In an era defined by rapid electrification, portable devices, compact machinery, and sustainability-driven engineering, the demand for small, powerful, and energy-efficient cooling technology has never been greater. OEM engineers and HVAC manufacturers are under pressure to develop systems that deliver higher performance in smaller footprints, operate reliably in harsh environments, and meet strict efficiency and emissions standards.

At the center of this technological shift is the BLDC compressor — a new generation of cooling engines that combine brushless motor technology, intelligent control, and compact architecture to outperform traditional AC compressors in nearly every key metric.

RIGID — a global leader in miniature and micro DC cooling systems — has pioneered the development of BLDC Compressors designed specifically for OEM integration. These compressors are purpose-built for applications where size, precision, and energy efficiency are critical design requirements.

This blog explores the technology, the market drivers, and the engineering advantages that make RIGID BLDC Compressors the preferred choice for OEMs designing the next wave of high-performance cooling solutions.

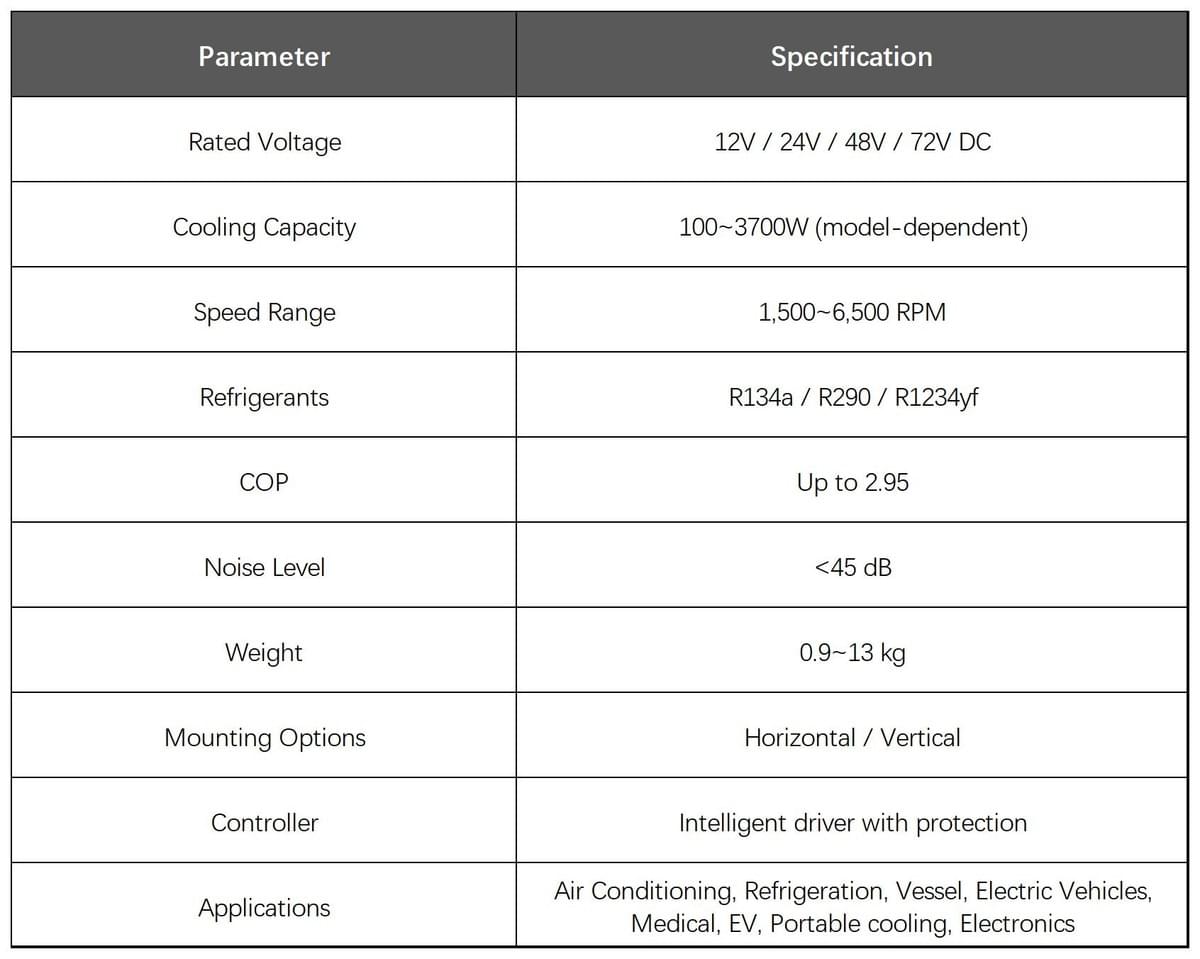

Technical Datasheet

RIGID Miniature BLDC Compressor Technical Comparison Table

1. Why OEM Engineers Are Moving to BLDC Compressors?

The HVAC and cooling landscape is transforming. Three core trends are driving the adoption of BLDC (Brushless DC) technology across industries:

1.1 Electrification & DC-Powered Systems

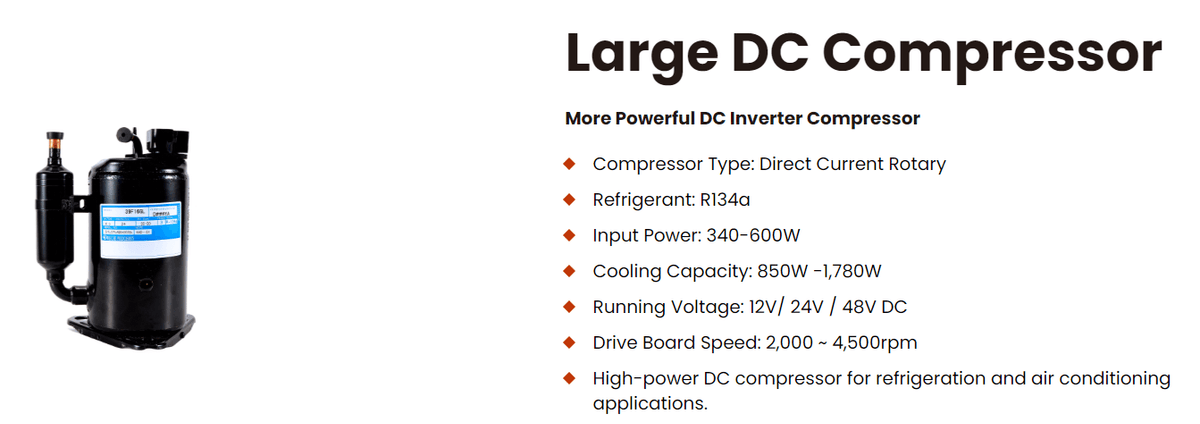

From electric vehicles to portable medical devices, more equipment runs on DC power, making AC compressors inefficient or incompatible. BLDC compressors operate directly on DC input—12V, 24V, 48V—optimizing integration for mobile, off-grid, and battery-powered applications.

1.2 Miniaturization Across Product Categories

Industrial and consumer products are getting smaller, smarter, and more portable. To match this evolution, OEMs require cooling solutions that are:

- Lightweight

- Compact

- Low-vibration

- Low-noise

- Configurable for tight spaces

RIGID’s BLDC compressors are engineered specifically around these constraints.

BLDC compressors offer higher efficiency, better modulation, and reduced energy waste — essential for:

- ESG compliance

- Green building certifications

- Off-grid power optimization

- Low-GWP refrigerant compatibility

With governments enforcing stricter efficiency policies, BLDC compressors have become the natural successor to traditional rotary compressors.

2. What Is a BLDC Compressor?

A BLDC compressor integrates two powerful technologies:

Brushless DC Motor (BLDC)

- No brushes = no friction

- Higher efficiency

- Longer life

- Precise speed control

- Significantly lower noise

Miniature Vapor-Compression System

RIGID’s design includes:

- Hermetic compressor

- Precision electronic driver

- Oil-based lubrication

- Eco-friendly refrigerants

- Compact architecture optimized for OEM use

The result is a compressor that:

✔ Consumes less power

✔ Produces less heat

✔ Operates with smoother torque

✔ Has longer service life

✔ Achieves high COP even at partial load

3. Why RIGID BLDC Compressors Outperform Traditional Compressors?

RIGID has become the partner of choice for hundreds of OEMs globally because the BLDC compressor platform consistently outperforms traditional AC compressors in mission-critical areas.

3.1 Ultra-Compact Size

Miniaturization is RIGID’s core strength. The BLDC compressors are:

- Up to 40% smaller than conventional rotary compressors

- Designed for tight OEM enclosures

- Lightweight, easy to mount

- Available in multiple configurations

This makes them ideal for portable and mobile cooling.

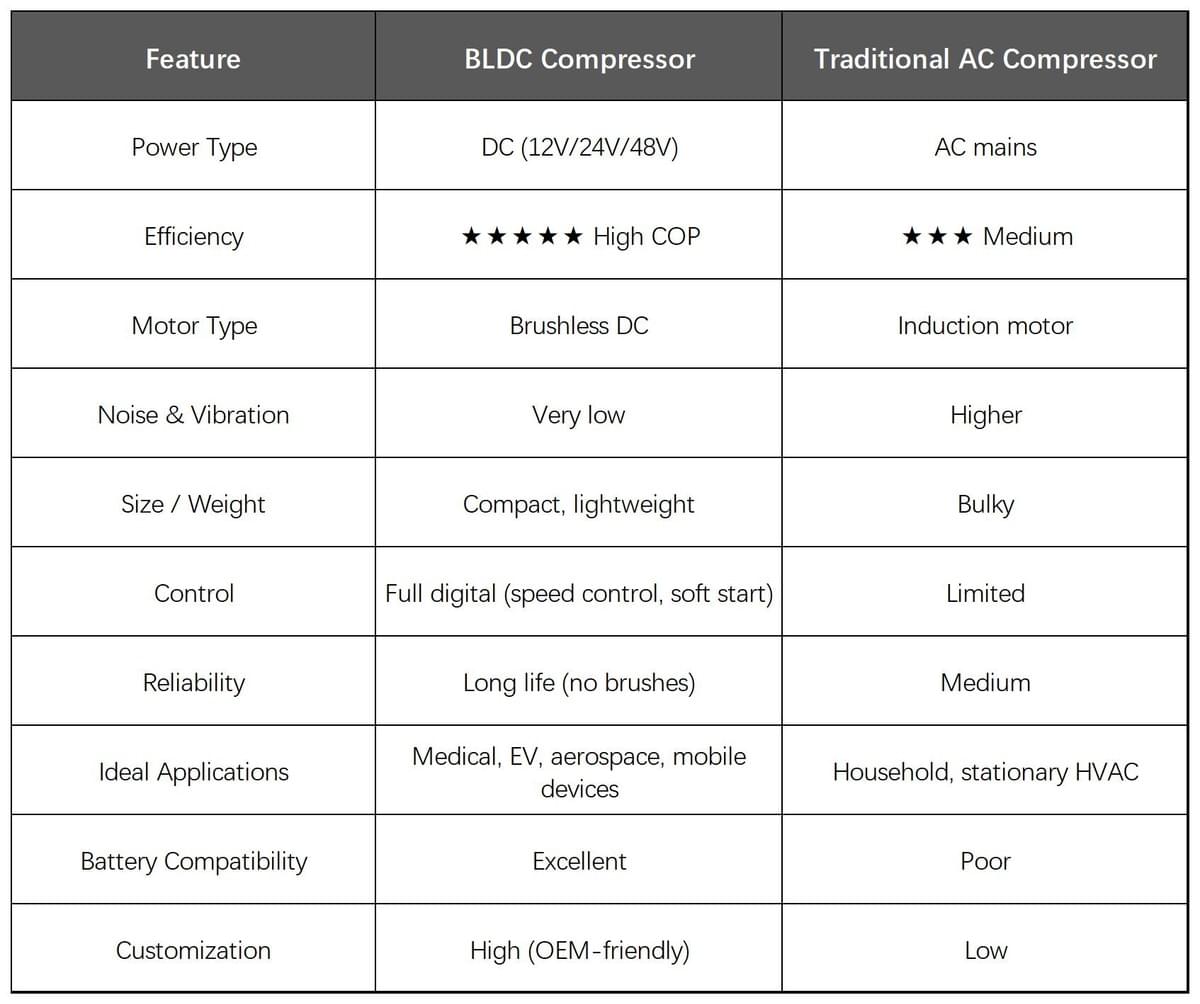

3.2 High Efficiency, Low Energy Draw

RIGID BLDC compressors achieve significant power savings, especially under part-load conditions. OEMs benefit from:

- Longer battery runtime

- Lower operating cost

- Reduced heat output

- Smoother and more stable cooling performance

3.3 Precision Digital Control

Each compressor is paired with an intelligent PCB driver that allows:

- Speed modulation

- Soft start

- Overload protection

- Real-time temperature control

- Fault monitoring

This offers engineers full control over cooling behavior.

3.4 High Reliability & Long Service Life

BLDC technology eliminates common failure points found in brushed or AC compressors. Combined with RIGID’s high-quality miniature components, the systems deliver exceptional reliability in:

- Automotive

- Medical

- Aerospace

- Industrial electronics

- Rugged mobile applications

3.5 Designed for OEM Customization

Unlike large HVAC suppliers, RIGID provides flexible engineering collaboration:

- Custom voltages

- Custom housings

- Custom performance ranges

- Custom evaporators

- Custom drivers

This makes the compressor highly adaptable across vertical markets.

4. Key Applications of BLDC Compressors Across Industries.

RIGID supports hundreds of engineers working across more than 20 application categories. Below are the most common use cases.

4.1 Medical & Life Sciences

Miniature BLDC compressors power temperature control in:

- Portable vaccine coolers

- DNA sequencers

- Medical laser cooling

- Diagnostic instruments

- Cryogenic devices

- Patient cooling systems

Reliability and low noise are essential — and RIGID meets both with ease.

4.2 Electric Vehicles & Battery Cooling

As EV batteries become more energy-dense, battery thermal management becomes mission-critical. RIGID BLDC compressors provide:

- Rapid heat extraction

- Stable temperature regulation

- Efficient 48V operation

Use cases include battery packs, inverters, fast chargers, and ultra-compact cabin cooling.

4.3 Aerospace, UAVs, and Defense

When payload space is limited, only ultra-compact compressors can fit. RIGID BLDC systems support:

- Avionics cooling

- Sensor cooling

- Laser optics

- Enclosure thermal stability

With low vibration and compact footprint, they excel in airborne platforms.

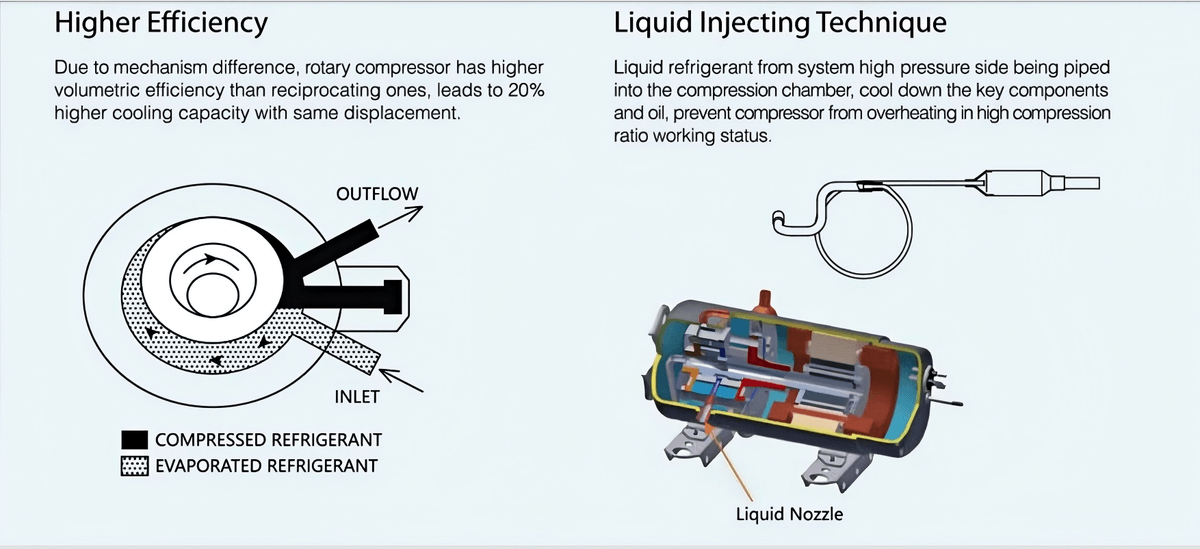

4.4 Portable and Mobile Refrigeration

The rise of mobile cooling has created strong demand for DC-powered systems:

- Camping refrigerators

- Micro air conditioners

- Cooling backpacks

- Wearable cooling

- Micro data server cooling

- Portable ice-makers

RIGID’s low-energy BLDC compressors extend battery life dramatically.

4.5 Industrial Electronics Cooling

Industrial-grade electronics require constant temperature control:

- Power electronics

- Inverters

- Computer systems

- Server racks

- High-density PCBs

BLDC compressors maintain stable operating conditions with high reliability.

5. Engineering Behind RIGID BLDC Compressors.

RIGID’s engineering philosophy is based on three pillars:

5.1 Precision Manufacturing

Every compressor is built with:

- High-grade copper windings

- Low-friction bearings

- Balanced rotor assemblies

- Noise-suppressing mounts

- Hermetically sealed construction

5.2 Advanced Control Electronics

RIGID's proprietary drivers enable:

- Smooth speed ramping from 1,500 to 6,500 RPM

- Temperature stability within ±0.1°C

- Intelligent load management

- Multi-sensor monitoring

- Real-time fault alerts

5.3 Thermal Optimization

Each compressor is optimized for:

- High COP

- Minimal heat leakage

- Tight internal clearances

- Optimized lubrication

This ensures maximum performance even under harsh and variable loads.

6. OEM Integration: Why RIGID Is a Preferred Engineering Partner.

OEMs love RIGID because the company doesn’t just supply components — it builds customized cooling solutions.

6.1 Flexible Integration

RIGID offers:

- Open-frame compressors

- Fully integrated chiller modules

- Compact micro air conditioners

- Liquid cooling systems

- Direct expansion micro units

6.2 Collaborative Engineering

RIGID provides:

- Custom CAD design

- Performance testing

- Rapid prototyping

- Custom firmware

- Private labeling options

6.3 Fast, Scalable Manufacturing

With advanced production lines and automated assembly, RIGID is able to support:

- Low-volume R&D

- Mid-volume OEM production

- High-volume mass manufacturing

7. Benefits OEM Engineers Gain From RIGID BLDC Compressors.

✔ Higher efficiency for greener systems

✔ Smaller size for tighter integrations

✔ Longer life, reduced maintenance

✔ High reliability for mission-critical sectors

✔ Full digital control for precision cooling

✔ Seamless customization and co-development

✔ Ideal for mobile, battery-powered, or off-grid platforms

8. The Future of Cooling Is DC-Powered.

As systems become increasingly electric, mobile, and environmentally friendly, the BLDC compressor is poised to replace traditional AC compressors in most compact applications.

RIGID’s BLDC compressors represent the next evolution — smaller, cleaner, and smarter.

9. Why Choose RIGID BLDC Compressors?

For OEMs building next-generation cooling systems, the choice is clear:

- If you need smaller - choose RIGID.

- If you need smarter - choose RIGID.

- If you need energy-efficient precision - choose RIGID.

RIGID’s BLDC compressor platform delivers unmatched performance, backed by a team that understands the unique demands of OEM development.

With a proven track record across dozens of industries and thousands of deployments worldwide, RIGID continues to redefine what compact cooling technology can achieve.

If you’re designing a compact cooling system or upgrading to more efficient components. RIGID’s engineering team is ready to support your project.

👉 Explore RIGID BLDC Compressors: https://www.rigidhvac.com/high-power-compressor

#BLDCCompressor #MiniatureCompressor #DCCompressor #MicroHVAC #OEMCoolingSolutions #CompactThermalManagement #12VCompressor #24VDCCompressor #BatteryCooling #PortableCooling #HighEfficiencyCooling #MicroRefrigeration #RIGIDCompressor #HVACOEM

#BrushlessDCCompressor