Introduction

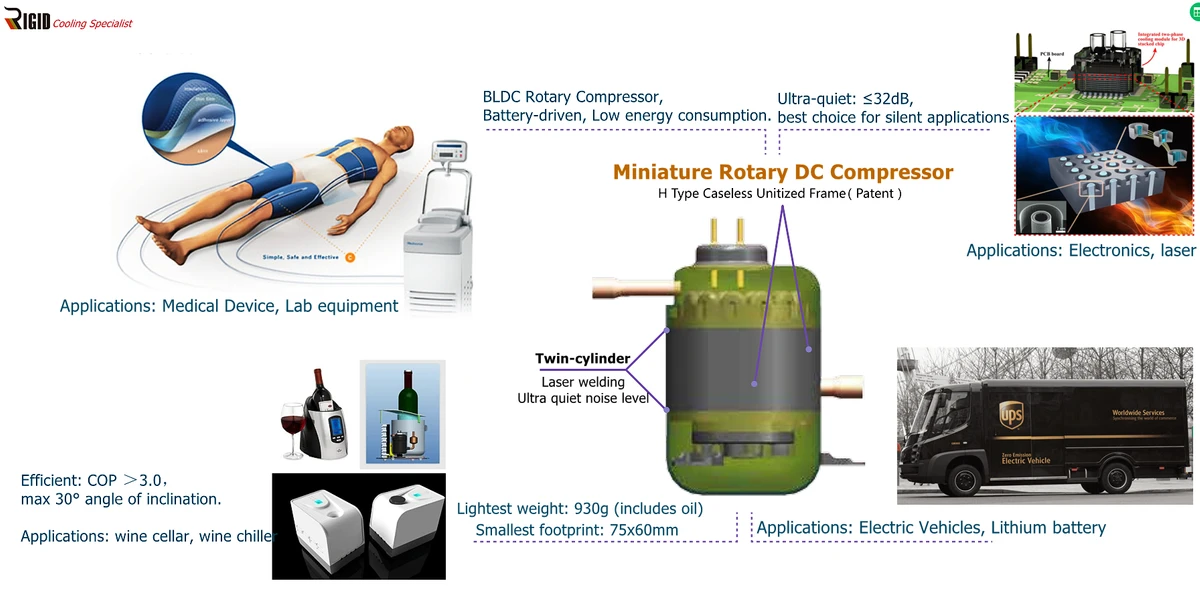

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

In the world of commercial refrigeration, compressor overheating is a sneaky villain that can wreak havoc on your cooling systems. Understanding the causes and consequences of this issue is crucial for maintaining efficiency and prolonging equipment life. By addressing common problems proactively, you can keep your operations running smoothly and avoid costly repairs.

Understanding Compressor Overheating

Compressor overheating occurs when the temperature of the compressor rises beyond its optimal operating range, leading to potential system failure. Factors such as inadequate lubrication, dirty condenser coils, and refrigerant issues all contribute to this phenomenon. Knowing how these elements interact helps in diagnosing problems early before they spiral out of control.

Importance of Preventing Overheating

Preventing compressor overheating is not just about avoiding breakdowns; it’s essential for maintaining energy efficiency and reducing operational costs. A well-maintained system not only saves money but also extends the lifespan of your equipment, making it a smart investment for any business. Incorporating a Commercial Refrigeration Maintenance Checklist into your routine will help you stay ahead of potential issues.

How to Address Common Issues

Addressing common issues that lead to compressor overheating requires vigilance and regular maintenance practices, including using a Commercial HVAC Maintenance Checklist. Simple steps like ensuring proper lubrication and cleaning condenser coils can make a significant difference in performance. Additionally, considering remanufactured commercial compressors can provide reliable solutions while minimizing downtime caused by overheating.

Inadequate Lubrication

When it comes to keeping your compressor running smoothly, lubrication is key. Inadequate lubrication not only leads to increased friction but can also cause your compressor to overheat, resulting in costly repairs and downtime. Understanding the role of proper lubrication is essential for anyone involved in commercial refrigeration or HVAC systems.

The Role of Proper Lubrication

Proper lubrication serves as the lifeblood of your compressor, ensuring that all moving parts operate seamlessly without excessive wear and tear. It helps dissipate heat, reducing the risk of compressor overheating while enhancing overall efficiency. Without adequate lubrication, components can grind against each other, leading to premature failure and a need for potentially expensive remanufactured commercial compressors.

Signs of Lubrication Failure

Recognizing the signs of lubrication failure early can save you from significant headaches down the line. Look out for unusual noises such as grinding or squeaking; these could indicate insufficient oil levels or poor lubricant quality. Additionally, if you notice an increase in operating temperatures or frequent trips to check your Commercial Refrigeration Maintenance Checklist due to performance issues, it may be time to investigate your lubrication system.

Solutions for Improved Lubrication

To ensure optimal performance and prevent compressor overheating, consider implementing a robust maintenance plan focused on lubrication practices. Regularly check oil levels and replace lubricants according to manufacturer guidelines; this should be a staple on your Commercial HVAC Maintenance Checklist. Furthermore, investing in high-quality lubricants designed specifically for refrigeration systems can significantly enhance performance and longevity while reducing the likelihood of needing remanufactured commercial compressors.

Dirty Condenser Coils

When it comes to the performance of your commercial refrigeration system, dirty condenser coils can be a silent but deadly enemy. This often-overlooked issue can lead to compressor overheating, reduced efficiency, and ultimately costly repairs or replacements. Maintaining clean coils is not just about aesthetics; it's crucial for the longevity and effectiveness of your equipment.

The Impact of Dirt on Efficiency

Dirt and debris accumulation on condenser coils can drastically hinder heat exchange, leading to increased pressure and temperature within the system. When coils are dirty, your compressor has to work harder to maintain desired temperatures, which directly contributes to compressor overheating. Over time, this extra strain can lead to premature failure of components like remanufactured commercial compressors that are designed for optimal performance.

Regular Cleaning Tips

To keep your condenser coils in peak condition, regular cleaning should be part of your routine maintenance schedule. Start by turning off the power supply before cleaning the coils with a soft brush or vacuum cleaner to remove any loose dirt and debris. For more stubborn grime, a gentle wash with a mild detergent followed by thorough rinsing will do wonders—just make sure everything is dry before powering up again!

Importance of a Commercial Refrigeration Maintenance Checklist

Creating and adhering to a Commercial Refrigeration Maintenance Checklist ensures that all aspects of your refrigeration system receive proper attention—including those pesky dirty condenser coils! This checklist should include regular inspections for dirt buildup as well as lubrication checks and refrigerant level assessments. By staying proactive with maintenance tasks outlined in both the Commercial HVAC Maintenance Checklist and specific refrigeration checklists, you’ll reduce the risk of compressor overheating while enhancing overall efficiency.

Refrigerant Issues

Refrigerant issues can significantly contribute to compressor overheating, making it crucial to address them promptly. A well-functioning refrigeration system relies on the proper balance and levels of refrigerant for efficient operation. Understanding how to recognize low refrigerant levels and manage them effectively can save you from costly repairs and extend the lifespan of your equipment.

Recognizing Low Refrigerant Levels

One of the first signs of low refrigerant levels is a noticeable drop in cooling efficiency. If your commercial refrigeration unit is struggling to maintain temperature, it could be due to insufficient refrigerant, leading directly to compressor overheating. Additionally, look for symptoms such as ice buildup on evaporator coils or unusual hissing sounds, which are clear indicators that something's amiss.

Regularly comparing your system's performance against a Commercial HVAC Maintenance Checklist can help identify these issues early on. Keeping an eye on pressure readings during routine checks will also provide valuable insights into your refrigerant levels. By being proactive and vigilant, you can catch problems before they escalate into more severe concerns.

Consequences of Improper Refrigerant Management

Failing to manage refrigerant levels properly can lead not only to compressor overheating but also to significant operational inefficiencies and increased energy costs. Over time, low refrigerant levels force the compressor to work harder than necessary, which ultimately shortens its lifespan and increases the likelihood of breakdowns. Moreover, improper management may result in environmental violations if leaks occur without timely detection.

The financial implications are serious; businesses may face hefty repair bills or even replacement costs for their compressors if these issues aren't addressed promptly. Additionally, subpar performance due to inadequate refrigerants can harm customer satisfaction if products aren’t kept at optimal temperatures—no one wants spoiled goods! Therefore, maintaining proper refrigerant management is essential for both operational efficiency and regulatory compliance.

How Remanufactured Commercial Compressors Help

Investing in a remanufactured commercial compressor can be a game-changer when dealing with recurring issues related to refrigeration systems. These compressors are restored using high-quality components and rigorous testing processes that ensure they perform like new while being more cost-effective than brand-new units. Choosing remanufactured options not only helps combat compressor overheating but also provides peace of mind knowing you're using reliable equipment.

Furthermore, incorporating remanufactured compressors into your operations aligns well with sustainable practices by reducing waste associated with manufacturing new units. They often come with warranties that guarantee their performance over time—making them a smart choice for budget-conscious businesses aiming for longevity in their systems. As part of your Commercial Refrigeration Maintenance Checklist, consider including regular assessments of whether it's time for a compressor upgrade or refurbishment.

In conclusion, addressing refrigerant issues is vital in preventing compressor overheating while ensuring efficient operations within your commercial refrigeration systems. By recognizing low refrigerant levels early on and understanding the consequences of poor management practices, you’ll be better equipped to keep everything running smoothly—and maybe even save some cash along the way!

Conclusion

In conclusion, understanding and addressing compressor overheating is crucial for maintaining the longevity and efficiency of your refrigeration systems. By recognizing the signs of inadequate lubrication, dirty condenser coils, and refrigerant issues, you can take proactive measures to prevent costly breakdowns. Regularly consulting a Commercial Refrigeration Maintenance Checklist can help ensure that your equipment stays in top shape.

Key Takeaways on Compressor Overheating

Compressor overheating is not just a minor inconvenience; it can lead to significant operational problems if left unchecked. Key factors include inadequate lubrication, dirt accumulation on condenser coils, and improper refrigerant management—all of which can be easily monitored with a Commercial HVAC Maintenance Checklist. By staying vigilant about these issues, you’ll not only extend the life of your equipment but also enhance overall performance.

Enhancing Efficiency with Regular Maintenance

Regular maintenance is the backbone of an efficient refrigeration system and plays a vital role in preventing compressor overheating. Implementing routine checks based on a thorough Commercial Refrigeration Maintenance Checklist ensures that all components are functioning optimally. Additionally, investing in remanufactured commercial compressors can provide reliable alternatives when repairs are needed, thus enhancing system efficiency.

The Role of RIGID in Innovative Cooling Solutions

RIGID stands at the forefront of innovative cooling solutions designed to combat common pitfalls like compressor overheating effectively. Their commitment to quality ensures that both new installations and remanufactured commercial compressors meet high standards for performance and reliability. By choosing RIGID products along with regular maintenance practices, businesses can significantly reduce downtime while maximizing energy efficiency.