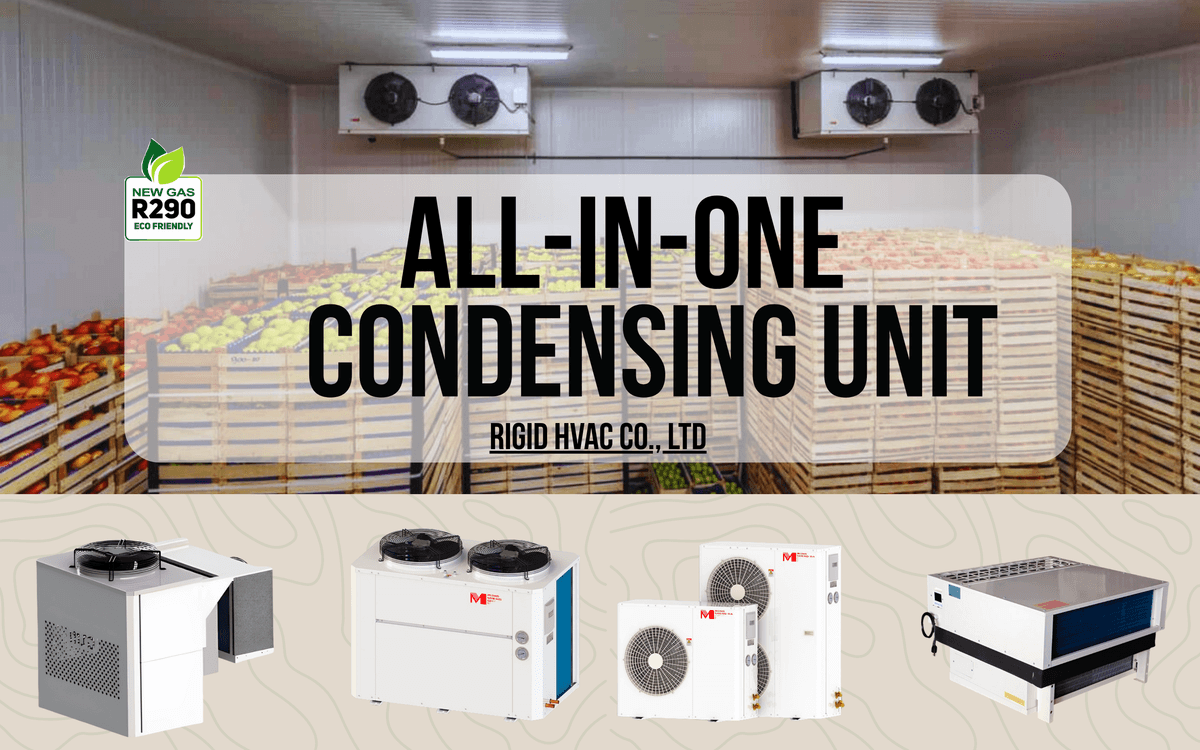

Introduction: Refrigeration in One of the World’s Toughest Climates

Designing reliable commercial refrigeration systems for Saudi Arabia is not simply a matter of selecting standard components. Ambient temperatures exceeding 45°C, extended operating hours, unstable grid conditions, and continuous high thermal loads present unique challenges that push conventional condensing units beyond their limits.

For supermarkets, cold storage facilities, seafood distribution centers, and fresh vegetable logistics hubs, refrigeration downtime is not an option. Product loss, operational disruption, and reputational damage are real risks when systems are not engineered specifically for extreme environments.

Over the past three years, RIGID has focused its engineering efforts on one critical question:

How can commercial condensing units maintain stable, energy-efficient, and long-life operation under sustained high ambient temperatures?

Our recent market visit to Saudi Arabia provided a clear answer—not in theory, but through real-world installations already operating successfully across the Kingdom.

Why Saudi Arabia Is a High-Growth Refrigeration Market

Saudi Arabia’s commercial refrigeration demand is expanding rapidly, driven by several structural factors:

- Rapid growth of modern supermarkets and retail chains

- Expansion of cold storage infrastructure supporting food security

- Increased demand for fresh seafood, meat, and vegetables

- Government-backed initiatives under Vision 2030

- Rising standards for food safety and cold-chain reliability

However, many refrigeration systems originally designed for moderate climates struggle to perform consistently in Saudi Arabia. Engineers and integrators often face recurring issues such as:

- High compressor discharge temperatures

- Reduced cooling capacity at peak ambient conditions

- Frequent high-pressure trips

- Accelerated component aging

- Increased maintenance frequency

RIGID’s approach has been to engineer solutions from the ground up for high-ambient operation—rather than adapting standard designs after the fact.

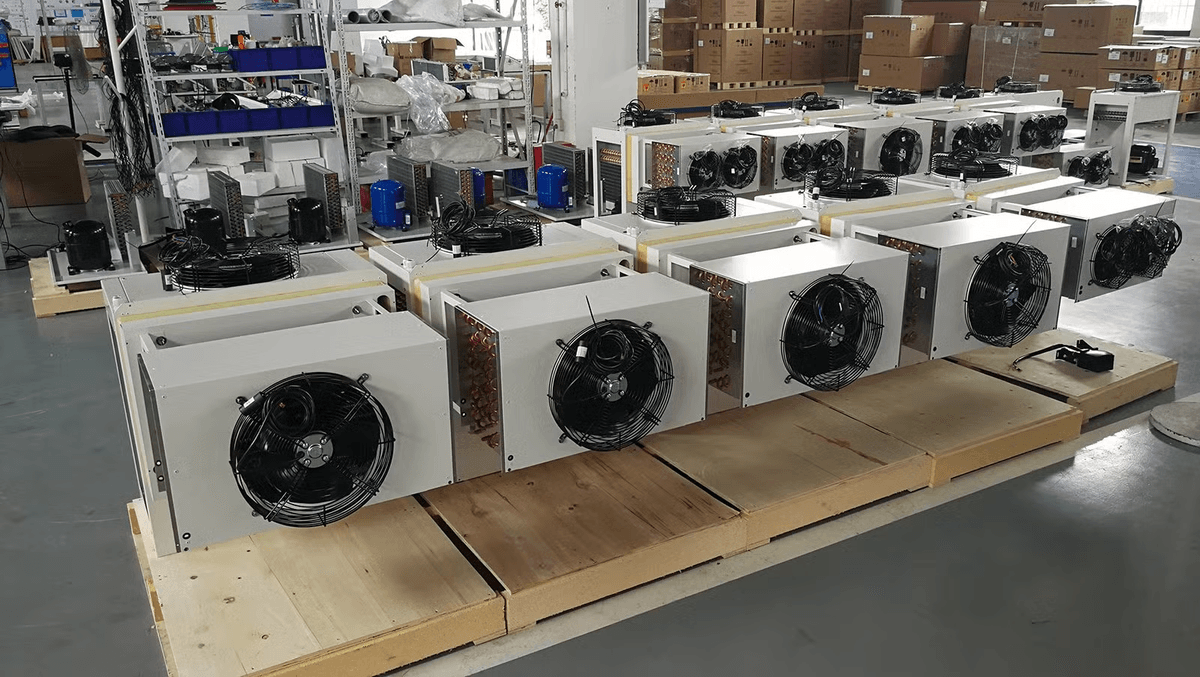

Three Years of Engineering Optimization: From Field Feedback to Final Design

1. Enlarged Condenser Design for High Ambient Heat Rejection

One of the most common failure points in high-temperature environments is insufficient condenser capacity.

In Saudi Arabia, where ambient temperatures remain elevated day and night, undersized condensers lead to:

- Elevated condensing temperatures

- Increased compressor power consumption

- Reduced system COP

- Frequent high-pressure alarms

RIGID addressed this by significantly increasing condenser surface area and optimizing fin-and-tube geometry for desert operating conditions.

Engineering benefits include:

- Improved heat rejection at 45–55°C ambient

- Lower condensing pressure under peak load

- Enhanced system stability during continuous operation

- Extended compressor service life

This design choice is particularly critical for cold storage and supermarket systems that operate 24/7 without load cycling.

2. High-Efficiency Variable-Frequency Compressors (VFD)

Traditional fixed-speed compressors operate at full capacity regardless of real-time cooling demand. In high-temperature regions, this leads to:

- Excessive energy consumption

- Thermal stress during peak hours

- Poor part-load efficiency

RIGID’s condensing units integrate high-efficiency variable-frequency compressors, allowing the system to dynamically match capacity to actual load conditions.

Key technical advantages:

- Soft start reduces electrical and mechanical stress

- Continuous capacity modulation improves temperature stability

- Significant energy savings at partial load

- Reduced compressor cycling and wear

For integrators, this also means greater flexibility in system sizing and easier adaptation to fluctuating load profiles common in retail refrigeration.

3. Liquid Injection Cooling: Thermal Protection Where It Matters Most

High ambient temperatures inevitably increase compressor discharge temperatures—especially during peak daytime operation.

To address this, RIGID applied liquid-injection cooling technology, which introduces controlled refrigerant injection to reduce discharge temperature under heavy load conditions.

Engineering outcomes:

- Stable discharge temperatures under extreme conditions

- Improved oil lubrication performance

- Protection against thermal overload

- Extended compressor lifespan

This technology is particularly valuable in Saudi Arabia, where systems often operate at or near maximum capacity for extended periods.

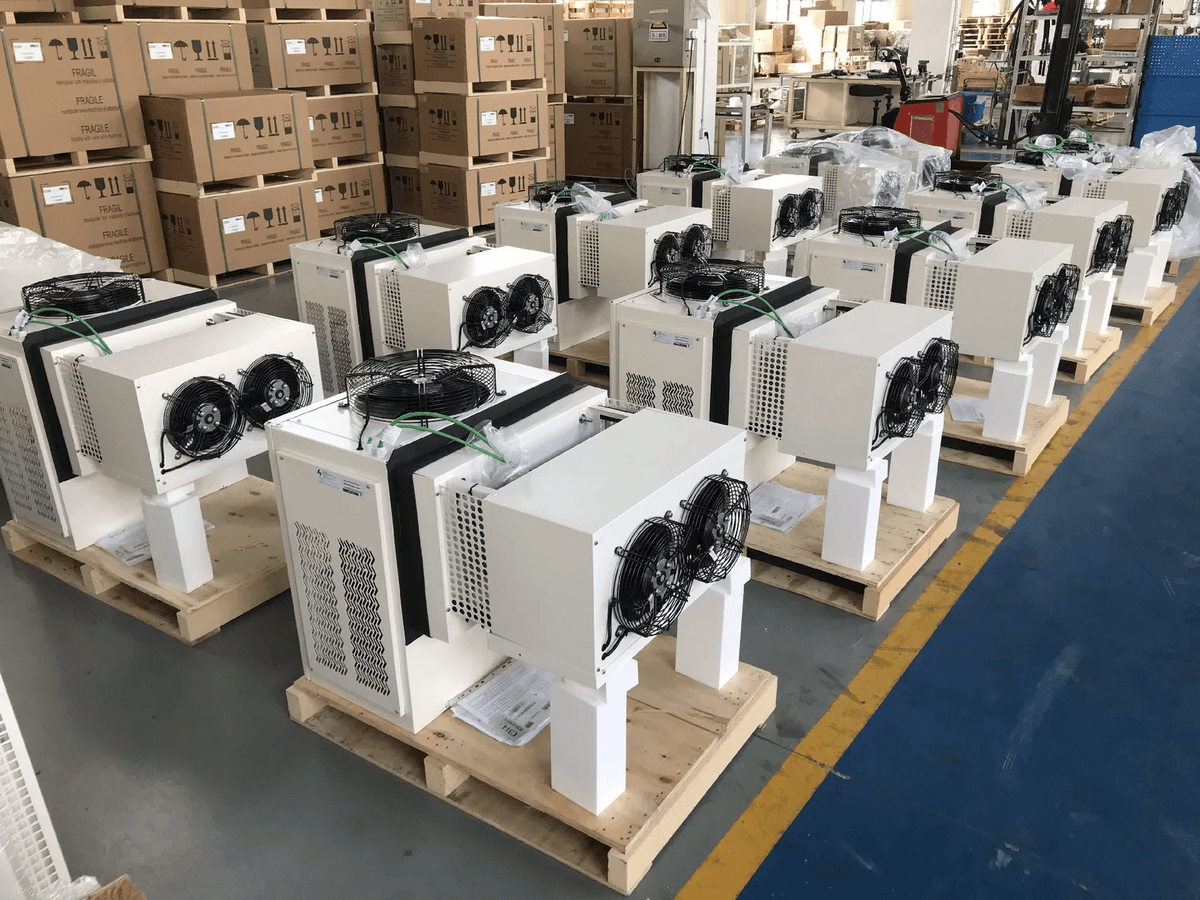

Field Validation: Proven Performance Across Saudi Arabia

During our recent visit, RIGID engineers and management teams conducted on-site inspections and customer meetings across multiple regions. We were proud to see RIGID condensing units actively operating in:

- Commercial supermarkets

- Base cold storage facilities

- Seafood refrigeration systems

- Vegetable and agricultural cold rooms

These were not pilot installations—they were live, revenue-generating systems supporting daily business operations.

Customers consistently reported:

- Stable system performance during peak summer temperatures

- Reduced maintenance intervention

- Lower unplanned downtime

- Improved overall system reliability

Several partners confirmed that since deploying RIGID solutions, their refrigeration operations had become a competitive advantage rather than a risk factor.

Engineering Value for System Integrators and OEM Partners

For refrigeration system integrators, component reliability directly impacts project success, service costs, and long-term customer relationships.

RIGID condensing units offer integrators:

- High-ambient-ready design without over-engineering

- Broad compatibility with commercial refrigeration architectures

- Stable control logic suitable for continuous duty

- Reduced service callbacks and warranty exposure

OEM partners also benefit from RIGID’s ability to customize condensing units based on application-specific requirements, including:

- Refrigerant selection

- Capacity optimization

- Electrical configuration

- Control integration

Energy Efficiency and Lifecycle Cost Advantages

While high-temperature operation often leads to higher energy consumption, RIGID’s optimized design mitigates this impact through:

- Variable-speed operation

- Lower condensing pressures

- Reduced compressor cycling

- Efficient heat rejection

For end users, this translates into:

- Lower total cost of ownership (TCO)

- Predictable operating expenses

- Improved return on investment

In markets like Saudi Arabia, where refrigeration systems run continuously, lifecycle efficiency matters more than nominal efficiency ratings.

Long-Term Commitment to the Saudi Market

RIGID’s success in Saudi Arabia is not the result of a short-term market push. It reflects a long-term strategy built on:

- Continuous product optimization

- Real-world performance validation

- Close collaboration with local partners

- Deep understanding of regional operating conditions

During this visit, discussions with existing customers confirmed plans for expanded cooperation in 2026, while new client engagements highlighted strong demand for high-performance commercial refrigeration solutions.

RIGID remains committed to:

- Advancing high-ambient refrigeration technology

- Supporting integrators with robust, field-proven solutions

- Building long-term partnerships based on trust and performance

Our goal is simple:

to ensure refrigeration systems remain stable, efficient, and dependable—no matter how challenging the environment.

Saudi Arabia represents one of the most demanding refrigeration markets globally. Through three years of focused engineering development, RIGID has proven that well-designed condensing units—featuring enlarged condensers, variable-frequency compressors, and liquid-injection cooling—can deliver consistent performance even under extreme heat.

From supermarkets to cold storage and fresh food logistics, RIGID condensing units are already supporting real businesses across the Kingdom.

For engineers, integrators, and cold-chain professionals seeking refrigeration solutions that work reliably in high-temperature environments, RIGID offers not just products—but proven engineering confidence.

#Commercial refrigeration Saudi Arabia #Condensing units high temperature #High ambient refrigeration systems #Supermarket refrigeration Saudi Arabia #Cold storage refrigeration Middle East #Variable frequency compressor refrigeration #Liquid injection cooling refrigeration #HVACR Saudi Arabia