Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

In the world of refrigeration and air conditioning, understanding condenser cooling methods is crucial for optimizing performance and efficiency. Choosing the right system can significantly impact energy consumption, maintenance costs, and overall effectiveness. This introduction will provide a clear overview of the differences between air cooled and water cooled condensers, setting the stage for a deeper exploration of their operational principles and applications.

Understanding Condenser Cooling Methods

Condenser cooling methods play a pivotal role in determining how effectively heat is dissipated from refrigerants during the cooling process. The choice between air cooled and water cooled systems often hinges on various factors such as environmental conditions, available space, and specific application requirements. By grasping the mechanics behind these two primary cooling mediums in refrigeration, users can make informed decisions that enhance performance while minimizing energy usage.

Importance of Choosing the Right System

Selecting the appropriate condenser system isn't just about preference; it can lead to significant differences in efficiency and cost-effectiveness over time. Each method comes with its own set of advantages and challenges that affect installation, use, and maintenance needs. Understanding these factors allows businesses to tailor their choices to align with their unique operational environments while ensuring optimal cooling effect.

Overview of Air Cooled vs Water Cooled

Air cooled condensers rely on ambient air to dissipate heat from refrigerants, making them ideal for specific environments where water resources may be limited or costly to access. In contrast, water cooled condensers utilize water as a cooling medium, offering superior efficiency under certain conditions but requiring more complex installation and ongoing maintenance considerations. By comparing these two systems' characteristics—such as their impact on condensing temperature—it becomes easier to determine which method best suits your needs.

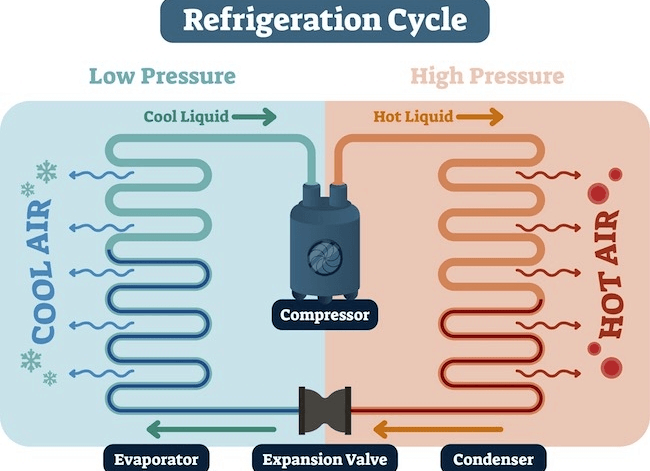

Operating Principles Explained

Understanding how air cooled and water cooled condensers operate is crucial in determining their effectiveness in various applications. The choice of cooling method significantly impacts the overall efficiency of refrigeration systems, influencing both performance and energy consumption. Let’s dive into the mechanics behind these two popular cooling mediums.

How Air Cooled Condensers Work

Air cooled condensers rely on ambient air to dissipate heat from the refrigerant. The process begins when the refrigerant vapor exits the compressor at a high temperature and pressure, entering the condenser coils. As air flows over these coils, it absorbs heat from the refrigerant, causing it to condense into a liquid state while simultaneously raising the temperature of the air around it.

This cooling method is often favored for its simplicity and lower installation costs, as it requires no additional water supply or complex plumbing systems. However, one must consider that air cooled systems can be less efficient in high ambient temperatures due to increased condensing temperature, which can hinder overall cooling effect. This highlights one key aspect of understanding the difference between air cooled and water cooled condenser systems: their dependence on external environmental factors.

Mechanics Behind Water Cooled Condensers

Water cooled condensers operate on a different principle by utilizing water as a primary cooling medium in refrigeration processes. In this setup, hot refrigerant gas flows through tubes submerged in a body of water or through a cooling tower system where heat exchange occurs. The surrounding water absorbs heat from the refrigerant more efficiently than air can, allowing for lower condensing temperatures and improved thermal performance.

The use of water significantly enhances cooling effect compared to air cooled units, especially in larger commercial applications where space permits such installations. However, this method does come with its own set of challenges; installation and use often require careful planning regarding plumbing infrastructure and ongoing maintenance to prevent issues like scaling or algae growth within the system. Therefore, understanding these mechanics is essential when evaluating which condensation method suits your needs best.

Key Differences in Cooling Medium

When comparing air cooled versus water cooled condensers, one cannot overlook how each system employs its respective cooling medium—air or water—and how this impacts operational efficiency. Air serves as a natural coolant but may struggle under extreme conditions where high ambient temperatures lead to elevated condensing temperatures; thus reducing overall efficiency and increasing energy costs over time. Conversely, water's superior thermal conductivity allows for more effective heat removal at lower temperatures but necessitates additional considerations regarding installation logistics and long-term maintenance requirements.

Moreover, each cooling method has distinct implications for applicable environments; while air cooled units thrive outdoors with ample airflow available, water-cooled systems are better suited for controlled settings like chilled-water plants or industrial facilities with access to reliable freshwater sources. Understanding these differences not only aids in selecting an appropriate condenser type but also informs decisions around operational efficiency and cost-effectiveness as you navigate your options within refrigeration technologies.

Cooling Efficiency Comparison

When it comes to cooling efficiency, the difference between air cooled and water cooled condensers can be quite pronounced. Each system operates under distinct principles that affect their overall performance, particularly regarding condensing temperature and cooling effect. By examining these factors, we can better understand which cooling method may be more suited for specific applications.

Comparing Condensing Temperature Impacts

The condensing temperature is a crucial aspect of how effectively a condenser can operate within its environment. In general, water cooled condensers tend to maintain lower condensing temperatures compared to their air cooled counterparts due to the superior thermal conductivity of water as a cooling medium in refrigeration. This leads to enhanced heat exchange efficiency, allowing for improved performance in high-load situations where maintaining optimal temperatures is essential.

Conversely, air cooled condensers are often subject to higher ambient temperatures, which can negatively impact their condensing temperature and overall efficiency. In regions where outdoor temperatures soar during summer months, the difference between air cooled and water cooled condenser systems becomes even more significant. Thus, understanding these impacts is vital when selecting the appropriate cooling method for your installation and use scenario.

Analyzing Cooling Effect in Different Systems

The cooling effect generated by each type of condenser varies significantly based on environmental conditions and system design. Water cooled systems generally provide a more consistent and powerful cooling effect due to their ability to absorb heat more effectively than air cooled systems. This makes them particularly advantageous in industrial settings or facilities with high thermal loads requiring reliable performance.

On the other hand, while air cooled systems are simpler to install and maintain—making them suitable for smaller applications—they may struggle under extreme heat conditions or heavy usage scenarios. The choice between these two methods should consider not only immediate needs but also long-term implications related to applicable environments where they will be deployed. Ultimately, analyzing the cooling effect of both systems helps users make informed decisions about which method best suits their unique requirements.

RIGID's Role in Optimizing Efficiency

RIGID plays a pivotal role in enhancing the efficiency of both air cooled and water cooled condensers through innovative solutions tailored for various applications. By incorporating advanced technologies into their designs, RIGID ensures that users experience optimal condensing temperatures while maximizing the overall cooling effect regardless of chosen system type. This commitment to excellence positions RIGID at the forefront of improving installation and use experiences across diverse environments.

Moreover, RIGID’s expertise extends beyond mere product offerings; they provide guidance on selecting the right system based on specific operational needs and environmental factors that influence performance outcomes over time. With an emphasis on sustainability and cost-effectiveness, RIGID demonstrates how thoughtful engineering can bridge differences between air cooled and water cooled condenser technologies while meeting contemporary demands for energy-efficient solutions.

Installation and Use Considerations

When it comes to the installation and use of condensers, several factors come into play that can significantly affect performance and efficiency. The difference between air cooled and water cooled condenser systems becomes evident not only in their operational methods but also in how they are installed and utilized. Understanding these aspects can help you make an informed decision tailored to your specific needs.

Installation Challenges: Air vs Water

The installation challenges for air cooled versus water cooled systems vary greatly, primarily due to their differing cooling methods. Air cooled condensers typically require less complex plumbing since they rely on ambient air for cooling, making them easier to install in many settings. In contrast, water cooled systems demand a more intricate setup involving piping, pumps, and a reliable water source—this can complicate installation and increase costs.

Additionally, the condensing temperature plays a crucial role in determining how these systems perform post-installation. For air cooled units, higher ambient temperatures might lead to reduced efficiency during peak summer months, while water cooled units can maintain better performance even under warmer conditions if properly installed. Therefore, understanding the nuances of each system's installation challenges is essential for achieving optimal cooling effect from your chosen method.

Space Requirements and Design Limitations

Space requirements are another key consideration when comparing the two types of condensers; this is especially true when factoring in the applicable environment where they will be deployed. Air cooled systems generally take up more horizontal space due to their need for adequate airflow around the unit—this can pose design limitations in compact or crowded settings like rooftops or small mechanical rooms.

On the other hand, water cooled condensers usually have a smaller footprint since they can be placed vertically or integrated into existing plumbing infrastructure. However, their dependence on additional equipment such as cooling towers or chillers might require more extensive planning regarding overall system layout. Ultimately, understanding these space dynamics will help you avoid pitfalls during both installation and use.

Maintenance Needs for Both Systems

Maintenance needs differ significantly between air cooled and water cooled condensers as well; neglecting these requirements can lead to decreased efficiency over time. Air cooled units often require periodic cleaning of coils to ensure optimal airflow—a task that's relatively straightforward but must be done regularly to maintain cooling effect effectiveness during operation.

Conversely, water-cooled systems necessitate more extensive upkeep due to potential issues like scale buildup within pipes or algae growth in water sources; this means that regular monitoring is essential for sustaining performance levels over time while managing condensing temperature effectively. Thus, being aware of maintenance demands associated with each cooling medium allows operators to plan ahead—ensuring longevity from their chosen system without unexpected downtime.

Applicable Environments

Choosing the right condenser cooling method isn't just about preference; it’s about matching the system to its environment. Understanding the applicable environments for air cooled and water cooled condensers can significantly affect their performance and efficiency. Each method has its own ideal settings, making it crucial to evaluate your situation before making a decision.

Ideal Settings for Air Cooled Systems

Air cooled systems shine in environments where water is scarce or difficult to manage. These systems utilize ambient air as their cooling medium, making them perfect for industrial facilities, commercial buildings, or remote locations where access to water is limited. Additionally, air cooled condensers tend to be easier and less expensive to install due to their simpler design and reduced infrastructure requirements.

In regions with low humidity levels, air cooled systems can operate efficiently while maintaining optimal condensing temperatures. Their reliance on natural airflow means they can effectively dissipate heat without requiring extensive plumbing or water management systems. This makes them particularly appealing for businesses looking for straightforward installation and use without the complexities of a water-based system.

Situations Suited for Water Cooled Condensers

Water cooled condensers are often preferred in settings where space is at a premium or cooling demands are particularly high. These systems excel in large-scale applications like power plants, refineries, or manufacturing facilities that require significant cooling effects over extended periods. The ability of water as a cooling medium allows these condensers to maintain lower condensing temperatures compared to their air-cooled counterparts.

Moreover, in densely populated urban areas where noise restrictions may apply, water cooled systems offer quieter operation since they don’t rely on large fans like air coolers do. They also provide better efficiency in high-temperature environments by utilizing chilled water from cooling towers or other sources as an effective means of heat exchange. This makes them highly adaptable for industries that demand consistent performance under varying conditions.

Adaptability in Different Climate Conditions

When considering the adaptability of each system across different climate conditions, it's essential to recognize how environmental factors influence performance. Air cooled condensers may struggle in extremely hot climates where high ambient temperatures can lead to increased condensing temperatures and reduced efficiency over time. Conversely, they perform exceptionally well in cooler climates where natural airflow aids in maintaining optimal operating conditions.

On the other hand, water cooled condensers thrive even when external temperatures soar because they rely on a stable supply of chilled water rather than fluctuating ambient conditions as their primary cooling medium. This adaptability makes them suitable for diverse applications ranging from tropical regions with high humidity levels to arid areas needing efficient heat dissipation solutions without sacrificing performance quality.

In conclusion, understanding the difference between air cooled and water cooled condenser setups significantly impacts your choice based on applicable environments and operational needs—each method brings unique advantages tailored for specific situations while ensuring effective temperature control and energy efficiency.

Cost Implications and Long-Term Savings

When it comes to selecting a cooling method, understanding the cost implications and potential long-term savings is crucial. The difference between air cooled and water cooled condensers can significantly affect both initial investments and ongoing operational expenses. By analyzing these factors, businesses can make informed decisions that align with their financial goals.

Initial Investment: A Side-by-Side Cost Analysis

The initial investment for air cooled versus water cooled condensers often varies widely, influenced by installation requirements and the complexity of the system. Air cooled systems typically have lower upfront costs due to simpler installation processes, requiring less infrastructure compared to their water-cooled counterparts. On the other hand, water cooled systems may demand additional expenses for cooling towers, pumps, and plumbing infrastructure—making the difference between air cooled and water cooled condenser choices even more pronounced.

Operating Costs Over Time

Operating costs over time reveal another layer of complexity in choosing a cooling method. While air cooled condensers might save money initially, they often consume more energy during peak temperatures due to higher condensing temperatures affecting efficiency. Water cooled systems generally operate at lower condensing temperatures, which can lead to reduced energy consumption over time—showing that while they may have a higher upfront cost, they could offer significant savings in the long run when considering cooling effect efficiency.

RIGID Solutions for Cost-Effective Cooling

RIGID solutions aim to bridge the gap between initial investment and long-term savings by optimizing both types of cooling methods effectively. Their innovative technology enhances performance across different environments while ensuring that maintenance needs are minimal—a key factor in reducing overall costs. With RIGID's focus on maximizing cooling medium in refrigeration applications, businesses can enjoy a tailored solution that balances upfront expenses with sustainable operating efficiency.

Conclusion

In wrapping up this exploration of condenser cooling methods, it's clear that the difference between air cooled and water cooled condensers is more than just a technical distinction; it can significantly impact efficiency, installation and use, and overall operational costs. Air cooled systems rely on ambient air as their cooling medium in refrigeration, making them simpler to install but potentially less efficient in extreme temperatures. On the other hand, water cooled condensers utilize a liquid cooling medium, often resulting in better performance under high-load conditions but requiring more complex installation and maintenance considerations.

Recap of Key Differences in Cooling Methods

To summarize the key differences between air cooled and water cooled condensers: air cooled systems are typically easier to install due to their reliance on ambient air for cooling effects, while water cooled systems tend to offer superior performance through better heat exchange capabilities. The choice of cooling medium plays a crucial role in determining the condensing temperature; lower temperatures can be achieved with water due to its higher thermal conductivity. Consequently, understanding these differences is essential for optimizing efficiency based on your specific application needs.

Choosing the Right Condenser for Your Needs

When deciding between an air or water cooled condenser, consider your unique requirements including installation and use constraints as well as applicable environments. If space is limited or if you're operating in a region with fluctuating temperatures, an air cooled system might be your best bet. However, if you need consistent performance under heavy loads regardless of external conditions, investing in a water cooled system may provide long-term savings despite higher initial costs.

Future Trends in Condenser Technology

As we look ahead at future trends in condenser technology, advancements are likely to focus on improving energy efficiency and reducing environmental impact across both types of systems. Innovations such as hybrid models that combine elements from both air and water cooling methods could emerge as viable solutions for diverse applications. Additionally, increased emphasis on sustainable practices will drive manufacturers toward developing more eco-friendly refrigerants and designs that optimize the cooling effect while minimizing resource consumption.