Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

In the world of temperature-sensitive storage, cold room systems play a pivotal role in ensuring that products remain fresh and safe. These specialized environments are designed to maintain specific temperature ranges, making them essential for various industries, from food service to pharmaceuticals. Understanding what a cold room system is and how it operates can significantly impact efficiency and product quality.

Understanding Cold Room Systems

At their core, cold room systems are climate-controlled spaces that provide optimal conditions for storing perishable goods. They utilize advanced refrigeration technology to maintain low temperatures, which is crucial for preventing spoilage and extending shelf life. By grasping the mechanics behind these systems, businesses can better appreciate their importance in preserving quality and safety.

Benefits of Efficient Cooling Solutions

Efficient cooling solutions offer a multitude of benefits that extend beyond just maintaining temperature; they also enhance operational efficiency and reduce energy costs. A well-designed cold room system minimizes energy consumption while maximizing performance, leading to significant cost savings over time. Additionally, these solutions help businesses comply with health regulations by ensuring that products are stored under the right conditions.

Popular Applications of Cold Rooms

Cold rooms find applications across various sectors, including food processing, healthcare, and biotechnology. In the food industry, they ensure that perishables like meat, dairy, and produce stay fresh until they're ready for sale or consumption. Meanwhile, in healthcare settings, cold room freezers safeguard critical medicines and vaccines by maintaining strict temperature controls necessary for efficacy.

What is a Cold Room System?

Cold room systems are specialized refrigeration units designed to maintain low temperatures for the storage of perishable goods. These systems play a crucial role in various sectors, ensuring that products remain fresh and safe for consumption or use. Understanding what a cold room system is can help businesses make informed decisions about their cooling needs.

Definition and Purpose

A cold room system is essentially an insulated space equipped with refrigeration technology to keep items at controlled temperatures. The primary purpose of these systems is to preserve food, pharmaceuticals, and other temperature-sensitive materials by preventing spoilage or degradation. In essence, they act as climate-controlled vaults where freshness meets efficiency.

Key Components of Cold Room Systems

Key components of cold room systems include insulation panels, refrigeration units, temperature monitoring devices, and shelving units for organized storage. Insulation panels help maintain the desired temperature by minimizing heat exchange with the outside environment. Meanwhile, refrigeration units work tirelessly to circulate cool air, ensuring that every corner of the cold room remains at optimal conditions.

Importance in Various Industries

Cold room systems are vital across multiple industries such as food service, pharmaceuticals, and agriculture. In the food industry, these systems prevent spoilage and extend shelf life—keeping everything from fresh produce to frozen meals in prime condition. Similarly, in pharmaceuticals, cold rooms ensure that vaccines and medications are stored safely to maintain their efficacy and safety standards.

What Are the Different Types of Cold Rooms?

Cold room systems come in various forms, tailored to meet specific storage needs across industries. Understanding the different types of cold rooms helps businesses select the most suitable option for their requirements. This section will explore walk-in and reach-in cold rooms, modular cold rooms, and temperature-specific solutions.

Walk-In vs. Reach-In Cold Rooms

When discussing what is a cold room system, one of the first distinctions to make is between walk-in and reach-in cold rooms. Walk-in cold rooms are larger spaces that allow personnel to enter for easy access to stored goods, making them ideal for businesses with substantial inventory needs. In contrast, reach-in cold rooms are smaller units designed for quick access without stepping inside, perfect for retail environments or establishments with limited space.

Both types serve distinct purposes within the realm of cold room systems; however, they share common features such as insulation and refrigeration capabilities that ensure optimal temperature control. For example, restaurants often utilize reach-in units for immediate access to ingredients while maintaining food safety standards. Meanwhile, larger warehouses may benefit from walk-in models that accommodate bulk storage and organization.

Ultimately, choosing between a walk-in or reach-in solution hinges on factors like available space and intended use—both options can effectively meet various industry requirements.

Modular Cold Rooms and Their Flexibility

Modular cold rooms offer a unique twist on traditional designs by providing customizable configurations that adapt to changing needs. These systems consist of pre-fabricated panels that can be assembled on-site to create tailored storage solutions without compromising efficiency in cooling processes. When considering what are the different types of cold rooms available today, modular options stand out due to their flexibility in size and layout.

The beauty of modular systems lies in their ability to expand or contract as business demands shift—perfect for industries experiencing fluctuating inventory levels or seasonal variations in storage needs. Additionally, these setups often boast energy-efficient designs that align with modern sustainability goals while ensuring compliance with health regulations regarding temperature-sensitive products.

In summary, modular cold room systems represent an innovative approach to efficient cooling solutions by allowing businesses to adapt quickly without sacrificing quality or performance.

Temperature-Specific Cold Storage Solutions

Temperature-specific cold storage solutions cater precisely to the varying needs of diverse industries by offering specialized environments for different products. From pharmaceuticals requiring strict temperature control to perishable foods needing just the right chill factor, these customized setups ensure optimal preservation conditions are met consistently throughout storage periods. This highlights why understanding what is a cold room system is crucial when selecting appropriate options based on product requirements.

For instance, some facilities may require ultra-low temperatures typically found in cryogenic storage units while others might only need moderate refrigeration levels suitable for dairy products or fresh produce—this versatility underscores how critical it is to assess specific cooling requirements before investing in a system. Furthermore, integrating advanced technology into these specialized setups can enhance monitoring capabilities and improve overall efficiency within operations.

In conclusion, temperature-specific solutions exemplify how varied applications influence choices surrounding what are the different types of cold rooms available today; ensuring each product's integrity while maximizing operational effectiveness remains paramount across all sectors involved in perishable goods management.

What is the Difference Between Chiller and Cold Room?

Cooling Mechanisms Explained

Chillers operate by circulating a refrigerant through a closed loop system that absorbs heat from a designated area, effectively cooling it down. This process usually involves evaporators, condensers, compressors, and expansion valves working together to maintain desired temperatures. On the other hand, cold room systems utilize insulated spaces that maintain low temperatures through refrigeration units designed to handle larger volumes of goods efficiently.

While chillers are often used for smaller-scale applications or where precise temperature control is needed—like in laboratories—cold room freezers are ideal for bulk storage in industries such as food service or pharmaceuticals. Understanding what is a cold room system is essential; it’s designed not just to cool but also to sustain those temperatures over time with minimal energy loss.

Pros and Cons of Each System

Chillers come with several advantages: they tend to be more compact than cold rooms and can provide precise temperature control tailored for sensitive items like medications or perishable foods. However, their capacity may limit them when dealing with larger quantities; thus, they might require multiple units for extensive operations.

Cold room systems excel in handling large volumes of products while maintaining consistent temperatures across a spacious area. The downside? They often require more floor space and can involve higher initial setup costs compared to chillers. In summary, both systems have their merits; choosing between them depends on your specific requirements regarding capacity and precision.

When to Choose a Chiller Over a Cold Room

Choosing between a chiller and a cold room system boils down to your unique needs—size matters! If you're storing small quantities of highly sensitive materials requiring exact temperature control (think pharmaceuticals), then chillers are your best bet due to their efficiency in limited spaces.

Conversely, if you’re managing bulk food supplies or large inventories needing stable conditions over extended periods—what are the different types of cold rooms?—a dedicated cold room would better suit your needs due to its expansive design capabilities and energy-efficient operation over time. Ultimately, understanding what are the requirements for a cold room can help inform your decision-making process as well.

What Are the Requirements for a Cold Room?

When it comes to cold room systems, understanding the requirements is crucial for ensuring optimal performance and safety. A well-designed cold room must meet specific specifications to maintain desired temperatures and protect stored items effectively. This section will explore essential specifications, compliance with health standards, and considerations for optimal location and setup.

Essential Specifications

To ensure that your cold room system operates efficiently, certain essential specifications must be adhered to. First, temperature control is paramount; most cold rooms should maintain a consistent temperature range between -20°C to 5°C depending on what you’re storing. Additionally, insulation quality plays a critical role—high-quality insulation materials can significantly reduce energy consumption while maintaining internal temperatures.

Another important specification involves the capacity of the cold room freezer or storage area; it should be tailored to accommodate your inventory size without overloading the system. The cooling capacity of the compressors used in these systems is also vital; they should be capable of handling peak loads effectively without compromising performance. Lastly, proper airflow design ensures that cool air circulates uniformly throughout the space, preventing hot spots that could jeopardize stored goods.

Compliance with Health and Safety Standards

Adhering to health and safety standards is non-negotiable when setting up any cold room system. Various regulations exist depending on industry requirements; for instance, food storage facilities must comply with guidelines set by organizations like the FDA or USDA in the United States. These regulations often dictate temperature thresholds, sanitation protocols, and maintenance schedules to ensure safe food handling practices.

Moreover, regular inspections are necessary to confirm compliance with local building codes and safety regulations regarding electrical installations and refrigeration systems. It’s also essential for operators of cold rooms to undergo training in best practices for handling equipment safely while maintaining hygiene standards within these environments. By following these guidelines diligently, businesses can avoid costly penalties and ensure their operations run smoothly.

Optimal Location and Setup Considerations

The location of your cold room system significantly impacts its efficiency and effectiveness in preserving goods over time. Ideally, a cold room should be situated away from direct sunlight or heat sources that could affect its internal temperature stability—this helps reduce energy costs associated with cooling efforts. Additionally, accessibility is crucial; placing your cold storage near loading docks or production areas can streamline operations while minimizing disruption.

When setting up a cold room freezer or any type of storage solution, consider factors such as ventilation needs for compressors as well as drainage systems for potential condensation issues within the unit itself. Proper layout planning ensures efficient use of space while allowing necessary movement around equipment for maintenance purposes—this can save time during routine checks or emergencies alike! Ultimately, thoughtful placement combined with strategic design choices can result in an optimized environment tailored specifically for your needs.

The Role of Cold Room Compressors

Cold room systems are heavily reliant on their compressors, which serve as the heart of the cooling process. These compressors are crucial for maintaining the desired temperature within a cold room, ensuring that stored items remain fresh and safe. Understanding the types of compressors used, particularly in cold room freezers, can help operators make informed decisions about their cooling systems.

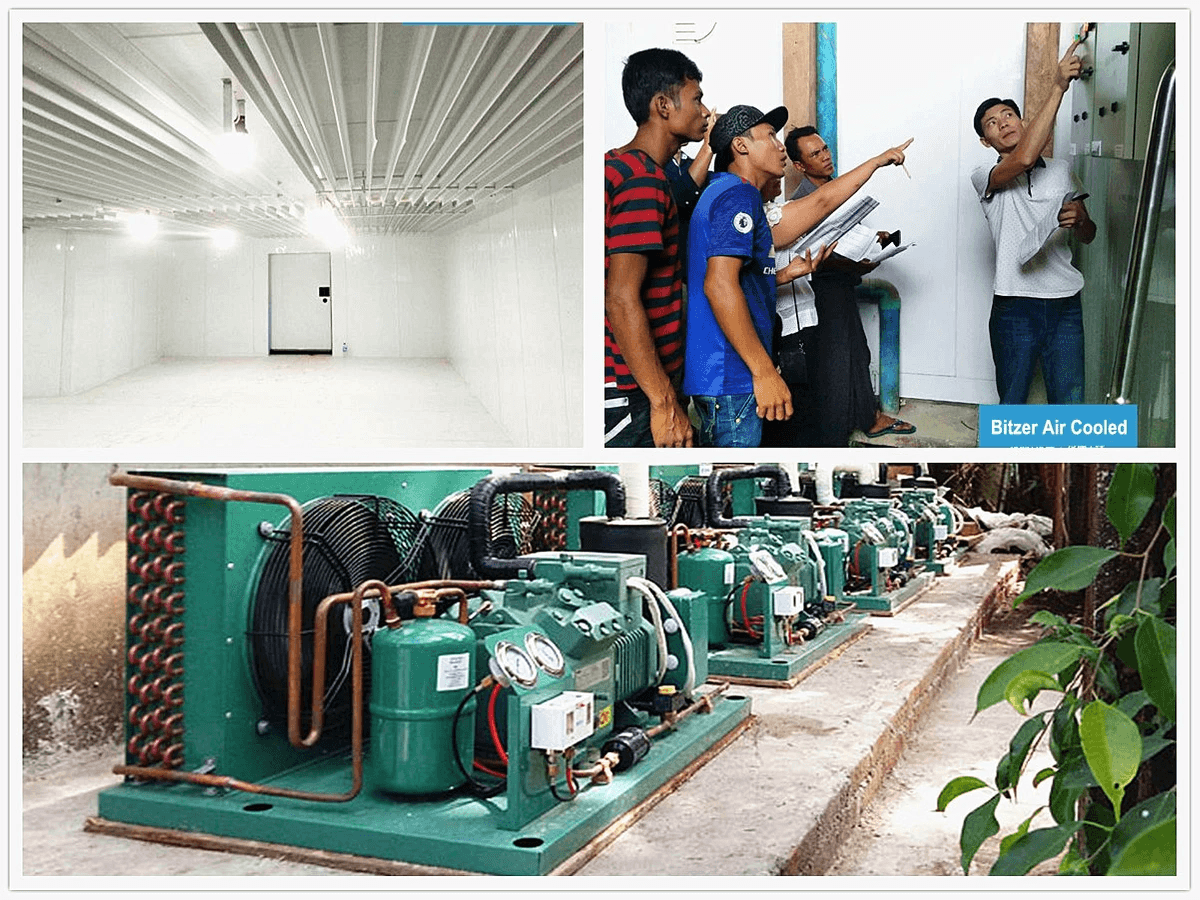

Types of Compressors Used

In cold room systems, there are several types of compressors commonly employed to achieve efficient cooling. The most prevalent types include reciprocating compressors, scroll compressors, and screw compressors. Each type has its unique advantages; for instance, reciprocating compressors are known for their reliability and cost-effectiveness, while scroll compressors offer quieter operation and higher efficiency levels.

When considering what is a cold room system?, it’s essential to recognize that the choice of compressor directly influences the overall performance and energy consumption. Additionally, some cold room freezers may utilize more advanced options like inverter-driven or variable-speed compressors to enhance energy efficiency further. Ultimately, selecting the right compressor type is vital for optimizing cold storage solutions.

RIGID Mini Compressors: Efficiency and Innovation

Among the various options available in the market today, RIGID mini compressors stand out for their exceptional efficiency and innovative design tailored specifically for cold room systems. These compact units provide powerful cooling capabilities while consuming significantly less energy compared to traditional models. This innovation not only reduces operational costs but also minimizes environmental impact—an increasingly important consideration in today's world.

What makes RIGID mini compressors particularly appealing is their versatility across different applications within what are the different types of cold rooms? Whether used in small walk-in units or larger modular setups, these mini-compressors maintain optimal temperatures effectively without compromising on performance or reliability. Their ability to adapt to varying load conditions makes them a top choice among industry professionals looking for dependable cooling solutions.

Maintenance Tips for Longevity

To ensure longevity and consistent performance from your chosen cold room compressor—be it a standard model or an advanced RIGID mini compressor—regular maintenance is key. Start by routinely checking refrigerant levels; low refrigerant can lead to inefficient cooling or even system failure over time. Additionally, cleaning condenser coils should be part of your maintenance routine since dirty coils hinder heat exchange efficiency in both conventional and cold room freezer setups.

Another vital aspect involves monitoring electrical connections and controls within your system; loose wiring can lead to operational issues that might affect overall performance in what is the difference between chiller and cold room? Lastly, scheduling professional inspections at least once a year will help identify potential problems before they escalate into costly repairs or downtime—keeping your cold storage solutions running smoothly.

Innovations in Cold Room Technology

In the fast-evolving world of cold room systems, innovation is the name of the game. The push for energy efficiency, smart technology integration, and customizable solutions has transformed how industries approach cold storage. Understanding these innovations can help businesses optimize their operations while ensuring compliance with industry standards.

Energy Efficiency Improvements

Energy efficiency improvements are at the forefront of advancements in cold room systems. With rising energy costs and increased environmental awareness, manufacturers are focusing on developing systems that minimize energy consumption without compromising performance. From high-efficiency compressors to advanced insulation materials, these innovations not only reduce operational costs but also extend the lifespan of cold room freezers.

Moreover, modern cold room systems often incorporate variable speed drives and enhanced control mechanisms that adapt to fluctuating loads and ambient conditions. This means that businesses can enjoy consistent temperatures while using significantly less energy. By investing in energy-efficient solutions, companies can align their operations with sustainability goals while benefiting from lower electricity bills.

Smart Cold Room Systems

The rise of IoT (Internet of Things) technology has given birth to smart cold room systems that revolutionize monitoring and management processes. These intelligent systems allow for real-time tracking of temperature and humidity levels, ensuring optimal conditions are maintained at all times. With alerts sent directly to mobile devices or computers, managers can quickly address any issues before they escalate into costly problems.

Furthermore, smart cold rooms often come equipped with predictive maintenance features that analyze performance data to forecast potential failures in components like the cold room compressor or refrigeration units. This proactive approach reduces downtime and enhances reliability across various applications. As industries continue embracing automation and data analytics, smart cold room solutions will be integral to efficient operations.

Custom Solutions from RIGID

RIGID is leading the charge in providing custom solutions tailored specifically for unique business needs within the realm of cold room systems. Understanding that one size does not fit all when it comes to temperature-controlled environments, RIGID offers bespoke designs that cater to specific requirements—whether it's a small-scale operation or a large industrial facility.

These custom solutions include specialized configurations for different types of cold rooms—be it walk-in units or modular setups—and even bespoke features like integrated shelving or specific temperature zones for diverse products. By focusing on client specifications and industry demands, RIGID ensures optimal functionality while maintaining compliance with health standards associated with what are the requirements for a cold room? Investing in such tailored solutions enables businesses to maximize efficiency while addressing their unique challenges head-on.

Conclusion

In summary, cold room systems are essential for various industries requiring temperature-sensitive storage. Understanding what is a cold room system allows businesses to make informed choices about their cooling needs. As we’ve explored the different types of cold rooms and the distinctions between chillers and cold rooms, it's clear that selecting the right solution can significantly impact operational efficiency.

Key Takeaways on Cold Room Systems

Cold room systems play a pivotal role in preserving perishable goods, making them indispensable in sectors like food service and pharmaceuticals. Knowing what are the requirements for a cold room ensures compliance with health standards while optimizing performance. Additionally, understanding the function of cold room compressors can lead to better maintenance practices and longer equipment lifespans.

Future Trends in Cold Storage Solutions

The landscape of cold storage is evolving rapidly with innovations aimed at enhancing energy efficiency and smart technology integration. Future trends suggest that advancements in automation will streamline operations within cold room systems, making them more user-friendly and efficient. Moreover, custom solutions tailored to specific industry needs will become increasingly popular as businesses seek competitive advantages.

Choosing the Right Cooling System for Your Needs

Understanding what are the different types of cold rooms available allows businesses to match their unique requirements with appropriate solutions effectively. Ultimately, whether opting for a chiller or a more traditional cold room freezer setup depends on specific operational demands and future growth plans.