Revolutionizing Pizza Production with RIGID’s Cutting-Edge Cooling Technology!

Project: Cooling Solution for Compact Pizza Machine

Cooling Approach: Air-cooled

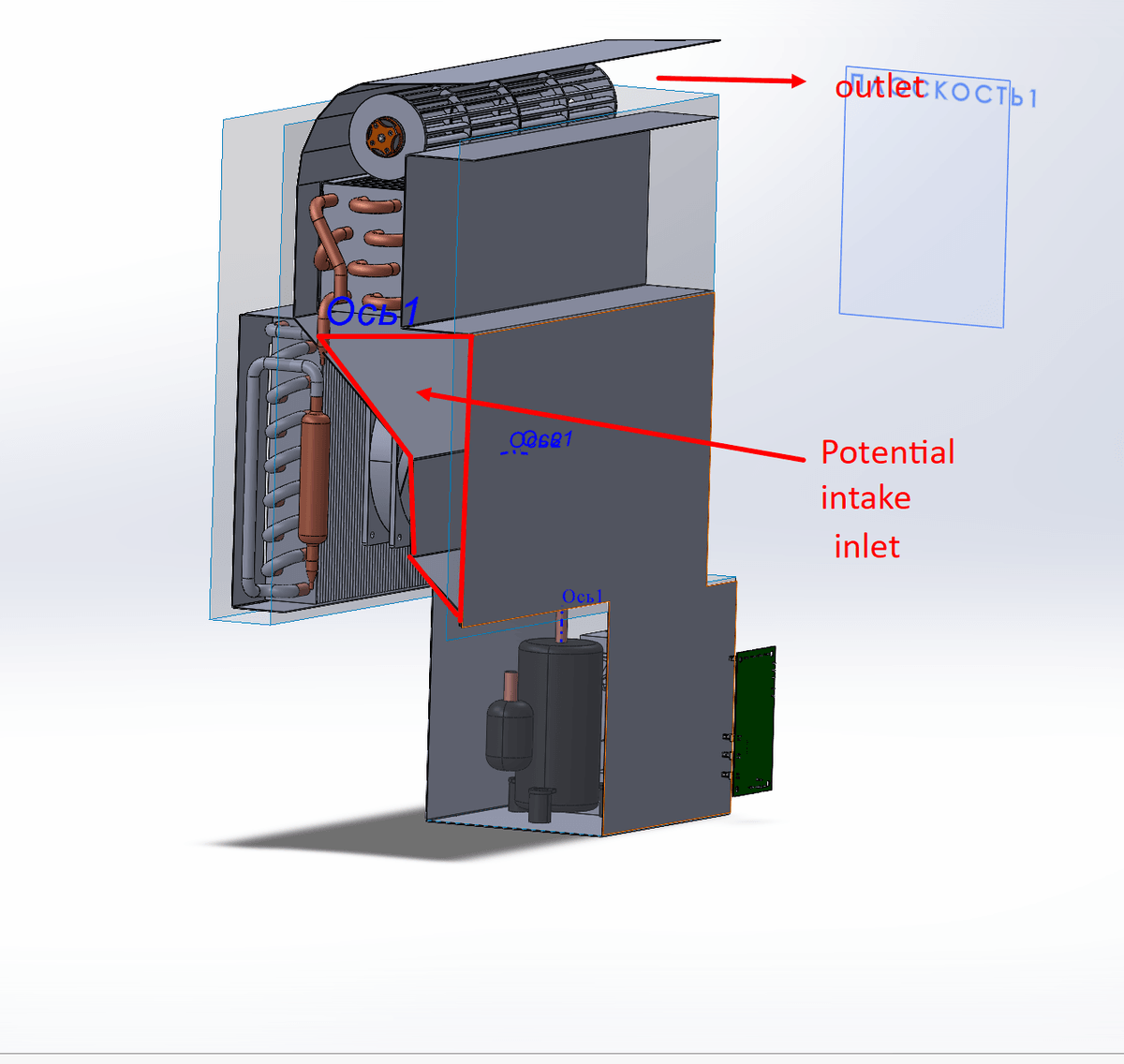

Cooling Approach: The cooling approach for the pizza machine is a compact, air-cooled system designed to operate on 24V DC. It maintains precise temperatures between 2°C to 4°C within a small space, using a custom evaporator and condenser configuration. A wide tangential fan enhances airflow for consistent cooling. The system is energy-efficient, low-maintenance, and easily scalable, making it ideal for the startup’s needs as production grows.

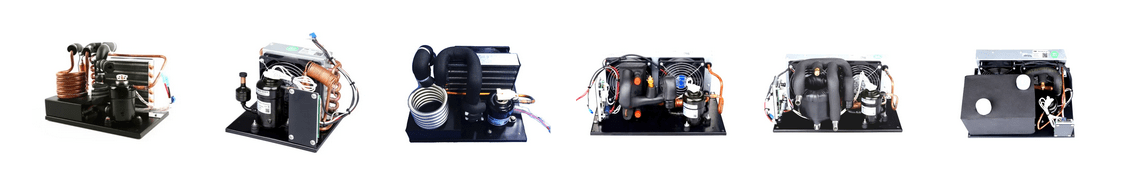

Recommended products: Custom Micro DC Aircon, DV3220E-AC

Background:

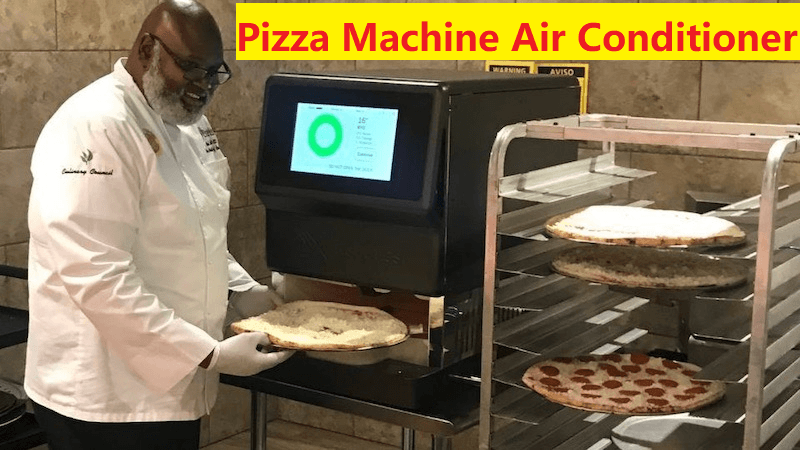

In the ever-evolving world of food technology, automation is becoming a key player in optimizing efficiency, quality, and sustainability. One startup that stands out in this revolution is a San Francisco-based pizza company, dedicated to enhancing the pizza-making process through automated solutions. This innovative startup has set its sights on creating the first truly accessible pizza-making robot, one capable of addressing the challenges of labor shortages, food waste, and inconsistent quality - all while delivering delicious pizza to consumers at scale.

However, every innovative product comes with its own set of challenges. For this pizza startup, a significant hurdle was developing a small countertop pizza machine that could maintain precise and consistent cooling to meet operational needs. The temperature inside the chamber of the machine had to be kept between 2°C to 4°C during operation—a task that demanded a highly efficient and compact cooling solution.

Enter RIGID, a company known for its exceptional R&D capabilities, highly responsive team, and precise cooling solutions. Through a collaborative effort, RIGID provided the startup with the perfect solution, demonstrating the importance of having a reliable partner to handle complex technical challenges.

Project Requirements:

- Effective Air-Cooling: Maintain temperatures between 2°C to 4°C inside the chamber during operation.

- Compact Size: The cooling system must be the smallest in size and volume to fit within the restricted space.

- 24V DC Operation: The cooling unit should operate at a 24V direct current voltage.

- Easy Installation: The cooling unit should be simple to install and integrate into the existing pizza machine.

- Minimal Maintenance: The cooling system should require little maintenance for long-term reliability.

A Challenging Problem: The Need for Compact, Efficient Cooling Solutions

The requirements presented by the pizza startup were clear but ambitious:

- Effective Air-Cooling Solution: The cooling system needed to be efficient enough to handle the temperature control requirements of the pizza machine, ensuring that the compartment maintained a range of 2°C to 4°C during operation.

- Small Size and Volume: Space was a critical factor. The cooling solution had to be compact enough to fit into the limited space available in the countertop pizza machine, without compromising on cooling efficiency.

- 24V DC Operation: The cooling unit had to be designed to operate on 24V DC, which is a standard voltage used in many compact systems and is ideal for powering small appliances.

- Easy Installation and Minimal Maintenance: The startup required a system that was not only easy to integrate into their existing machine design but also needed minimal maintenance to ensure long-term reliability and ease of use in a commercial kitchen setting.

These requirements set the stage for an exciting collaboration between the pizza startup and RIGID. The startup had already tried other suppliers but found it difficult to find a solution that met all their needs. Despite the best efforts from previous partners, the cooling systems provided were either too large or lacked the efficiency required for the tight space and precise temperature control. That’s when RIGID stepped in to solve the problem.

RIGID’s Approach: Innovation, Expertise, and Collaboration

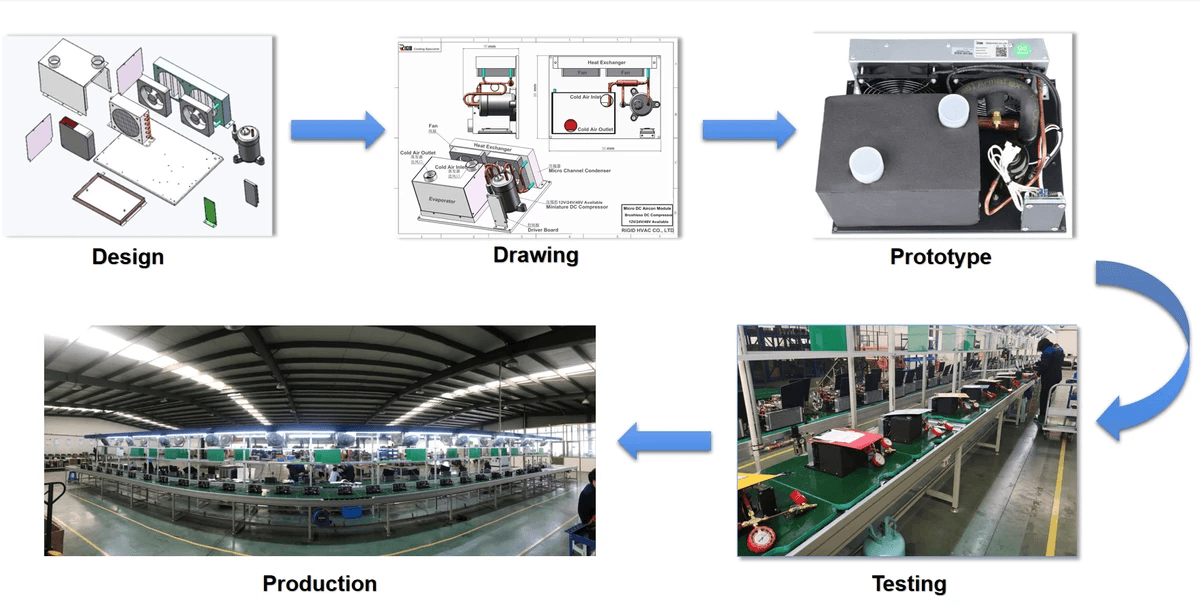

At RIGID, customization and innovation are at the heart of every solution. The company's extensive experience in providing compact, high-performance cooling systems made it an ideal partner for the pizza startup. By combining their expertise in thermal management, advanced design capabilities, and rapid prototyping, RIGID was able to meet the startup's exact specifications and deliver an optimal cooling solution.

Design & Development: Tailoring the Solution to Exact Requirements

RIGID’s first task was to understand the exact cooling power needed by the pizza machine. The startup’s cooling system required enough power to handle about 0.12 cubic meters of compartment volume, with a target temperature of 5°C from an initial 23°C. Time was also a critical factor, as the machine needed to cool the compartment within 30 minutes of operation.

The challenge was to design a system that could fit within the limited space of the pizza machine while ensuring efficient cooling. This was no easy task, but RIGID’s expert engineers and designers quickly got to work. They considered the key factors:

- The type of compressor: RIGID worked with the startup to determine the ideal compressor type, ensuring it would provide the necessary cooling power without consuming too much space or energy.

- Evaporator and condenser sizes: The system’s evaporator and condenser sizes were carefully matched to ensure that the cooling power was optimal for the machine's needs, taking into account the required cooling time and airflow.

- Fan and airflow design: The cooling system also needed to incorporate a recirculating fan that would guide the airflow in the most effective manner. After studying the startup’s existing system, RIGID designed a system that used a wide tangential fan above the evaporator to maximize airflow while maintaining efficient cooling.

Prototyping and Testing: Ensuring Performance and Reliability

Able to reach target temperature 2℃ degree within 20 minutes.

- Custom-built evaporators and condensers: RIGID produced high-efficiency evaporators and condensers that were specifically tailored to fit the startup’s system.

- Temperature control: The system was integrated with four temperature sensors that measured compartment temperature, evaporator temperature, condenser temperature, and compressor temperature to ensure that the system maintained optimal performance throughout its operation.

The results of the initial tests were outstanding. The cooling system performed exactly as required, maintaining temperatures within the desired 2°C to 4°C range while operating efficiently within the tight confines of the pizza machine. Additionally, the unit was easily integrated into the machine design, with minimal maintenance requirements.

Iterating and Scaling: Preparing for the Future

With the success of the initial prototype, RIGID and the startup moved forward with plans for scaling production. The pizza startup initially required only a handful of units for testing and validation, but as the company prepared for mass production, they realized the potential for broader adoption of this technology. RIGID worked closely with the startup to ensure that the cooling solution could be scaled up, meeting the increased demands as production grew.

The pizza startup’s plans included increasing production to 20 units per month by the end of 2023, with the goal of reaching 100 units per month by 2024. RIGID’s ability to rapidly scale their solution was a key factor in the partnership’s success.

The Impact of the Collaboration

This successful partnership between RIGID and the San Francisco pizza startup has proven that innovation, responsiveness, and expert engineering are crucial to overcoming technical challenges in the food technology industry. RIGID demonstrated its ability to quickly adapt to customer needs, offering custom cooling solutions that were both compact and highly effective. The cooling system designed for the pizza machine is a testament to RIGID’s commitment to excellence in engineering and design.

RIGID Advantage: Expertise and Customer-Centric Solutions

Throughout the collaboration, the team at RIGID was consistently able to deliver:

- Innovative Solutions: By taking the time to understand the unique needs of the pizza startup, RIGID was able to develop a customized solution that met all performance requirements.

- Responsive Customer Support: RIGID’s commitment to quick response times and hands-on customer support allowed the pizza startup to continue testing and refining their product without delays.

- Future-Proofing: As the pizza startup prepares for large-scale production, RIGID’s ability to scale their solution seamlessly ensures that the cooling system will meet future demands.

Conclusion: A Recipe for Success

The collaboration between RIGID and the San Francisco pizza startup highlights the power of effective partnerships in solving real-world problems. By leveraging RIGID’s expertise in thermal management and engineering, the startup was able to overcome its cooling challenges and build a high-performance, energy-efficient pizza-making machine.

As the food tech industry continues to evolve, RIGID’s ability to deliver tailored, high-quality solutions will play an integral role in shaping the future of food automation. Whether you’re creating the next big kitchen innovation or scaling a production line, RIGID’s commitment to providing the right solutions at the right time will always ensure you’re on the cutting edge.