functionality or performance.

By incorporating vibration- and shock-resistant features into their designs, manufacturers can mitigate potential damage caused by external forces. This, in turn, ensures the reliability and durability of rugged electronic systems, even in the most demanding conditions.

Designing for Harsh Environments

In the world of rugged electronics, designing for harsh environments is crucial to ensure the longevity and performance of devices such as programmable logic controllers (PLCs) and digitel systems. RIGID Technology, a leader in miniature refrigerated compressor innovation, offers customized solutions that address the challenges faced in these environments.

Waterproofing and Dustproofing Techniques

When it comes to rugged electronics, waterproofing and dust proofing techniques are essential to protect sensitive components from moisture and debris. RIGID's research and development team has developed advanced sealing methods that create a tight barrier against water ingress and dust particles. These techniques ensure that the internal components of PLCs and other devices remain safe and functional even in extreme conditions.

One effective technique employed by RIGID is the use of specialized gaskets and seals that provide a high level of protection against water intrusion. These seals are designed to withstand pressure differentials, ensuring that no water can penetrate the device. Additionally, RIGID incorporates specially designed vents that equalize pressure while preventing any moisture or dust from entering.

Corrosion Prevention Methods

Corrosion is a major concern in harsh environments, as it can lead to device failure and performance degradation. RIGID employs various corrosion prevention methods to combat this issue in its rugged electronics design.

One method RIGID utilizes is corrosion-resistant materials for critical components such as connectors, circuit boards, and enclosures. These materials are carefully selected based on their ability to withstand exposure to moisture, saltwater, chemicals, and other corrosive elements commonly found in harsh environments.

Furthermore, RIGID implements protective coatings on sensitive electronic components to provide an additional defense against corrosion. These coatings are a barrier between the components and external factors that could cause damage over time.

EMI Shielding Solutions for Enhanced Performance

Electromagnetic interference (EMI) can severely impact the performance of rugged electronics, leading to signal disruptions and malfunctions. To ensure reliable operation, RIGID incorporates EMI shielding solutions into their design.

RIGID's EMI shielding solutions use specially designed enclosures and shielding materials that effectively block out unwanted electromagnetic radiation. These shields are strategically placed around sensitive components to minimize the risk of interference from external sources.

By implementing these shielding solutions, RIGID's rugged electronics can operate seamlessly in environments where electromagnetic noise is prevalent, such as industrial settings or military applications. This ensures the consistent and accurate performance of PLCs and other digital systems, even in the presence of strong electromagnetic fields.

Power Optimization in Rugged Electronics

Power optimization is crucial to ensuring efficient and reliable performance in rugged electronics. This section will explore various strategies to enhance energy efficiency, battery management, and power supply design. Additionally, we will introduce RIGID's Miniature DC Compressor as a compact and efficient cooling solution.

Energy Efficiency Strategies

When it comes to rugged electronics, energy efficiency plays a vital role in maximizing the lifespan of devices and minimizing power consumption. By implementing intelligent power management techniques such as sleep modes, dynamic voltage scaling, and power gating, manufacturers can significantly reduce energy wastage during idle or low-power operations.

Furthermore, optimizing software algorithms and reducing unnecessary computational tasks can help conserve power without sacrificing performance. Manufacturers can achieve remarkable energy savings in rugged electronic systems by employing advanced power management ICs and selecting low-power components.

Battery Management and Power Supply Design

Battery life is critical to any portable or mobile rugged electronic device. Effective battery management strategies are essential to ensure uninterrupted operation in demanding environments. Implementing intelligent charging algorithms that optimize charging cycles based on battery conditions can significantly extend battery life.

Moreover, incorporating advanced power supply designs with high-efficiency converters and voltage regulation techniques can minimize energy losses during conversion. This improves overall system efficiency and reduces heat generation within the device.

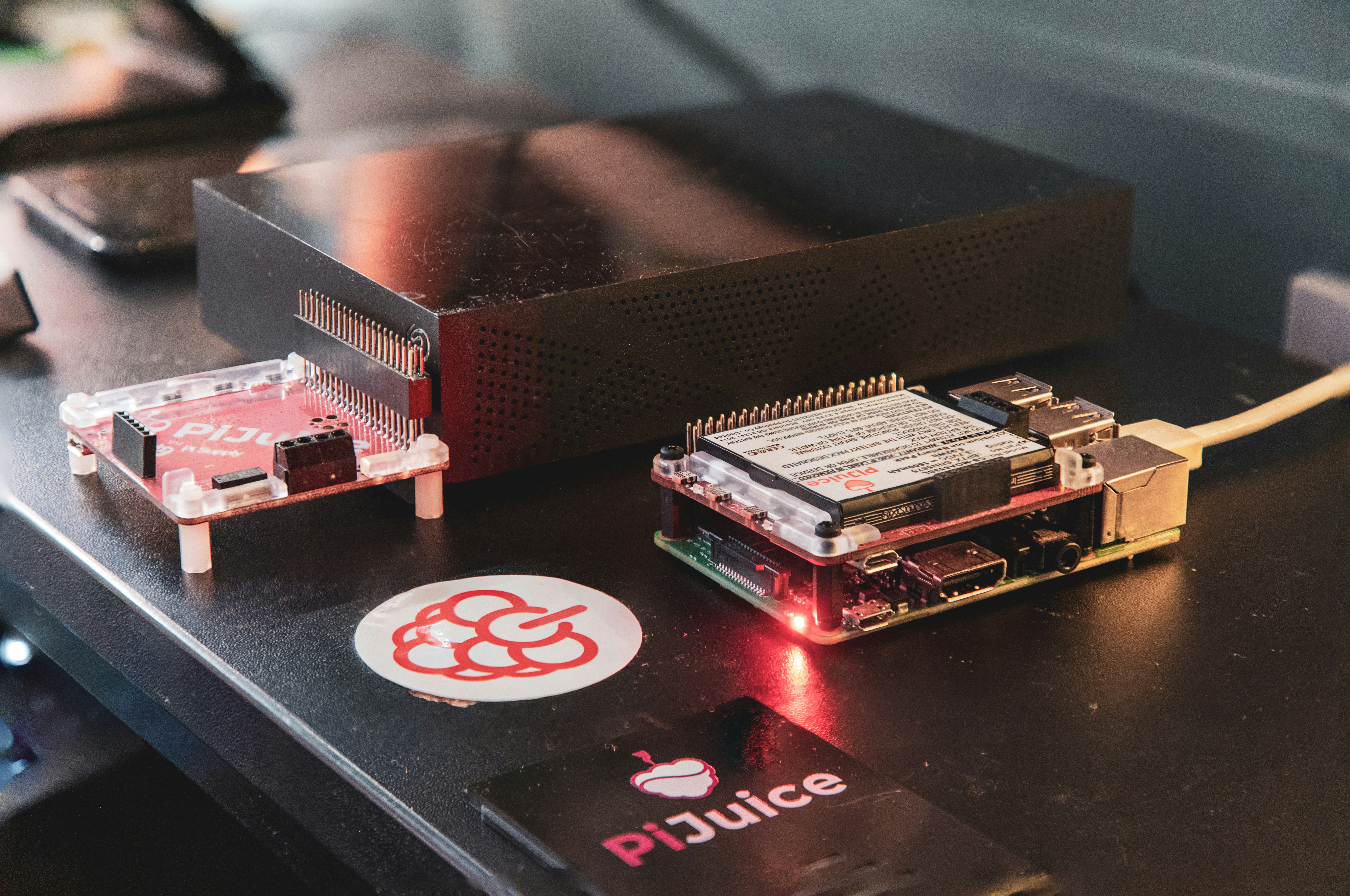

RIGID's expertise in miniature compressor technology extends to battery-powered applications. Their compact compressors offer efficient cooling solutions for portable devices while minimizing the impact on battery life.

RIGID's Miniature DC Compressor for Compact and Efficient Cooling

RIGID Technology is at the forefront of innovation when it comes to miniature refrigerated compressors for rugged electronics applications. Their cutting-edge Miniature DC Compressor offers a compact yet powerful cooling solution for small form factor devices such as programmable logic controllers (PLCs) or digitel systems.

Manufacturers can achieve efficient cooling in space-constrained environments by leveraging RIGID's Miniature DC Compressor without compromising performance. This innovative solution ensures reliable operation and extends the lifespan of rugged electronic devices.

Testing and Certification for Rugged Electronics

Rugged electronics, such as programmable logic controllers (PLCs), are essential components in various industries where reliability and durability are crucial. To ensure the quality and performance of these rugged devices, rigorous testing and certification processes are necessary.

Compliance with Industry Standards and Regulations

Compliance with industry standards and regulations is vital in designing and producing rugged electronics. RIGID Technology understands the importance of adhering to these requirements to guarantee the safety and reliability of their products. By following established guidelines, RIGID ensures that its miniature cooling systems meet industry standards for ruggedness.

Reliability Testing Methods

Reliability testing significantly ensures that rugged electronics can withstand harsh operating conditions without compromising performance. RIGID's research and development team utilizes various testing methods, including environmental stress screening (ESS), accelerated life testing (ALT), and HALT/HASS (Highly Accelerated Life Testing/Highly Accelerated Stress Screening). These tests simulate extreme temperatures, vibrations, shocks, humidity, and other environmental factors to evaluate the reliability of their custom cooling solutions.

Certifications to Ensure Quality and Performance

Certifications serve as official recognition that rugged electronic devices meet specific quality standards. RIGID Technology prioritizes obtaining certifications from reputable organizations to validate their commitment to excellence. Certifications such as ISO 9001:2015 demonstrate RIGID's dedication to quality management systems, while RoHS compliance ensures their products are free from hazardous substances.

Conclusion

In conclusion, the future of rugged electronics design is rapidly evolving, and staying ahead of the curve is essential. By embracing technological advancements and understanding the unique challenges faced by rugged electronics, we can create innovative solutions that meet the demands of various industries.

RIGID's expertise in miniature compressors and micro DC aircon has revolutionized rugged electronics. Their commitment to research and development allows them to provide customized cooling solutions that are compact, efficient, and reliable.

With RIGID's cutting-edge technology, achieving reliable and cutting-edge rugged electronics solutions is now possible. RIGID has the solution, whether it's for programmable logic controllers (PLCs), PLC controls, PLC systems, or any other digital system requiring robust design and performance.

By leveraging RIGID's expertise in miniature compressors and micro DC aircon, companies can ensure that their rugged electronics are equipped with top-of-the-line cooling systems. This enhances reliability and extends the lifespan of components, leading to cost savings in the long run.

In a world where mobile devices are becoming increasingly prevalent, RIGID's miniaturized cooling systems offer a compact solution for on-the-go applications. These customized designs provide efficient cooling without compromising performance or durability.

To succeed in rugged electronics design, partnering with companies like RIGID that prioritize research and development is crucial. Their dedication to innovation ensures that they stay at the forefront of technological advancements and deliver solutions that exceed industry standards.

Why settle for anything less when you have reliable, cutting-edge, rugged electronics solutions? Choose RIGID as your trusted partner for all your cooling needs. Embrace the future of rugged electronics design with confidence!