Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

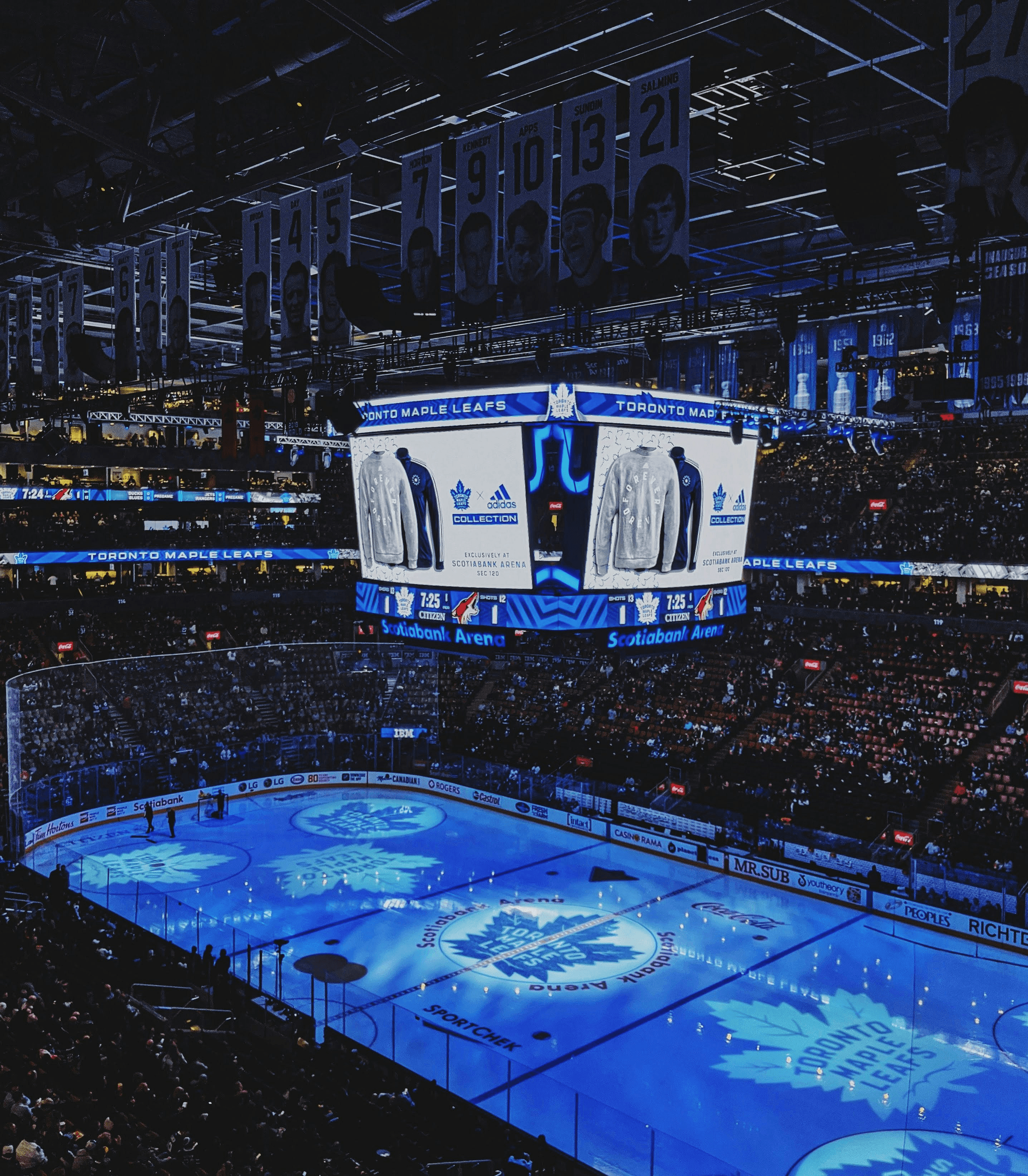

Ice rinks are more than just frozen surfaces for skating; they are complex facilities that rely heavily on sophisticated ice rink refrigeration systems to maintain optimal conditions. Understanding these systems is crucial for anyone involved in the management, operation, or construction of ice arenas. From the mechanics of how these systems function to the specific components that make them effective, a deep dive into ice rink refrigeration reveals the intricacies behind that perfect glide.

Understanding Ice Rink Refrigeration Systems

When we ask, What are the cooling systems for ice rinks? we're delving into a world where engineering meets athleticism. Ice rink refrigeration systems utilize various technologies to keep the ice surface at consistent temperatures, ensuring it remains solid and safe for skaters. Knowing how does an ice rink refrigeration system work can help in appreciating the delicate balance of temperature control necessary for maintaining high-quality ice.

The Importance of Efficient Cooling Solutions

The importance of efficient cooling solutions in an ice rink cannot be overstated; they directly impact both performance and energy consumption. An efficient ice rink refrigeration system not only provides a better skating experience but also reduces operational costs significantly over time. This efficiency becomes even more critical when considering factors such as climate change and rising energy prices, making it essential to explore options like DIY ice rink refrigeration system solutions.

Key Components of an Ice Rink Refrigeration System

Understanding the key components of an ice rink refrigeration system is vital for anyone looking to optimize their facility's operations or consider upgrades. From compressors and chillers to evaporators and refrigerants—each plays a crucial role in maintaining that pristine layer of ice. Additionally, questions like What refrigerant is used in ice rinks? come into play when assessing environmental impacts and compliance with regulations surrounding these cooling systems.

Overview of Ice Rink Refrigeration Systems

Understanding the intricacies of ice rink refrigeration systems is vital for maintaining the perfect ice surface for skaters and hockey players alike. These systems are designed to provide efficient cooling solutions that ensure optimal conditions within ice arenas. By delving into how these cooling systems operate, we can better appreciate their importance in preserving the quality and safety of the ice.

What are the cooling systems for ice rinks?

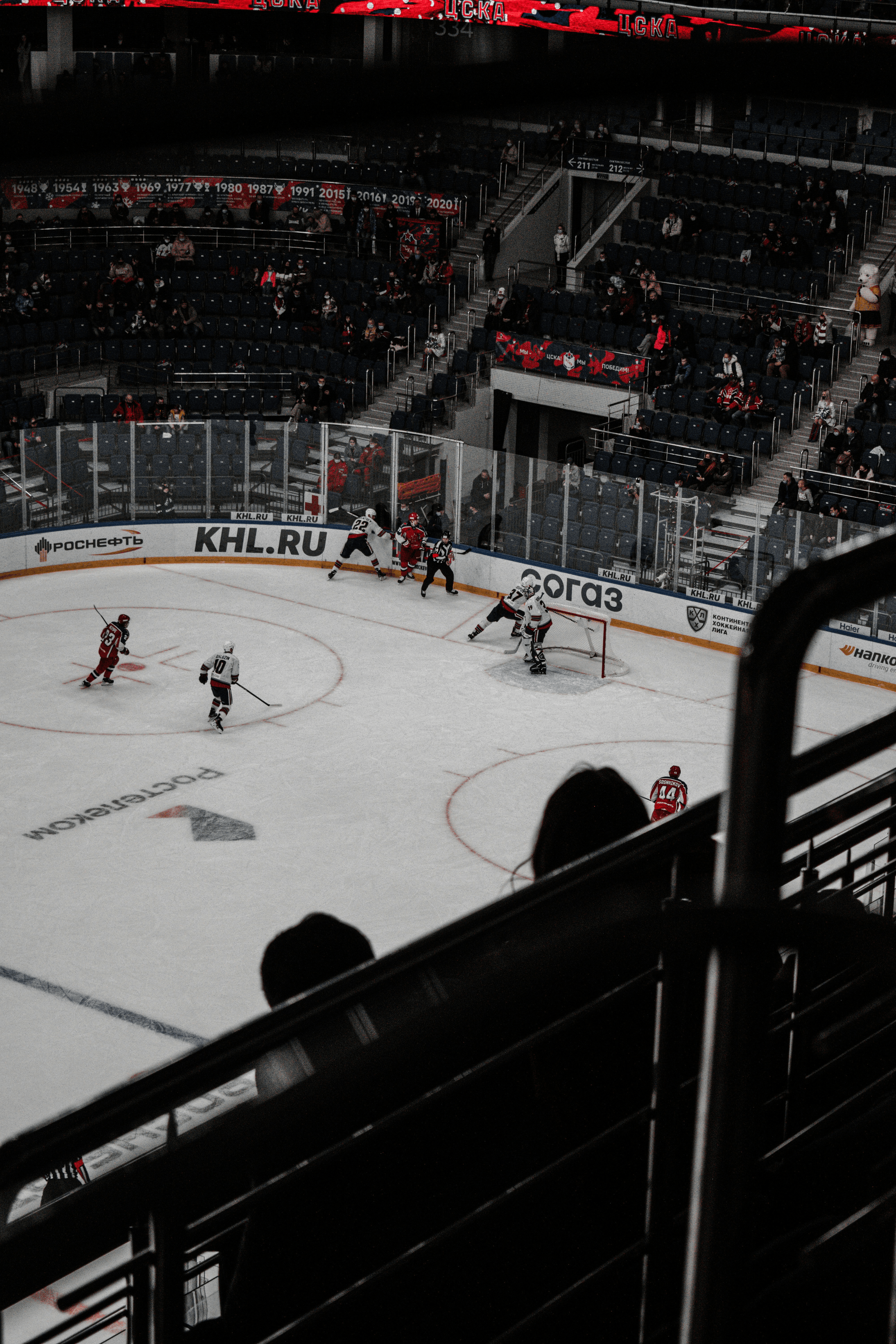

Cooling systems for ice rinks primarily consist of specialized refrigeration units that chill a network of pipes embedded beneath the rink's surface. These pipes circulate a refrigerant, which absorbs heat from the ice and transfers it away, keeping the surface frozen even during peak usage times. The most common types of cooling systems include traditional mechanical refrigeration units, glycol-based systems, and more innovative solutions like ammonia or CO2 refrigeration setups.

How does an ice rink refrigeration system work?

An ice rink refrigeration system operates through a continuous cycle involving compression, condensation, expansion, and evaporation. Initially, a compressor pressurizes the refrigerant gas before it moves to a condenser where it releases heat and transforms into liquid form. This liquid then travels through evaporator coils under the rink's surface; as it evaporates back into gas form, it absorbs heat from the surrounding area—keeping your beloved hockey rink cool and ready for action!

Importance of temperature control in ice arenas

Temperature control is crucial in maintaining an ideal skating environment within an arena; fluctuations can lead to poor playing conditions or even damage to the rink itself. An efficient ice rink refrigeration system ensures consistent temperatures by monitoring heat loads from both external sources (like sunlight) and internal activities (such as skaters). Proper temperature management not only enhances performance but also extends equipment lifespan while reducing energy costs—making it essential for any facility looking to maximize efficiency.

Essential Equipment in Refrigeration Systems

Compressors: The Heart of the System

Compressors are often referred to as the heart of any ice rink refrigeration system, and for good reason! They are responsible for compressing refrigerant gases, which subsequently circulate through the cooling system to remove heat from the ice surface. Without a reliable compressor, maintaining consistent ice quality would be nearly impossible; it's like trying to keep your drink cold without a fridge!

In essence, these machines help regulate temperatures by cycling refrigerants through various phases—liquid and gas—allowing for effective heat exchange. The efficiency of compressors directly impacts how well an ice rink refrigeration system operates; thus investing in high-quality compressors can pay off in lower energy costs and improved performance over time.

RIGID Mini Compressors and Their Advantages

One standout option in the world of compressors is the RIGID Mini Compressor, which has gained popularity among those exploring DIY ice rink refrigeration systems. These compact units pack a punch while saving space and energy—a perfect combination for smaller rinks or home setups! With their advanced technology, RIGID Mini Compressors provide reliable cooling without overwhelming your electricity bill.

Another advantage lies in their ease of installation and maintenance; even novices can tackle setup without professional help. This makes them particularly appealing for those asking themselves: What are the cooling systems for ice rinks? If you're looking to create your own DIY solution, these mini compressors could be just what you need.

Various Refrigerants Used in Ice Rinks

When discussing how does an ice rink refrigeration system work? One cannot overlook the importance of refrigerants used within these systems. Common options include ammonia (R717), propylene glycol, and Freon (R-134a), each with its own set of benefits and drawbacks depending on environmental considerations and safety regulations.

Ammonia is highly efficient but requires careful handling due to its toxicity; however, it remains popular due to its effectiveness at low temperatures. On the other hand, propylene glycol offers a safer alternative that’s often utilized in smaller rinks or DIY setups where safety is paramount—especially when considering how much does a hockey rink refrigeration system cost? Selecting an appropriate refrigerant can significantly influence both initial investment and long-term operational costs.

Cooling Components and Mechanisms

When it comes to an ice rink refrigeration system, understanding the cooling components and mechanisms is crucial for maintaining optimal ice conditions. From chillers that lower temperatures to evaporators that help maintain the ice surface, each component plays a vital role in ensuring a smooth skating experience. Let's dive into these essential elements and see how they contribute to what are the cooling systems for ice rinks.

Chillers: Types and Functions

Chillers are the backbone of any effective ice rink refrigeration system, designed to remove heat from the water circulating beneath the rink's surface. There are various types of chillers, including air-cooled and water-cooled options, each with its own set of advantages depending on your specific needs. Understanding how does an ice rink refrigeration system work involves recognizing that these chillers not only cool the liquid but also help regulate temperature across large surfaces, which is critical for maintaining consistent ice quality.

In addition to their primary function of cooling, chillers can significantly impact operational costs associated with an ice rink refrigeration system cost analysis. Energy-efficient models can lead to substantial savings over time while ensuring that your facility remains competitive in terms of maintenance expenses. When exploring options for a DIY ice rink refrigeration system, selecting the right chiller is paramount; it can make or break your project’s success.

The Role of Evaporators in Ice Maintenance

Evaporators play a crucial role in maintaining high-quality ice by facilitating efficient heat exchange between refrigerants and water circulating through pipes embedded in the rink floor. These components absorb heat from the water before returning it back into circulation at a lower temperature, effectively keeping the surface solid and skate-friendly. By understanding how does an ice rink refrigeration system work holistically, you’ll see that evaporators are integral in preventing issues like slush or uneven surfaces.

Moreover, evaporators contribute directly to energy efficiency within an ice rink refrigeration system by maximizing cooling potential while minimizing energy consumption. This efficiency not only enhances performance but also affects overall operating costs—essential information when considering how much does a hockey rink refrigeration system cost? As you contemplate building or upgrading facilities, remember that investing in high-quality evaporators can yield long-term benefits.

Heat Exchangers: Balancing Temperatures

Heat exchangers serve as essential mediators within an ice rink refrigeration system by balancing temperatures between different fluids involved in cooling processes. They help transfer thermal energy from one medium (like refrigerant) to another (such as brine) without mixing them together—ensuring maximum efficiency throughout operations. By controlling temperature differences effectively, these devices contribute significantly to what are the cooling systems for ice rinks.

The importance of having well-functioning heat exchangers cannot be overstated; they directly affect both performance levels and operational costs associated with your setup—factors critical when conducting an ice rink refrigeration system cost analysis. Plus, if you're considering DIY solutions for your project or facility upgrades, understanding how heat exchangers operate will guide you toward making informed decisions about necessary equipment investments.

Cost Considerations for Ice Rink Systems

When diving into the world of ice rink refrigeration systems, understanding the financial implications is crucial. The costs associated with these systems can vary significantly based on factors like size, type, and technology used. This section will break down the expenses involved in establishing and maintaining an efficient cooling solution for your ice rink.

How much does a hockey rink refrigeration system cost?

The price tag for a hockey rink refrigeration system can range anywhere from $100,000 to over $1 million, depending on various factors such as rink size and complexity of the system. For smaller, DIY ice rink refrigeration systems, initial investments may be lower but could lead to higher operational costs if not properly designed. Understanding what refrigerant is used in ice rinks also plays a part; some refrigerants are more expensive than others and can affect overall installation costs.

Ice rink refrigeration system cost analysis

Conducting a thorough ice rink refrigeration system cost analysis involves looking beyond just initial setup expenses. Factors like energy consumption, maintenance needs, and potential upgrades all contribute to long-term financial commitments. Additionally, assessing what are the cooling systems for ice rinks will help you choose one that balances upfront costs with ongoing efficiency; sometimes spending more initially pays off in reduced operational expenses over time.

Budgeting for maintenance and upgrades

Budgeting for maintenance and upgrades is essential when considering an ice rink refrigeration system's total cost of ownership. Regular maintenance can prevent costly breakdowns and ensure optimal performance; setting aside about 5-10% of your initial investment annually is a good rule of thumb. Moreover, planning for future upgrades—whether it's incorporating new technology or switching to more sustainable refrigerants—can save you headaches down the line while keeping your facility competitive.

DIY Ice Rink Refrigeration Solutions

Creating your own ice rink can be a fun and rewarding project, but understanding the intricacies of a DIY ice rink refrigeration system is key to maintaining that perfect surface. By exploring various options available for cooling systems, you can better appreciate how they work and which components might be right for your setup. Whether you're looking to build a small backyard rink or something more substantial, knowing what refrigerant is used in ice rinks and how these systems function will give you a solid foundation.

Exploring DIY ice rink refrigeration system options

When it comes to DIY ice rink refrigeration systems, there are several approaches you can take depending on your needs and budget. Common options include using portable chillers or creating a custom piping layout with glycol solutions to circulate cold fluid beneath the ice surface. For those asking, What are the cooling systems for ice rinks? it's essential to consider both traditional methods and innovative alternatives that suit your specific situation.

Understanding how does an ice rink refrigeration system work is crucial in this phase; typically, these systems involve circulating cold refrigerant through pipes embedded under the ice layer, creating a solid freeze while maintaining temperature control. You may also want to explore using existing HVAC equipment if you have access to it—this can save costs while still delivering efficient performance. However, ensure that whatever method you choose aligns with local regulations regarding outdoor installations.

Benefits and Challenges of DIY systems

The appeal of a DIY ice rink refrigeration system lies in its potential cost savings and customization options tailored specifically to your needs. By opting for a self-built solution, you gain flexibility in design and operation while possibly reducing installation costs significantly compared to commercial alternatives—after all, how much does a hockey rink refrigeration system cost? The answer often hovers in the thousands; thus, saving money could make your endeavors even more enjoyable.

However, challenges abound when diving into the world of DIY refrigeration solutions. You must consider factors like energy efficiency and maintenance requirements; failure to do so could lead to higher operational costs over time—think about those pesky bills! Additionally, without proper knowledge about what refrigerant is used in ice rinks or how different components interact within an overall system framework, things could quickly spiral out of control.

When to consult professionals for custom solutions

While embarking on a DIY journey can be thrilling, there are times when consulting professionals becomes essential for ensuring success with your ice rink refrigeration system. If you're unsure about critical aspects like sizing equipment or selecting appropriate materials based on local climate conditions—it's best not to gamble with trial-and-error methods! Professionals bring valuable expertise that helps avoid costly mistakes down the road.

Moreover, if you're planning on constructing larger facilities or need specialized equipment beyond simple chilled water lines—consider bringing an expert onboard who understands complex designs tailored specifically for hockey rinks or figure skating arenas. They will guide you through intricate processes such as heat exchange mechanisms while ensuring compliance with safety standards applicable within your region's jurisdiction.

Ultimately, striking the right balance between doing it yourself versus seeking professional assistance will determine whether you'll glide smoothly across frozen surfaces or find yourself battling unexpected issues along the way!

Conclusion

In wrapping up our exploration of ice rink refrigeration systems, it's clear that the future holds exciting innovations poised to enhance performance and sustainability. As technology advances, we can expect more efficient cooling solutions that reduce energy consumption while maintaining optimal ice conditions. These developments will not only improve the experience for skaters but also contribute to a greener planet.

Future Innovations in Ice Rink Refrigeration

Future innovations in ice rink refrigeration systems are likely to focus on eco-friendly refrigerants and advanced automation technologies. With a growing emphasis on sustainability, new refrigerants will replace traditional options, reducing environmental impact while still delivering effective cooling solutions. Additionally, smart technology integration will allow for real-time monitoring and adjustments in temperature control, ensuring that every inch of the ice remains perfectly maintained.

Maximizing Efficiency for Sustainability

Maximizing efficiency in ice rink refrigeration systems is crucial for both operational cost savings and environmental responsibility. By investing in high-quality equipment and regularly maintaining existing systems, rink operators can significantly lower energy bills while minimizing their carbon footprint. Moreover, exploring DIY ice rink refrigeration system options can empower enthusiasts to create sustainable setups at home without breaking the bank.

Choosing the Right System for Your Needs

When it comes to selecting an ice rink refrigeration system, understanding your specific needs is paramount. Factors such as size, budget constraints (how much does a hockey rink refrigeration system cost?), and desired performance levels will influence your decision-making process. Whether you opt for commercial-grade solutions or consider a DIY ice rink refrigeration system approach, making an informed choice ensures you get the best value while keeping your ice surface pristine.