1. Project Background

Water scarcity is no longer a distant challenge—it is a present and growing global issue. According to international studies, billions of people already live in regions facing seasonal or permanent water stress. The challenge becomes even more severe in arid, off-grid, and disaster-prone environments, where traditional water infrastructure is either unavailable or unreliable.

Since 2016, a Holland-based company has focused on developing safe drinking water solutions for challenging environments, including deserts, remote villages, humanitarian response zones, and off-grid industrial sites. Their mission is clear: make clean water accessible anywhere, regardless of climate, infrastructure, or grid availability.

The company’s technology portfolio emphasizes sustainability and resilience, combining:

- Air-to-Water systems that extract moisture directly from ambient air

- Water-to-Water purification technologies

- Power flexibility, enabling operation via solar, wind, grid, or generator

A key challenge, however, remained unresolved:

How to efficiently and reliably condense water from air in extreme desert conditions using limited renewable energy?

The Engineering Problem

The client required a compressor-based condensing cooling system that could:

- Operate in high ambient temperatures (~30 °C)

- Deliver stable condensation performance

- Run on 24V DC power for solar and battery integration

- Provide adaptive capacity control to maximize water yield

- Remain compact, reliable, and serviceable in remote locations

Additionally, the system needed to integrate with advanced water harvesting technologies, including Metal-Organic Frameworks (MOFs)—materials capable of absorbing water vapor even at extremely low relative humidity (7–20%).

This was not a standard HVAC application. It required precision cooling engineering, system customization, and deep understanding of energy-water coupling.

2. RIGID Solution

2.1 System Architecture Overview

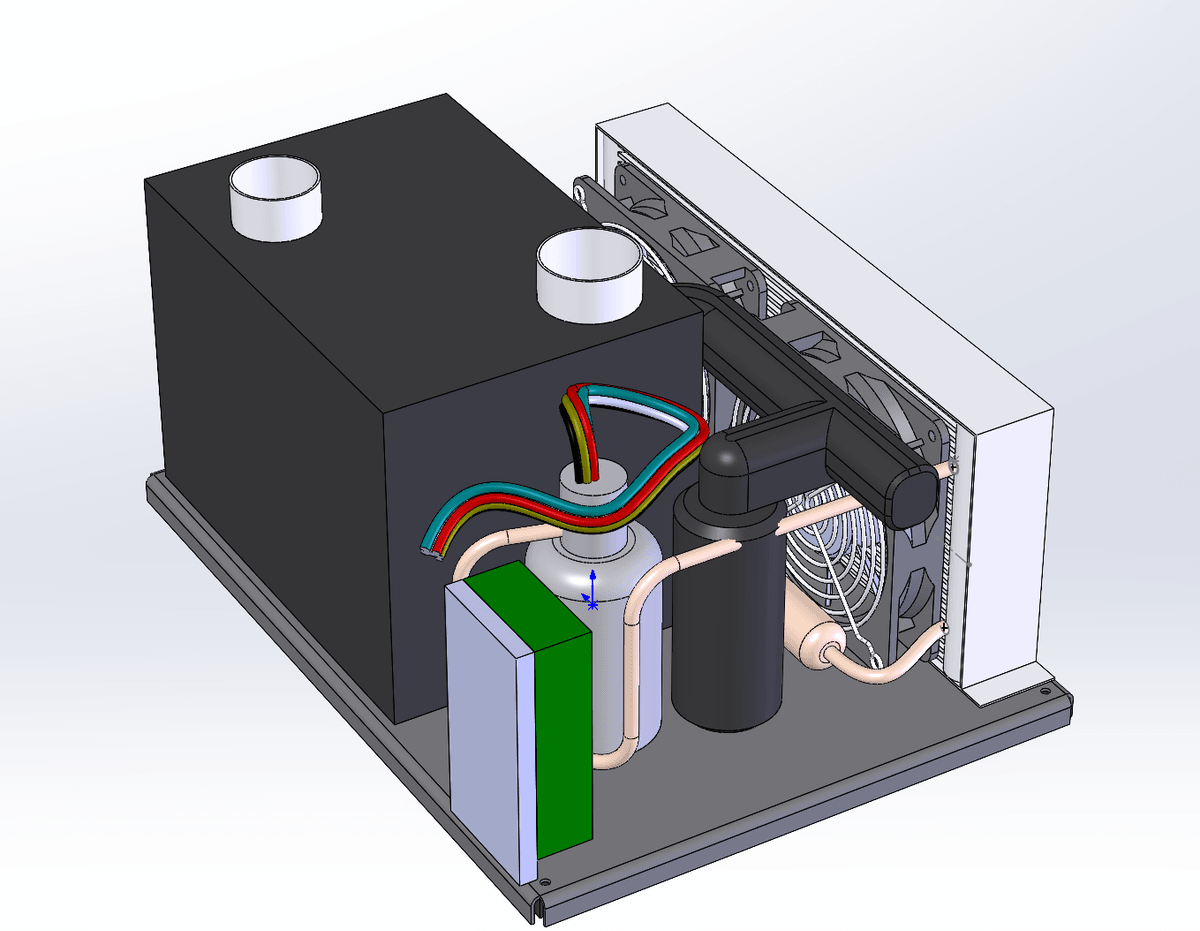

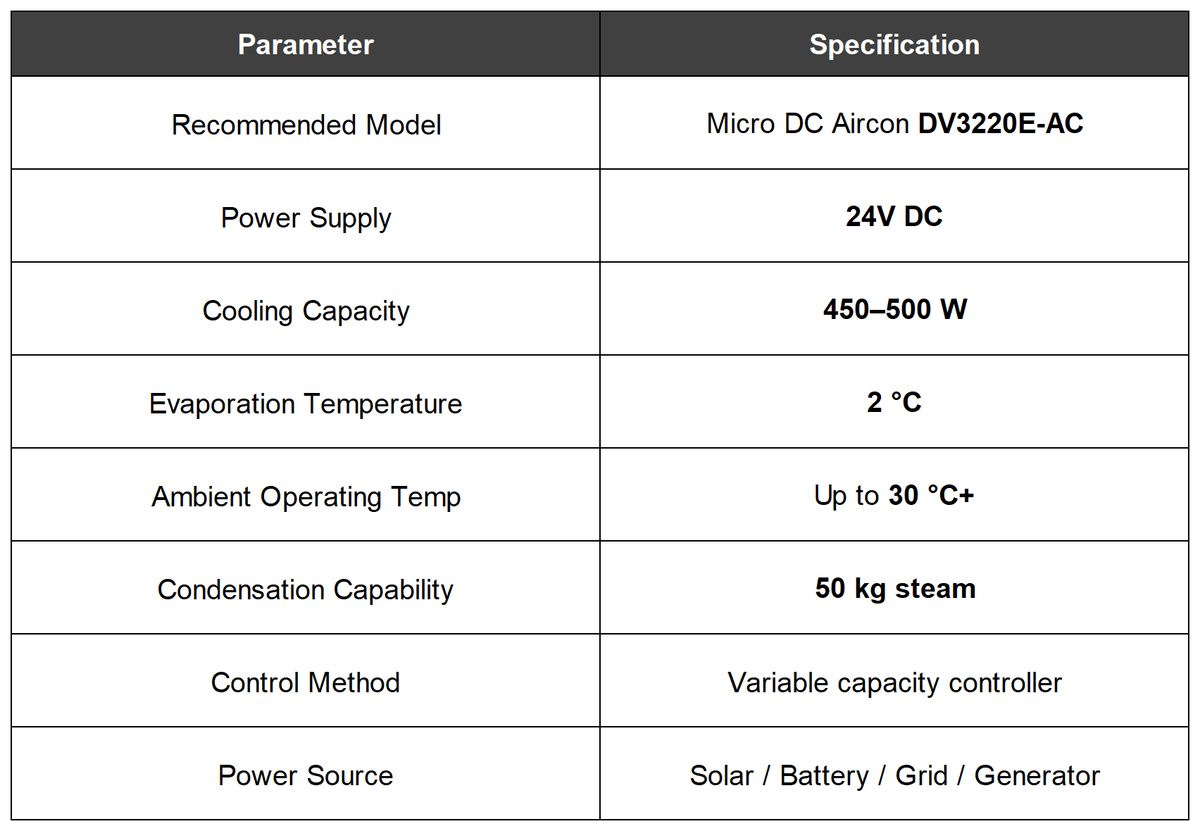

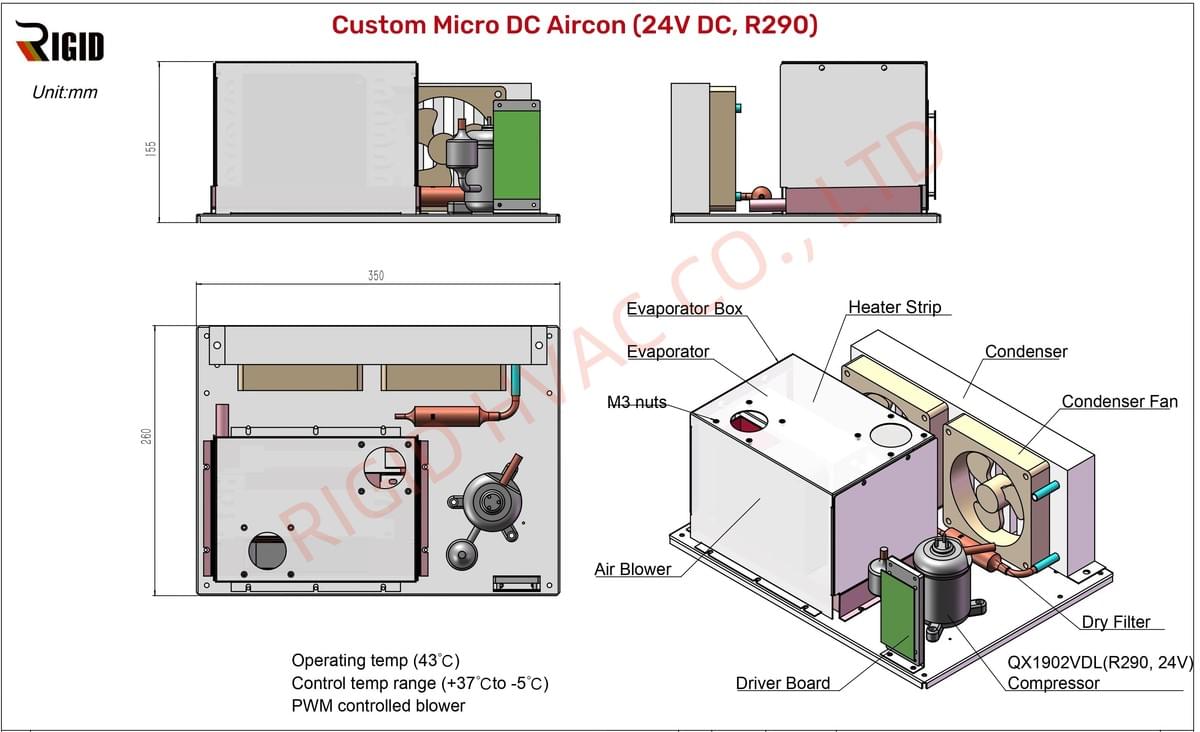

RIGID HVAC engineered a customized compressor condensing system based on its proven Micro DC Aircon platform, with the DV3220E-AC (24V) selected as the core cooling engine.

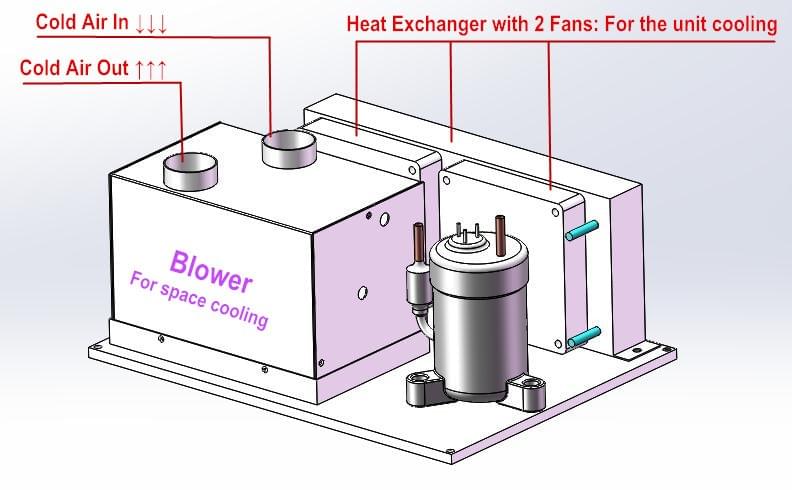

The solution was designed as a modular cooling loop, easily integrated into the client’s atmospheric water harvesting system.

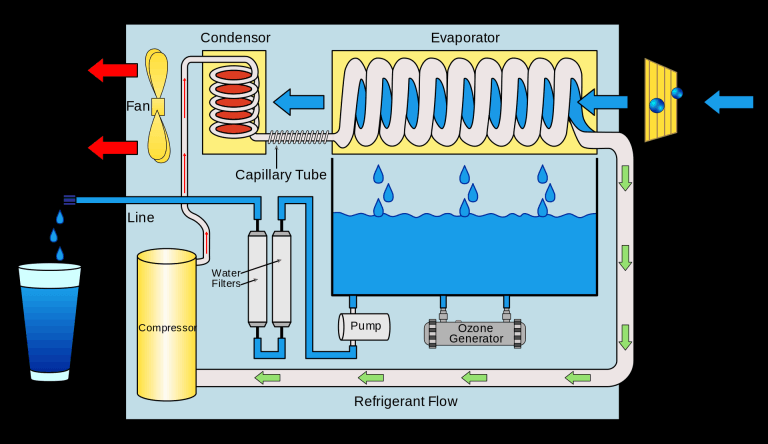

Core system elements include:

- DC inverter compressor

- Evaporator for moisture condensation

- Condenser for heat rejection

- Capillary tube expansion system

- Integrated capacity controller

- Solar-battery compatible power electronics

2.2 Key Technical Specifications

These specifications were carefully balanced to ensure maximum water yield per watt, a critical metric in renewable-powered systems.

2.3 Working Principle: From Air to Water

The system operates on a compressor-based refrigeration cycle, optimized for water extraction rather than comfort cooling.

Step-by-step process:

- Air Intake

Ambient air—containing moisture even in desert climates—is drawn into the system via controlled airflow. - Cooling & Dew Point Crossing

The air passes across the evaporator, where the Micro DC Aircon lowers its temperature below the dew point. - Condensation

Water vapor condenses into liquid droplets on the evaporator surface. - Water Collection & Purification

The condensed water is collected, filtered, and routed to purification modules to meet drinking-water standards. - Heat Rejection

Heat absorbed during condensation is expelled through the condenser, returning air to near-ambient temperature. - Adaptive Capacity Control

Cooling capacity dynamically adjusts based on humidity, temperature, and steam availability—maximizing efficiency.

Micro DC Aircon, DV3220E-AC external drawing

2.4 Integration with MOF Water Harvesting Technology

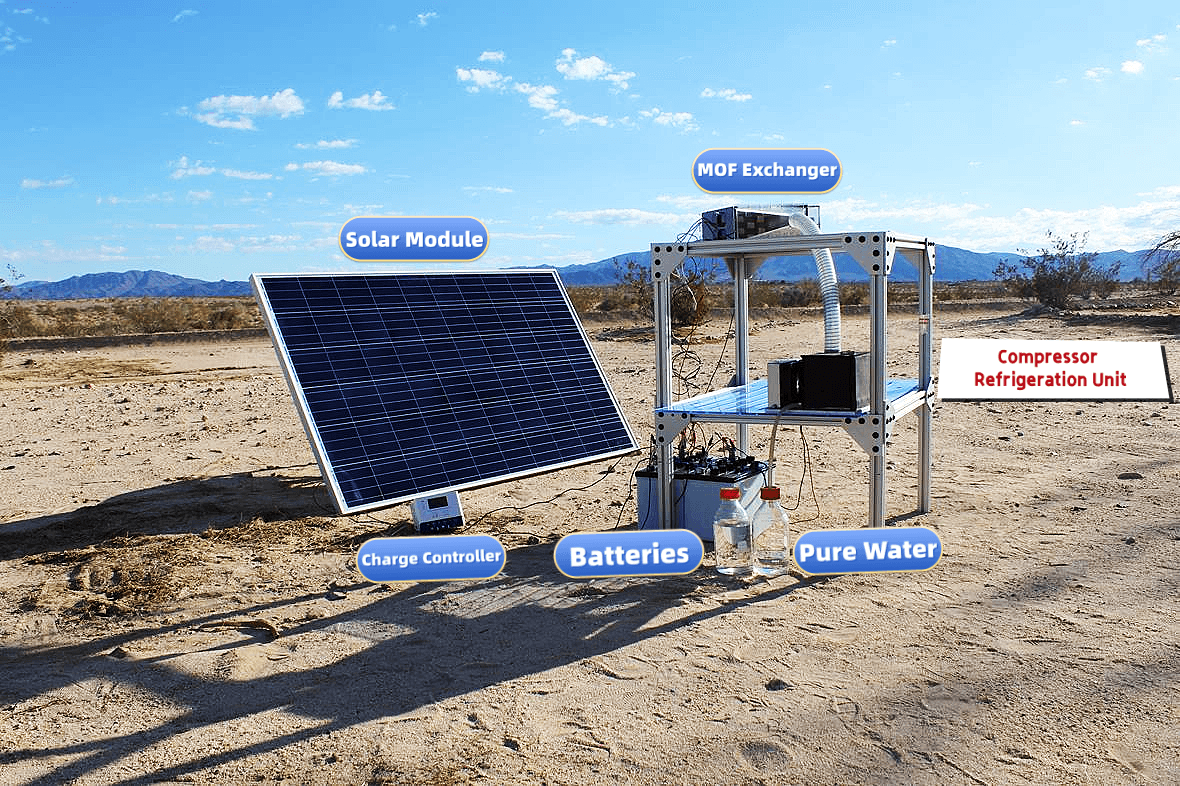

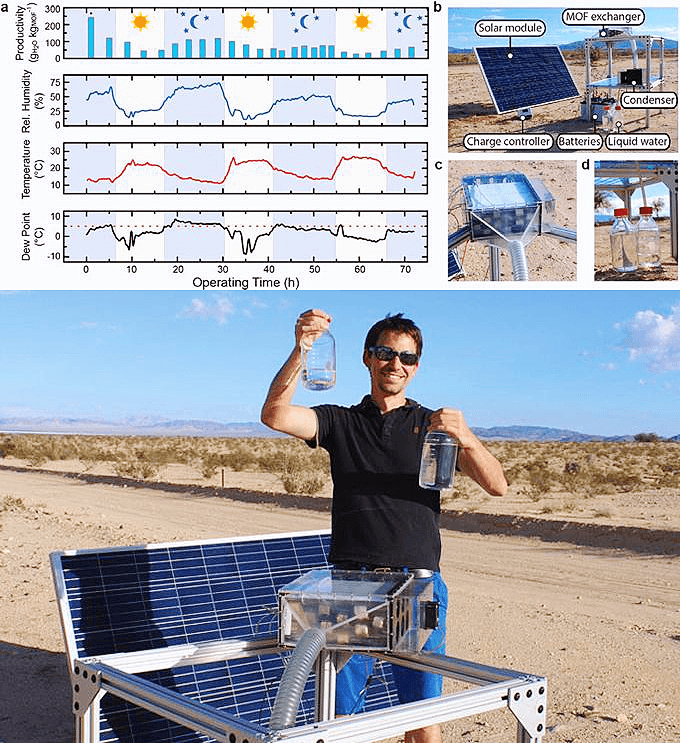

In advanced configurations, RIGID’s cooling system supports MOF-based atmospheric water harvesting.

Why MOFs matter:

- MOFs have exceptionally large internal surface areas

- 1 gram of MOF can have a surface area comparable to a football field

- They absorb water vapor even at 7% relative humidity

System synergy:

- At night, MOFs absorb moisture from ambient air

- During the day, solar power heats the MOF material

- Released water vapor is directed to RIGID’s condensing system

- The Micro DC Aircon converts vapor into liquid water efficiently

This hybrid approach dramatically increases daily water yield—up to 10× improvement per kilogram of MOF compared to passive systems.

2.5 Features That Make the Difference

✔ DC Inverter Compressor

Optimized for partial-load efficiency and low-power operation.

✔ 24V Low-Voltage Design

Ideal for off-grid solar systems and battery storage.

✔ Capacity Controller

Automatically adapts cooling output to real-time conditions.

✔ Compact & Modular

Easy to integrate into mobile, containerized, or fixed installations.

✔ High Reliability

Designed for harsh environments with minimal maintenance.

✔ Environmentally Responsible

Supports renewable energy and minimizes water-energy footprint.

2.6 Advantages for Water-from-Air Applications

- Higher water yield per kWh

- Stable performance in extreme climates

- Scalable from small devices to village-scale systems

- Compatible with next-generation materials (MOFs)

- Reduced operational costs

- Future-proof system architecture

This project demonstrates how cooling is no longer just thermal management—it is infrastructure.

3. Project Summary

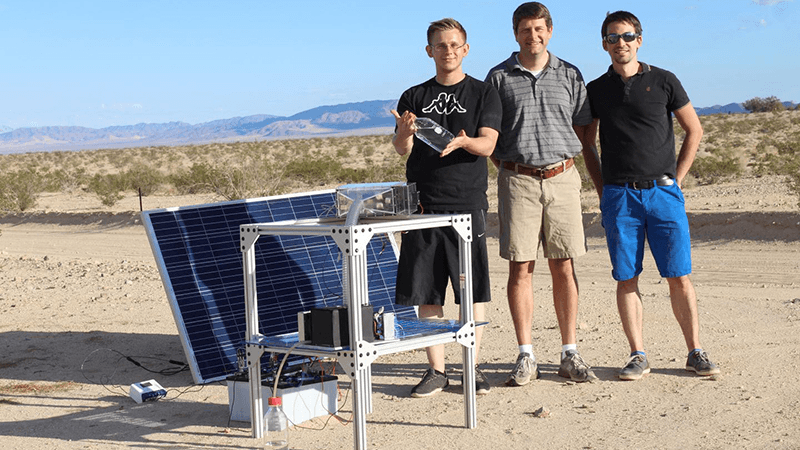

This case study highlights how RIGID’s Micro DC Aircon technology enables real-world atmospheric water harvesting, even in some of the harshest environments on Earth.

By delivering:

- Precise temperature control

- Renewable-ready power architecture

- Adaptive capacity modulation

- Seamless system integration

RIGID helped transform air into a reliable source of drinking water.

The collaboration proves that engineering-driven cooling solutions can directly address global challenges such as water scarcity, climate resilience, and sustainable development.

💧 Are you building solutions for water, energy, or sustainability?

Whether you are developing:

- Atmospheric water generators

- MOF-based harvesting systems

- Off-grid environmental technologies

- Renewable-powered infrastructure

RIGID can help you engineer the cooling system behind your innovation.

👉 Contact our technical team to discuss your project requirements. quinn@rigidhvac.com

5. Why RIGID?

At RIGID, we believe cooling is an enabling technology.

What sets us apart:

- Deep expertise in Micro DC & precision cooling

- Strong custom engineering capability

- Proven experience in extreme and off-grid applications

- Close collaboration with client engineering teams

- Fast development cycles and reliable global support

We don’t just deliver products—we co-engineer solutions that turn ideas into deployable systems.

RIGID Cooling.

Engineering the systems that make sustainability possible.