Introduction

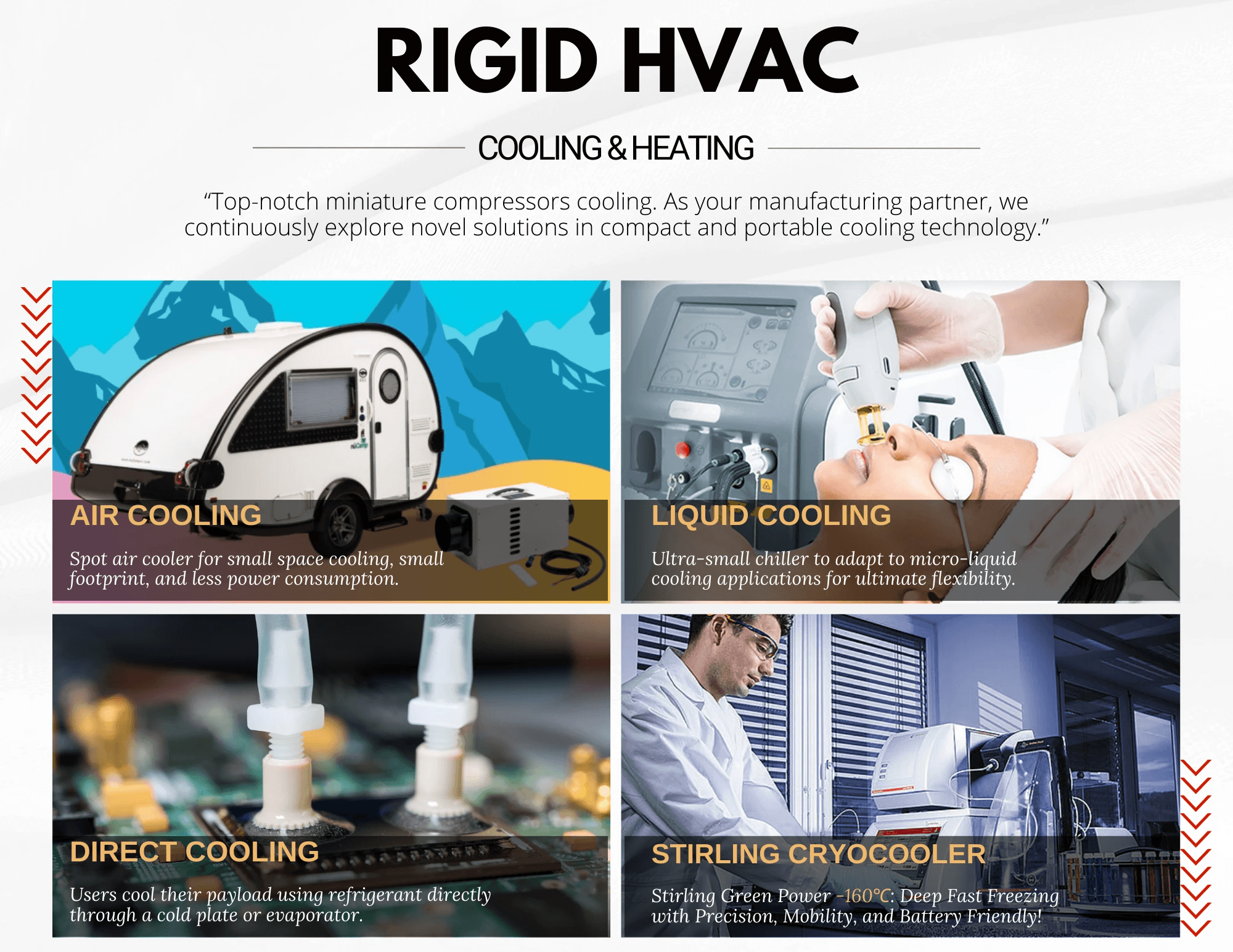

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

In the world of refrigeration and air conditioning, compressors play a pivotal role in maintaining optimal temperatures and humidity levels. Choosing the right compressor can significantly impact efficiency, performance, and overall system reliability. With a diverse range of options available, understanding the differences between horizontal compressors and their vertical counterparts is essential for making informed decisions.

Understanding Compressor Types

Compressors come in various shapes and sizes, each designed for specific applications. Horizontal compressors, such as the Horizontal Miniature Compressor and Horizontal air conditioner rotary compressor, are popular choices due to their compact design and efficient operation. These units can be found in various systems including water source heat pumps, RV air conditioners, home dehumidifiers, and commercial rooftop dehumidifiers.

Importance of Choosing the Right Compressor

Selecting the appropriate compressor is crucial for achieving desired cooling or heating outcomes while minimizing energy consumption. An ill-suited compressor can lead to increased operational costs and reduced system lifespan. By understanding your specific needs—whether it’s for an RV air conditioner or a commercial rooftop dehumidifier—you can ensure that you invest in a horizontal compressor that meets your performance criteria.

Overview of RIGID's Innovations

RIGID has established itself as a leader in innovative compressor technology by developing advanced solutions tailored to meet diverse industry demands. Their commitment to quality ensures that products like the Horizontal Miniature Compressor not only perform efficiently but also adapt seamlessly to varying conditions. As we delve deeper into the types of compressors available today, RIGID's cutting-edge designs will serve as benchmarks for excellence in performance and reliability.

What is a Horizontal Compressor?

Horizontal compressors are mechanical devices designed to compress gases, typically refrigerants, by reducing their volume. Unlike their vertical counterparts, these compressors operate with a horizontal orientation, allowing for unique applications and advantages across various industries. With innovations like the Horizontal Miniature Compressor and specialized designs for air conditioning systems, these machines have become essential in modern cooling technologies.

Definition and Working Principle

A horizontal compressor functions by utilizing a piston that moves back and forth within a cylinder to compress gas. As the piston moves down, it creates a vacuum that draws in refrigerant gas; when it moves up, the gas is compressed and expelled through an outlet valve. This simple yet effective mechanism makes horizontal compressors particularly suited for applications such as water source heat pumps and RV air conditioners.

The working principle of horizontal compressors can be likened to breathing: inhaling (drawing in gas) followed by exhaling (compressing and releasing gas). This cyclical process enables efficient cooling performance in various systems, from home dehumidifiers to commercial rooftop dehumidifiers. By maintaining consistent pressure levels, horizontal air conditioner rotary compressors ensure optimal functionality across different environments.

Applications in Various Industries

Horizontal compressors find their place in numerous sectors due to their versatility and efficiency. In residential settings, they are commonly used in home dehumidifiers to maintain comfortable humidity levels while preventing mold growth. Meanwhile, commercial rooftop dehumidifiers rely on these machines for effective moisture control in large buildings.

In the HVAC industry, horizontal air conditioner rotary compressors are favored for their compact design and energy efficiency. They play a crucial role in water source heat pumps that provide both heating and cooling solutions for homes and businesses alike. Additionally, RV air conditioners benefit from the lightweight nature of horizontal compressors, making them ideal for mobile applications where space is at a premium.

Advantages of Horizontal Compressors

One of the standout advantages of horizontal compressors is their compact design which allows them to fit into tighter spaces without sacrificing performance. This makes them particularly appealing for manufacturers focusing on products like Horizontal Miniature Compressors that cater to niche markets where size constraints are critical. Furthermore, their design often leads to lower vibration levels during operation compared to vertical models.

Another significant benefit lies in energy efficiency; many horizontal models are engineered with advanced technology that reduces power consumption while maximizing output—ideal for both residential use with home dehumidifiers or commercial settings using rooftop units. Additionally, maintenance tends to be easier with horizontal configurations because components are more accessible compared to vertical counterparts.

Lastly, flexibility is key; whether it's an RV air conditioner or a water source heat pump application, these compressors can adapt seamlessly across various platforms without compromising on reliability or performance standards—making them a go-to choice across industries looking for dependable cooling solutions.

What is a Vertical Compressor?

Vertical compressors are an essential component in various cooling and refrigeration systems, providing efficient compression of gases. Unlike their horizontal counterparts, these compressors are designed to operate in an upright position, which can offer distinct advantages in terms of space-saving and operational efficiency. Understanding their definition and working principle is crucial for anyone considering the best options for their specific needs.

Definition and Working Principle

A vertical compressor is a type of positive displacement compressor that utilizes a vertical cylinder configuration to compress refrigerants or gases. The working principle involves drawing gas into the cylinder as the piston descends, then compressing it as the piston ascends, effectively increasing pressure before releasing it into the system. This design allows for effective heat dissipation and can be particularly beneficial in applications requiring high efficiency.

In contrast to horizontal compressors, which may require more floor space, vertical compressors can be installed in tighter areas without sacrificing performance. This characteristic makes them ideal for applications where space is at a premium, such as RV air conditioners or water source heat pumps. The ability to operate efficiently while occupying less ground area often makes them a preferred choice for many industries.

Key Applications and Use Cases

Vertical compressors find extensive use across various sectors due to their unique design and operational benefits. They are commonly employed in commercial rooftop dehumidifiers where efficient moisture removal is essential for maintaining indoor air quality. Additionally, they play a vital role in residential settings through home dehumidifiers that help manage humidity levels effectively.

In industrial applications, vertical compressors are often utilized within water source heat pumps due to their ability to handle varying loads efficiently while maintaining compact dimensions. Furthermore, these compressors are invaluable in specialized setups like refrigerated transport systems where space constraints necessitate innovative solutions without compromising on performance or reliability. Their versatility makes them suitable not only for HVAC systems but also for food processing plants requiring precise temperature control.

Advantages of Vertical Compressors

One of the primary advantages of vertical compressors lies in their compact design, allowing them to fit into spaces where horizontal models might struggle—think tight basements or crowded rooftops! This space-saving feature doesn’t mean they compromise on power; many models deliver impressive performance levels comparable to larger horizontal units like Horizontal Miniature Compressors used in air conditioning applications.

Another significant benefit is their enhanced cooling efficiency—vertical configurations facilitate better airflow around components during operation compared to horizontal designs that may limit ventilation opportunities. This results not only in improved energy consumption but also extends the lifespan of the equipment by reducing wear over time—a win-win situation! Moreover, with advancements from companies like RIGID focusing on innovation within this segment, users can expect cutting-edge technology that further enhances reliability and efficiency.

In summary, whether you're considering a new RV air conditioner or looking at options for commercial rooftop dehumidifiers, understanding vertical compressors' capabilities will help you make informed decisions tailored specifically to your needs.

Key Differences Between Horizontal and Vertical Compressors

When it comes to choosing between horizontal and vertical compressors, understanding their key differences is crucial for making an informed decision. Each design offers unique benefits suited to specific applications, impacting not only performance but also installation and maintenance considerations. Let's dive into the nuances that set these two types apart.

Design Variations Explained

The design of a horizontal compressor typically features a layout where the crankshaft is oriented horizontally, allowing for a compact footprint that can fit into tight spaces. This makes the horizontal miniature compressor particularly advantageous in applications like RV air conditioners or home dehumidifiers, where space is at a premium. On the other hand, vertical compressors have an upright design that can be beneficial for larger installations such as commercial rooftop dehumidifiers or water source heat pumps, providing easier access for maintenance.

In terms of construction, horizontal air conditioner rotary compressors often utilize fewer components than their vertical counterparts, potentially leading to lower manufacturing costs and easier assembly. The simplicity in design allows manufacturers like RIGID to innovate with lightweight materials while maintaining durability and efficiency. Meanwhile, vertical compressors may require more complex engineering due to their height and orientation but can offer superior cooling capabilities in certain scenarios.

Ultimately, whether you opt for a horizontal or vertical compressor will depend on your specific application needs and spatial constraints. Understanding these design variations helps customers choose the right type that aligns with their operational requirements while maximizing efficiency.

Performance in Different Conditions

Performance can vary significantly between horizontal and vertical compressors depending on environmental conditions and application demands. Horizontal compressors tend to excel in low-profile installations where airflow dynamics are advantageous; they are often more efficient when integrated into systems like RV air conditioners or home dehumidifiers designed for residential use. Their design allows them to handle varying load conditions effectively without compromising performance.

Conversely, vertical compressors may perform better under high-capacity demands found in commercial settings such as rooftop dehumidifiers or industrial water source heat pumps where space isn't as constrained. The upright configuration enables better heat dissipation during operation, which is critical when cooling large areas or managing significant moisture loads efficiently. Therefore, understanding your operating environment is essential when selecting between these two types of compressors.

Moreover, each type has its own thermal characteristics; while horizontal models might exhibit lower noise levels under certain conditions due to their compactness, vertical units can sometimes provide higher output levels necessary for demanding applications without sacrificing reliability.

Cost Considerations

Cost plays an integral role when deciding between horizontal and vertical compressors because it encompasses not just the initial purchase price but also long-term operational expenses. Generally speaking, horizontal miniature compressors may present a lower upfront investment compared to larger vertical options due to simpler designs and fewer components involved in manufacturing processes—making them ideal for budget-conscious projects like home dehumidifiers or small-scale cooling systems.

However, it's essential not to overlook potential savings related to energy efficiency over time; well-designed horizontal air conditioner rotary compressors could lead to reduced electricity bills if properly matched with system requirements—especially in residential setups where energy consumption matters significantly. In contrast, while initial costs of vertical units might be higher due to their complexity and size advantages in commercial applications like water source heat pumps or rooftop dehumidifiers might justify the expense through enhanced performance longevity.

Ultimately assessing both short-term costs against long-term value will help guide your decision-making process regarding which compressor type best meets your financial constraints while delivering optimal results tailored specifically towards your needs.

Choosing the Right Compressor for Your Needs

Selecting the right compressor can be a daunting task, especially with so many options available in the market. Whether you’re considering a horizontal compressor or a vertical one, it’s crucial to understand your specific cooling needs and how different compressors perform under varying conditions. RIGID offers innovative solutions that cater to diverse requirements, ensuring that you find the perfect match for your applications.

Evaluating Your Cooling Requirements

When evaluating your cooling requirements, consider factors such as space constraints, desired temperature ranges, and energy efficiency. A horizontal air conditioner rotary compressor may be ideal for compact spaces due to its design and efficiency in delivering cool air effectively. If you're looking for something more specialized, like a water source heat pump for a residential or commercial setting, understanding how much cooling power you need will help narrow down your choices.

For example, if you're outfitting an RV air conditioner or a home dehumidifier, knowing the specific BTU (British Thermal Unit) level required will guide you toward selecting an appropriate horizontal compressor model. Additionally, keep in mind that commercial rooftop dehumidifiers have unique demands compared to standard home units; thus, their specifications must align with your operational needs. Ultimately, taking time to assess these factors will lead you to make an informed decision.

RIGID's Custom Solutions for Clients

RIGID stands out in the industry by providing tailored solutions designed specifically for client needs. Whether it's developing a Horizontal Miniature Compressor suited for tight spaces or customizing larger systems like water source heat pumps for industrial use, RIGID’s expertise ensures optimal performance across various applications. Their team collaborates closely with clients to understand their unique challenges and offer bespoke solutions that enhance efficiency.

Moreover, if you’re dealing with specialized environments such as RV air conditioners or commercial rooftop dehumidifiers requiring specific configurations and capacities, RIGID can adapt its products accordingly. This commitment not only boosts performance but also helps clients save on long-term operational costs by maximizing energy efficiency and reducing waste. With RIGID’s custom solutions at hand, achieving precise cooling control has never been easier.

Budget Considerations when Selecting

Budget plays a critical role when selecting compressors; however, it shouldn't be the sole deciding factor. While horizontal compressors might present an upfront cost advantage due to their simpler design and manufacturing process compared to some vertical models, consider long-term savings through energy efficiency as well. Investing in quality—like RIGID's Horizontal Miniature Compressor—can lead to reduced maintenance costs and improved reliability over time.

Additionally, when evaluating options such as home dehumidifiers versus commercial rooftop dehumidifiers or even water source heat pumps versus standard models of similar capacity—understanding operational costs associated with each type is vital. Don’t forget about potential rebates or incentives available from manufacturers that could ease initial financial burdens while promoting eco-friendly choices! Ultimately balancing initial investment against future savings will help ensure you select the right compressor without breaking the bank.

The Future of Compressors in Industry

As we look ahead, the compressor industry is on the brink of exciting innovations that promise to redefine efficiency and performance. RIGID is at the forefront of these advancements, developing cutting-edge technologies that cater to various applications, from residential cooling solutions to commercial systems. With a commitment to sustainability and energy efficiency, RIGID's technological innovations are set to elevate both horizontal compressors and vertical compressors into new realms of capability.

Technological Innovations by RIGID

RIGID has been pioneering advancements in horizontal compressor design, focusing on creating more compact and efficient models such as the Horizontal Miniature Compressor. This innovative approach not only reduces space requirements but also enhances performance in tight environments like RV air conditioners or home dehumidifiers. Additionally, RIGID's development of smart control systems allows for better integration with modern HVAC solutions, ensuring optimal operation across varied conditions.

The introduction of advanced materials and manufacturing techniques has also played a crucial role in improving the durability and reliability of horizontal air conditioner rotary compressors. These innovations enable these compressors to withstand harsher operating conditions while maintaining energy efficiency—essential for applications like water source heat pumps or commercial rooftop dehumidifiers. By continuously refining their technology, RIGID ensures that their products remain competitive in an ever-evolving market.

Moreover, RIGID is embracing IoT (Internet of Things) technologies that allow users to monitor and manage their systems remotely. This feature is especially beneficial for users of RV air conditioners or home dehumidifiers who demand convenience and real-time performance feedback. As technology continues to evolve, we can expect even more groundbreaking features from RIGID's lineup.

Trends in Micro Refrigeration and Air Conditioning

The trend towards micro refrigeration solutions is gaining momentum as industries seek more compact options without sacrificing performance. Horizontal compressors are leading this charge with designs tailored for smaller appliances while delivering exceptional cooling capabilities—think about how a Horizontal Miniature Compressor can revolutionize your cooling system! As consumer preferences shift towards smaller yet efficient products, manufacturers are increasingly turning to horizontal designs for their versatility.

Additionally, there’s a growing demand for eco-friendly refrigerants that align with global sustainability goals; this trend is influencing compressor design significantly. Both horizontal air conditioner rotary compressors and vertical models are being engineered to accommodate these new refrigerants without compromising efficiency or effectiveness. The shift towards greener solutions not only benefits the environment but also positions companies like RIGID as leaders in responsible manufacturing practices.

Furthermore, as urban living spaces become smaller and more densely populated, the need for effective space-saving appliances rises sharply. Horizontal compressors excel here by fitting seamlessly into limited spaces while providing robust cooling options—ideal for everything from RV air conditioners to commercial rooftop dehumidifiers designed for urban rooftops! This adaptability ensures that manufacturers can meet diverse consumer needs across different markets.

The Role of Horizontal and Vertical Compressors

Horizontal and vertical compressors each have unique roles within the industry landscape; however, trends indicate a rising preference for horizontal designs due to their compactness and versatility in various applications. For instance, when it comes to home dehumidifiers or water source heat pumps used in residential settings, horizontal configurations often prove advantageous due to their space-saving nature without compromising on output capacity.

In contrast, vertical compressors tend to shine in larger industrial applications where floor space isn't as constrained but high output is necessary—think large-scale HVAC systems where efficiency reigns supreme! Nevertheless, both types will coexist harmoniously as they cater specifically to differing needs across sectors—from small-scale residential units using Horizontal Miniature Compressors all the way up through expansive commercial installations employing robust vertical models.

Ultimately, understanding each compressor type's strengths allows businesses like RIGID not only to innovate effectively but also tailor solutions precisely suited for clients' needs—whether they require a sleek RV air conditioner or an efficient commercial rooftop dehumidifier! As we move forward into this exciting future filled with possibilities driven by technology advancements from companies like RIGID—the best days lie ahead!

Conclusion

In wrapping up our discussion on compressors, it’s clear that both horizontal and vertical compressors have unique strengths tailored to specific applications. The horizontal compressor, including the Horizontal Miniature Compressor and the Horizontal air conditioner rotary compressor, excels in various settings from residential to commercial. Each type serves distinct functions, making them invaluable in industries ranging from HVAC to refrigeration.

Summary of Compressor Types

We've explored a range of compressor types, highlighting the functionality of horizontal compressors alongside their vertical counterparts. The versatility of a horizontal compressor is evident in applications such as water source heat pumps and RV air conditioners, where space-saving designs are crucial. Meanwhile, vertical compressors often find their niche in larger systems like commercial rooftop dehumidifiers, showcasing the diverse landscape of compressor technology.

Importance of Tailored Solutions

Choosing the right compressor isn't just about picking one off the shelf; it’s about finding a solution that meets specific needs. Whether you require a home dehumidifier or a compact Horizontal Miniature Compressor for an RV air conditioner, tailored solutions ensure optimal performance and efficiency. RIGID understands this necessity and offers customized options designed to fit individual requirements seamlessly.

RIGID's Commitment to Quality and Innovation

RIGID stands at the forefront of innovation within the compressor industry, consistently pushing boundaries with new technologies and designs. Their dedication to quality ensures that every product—from horizontal compressors to robust water source heat pumps—meets rigorous standards for reliability and performance. As trends evolve toward more efficient systems like commercial rooftop dehumidifiers, RIGID remains committed to providing innovative solutions that meet tomorrow's challenges today.